3. TYPE 'n' CERTIFICATION

3.1 Certificate of Assurance

BASEEFA has issued the BA374NC with a

Certificate of Assurance BAS No. 96Y4522

confirming compliance with BS6941:1988. This

verifies that in normal operation the BA374NC is

not capable of igniting a surrounding explosive

atmosphere, and a fault capable of causing ignition

is not likely to occur.

3.2 ATEX certification

The BA374NC complies with the European ATEX

Directive 94/9/EC for Group II, Category 3G

equipment. It has been assessed using the

'Internal Control of Production' procedure specified

in Annex 8 of the Directive. A Technical Dossier

has been prepared and a EC Declaration of

Conformity number N0014 has been issued.

The instrument bears the Community Mark and,

subject to local codes of practice, may be installed

in any of the European Economic Area (EEA)

member countries. i.e. Austria, Belgium,

Denmark, Finland, France, Germany, Greece,

Ireland, Italy, Luxembourg, The Netherlands,

Portugal, Spain, Sweden, and the United Kingdom.

ATEX certificates are also accepted in Norway,

Iceland, Liechtenstein, Switzerland and the Czech

Republic. This manual describes installations

which conform with BS EN60079:Part14:1997

Electrical Installation in Hazardous Areas. When

designing systems for installation outside the UK,

the local code of practice should be consulted.

3.3 Zones, gas groups and T rating

The BA324NC has an EEx nL IIC T5, Tamb -40 to

60oC safety code as defined in BS EN50021:1999

Electrical apparatus for potentially explosive

atmospheres - Type of protection 'n'.

'L' indicates that the BA374NC uses an

energy-limiting technique to achieve compliance

as defined in Clause 21 of BS EN50021:1999.

This technique is based on the philosophy of

intrinsic safety which limits the current and voltage

applied to components which may generate a

spark in normal operation e.g. switches and

switches and potentiometers.

These approvals confirm that the BA374NC is

'safe in normal operation' and may be installed in:

Zone 2 explosive gas air mixture not

likely to occur, and if it does, it

will only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

Having a temperature classification of:

T1 450oC

T2 300oC

T3 200oC

T4 135oC

T5 100oC

This allows the BA374NC to be installed in Zone 2

and to be used with most common industrial

gases.

