TAM 00682 3

DSC 045-100 07 / 2012

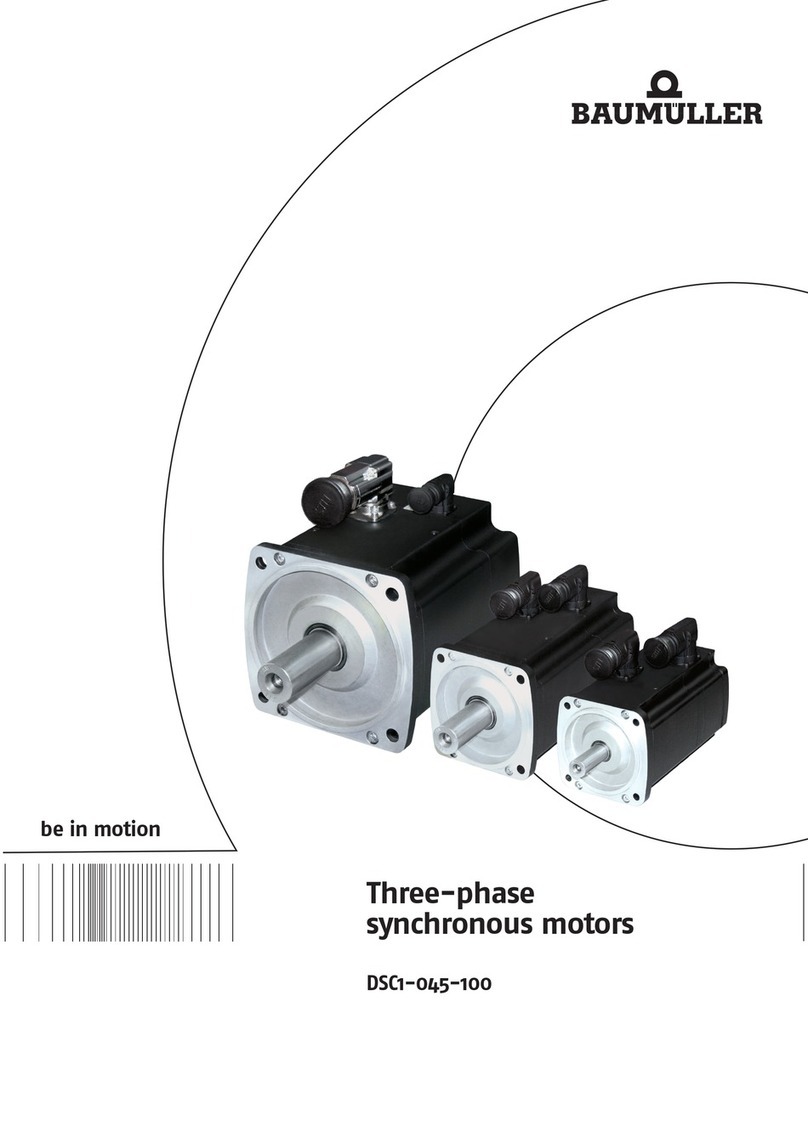

Three-phase synchronous motor English

Table of contents

1General safety instructions............................................................................4

1.1Safety...........................................................................................................................................4

1.2Designated purpose.....................................................................................................................5

1.3Prohibition of unauthorized modifications and changes..............................................................6

2Operating conditions ......................................................................................6

2.1Product description......................................................................................................................6

2.2Items supplied..............................................................................................................................6

2.3Nameplate ...................................................................................................................................7

2.4Technical data .............................................................................................................................8

2.5Transport, intermediate storage ..................................................................................................9

2.6Installation conditions, cooling details .......................................................................................10

2.7Balancing, output elements, vibration........................................................................................11

3Mounting........................................................................................................13

3.1Safety instructions .....................................................................................................................13

3.2Installation, fixing .......................................................................................................................13

4Electrical connections ..................................................................................14

5Commissioning, operation...........................................................................15

5.1Safety instructions .....................................................................................................................15

5.2Checks prior to commissioning..................................................................................................16

5.3Commissioning, operation .........................................................................................................16

5.4Malfunctions in operation...........................................................................................................17

6Inspection and maintenance........................................................................18

6.1Inspection ..................................................................................................................................18

6.2Maintenance ..............................................................................................................................19

7Disposal .........................................................................................................19

8Annex 1: pole assignment (main connection and control port) ...............20

8.1Main connection via plug ...........................................................................................................20

8.2Main connection via the terminal box (Standard design acc. to catalogue)..............................20

8.3Main connection via the terminal box (customer specific design acc. to EN 60034; non UL-

approved)...................................................................................................................................21

8.4Main and control connection via combination-mounting-box (customer specific design) .........22

8.5Fan connection ..........................................................................................................................23

8.6Control port: Resolver................................................................................................................23

8.7Control port: SRS / SRM 50 ......................................................................................................24

8.8Control port: SEK / SEL 52........................................................................................................24

8.9Control port: ECN 1313 / EQN 1325 .........................................................................................25

8.10Control port: ECN 1325 / EQN 1337 (M23) (encoder with EnDat 2.2-port from Heidenhain

companies) ................................................................................................................................25

9Appendix 2: water-cooled machines ...........................................................26

9.1Definitions of power ratings for water-cooled machines............................................................26

9.2Motorcooling ..............................................................................................................................26

9.3Instructions for installation .........................................................................................................27

9.4Electrical connections................................................................................................................27

9.5Specifications for required coolant volume flows ......................................................................27

9.6Coolant consistency...................................................................................................................28

9.7Min. coolant temperature against ambient temperature and humidity ......................................28

9.8Malfunctions in operation...........................................................................................................30

9.9Inspection ..................................................................................................................................30