Baur DPA 75 User manual

0-1

Fully Automatic

Insulating Oil Tester DPA 75

Designed for the fully automatic measuring of the

electric breakdown strength of insulants

Operating Instruction

12/98

Ident no. 822-073

BAUR Prüf- und Messtechnik GmbH

Raiffeisenstrasse 8, A-6832 Sulz / Austria Tel +43 / 55 22 / 49 41-0

Fax +43 / 55 22 / 49 4 13

e-mail: headoffice@baur.at

internet: http://www.baur.at

0-2

0-3

© BAUR Prüf- und Messtechnik GmbH,

A-6832 Sulz / Austria

All rights reserved.

No part of this publication may be produced,

transmitted, stored in a data processing system or

translated into another language without the written

permission of Baur/Sulz, Austria.

In the interest of our customers we reserve the rights

for modifications due to technical progress.

Illustrations, descriptions and delivery content are

therefore not binding.

Copyright

© Copyright by BAUR

Guide to this Operating Instruction

For fast finding of important information the

corresponding text passages are marked with symbols

(symbols not stated here are self-explaining):

More and special information concerning the respective

subject are available from BAUR.

Important unit information!

In any case, read carefully!

Important information text.

Subject to modification!

Observe

info signs!

☞

Copyright

0-4

BAUR Prüf- und Messtechnik GmbH,

Raiffeisenstrasse 8

A-6832-Sulz / Austria

or refer to your nearest BAUR representative.

Preface

Tel +43 / 55 22 / 49 41-0

Fax +43 / 55 22 / 49 41 3

This manual contains all information necessary for the

correct handling and use of the Fully Automatic

Insulating Oil Tester DPA 75.

Before using the DPA 75 unit please read carefully this

Operating Instruction.

If you have any question please contact directly:

Preface

0-5

- The Insulating Oil Tester DPA 75 is built in

accordance with today’s state of engineering and is

safe to operate.

Individual components and the finished unit are

inspected continually by our qualified staff within the

framework of our Quality Assurance Provisions.

Each unit is subjected to thorough testing prior to

shipment.

- It is imperative to every person who is involved with

the installation, start-up, operation and maintenance

to have read and understood the complete Operating

Instruction.

- The user is responsible for ensuring that no

unauthorized personnel works with the unit. He has

an obligation to report immediately any changes to

the unit which affect its safety.

- Use as directed:

The DPA 75 unit may be used exclusively for

insulating liquids with a flash point of ³110C (230F).

The local safety and accident prevention

regulations are always applicable to the operation

of the DPA 75 unit.

Safety Precautions

In any case read Operating

Instruction before using the

unit!

Only authorized personnel!

Use the DPA 75 unit as

directed!

Please read now and

avoid damage and

injury later!

Safety Precautions

0-6

At the customer’s written request we undertake to

repair or replace at our discretion and as quickly as

possible all parts that become faulty or useless as the

demonstrable result of poor material, faulty design or

defective execution.

We shall bear the costs of any faulty parts requiring

replacement, but not the costs of transport to us and

back to the customer, nor the costs of packing and

insurance!

The 12 month warranty time starts with delivery.

We shall not be liable for any damage resulting from

normal wear and tear, improper handling, non-

observance of Operating Instruction and safety

regulations.

We shall also refuse to accept any liability if the

customer carries out repairs or changes to the unit

himself or has others carry out them!

The warranty does not cover damage in transit,

batteries, fuses and any readjustments in accordance

with the Operating Instruction!

We draw attention in addition to the ‘General Terms of

Sales and Delivery’ of:

BAUR Prüf-und Messtechnik GmbH,

A-6832 Sulz / Austria

Warranty Terms

12 month warranty time

Warranty Terms

0-7

Contents

1. Product Information ....................................................................... 1-1

1.1 Test cycle .............................................................................. 1-2

1.2 Construction / Principle ......................................................... 1-3

1.3 Function and control elements .............................................. 1-5

1.4 Control panel......................................................................... 1-7

1.5 Menu overview...................................................................... 1-7

1.6 Technical data ....................................................................... 1-9

1.7 RBM switching off ............................................................... 1-11

2. Packing and Delivery ..................................................................... 2-1

2.1 Unpacking............................................................................. 2-1

2.2 Damage during transport ...................................................... 2-1

2.3 Check extent of delivery........................................................ 2-2

2.4Installation............................................................................. 2-4

