8

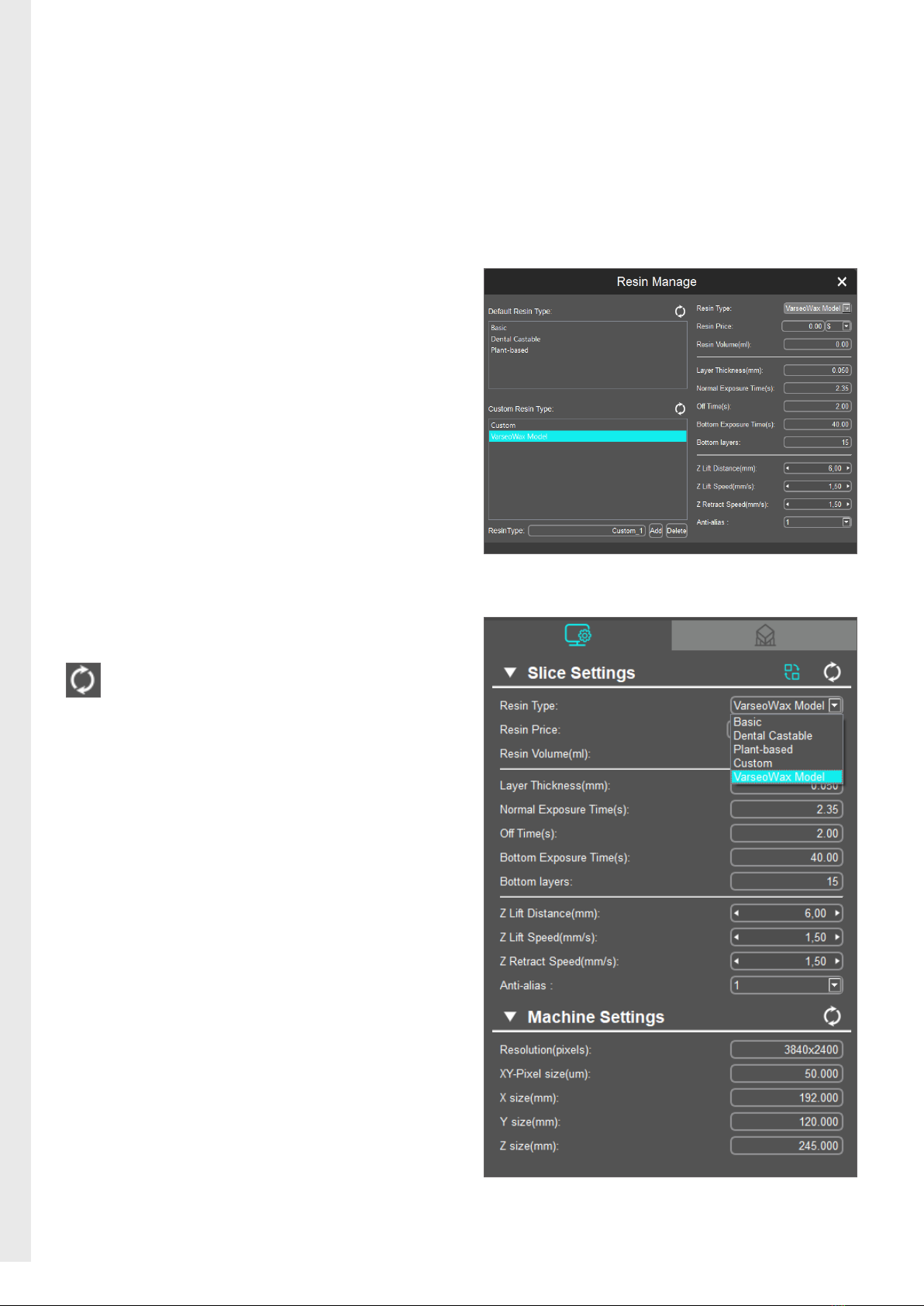

Now perform the nesting of the objects to be printed from

VarseoWaxModel (see also video tutorial).

Load your .STL file into the nesting program using drag and drop.

Select the loaded object so that it is highlighted. You now have the

option of positioning the object manually on the construction field

using the left mouse button.

