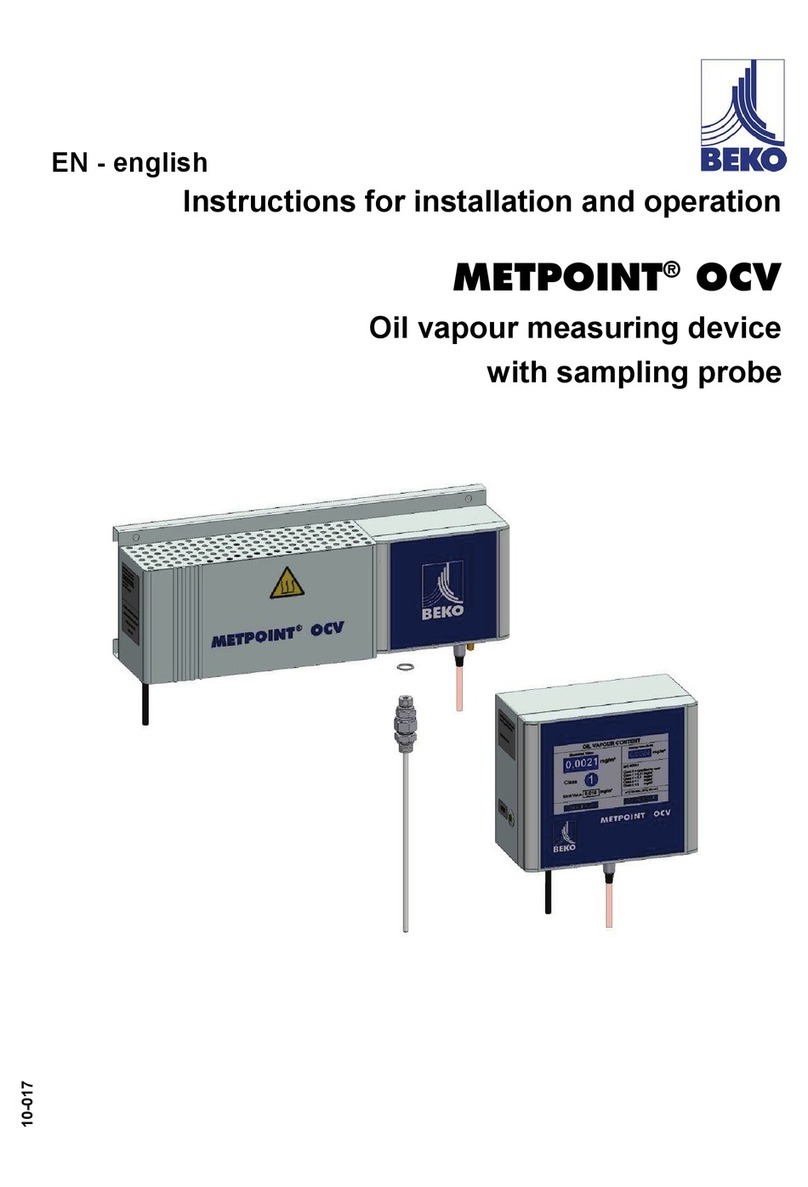

Installation and operating manual EN

2 METPOINT®SF53

Contents

1. Safety-related information.............................................................................................................................. 4

1.1. Pictograms and symbols.......................................................................................................................... 4

1.1.1. In this documentation........................................................................................................................................................4

1.1.2. On the device.......................................................................................................................................................................4

1.2. Signal words ........................................................................................................................................... 4

1.3. Safety instructions.................................................................................................................................. 5

