9

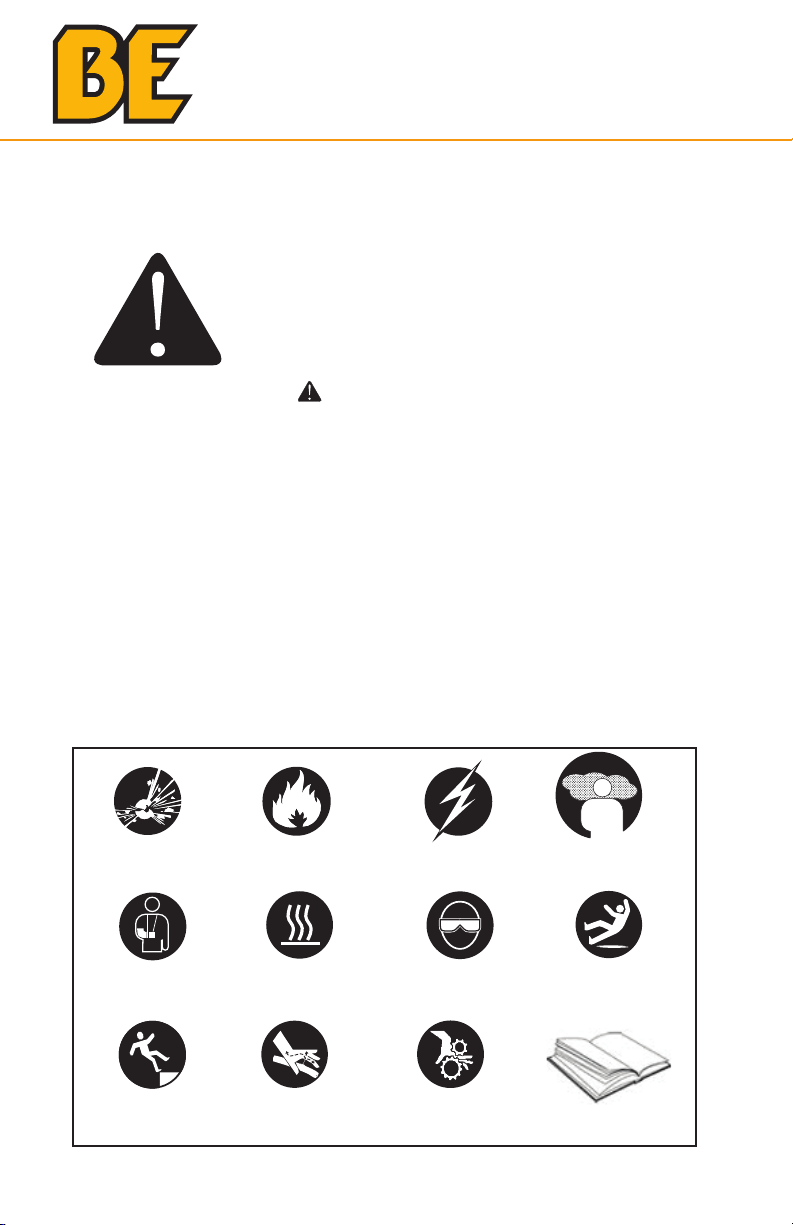

safety

WARNING

AIR TANK WARNING: Drain liquid from air tank daily,

or after each use, using the drain valve located on

the bottom of the lower air tank. Failure to properly

drain liquid from the tank will cause rust from mois-

ture buildup, which weakens the tank and could lead

to a violent tank explosion, Periodically inspect the

tanks for unsafe conditions such as corrosion.

Never attempt to repair or make modifications to the tank or its at-

tachments. Welding, drilling or any other modifications may weaken

the tank, which may result in damage from rupture or explosion.

Never remove or attempt to adjust the pressure switch, safety

valve, or other factory set operating pressures.

WARNING

FIRE WARNING: Avoid dangerous environments. Do

not use compressor near gasoline or other flamma-

ble materials. Keep work area well lit. Normal spark-

ing of a motor or sparking from grinding metal could

ignite fumes. Do not spray flammable materials in the

vicinity of an open flame or other ignition source, in-

cluding the air compressor itself. Do not direct paint

or other spray material towards the compressor.

Read and follow all safely instructions for the material you are

spraying. Be sure to use an approved respirator designed for use

with your specific application.

WARNING

BREATHABLE AIR WARNING: This air compres-

sor in not designed, nor intended for the supply of

breathable quality air. Air produced by this unit may

contain carbon monoxide or other toxic vapors.

Do not inhale air from the compressor or from a breathing device

connected to it.