6.2 Description of configuration menu

functions

This section contains a detailed description of each

function in the configuration menu. It should be read

in conjunction with Figs 5, 6 & 7.

6.2.1 Transmitter input ‘InPut’

This function enables the BA678C indicating

temperature transmitter to be conditioned to operate

with a thermocouple, 3 or 4 wire resistance

thermometer, voltage or 3 or 4 wire resistance input.

A differential resistance thermometer input may also

be selected. A differential thermocouple input is

achieved by selecting the thermocouple input in this

function and turning the cold junction compensation

off in the CJC function – see 6.2.5.

Sensor Transmitter

display

Thermocouple ‘tHC’

3 wire RTD ‘3rtd’

4 wire RTD ‘4rtd’

Differential RTD ‘d_rtd’

Voltage ‘VoLt’

3 wire resistance ‘3rES’

4 wire resistance ’4rES’

The ‘InPut’ function is the first function displayed

when entering the configuration menu, or it may be

selected from within the menu by operating the or

button. To enter the function press Pto reveal the

existing setting which may be changed using the

or button. When the required input has been

selected press Eto enter the selection and return to

the ‘InPut’ prompt in the configuration menu.

6.2.2 Thermocouple type ‘t.tYPE’

This function enables one of eight common

thermocouples to be selected. The following table

shows the thermocouple types, indicator display and

the operating temperature range.

THC BA678C Temperature

Type Display range oC

B ‘b’ 200 to 1820

E ‘E’ -200 to 1000

J ‘J’ -210 to 1200

K ‘H’ -200 to 1372

N ‘n’ -200 to 1300

R ‘r’ -50 to 1768

S ‘S’ -50 to 1768

T ‘t’ -200 to 400

The ‘t.tYPE’ function may be selected from within the

menu by operating the or button. To enter the

function press Pwhich will reveal the existing setting

which may be changed using the or button.

When the required thermocouple has been selected,

press Eto enter the selection and return to the

‘t.tYPE’ prompt in the configuration menu.

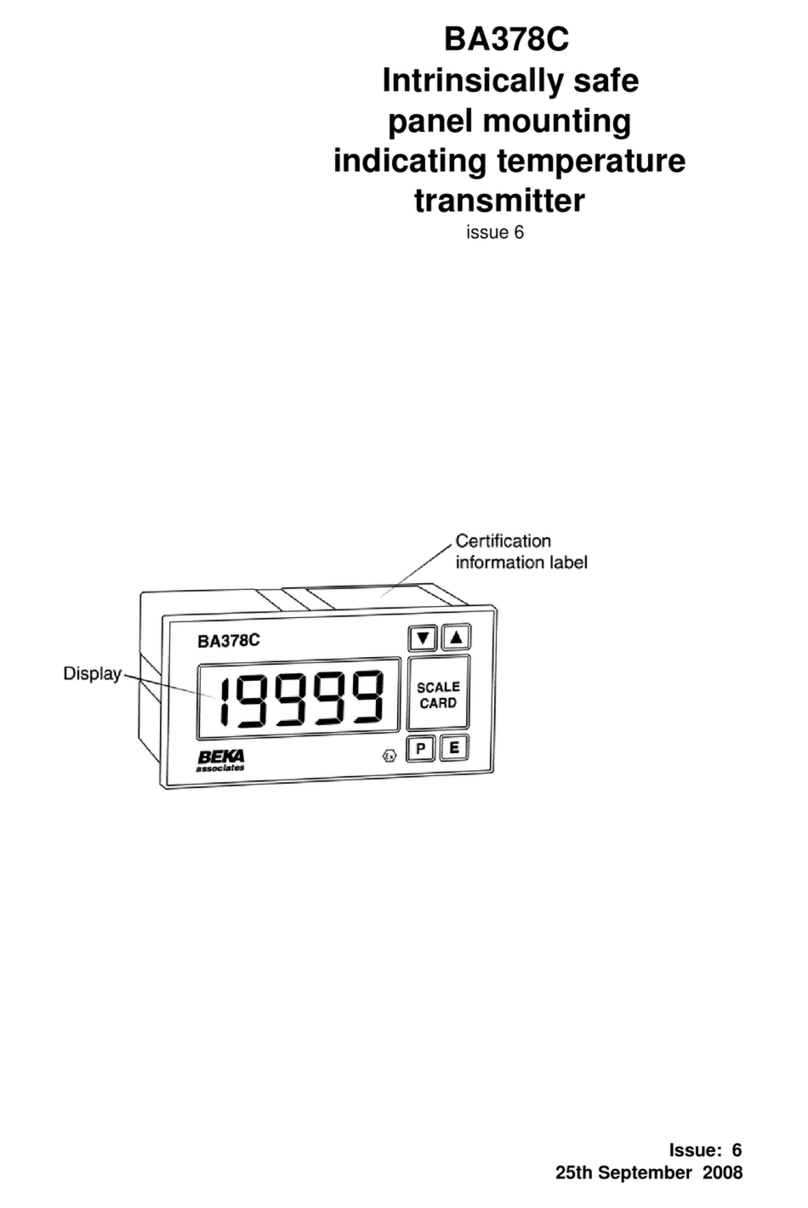

6.2.3 Units of digital display ’dEG’

The transmitter digital display may be in one of four

units of temperature.

Units Transmitter Display

oC

oC

oF

oF

r r

K H

When oCoroF are selected the units of measurement

are shown at the top left hand corner of the display

when the transmitter is in the operating mode.

The ‘dEG’ function may be selected from within the

menu by operating the or button. To enter the

function press Pwhich will reveal the existing setting

which may be changed using the or button.

When the required units have been selected, press E

to enter the selection and return to the ‘dEG’ prompt

in the configuration menu.

6.2.4 Display resolution ‘rESn’

This function defines the resolution of the transmitter

display but does not affect the resolution of the

4/20mA output current.

Resolution Transmitter Display

Lo 0 0 0 0 0

Hi 0 0 0 0.0

The ‘rESn’ function may be selected from within the

menu by operating the or button. To enter the

function press Pwhich will reveal the existing setting

which may be changed using the or button.

When the required resolution has been selected,

press Eto enter the selection and return to the ‘rESn’

prompt in the configuration menu.

6.2.5 Cold junction compensation ‘CJC’

The temperature of the thermocouple cold junction,

which is the transmitter input terminals, is measured

and added to the thermocouple output so that the

transmitter displays and transmits the hot junction

temperature. If cold junction compensation is not

required e.g. for differential measurements with two

thermocouples, this function allows it to be turned off.

The ‘CJC’ function may be selected from within the

configuration menu by operating the or button.

To enter the function press Pwhich will reveal the

existing setting which may be changed using the

or button. When set as required, press Eto enter

the selection and return to the ‘CJC’ prompt in the

configuration menu.

10