3. INTRINSIC SAFETY CERTIFICATION

3.1 ATEX certificate

The BA378C has been issued with an EC-Type

Examination Certificate number BAS02ATEX1185X

by EECS showing compliance with the European

ATEX Directive 94/9/EC for Group II, Category 1

gas atmospheres, EEx ia IIC T5. The instrument

bears the Community Mark and, subject to local

codes of practice, may be installed in any of the

European Economic Area (EEA) countries. i.e.

Austria, Belgium, Denmark, Finland, France,

Germany, Greece, Ireland, Italy, Luxembourg, The

Netherlands, Norway, Portugal, Spain, Sweden,

Switzerland and the United Kingdom. ATEX

certificates are also accepted in Norway, Iceland,

Liechtenstein, Switzerland and the Czech Republic.

This manual describes installations which conform

with BS EN60079: Part 14: 1997 Electrical

Installation in Hazardous Areas. When designing

systems for installation outside the UK, the local

Code of Practice should be consulted.

3.2 Other intrinsic safety certifications

Please contact BEKA for a list of non-European

intrinsic safety approvals.

3.3 Zones, Gas Groups and T rating

The BA378C and accessories have been certified

EEx ia IIC T5. When connected to an approved

system the transmitter may be installed in:

Zone 0 explosive gas air mixture

continuously present.

Zone 1 explosive gas air mixture likely

to occur in normal operation.

Zone 2 explosive gas air mixture not

likely to occur, and if it does,

it will only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

Having a temperature classification of:

T1 450oC

T2 300oC

T3 200oC

T4 135oC

T5 100oC

This allows the BA378C to be installed in all Zones

and to be used with most common industrial gases

at ambient temperature between -40 and +60oC.

Note: minimum operating temperature is -20oC.

