TAM 00746 3

DSP1 045 - 100 11 / 2019

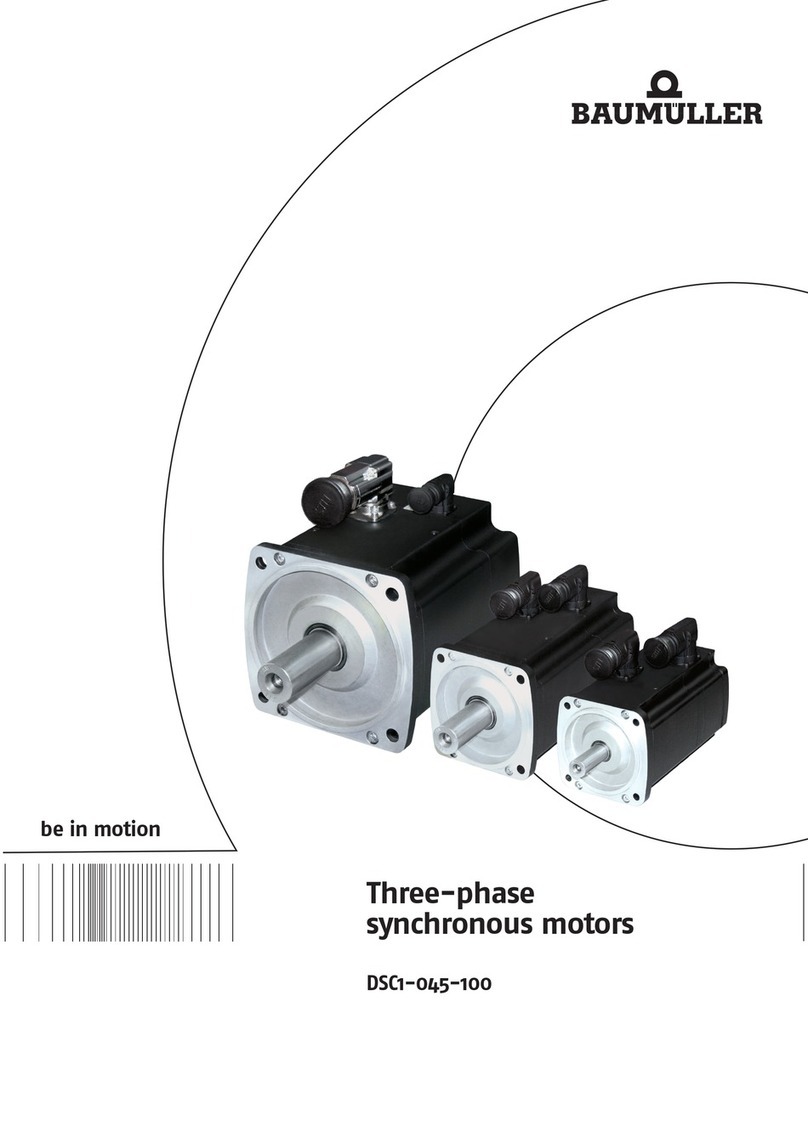

Three phase synchronous motor English

Content

1General Safety Notes..........................................................................................4

1.1 Safety........................................................................................................................................4

1.2 Intended use..............................................................................................................................5

1.3 Prohibition of unauthorized modifications and alterations.........................................................6

2Operating conditions..........................................................................................6

2.1 Product description....................................................................................................................6

2.2 Scope of delivery.......................................................................................................................7

2.3 Type plate..................................................................................................................................7

2.4 Technical data...........................................................................................................................8

2.5 Transport, shaft lock, temporary storage ..................................................................................9

2.6 Installation conditions, cooling data.........................................................................................10

2.7 Balancing, output elements, vibrations....................................................................................11

3Mounting............................................................................................................13

3.1 Safety notes ............................................................................................................................13

3.2 Setting up and fixing................................................................................................................13

3.3 Vibrations and vibration resistance .........................................................................................14

4Electric connection...........................................................................................16

5Commissioning, operation...............................................................................18

5.1 Safety notes ............................................................................................................................18

5.2 Tests before commissioning...................................................................................................18

5.3 Commissioning, operation.......................................................................................................19

5.4 Failures....................................................................................................................................20

6Inspection and maintenance............................................................................22

6.1 Inspection................................................................................................................................22

6.2 Maintenance............................................................................................................................22

7Disposal.............................................................................................................22

8Appendix 1: Pole assignments (power and control connections)................23

8.1 Main connection via the plug...................................................................................................23

8.2 Main connection via terminal box (standard version according to the catalogue)..................23

8.3 Main connection via terminal box (customer-specific version according to EN 60034; not UL-

approved)................................................................................................................................24

8.4 Main and control connection via combination mounting socket (customer-specific version)..25

8.5 Fan connection 24 V DC / 115 V AC / 230 V AC ....................................................................26

8.6 Control connection: Resolver..................................................................................................26

9Appendix 2: Version with water cooling.........................................................27

9.1 Performance definition for water-cooled machines.................................................................27

9.2 Motor cooling...........................................................................................................................27

Mounting notes ..........................................................................Fehler! Textmarke nicht definiert.

9.3 Electric connection..................................................................................................................28

9.4 Information on the required coolant volume rate of flow.........................................................29

9.5 Cooling water quality...............................................................................................................30

9.6 Minimum coolant temperature in dependance of the ambient conditions...............................30

9.7 Operating malfunctions ...........................................................................................................32

9.8 Inspektion................................................................................................................................32