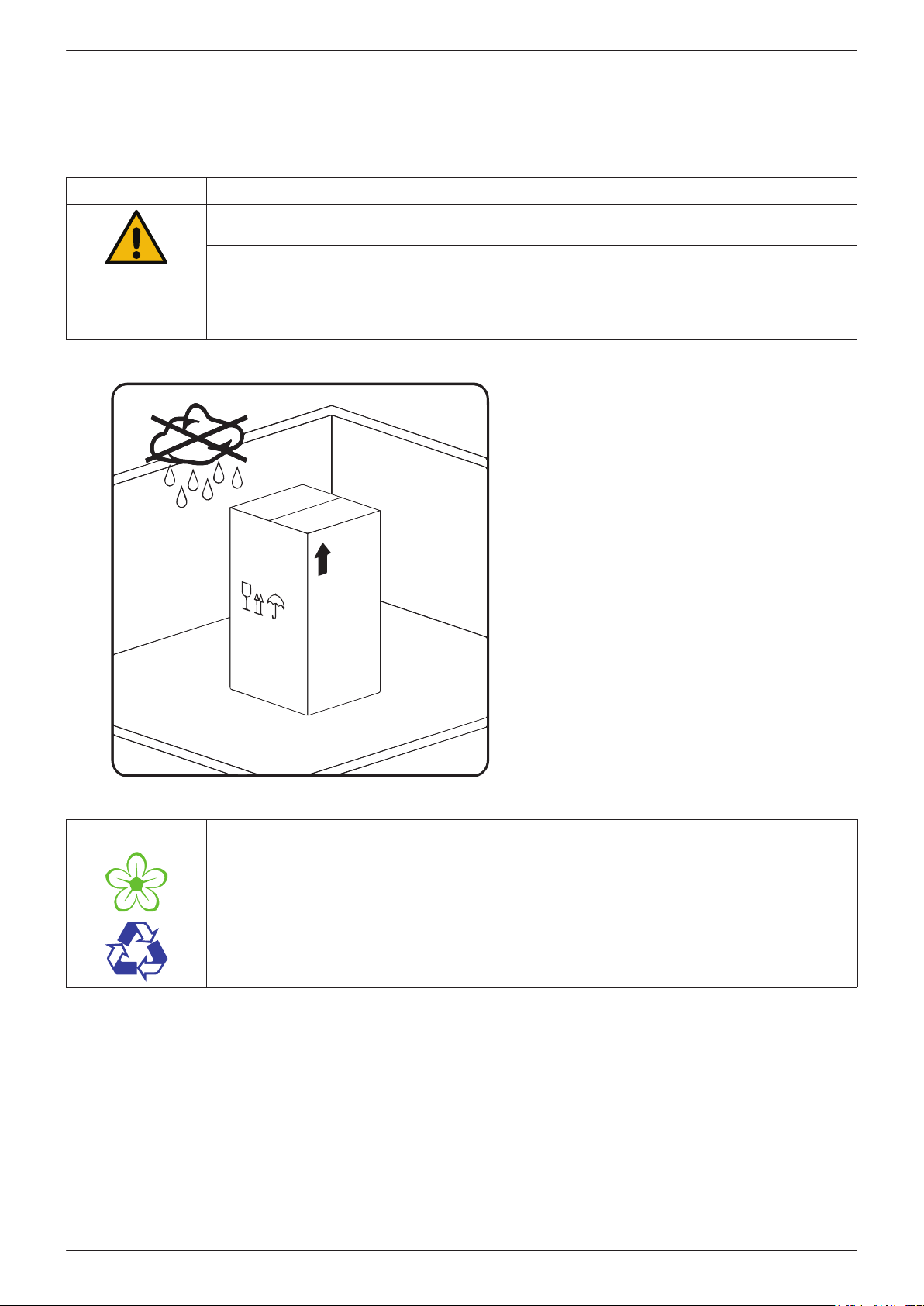

1.4. Transport and storage ............................................................................................................................. 6

1.5. Intended use........................................................................................................................................... 7

1.6. Warranty and liability for defects ............................................................................................................ 7

2. Product information ....................................................................................................................................... 8

2.1. Scope of delivery .................................................................................................................................... 8