3. Putting into Operation ................................................................... 3-1

3.1 Selecting language ............................................................... 3-2

3.2Adjust contrast of display ...................................................... 3-3

3.3 Set actual date ...................................................................... 3-4

3.4 Set actual time ...................................................................... 3-5

3.5 Cleaning of electrodes .......................................................... 3-6

4. Testing Preparations ..................................................................... 4-1

4.1 Checking battery state of charge .......................................... 4-1

4.2 Switching printer on/off.......................................................... 4-2

4.3 Enter report no. ..................................................................... 4-3

4.4Adjust electrode spacing ....................................................... 4-4

4.5 Sampling of insulating liquids ................................................ 4-5

4.6 Filling test vessel................................................................... 4-7

4.7 Carry out DPAtest ................................................................ 4-9

Contents

0-8

5. Standard Test.................................................................................. 5-1

5.1 Start standard test................................................................. 5-1

5.2 Indication of test results - standard test................................. 5-3

5.3 Printer report (option) - standard test .................................... 5-4

6. Customer-specific Test Cycle ...................................................... 6-1

6.1 Define and store customer-specific test cycle ....................... 6-1

6.2 Start customer-specific test cycle.......................................... 6-9

6.3 Indication of test results - customer-specific test cycle........ 6-10

6.4 Printer report (option) - customer-specific test cycle ........... 6-11

7. Single Test ..................................................................................... 7-1

7.1 Start single test ..................................................................... 7-1

7.2 Indication of test results - single test ..................................... 7-2

7.3 Printer report (option) - single test......................................... 7-2

8. Maintenance and Care ................................................................... 8-1

8.1 Replacing mains fuse............................................................ 8-1