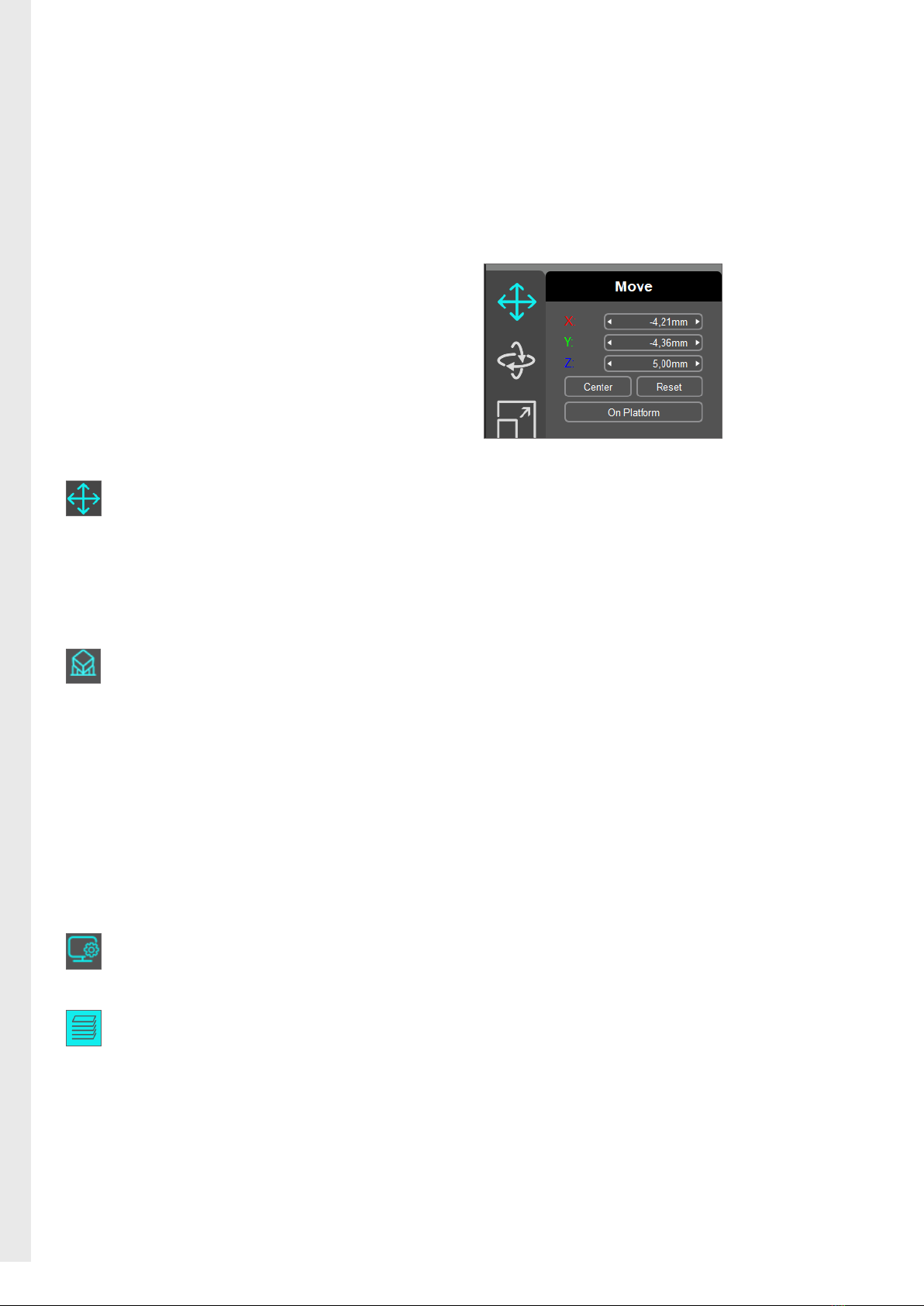

To move the object in a defined way in the respective axes by

changing the X/Y/Z values, click on the following symbol:

For hollow models and tooth stumps, we recommend printing with

support structures. To do this, position the object manually or by

adjusting the Z axis to at least 5 mm.