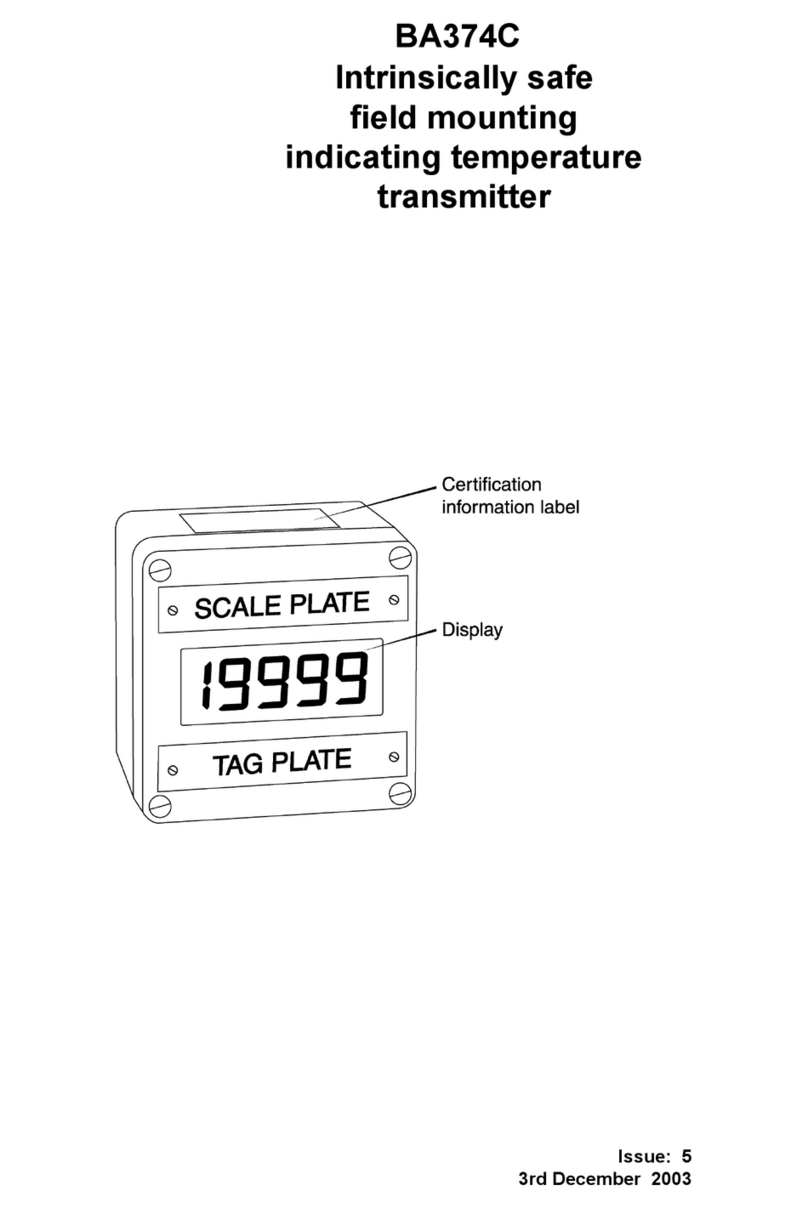

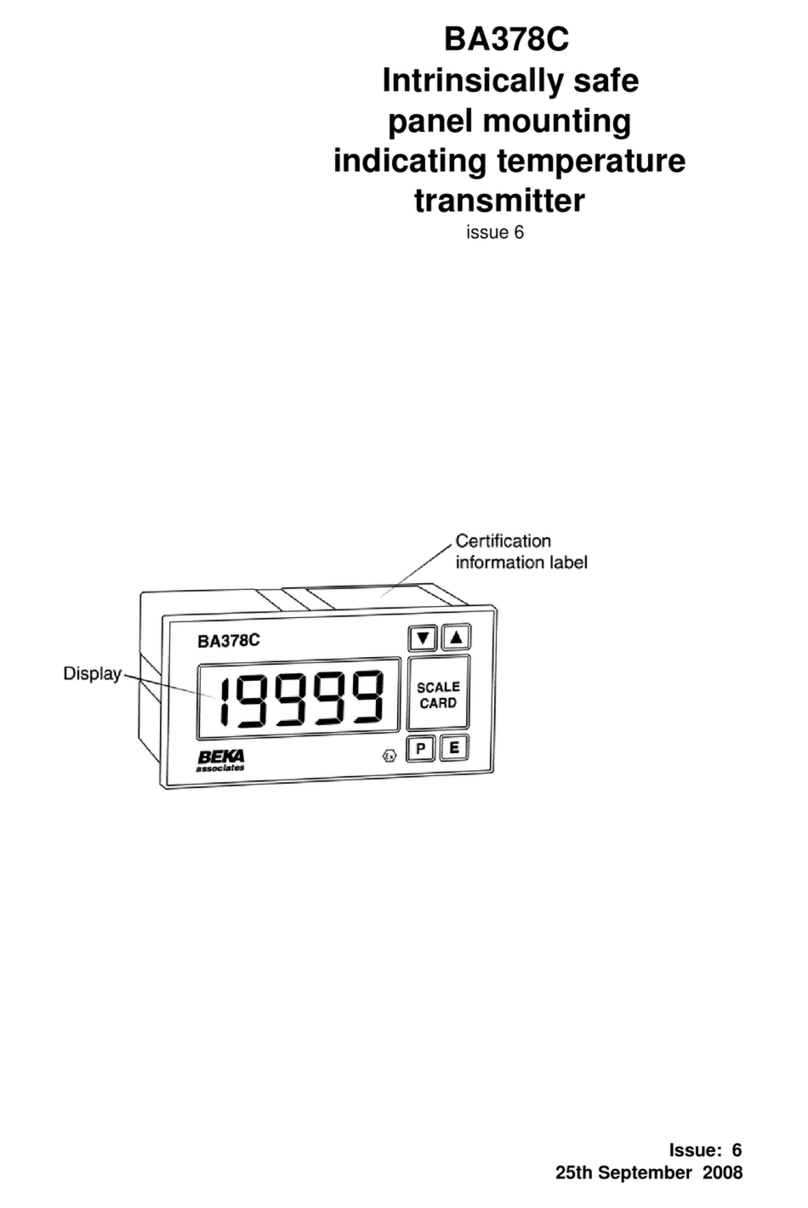

3.4 Certification label information

Certification information is shown on a label fitted

in a recess on the top outer surface of the

enclosure. It shows the ATEX certification

information and the Certificate of Assurance with

BS6941:1988. The instrument serial number and

date of manufacture are shown on a separate label

within the enclosure.

4. ELECTRICAL SYSTEM DESIGN FOR

INSTALLATION IN HAZARDOUS AREAS

There are two basic requirements when designing

a loop incorporating a BA374NC:

1. To comply with the EEx nL certification, in

normal operation i.e. without any faults, the

safe area power supply must have an output

voltage of less than 30V.

The safety compents within the BA374NC

will automatically ensure that the output

current does not exceed 25mA in normal

operation.

2. To ensure correct operation of the

transmitter the voltage between terminals 5

& 6 of the BA374NC must be between 10

and 30V at all output currents.

Fig 2 illustrates a typical temperature measuring

loop. The BA374NC is located in Zone 2 and

powered from a supply in the safe area.

WARNING

The enclosure cover should only be

removed when the measurement loop

is not energised, or when there is no

risk of a flammable atmosphere being

present and dust or water can not enter

the enclosure. Before replacing the

enclosure cover ensure that the sealing

gasket is undamaged and is free from

dirt and foreign bodies.

6