8.2 Replacing printer ribbon (option) ........................................... 8-3

8.3 Replacing printer paper roll (option) ...................................... 8-4

9. Spare and Wearing Parts............................................................... 9-1

10. Test Standards............................................................................ 10-1

11. Index .............................................................................................11-1

1-1

Product Information

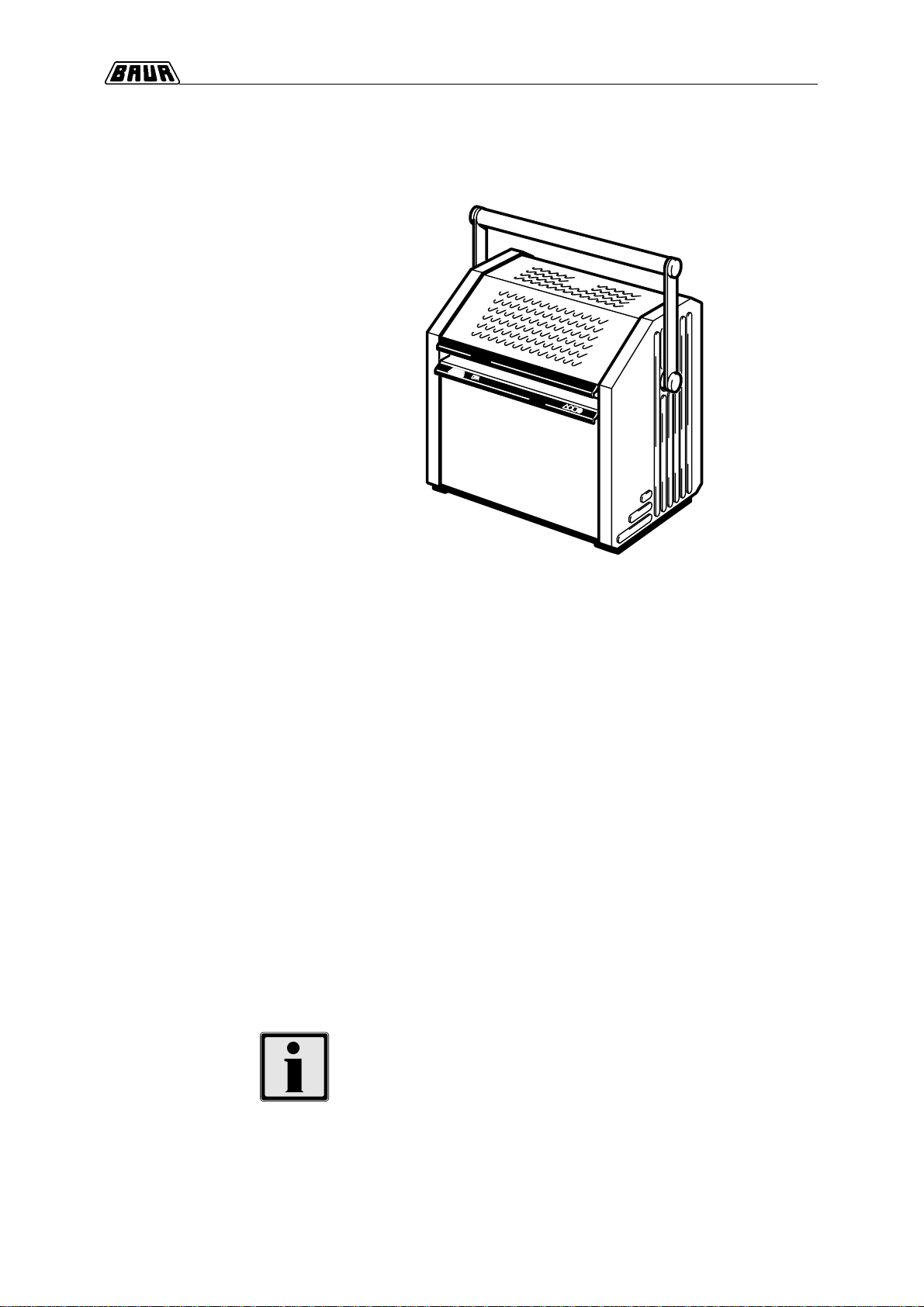

1. Product Information

The Insulating Oil Tester DPA 75 is used to measure

the electric breakdown strength of insulating

liquids (eg insulating oil of transformers etc).

The dissipation factor tan dand the relative

permittivity er, together with the breakdown voltage, are

the most important parameter for which insulating

liquids are tested.

The breakdown voltage shows the degree of

contamination by cellulose fibres and water.

For the operating safety of oil insulated high voltage

units the electrical breakdown strength of insulants is

the deciding factor.

For further information also see the technical report ‘Testing of

dielectric properties of insulating liquids’ by M. Krüger.

Obtainable from BAUR under no. 8602e.

The Insulating Oil Tester

DPA 75

Measuring the electric breakdown

strenght of insulating liquids

In all fig. units are shown with options

A judgement criterion for the quality of

insulating liquids

1-2

Product Information

1Open protective hood and remove test vessel.

Test vessel must comply with selected test standard.

2Insert electrodes corresponding to selected test

standard into the test vessel and adjust electrode

spacing.

3Fill insulating liquid into test vessel considering

standards

IEC 475 / VDE0370 part 3/2.80 and

IEC 156 / VDE0370 part 5

and insert test vessel into DPA unit again.

4Close protective hood.

5Fold out front panel.

The DPA unit is switched on automatically.

6Select desired test standard via function keys.

Before starting test pay attention to indicated and

actual electrode form and spacing:

13 pre-programmed test standard cycles are

available with the DPA 75 unit. Additionally, all

parameters can be freely programmed acc. to a

customer-specific test cycle.

7After starting the test cycle the measured data are

automatically reported via integrated printer (option).

8After conclusion of the test cycle close front panel.

The DPA unit is switched off automatically.

1.1 Test cycle

For more and detailled information in operating the

DPA 75 unit refer to section 4. Testing Preparations.

1

23

4

5

6

7

8

selected standard

electrode form

electrode spacing

warning sign

(flashing)