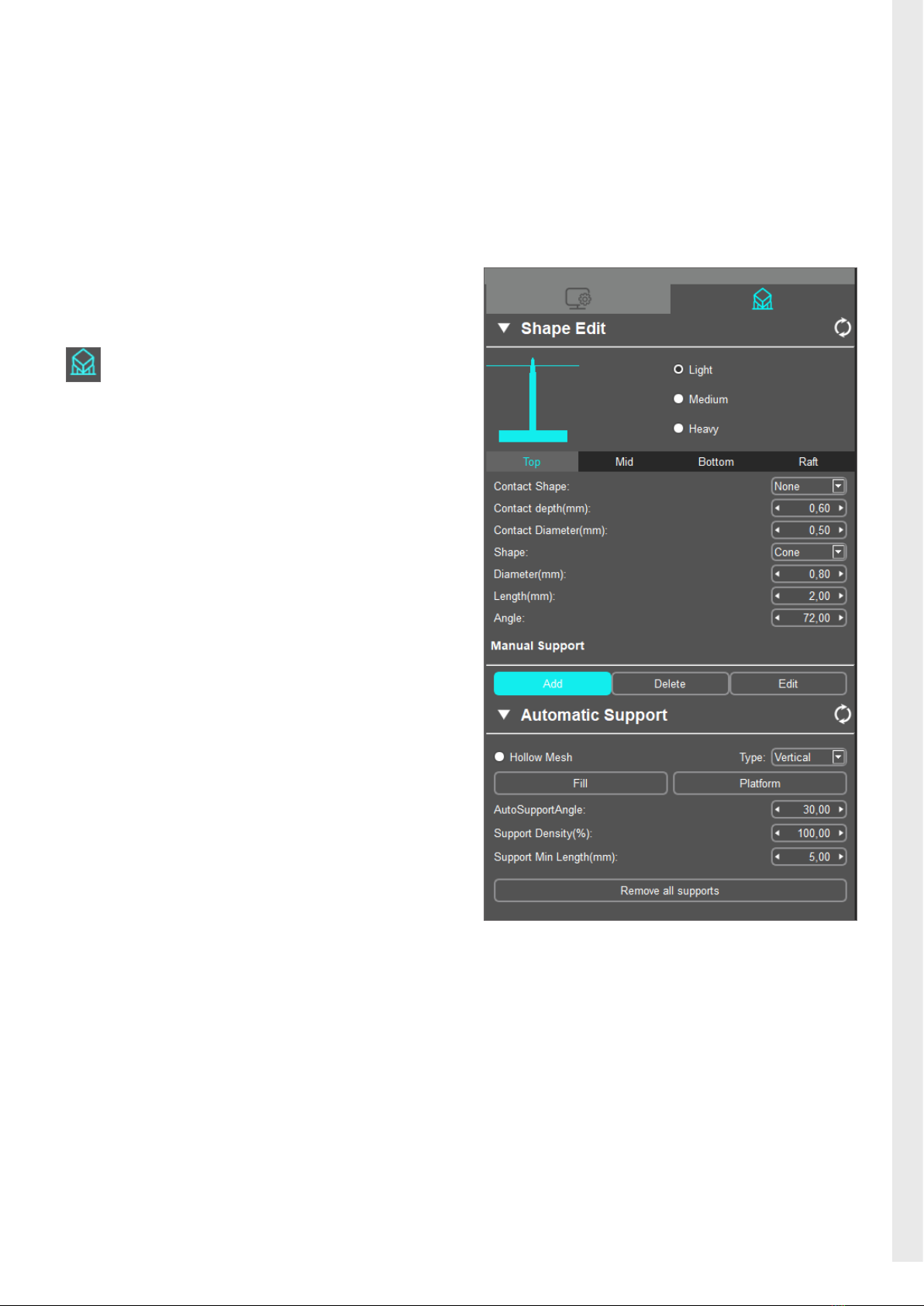

To set the supports for the objects to be printed, go to the menu item

Supports with the following button:

Then click Fill to generate supports automatically. By selecting the

Add or Delete button, you can manually add or remove supports.

5. Nesting

Generate print file:

To return to the main menu, click on the following icon:

Now generate the print file by clicking the following button:

Save the file to the supplied USB stick and wait for the print file to be

created successfully.

You will be given the opportunity to check the print process

by clicking Preview after the creation of the print file has been

completed.

Please note that using special characters in the print file name could

cause complications.

Go directly to the video tutorial at:

www.bego.com/3d-printing/compatibility-overview/#anycubic