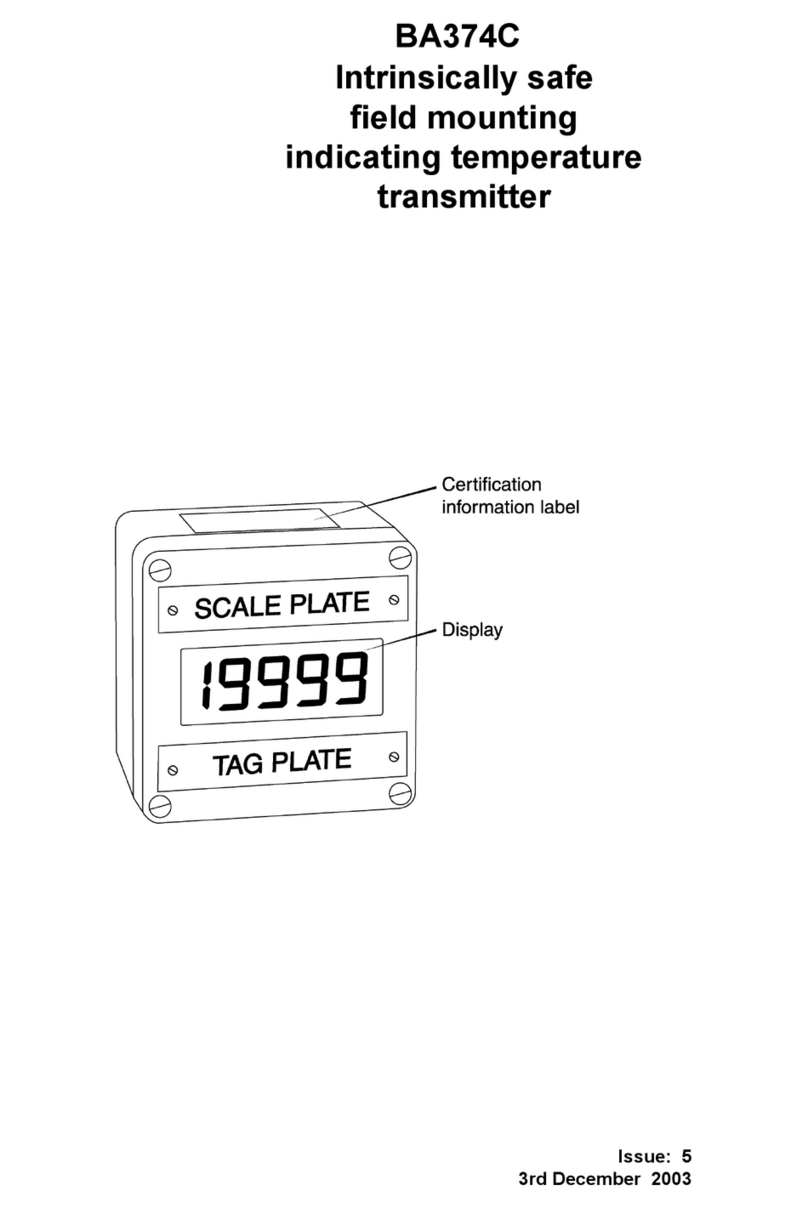

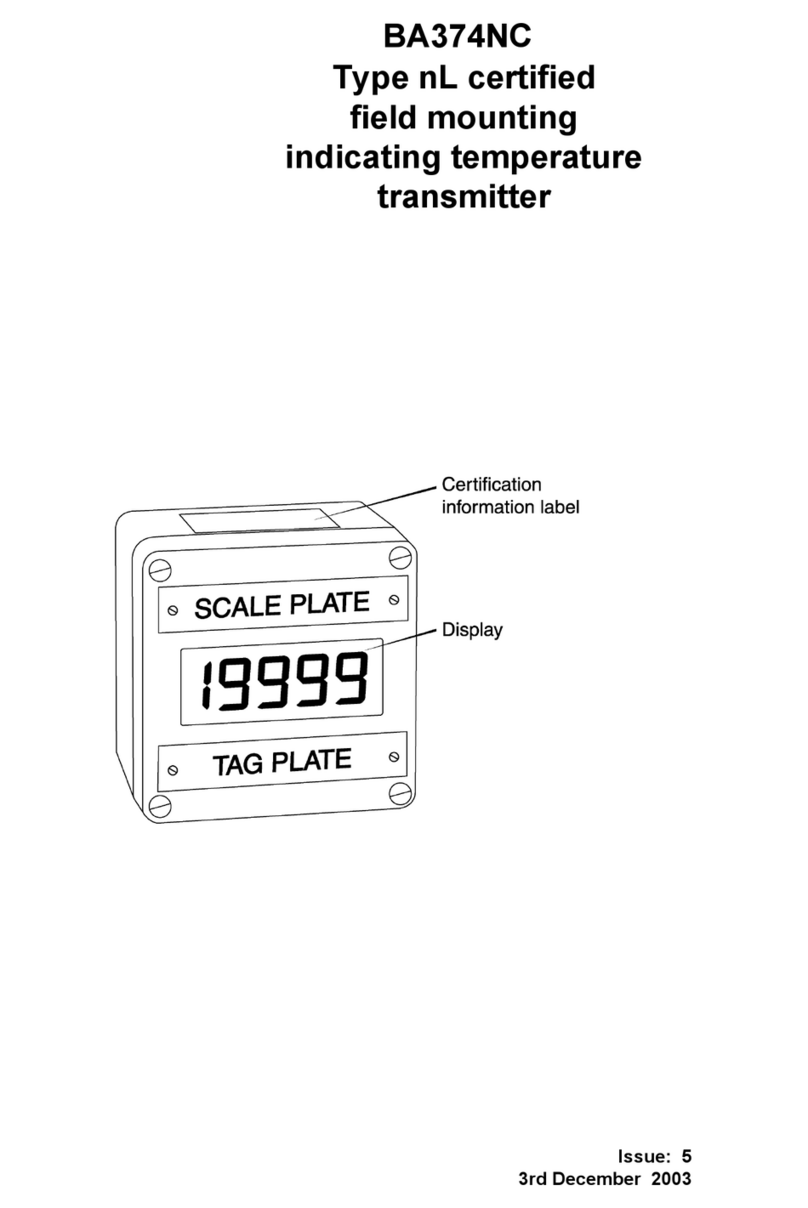

3.4 Certification information label

The certification information label, which is fitted on

the side of the instrument, shows the ATEX

certification information plus the instrument serial

number and date of manufacture.