MENU START

IEC 156/63

2.5 mm

☞

1-3

Product Information

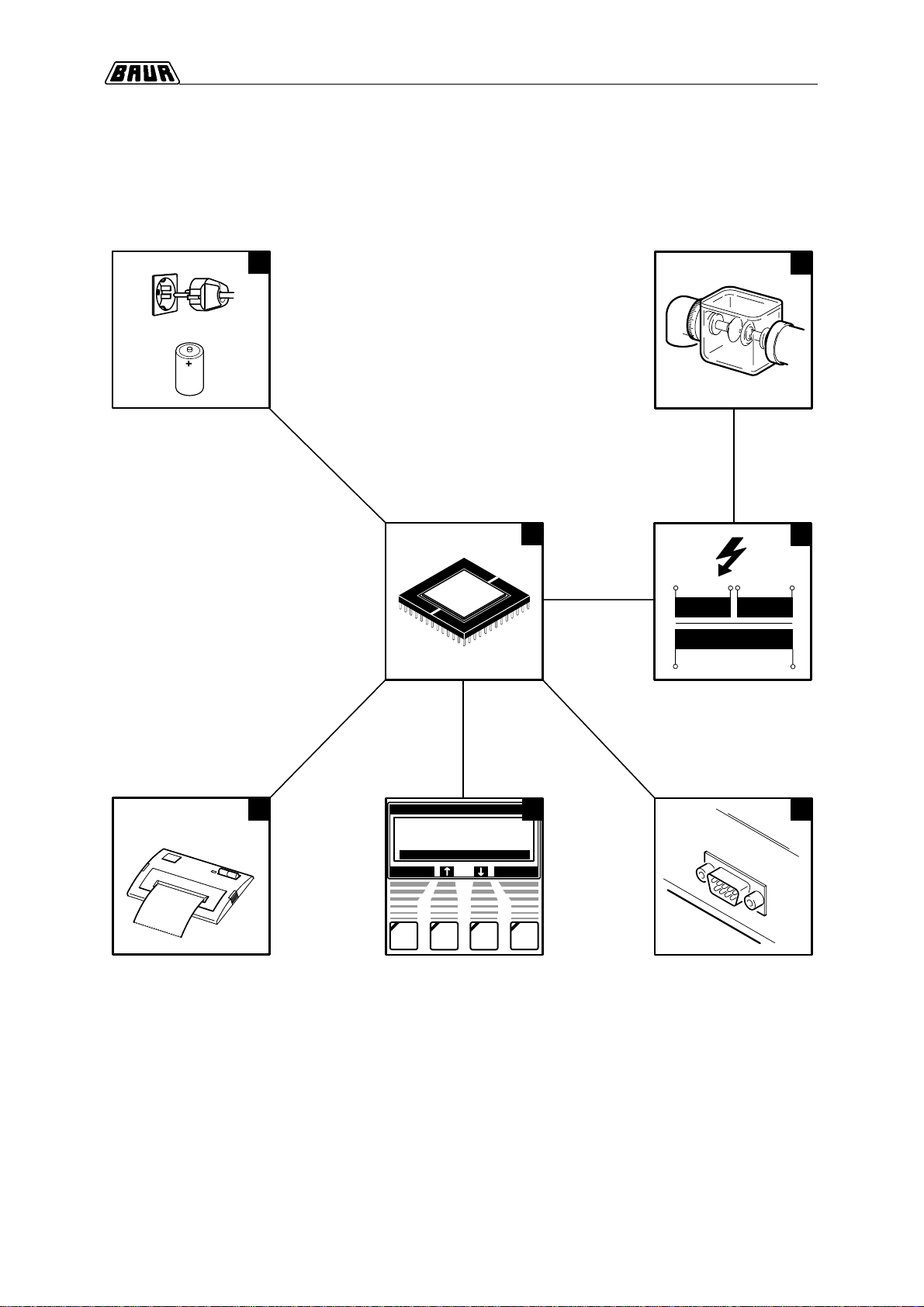

1.2 Construction / Principle

RETURN ENTER

MENU

STANDARD

INSTRUMENT SETTING

SINGLE TEST

1

6

5

3

24

EXTRA

7

CPU

Power Supply

High-voltage

Transformer

Control Unit

Control Panel RS232 Interface

bidirectional

Plain Paper Printer

(option)

Test Vessel and

Electrodes

1-4

Product Information

1 Power supply

- Mains operation (100 ... 240 V / 50/60 Hz) possible

via mains cable, even if battery is discharged.

With mains operation this symbol appears in the

upper right corner of any menu:

- Battery operation via internal and rechargable battery

(2 x 6V / 6.5Ah).

With connected mains cable battery charging

happens even with switched off unit.

2 Control unit

Coordinates all unit functions according to the

selected and actual menu.

3 Control panel

For selecting the desired menus.

4 High-voltage transformer

For generating the test voltage (max. 75 kV).

5 Test vessel and electrodes

Individually configurable depending on test standard.

Temperature acquisition of the insulating liquid via

sensor.

6 Plain-paper printer (option)

Reports test data automatically.

7 Interface RS232

Bidirectional interface on the rear of the unit for data

communication with a PC.

1-5

Product Information

1.3 Function and control elements

3

2

5

6, 7

1

9

8

4

10

1-6

Product Information

1Gripping strip for opening/closing the protective

hood.

2Protective hood with self-acting mechanical locking

mechanism (double interlock switch - forced contact).

For highest operational safety!

3Test vessel with electrodes - available for all current

standards. Quickly removable test vessel for easy

cleaning, with a built-in vernier for exact setting of

electrode spacing.

