9

7. CONFIGURATION

The BA478C Indicating Temperature Transmitter

may be configured and calibrated via HARTdigital

communication, or configuration may be performed

using the menu accessed via the front panel push

buttons see Fig 5.

Configuration and calibration via HARTmay be

performed using a portable configurator connected

directly to the BA478C or to the galvanic isolator

powering the transmitter, alternatively proprietary

configuration software operating on a personal

computer may be used. In addition to the

configuration functions available via the transmitter

push buttons, HARTcommunication enables loop

calibration and custom linearisation to be performed.

Details of the HARTcommunication are contained in

the BEKA HARTInterface Guide which may be

downloaded from www.beka.co.uk/manuals

7.1 Configuration menu

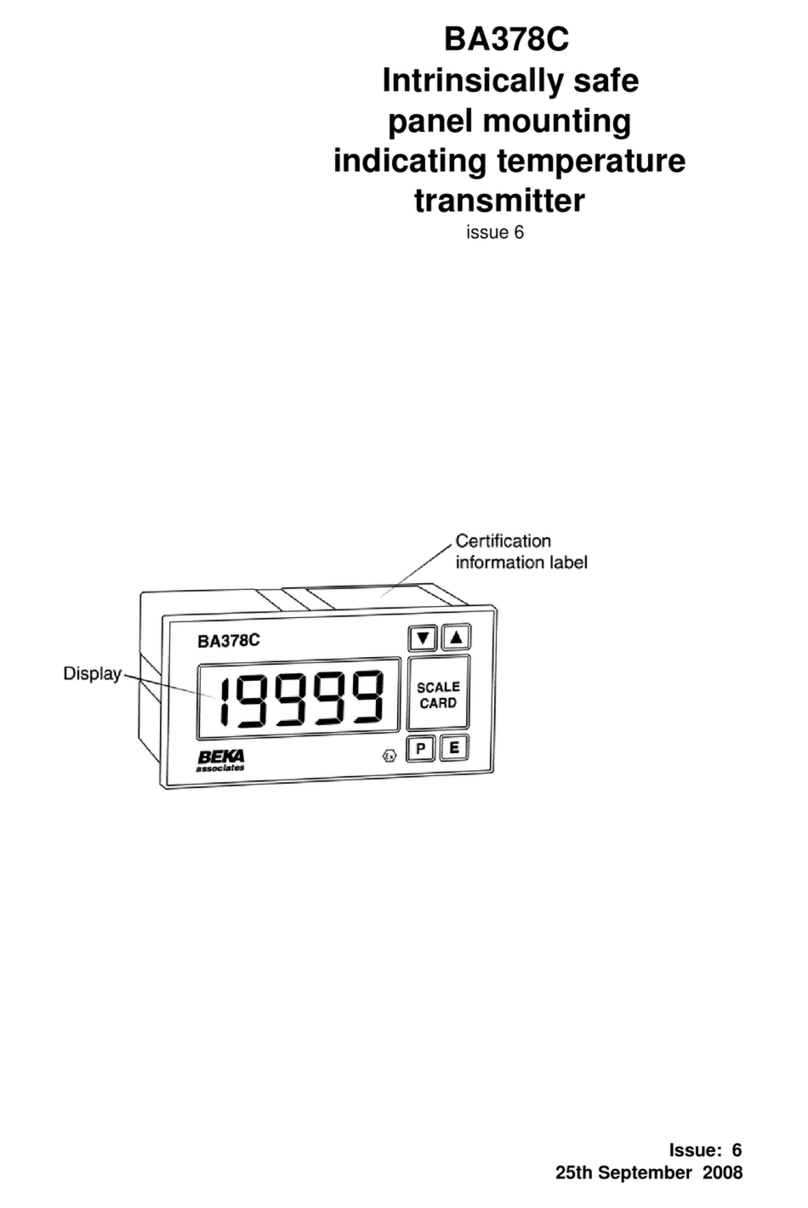

Throughout this manual the BA478C push buttons

are identified P E ▼▲and legends displayed by

the transmitter are shown within inverted commas

e.g. ‘CAL’ and ‘dEG’. Section 7.1.2 contains a

summary of each configuration function including a

cross reference to a more detailed description.

The functions contained in the configuration menu

vary depending upon the transmitter input selected,

see Figs 7, 8 & 9.

When the transmitter is being configured, the

transmitter 4/20mA output current is locked at the

value prior to entering the configuration menu.

When the optional alarms are fitted additional

functions are added to the configuration menu which

are described in section 10.3.

7.1.1 Access

Access to the configuration menu is obtained by

operating the Pand Ebuttons simultaneously. If the

transmitter is not protected by an access code the

first parameter 'InPut’ will be displayed. If the

transmitter is protected by an access code, ‘CodE’

will be displayed first. Pressing Pwill allow the four

digit security code to be entered digit by digit using

the or button to adjust the flashing digit and Pto

move control to the next digit. When the correct code

has been entered, pressing Ewill cause the first

parameter ‘InPut’ to be displayed. If an incorrect

code is entered, or no button is pressed for ten

seconds, the transmitter will automatically return to

the operating mode.