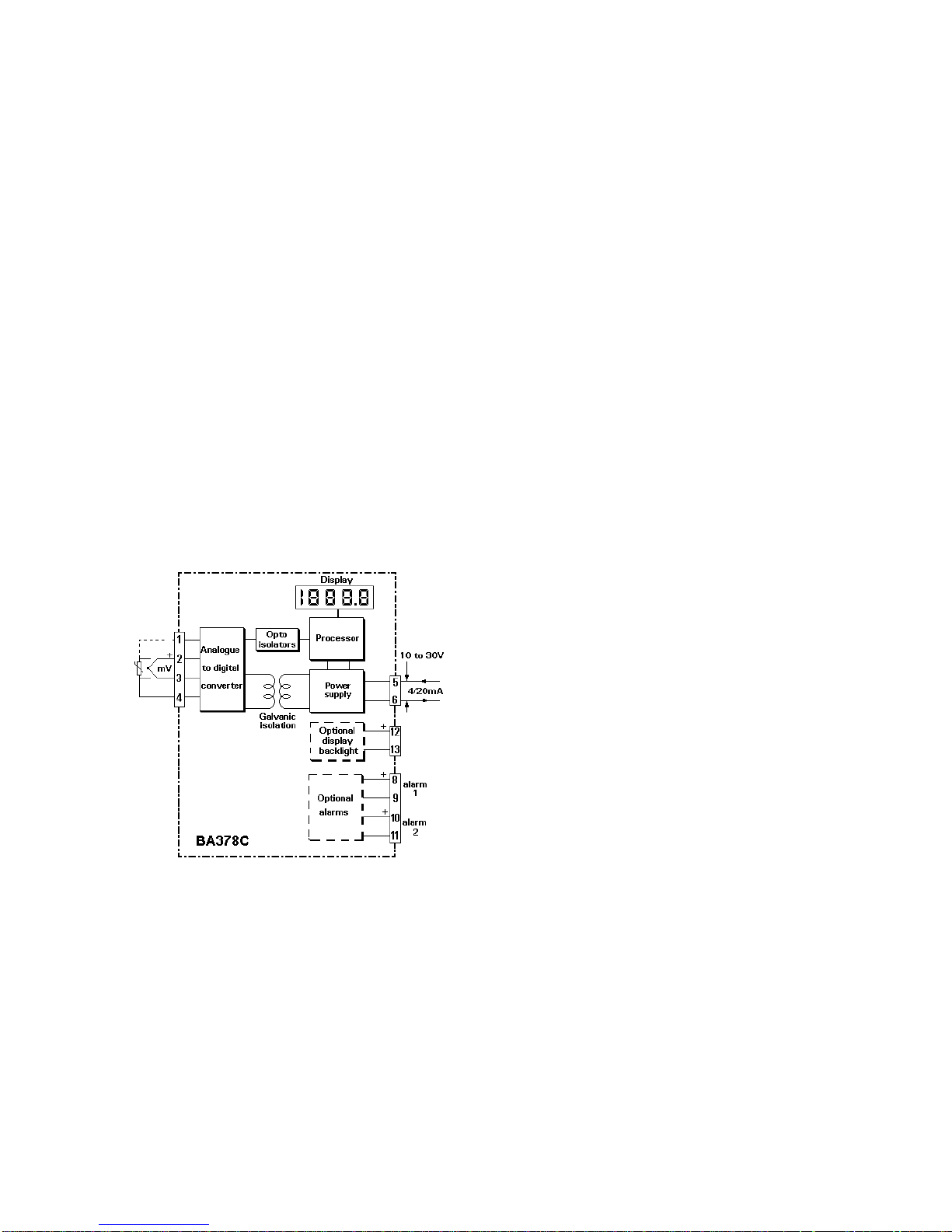

3.5 Input terminals 1, 2, 3 & 4

When the BA378C is installed in a hazardous area

the input terminals may be connected to any

floating or earthed sensor complying with the

requirements for simple apparatus as defined in

Clause 5.4 of EN50020:1994. i.e. the sensor

generates less than 1.5V, 100mA, or 25mW.

Thermocouples and resistance thermometers are

simple apparatus and any floating or earthed

device may be connected to the BA378C, providing

that both are installed within the hazardous area.

The permitted maximum parameters for the cables

connecting the transmitter to the sensor are 4µF

and 9.2mH in the most onerous gas group IIC

(hydrogen). These are large and are very unlikely

to be exceeded on any thermocouple or resistance

thermometer installation.

If the transmitter input is to be connected to a

device which does not comply with the

requirements for simple apparatus, a system

certificate should be obtained, or the safety of the

system assessed using the entity concept. The

certified safety description of the BA378C input

terminals is: Uo = 8.61V

Io = 62mA dc

Po = 0.14W

6