4Easy-to-clean oil pan.

Suitable for cleaning with petroleum ether.

5Carrying handle (option) and shoulder strap - for

easy and simple mobile use.

6Built-in rechargeable battery - for mains independent

operation.

Integrated power supply unit for controlled battery

charging, even during a test.

7Bidirectional RS232 interface - for data

communication with a PC.

8Folding front panel - switches the DPA unit on/off

automatically.

9Built-in plain paper printer - for automatic reporting of

test data and test conditions (option).

10Control panel with self-explanatory menu-guiding.

Product Information

1-7

Product Information

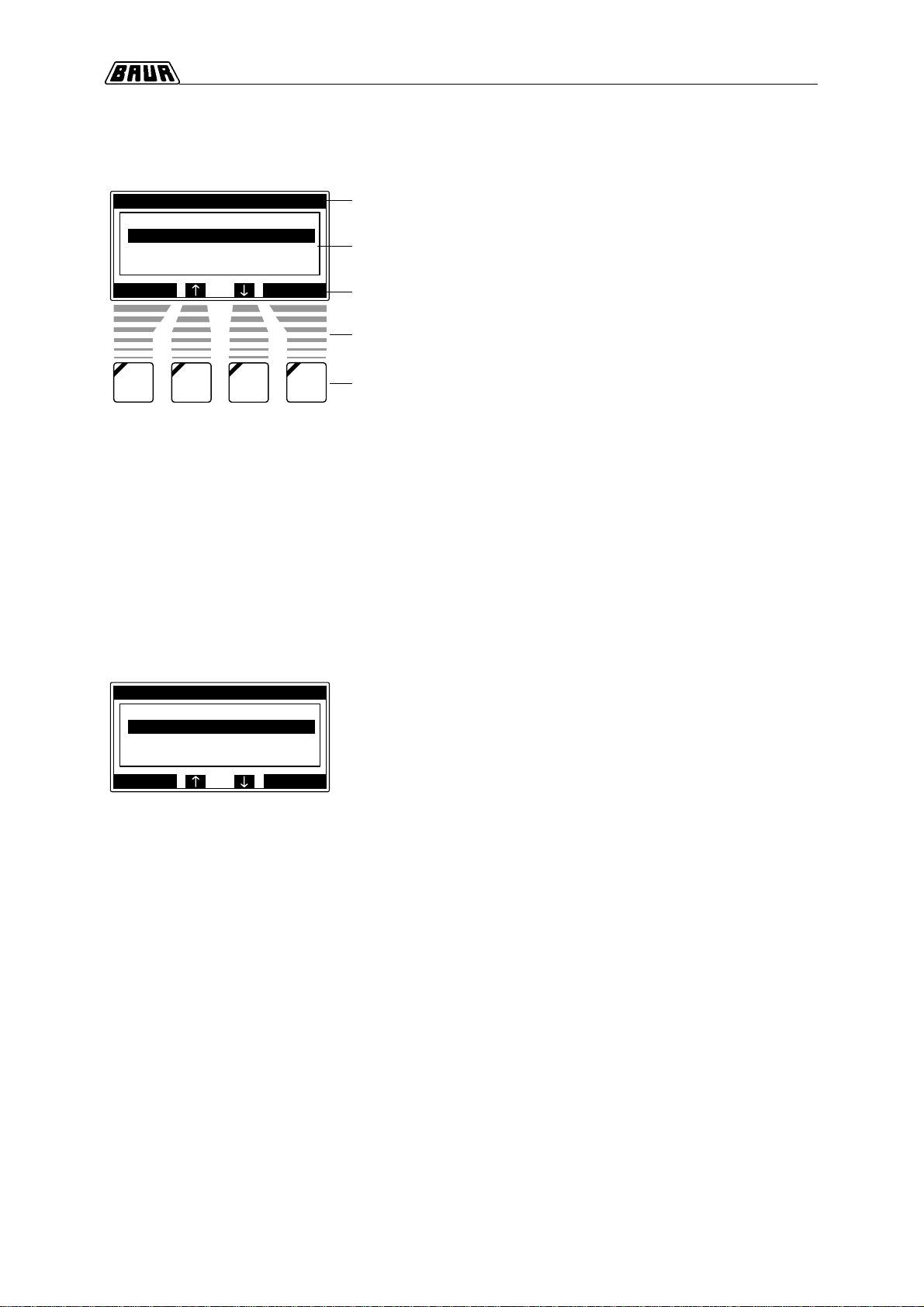

Features:

- backlit dot matrix graphic display

- self-explanatory menu-guiding

- keys which can be activated and active menu

functions are highlighted with a black bar

INSTRUMENT SETTING

- CONTRAST: setting of display contrast

- LANGUAGES: selection of desired language:

GERMAN, ENGLISH, FRENCH,

SPANISH

- PRINTER: Disabling of the integrated printer is

possible

- RS232 INFO: Information to the interface

configuration RS232 for:

- service-mode

- cablibration-mode

- remote control

(with BAUR PC software)

- DATE: setting of actual date

- TIME: setting of actual time

Product Information

control keys

control keys assigned

display of functions to be activated

menu window

actual menu

RETURN ENTER

STANDARD

ASTM

ASTM

BS

CEI

D 877/87

D 1816/84

5874/80

10-1/73

1.4 Control panel

1.5 Menu overview

RETURN ENTER

MENU

STANDARD

INSTRUMENT SETTING

SINGLE TEST

EXTRA

1-8

Product Information

STANDARD

- 13 pre-programmed test standards are available:

ASTM D 1816/84 ASTM D 877/87

BS 5874/80 CEI 10-1/73

CSSR RVHP/85 IEC 156/95

IRAM 2341/72 JIS C2101/78

PN 77/ED4408 SEV 3141/69

UNE 21 309/89 UTE ✳60

VDE 0370/78

- Additionally in the submenu DEFINE TEST CYCLE

5 customer-specific test sequences are freely

programmable.

TEST CYCLE 1

TEST CYCLE 2

TEST CYCLE 3

TEST CYCLE 4

TEST CYCLE 5

SINGLE TEST

- Start of a single test

- Voltage rate of rise adjustable

(0.5 - 1 - 2 - 3 - 5 kV/s)

EXTRA

- BATTERY: Load status of rechargeable battery

and no. of further possible

breakdowns until recharge

- REPORT NO.: Input of a max. 12-digit report number

- ELECTRODES CLEAN.:

24 cleaning breakdowns are carried

out (when using new electrodes the

first time)

- DPA TEST: Menu item for high voltage testing

with calibrator KA 75.

- INFO: No. of software version.

Indication of date of the last

calibration (calibration of DPA unit

should be carried out once a year)

RETURN ENTER

MENU

STANDARD

INSTRUMENT SETTING

SINGLE TEST

EXTRA

MENU START

SINGLE TEST

2.0 kV/s

2.5 mm

RETURN ENTER

EXTRA

REPORT NR.

BATTERY

ELEKTRODES CLEAN.