If the transmitter displays ‘LoC’ when the Pand E

buttons are operated simultaneously, the transmitter

push buttons have been locked by a HART

command - see the BEKA HARTInterface Guide

which may be downloaded from

www.beka.co.uk/manuals

7.1.2 Summary of functions

The functions that may be configured vary depending

upon the input selected.

Thermocouple and RTD inputs

The BA478C will always display sensor temperature.

Configuration allows:

Digital display units and resolution to be selected.

Bargraph display to represent required part of the

digital displayed range.

4/20mA output current to represent required part

of transmitter input range.

Voltage and resistance inputs

The BA478C can display the voltage or resistance

input in any engineering units.

Configuration allows:

Zero and span of digital display to be adjusted.

Bargraph display to represent required part of the

digital displayed range.

4/20mA output current to represent required part

of the transmitter input range.

Each of the functions in the configuration menu is

summarised below, including a cross-reference to a

more detailed description.

Transmitter Summary

display of function

‘InPut’ Transmitter input

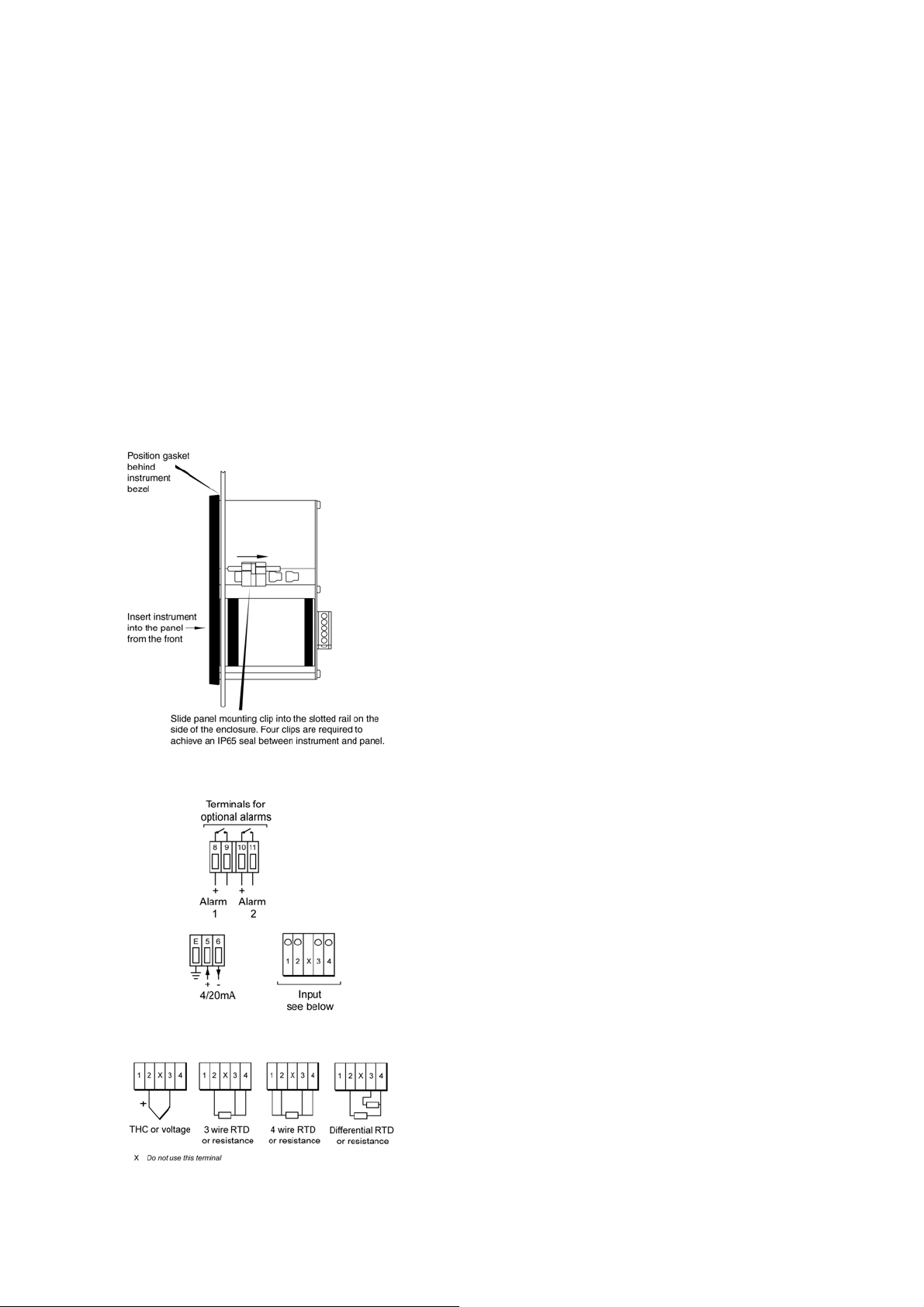

Selects one of the following inputs:

Thermocouple ‘tHC’

3 wire RTD ‘3rtd’

4 wire RTD ‘4rtd’

Differential RTD ‘d_rtd’

Voltage ‘Volt’

3 wire resistance ‘3rES’

4 wire resistance ’4rES’

See section 7.2.1

The content of the configuration menu depends upon

which transmitter input is selected, see following

summary and Figs 7, 8 and 9.