3

1. DESCRIPTION

The BA474D is a field mounting, intrinsically safe

4/20mA loop powered temperature transmitter with a

large easy to read display. The instrument, which is

HARTenabled, may be conditioned on-site to

operate with most common thermocouples and

resistance thermometers and will provide a linear

4/20mA output proportional to temperature, plus a

digital temperature display. Voltage and resistance

inputs may be scaled allowing the BA474D to display

variables other than temperature such as position

and weight.

Optional factory fitted alarms provide two galvanically

isolated solid state outputs that may be

independently configured for high or low operation.

For installation in poorly illuminated areas, an

optional factory fitted loop powered display backlight

is available.

The BA474D has been certified intrinsically safe and

as associated apparatus by European Notified Body

Intertek Testing and Certification Ltd (ITS). The

transmitter complies with the ATEX Directive 94/9/EC

for use in explosive gas and combustible dust

atmospheres. ATEX dust certification is an option -

see Appendix 1.

For international applications the BA474D has IECEx

intrinsic safety and associated apparatus certification

for use in explosive gas and combustible dust

atmospheres. IECEx dust certification is an option –

see Appendix 3. A version with FM and cFM

approval is available – see Appendix 2.

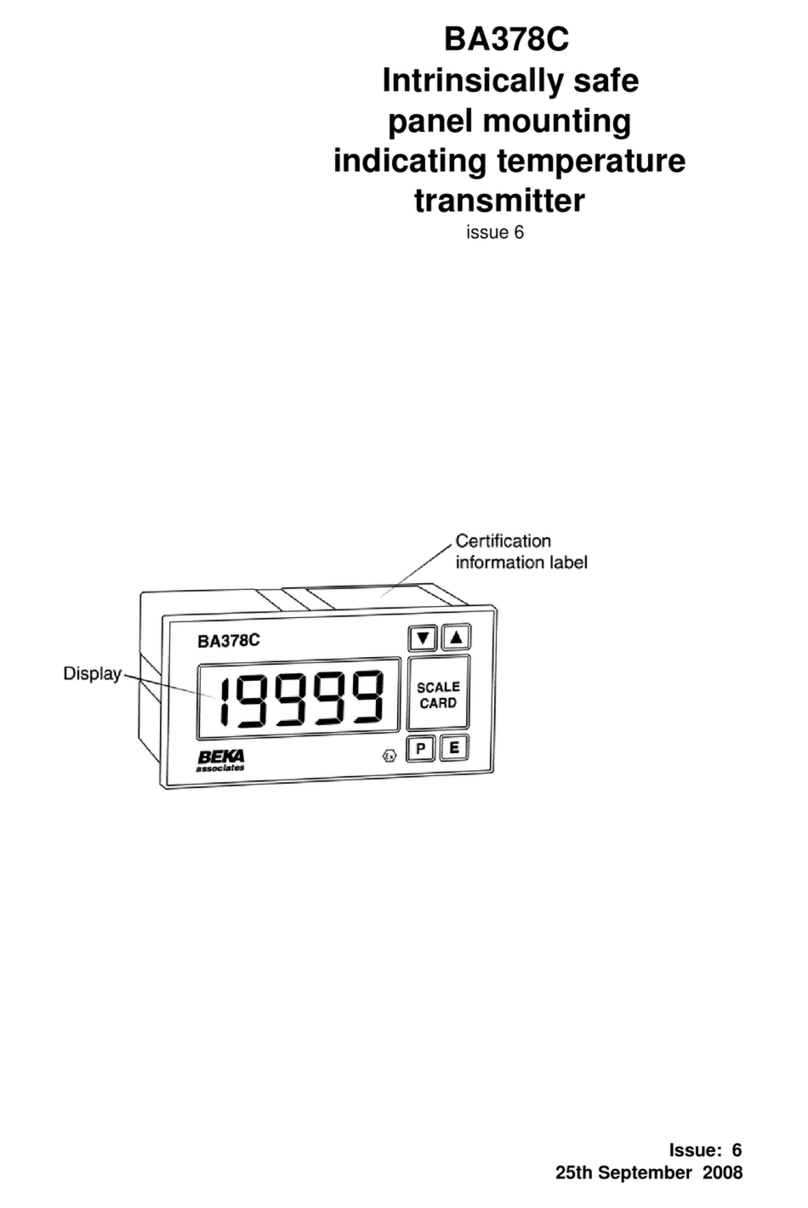

Fig 1 Simplified block diagram

2. DOCUMENTATION

This instruction manual describes the installation and

configuration of the BA474D Indicating Temperature

Transmitter for ATEX intrinsically safe and associated

apparatus applications.

System design information for IECEx and other non-

ATEX certifications and for use in combustible dust

atmospheres is contained in Appendices to this

manual.

The transmitter is HART Registered and is compliant

with HART protocol standard revision 7. HART

commissioning information is included in the

BA47X/67X Indicating Temperature Transmitter

HARTInterface Guide which may be downloaded

from www.beka.co.uk/manuals

3. OPERATION

Fig 1 shows a simplified diagram of the BA474D

Indicating Temperature Transmitter. The input,

which may be from a resistance thermometer,

thermocouple, or a dc voltage or resistance, is

digitised and transferred to the instrument processor

via an optical isolator. The processor linearises the

input signal, displays the resulting temperature in the

selected units and controls the 4/20mA output

current.

3.1 Controls

All functions of the transmitter may be configured via

the four push buttons which are located behind the

removable switch cover – see Fig 7. For applications

where frequent adjustments are required the BA474D

transmitter is available with an optional external

membrane keypad. Buttons respond within 0.5

seconds of being operated and unless continuously

pushed the transmitter display will return to the

operating mode after 2 seconds.

In the operational mode, i.e. when the transmitter is

displaying the input signal, these push buttons have

the following functions:

Button Function

While this button is operated the transmitter

will show the display corresponding to 4mA

output.

▲While this button is operated the transmitter

will show the display corresponding to

20mA output.

+Transmitter displays output current in mA

followed by output as % of the range.

P + Transmitter displays HARTshort address

followed by firmware version number.

P + EEntry to configuration menu.

When fitted with optional alarms

P + Entry to alarm set point menu. See 10.4.12

E + Transmitter displays alarm 1 setpoint

E + Transmitter displays alarm 2 setpoint

P Activated alarm reverts to the non-alarm

condition for the configured alarm silence

time. See 10.4.11