DPA TEST

1-9

Product Information

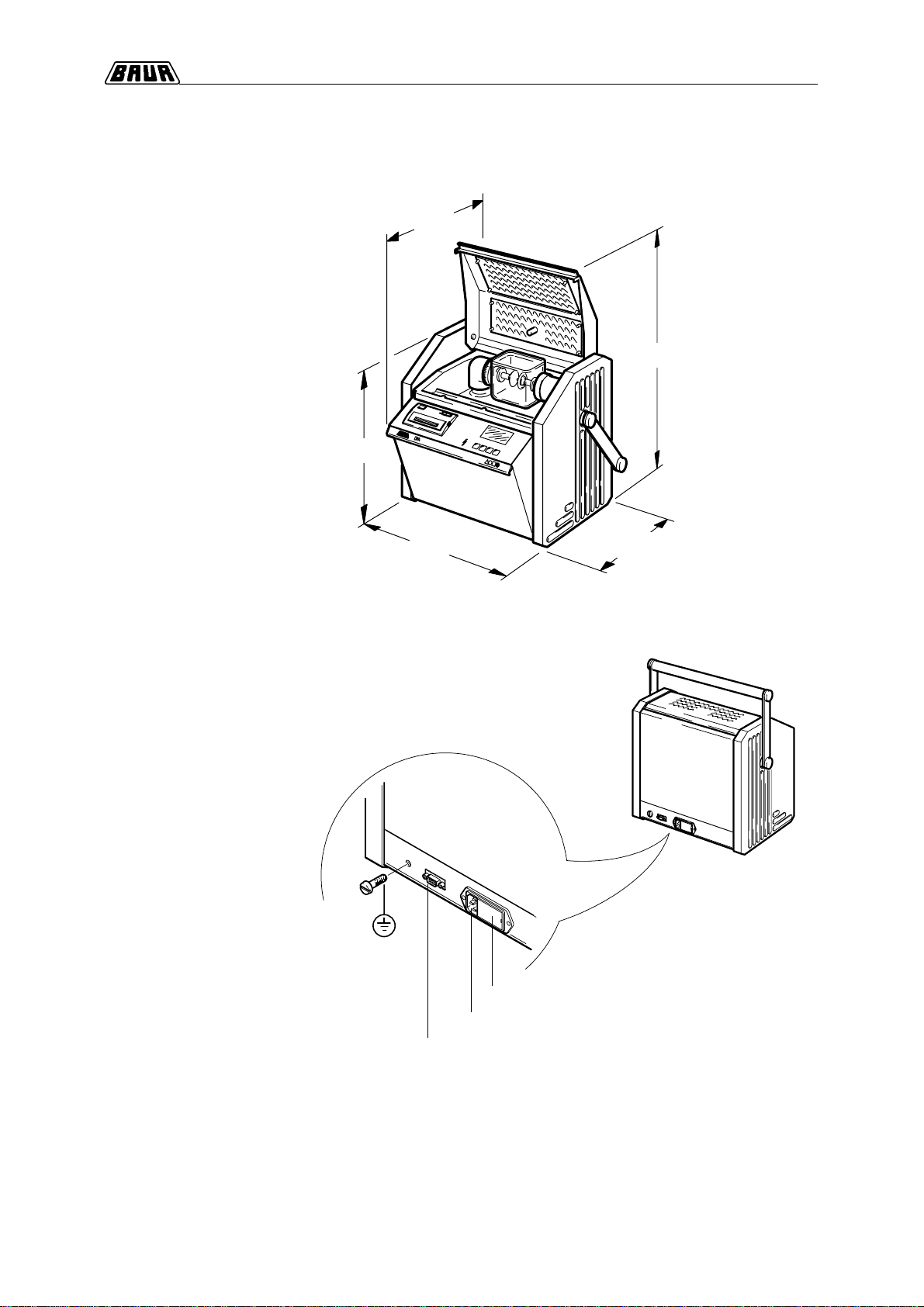

1.6 Technical data

DPA main dimensions

Dimensions in mm

T 4 A / fuse

90 . . . 264 V AC / mains supply

RS232 bidirectional / 9 pin Sub D

360

345

405 275

554

M6

connection

protective earthing

DPA interfaces

1-10

Product Information

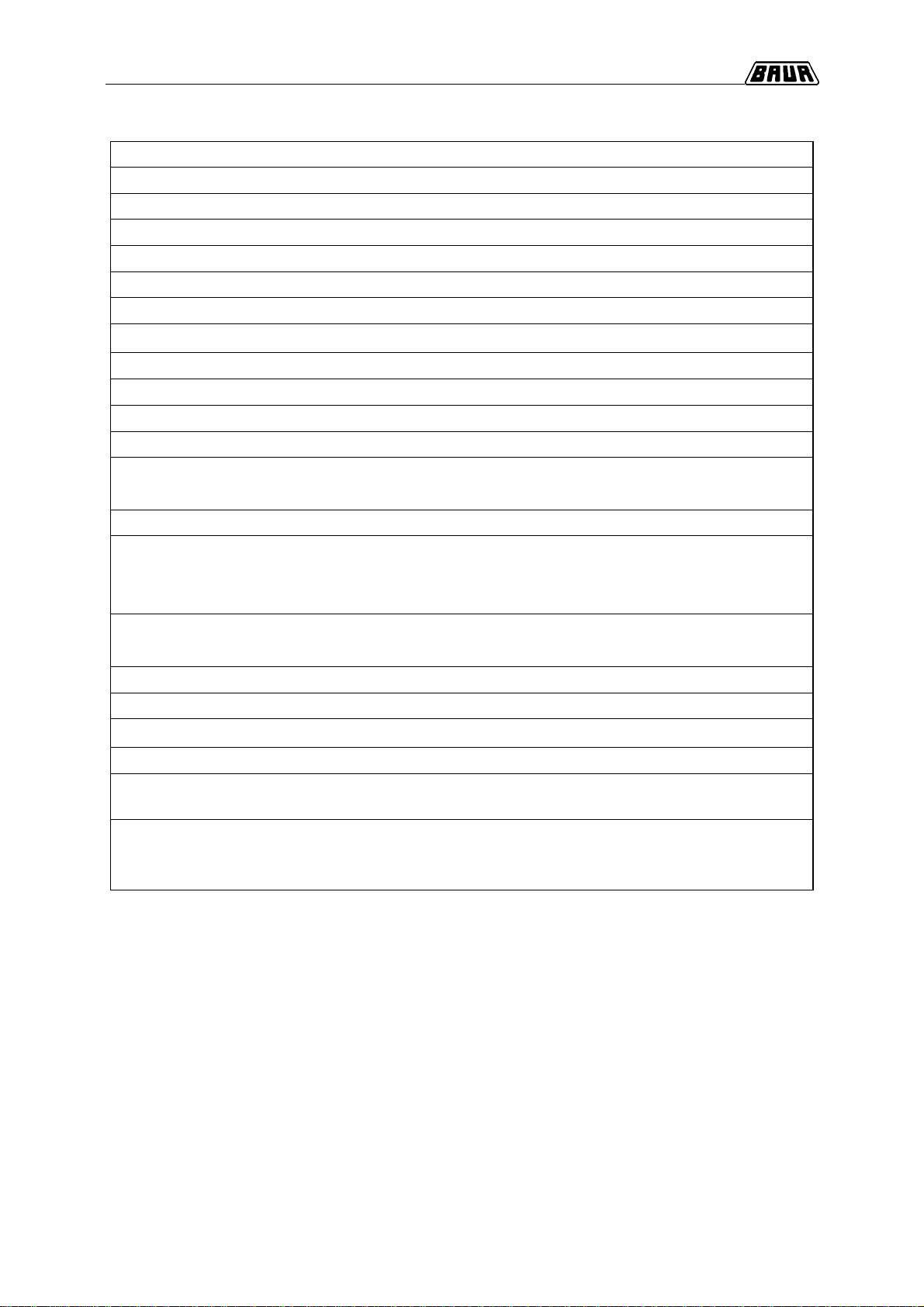

Product Information

Power supply 100 ... 240 V (50 / 60 Hz)

Power consumption approx. 120 VA

Internal, rechargeable battery (option) 2 x 6 V / 6.5 Ahrs

Output voltage, dielectric strength test 0 ... 75 kVrms symmetric

For insulating liquids with tan dvalues < 4.5 or specific resistance r > 30 MWm

Voltage rate of rise 0.5 / 1 / 2 / 3 / 5 kV/s

Switch off current 4 mA

Switch-off time on breakdown £1 ms

Error message Real Breakdown Monitoring (RBM) detects actual flash over

Internal temperature acquisition of oil sample 0 - 99C/+32F...+120F

Temperature resolution 1C/1.8F

Display Back lit, 160 x 80 dot matrix LCD

Voltage indication digital 0 - 75 kV ± 1 kV

Resolution (displayed) 0.1 kV

Languages German, English, French, Spanish, ask for other languages

Interface bidirectional RS 232; 9600 Baud; 8 Bit

1 stopbit; no parity

9 pin sub D

Printer (option) matrix printer, 24 char.

57 mm / 2 1/4" plain paper

Operating temperature 0C ... +45C/+32F...+113F

Storage temperature - 20C ... +55C/-4F...+131F

Relative humidity £90 %

Dimensions 405 x 345 x 275 mm / 16" x 13 1/2" x 10 3/4"

Weight without battery 18.7 kg / 43.6 lbs

with battery (option) 21 kg / 49 lbs

Designed and built acc. to the following standards: IEC 1010,

EN 61010-1,

VDE 0411 Part 100

1-11

Product Information

1.7 RBM switching off

RBM is an electronic monitoring of the kV indication

which controls the measuring process at breakdown.

RBM monitors the linearity of voltage rate of rise within

a specified tolerance range.

RBM

Real Breakdown Monitoring

CONT.

WARNING 8

RBM SWITCHING OFF

IS ACTIVATED!

With key CONT. jump back to the actual menu.

Indication at

RBM switching off

- air breakdowns

- insulating liquid too low-resistive (eg with water)

- insulating liquid to be tested does not correspond

with the following specifications:

insulating liquid with tan dvalues < 4.5 resp. specific

resistance r > 30 MWm

Causes of RBM switching off

Condition for RBM Calibrated DPA 75 unit.

Calibration of the DPA 75 unit should be carried out

once per year.

With RBM switching off the test cycle is canceled

automatically. On the display appears:

1-12

Product Information

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes

Table of contents

Other Baur Test Equipment manuals