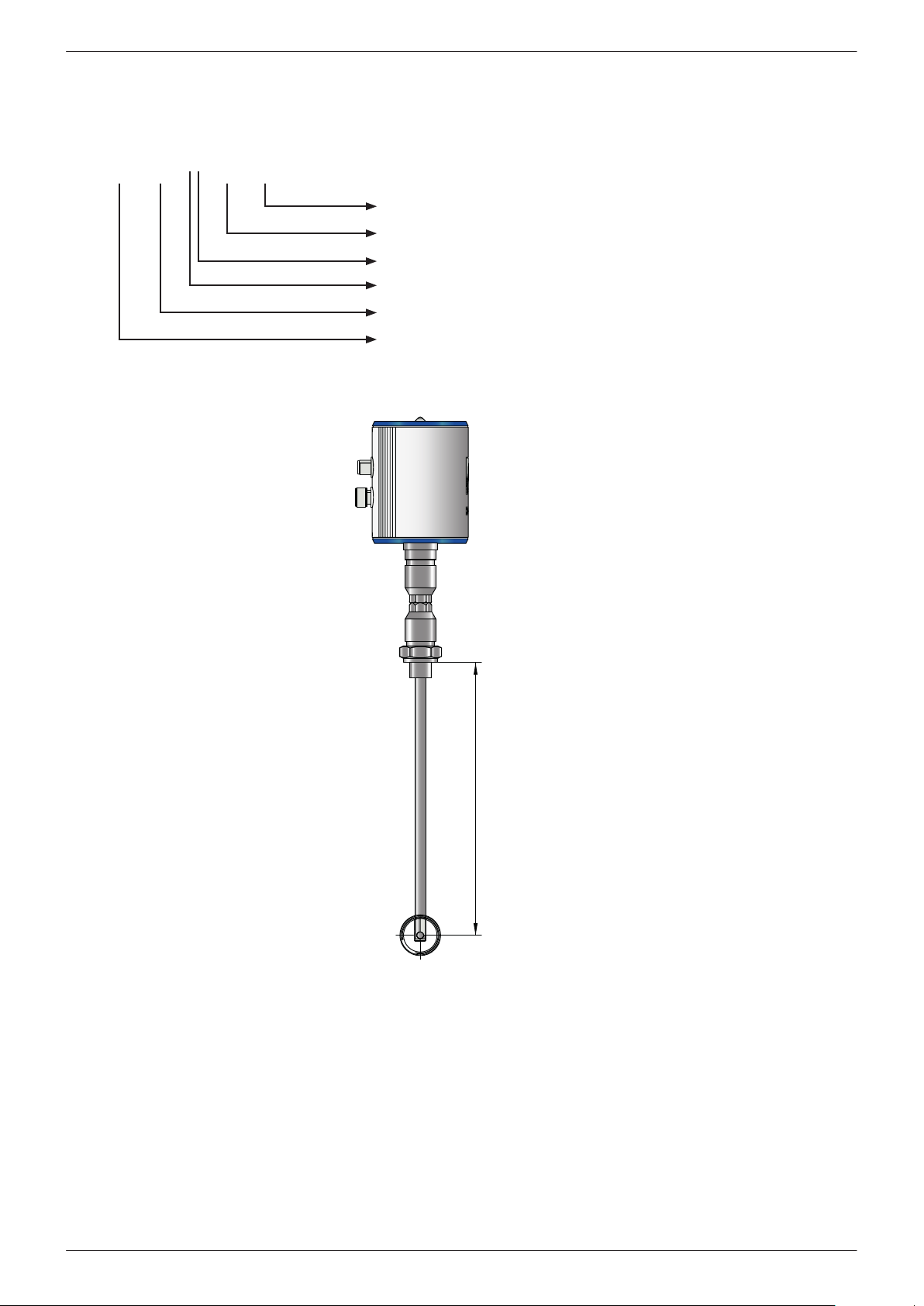

2.2. Type plate............................................................................................................................................... 8

2.3. Product overview and description ........................................................................................................... 9

2.3.1. Identication based on product code.............................................................................................................................9

2.3.2. Product description ......................................................................................................................................................... 10

2.3.3. Basic operating principles.............................................................................................................................................. 10

2.4. Control and display elements ................................................................................................................ 11

2.4.1. Model with display........................................................................................................................................................... 11

2.4.2. Model with LED ................................................................................................................................................................ 11

2.4.3. Direction of ow............................................................................................................................................................... 12

2.5. Dimensions........................................................................................................................................... 13

2.6. Technical data....................................................................................................................................... 14

2.7. Measuring ranges ................................................................................................................................. 15

3. Set up ........................................................................................................................................................... 17

3.1. Warning notices.................................................................................................................................... 17

3.1.1. Requirements for pipelines............................................................................................................................................ 17

3.1.2. Requirements for the inlet/outlet pipe section ........................................................................................................ 17

3.1.3. Turning the housing......................................................................................................................................................... 18

3.2. Assembly steps ..................................................................................................................................... 19

4. Electrical installation .................................................................................................................................... 20

4.1. Pin assignment of plug-type connectors ................................................................................................ 20

4.2. Connection options............................................................................................................................... 20

4.2.1. Bidirectional RS485 bus system.................................................................................................................................... 20

4.2.2. Current output 4 ... 20 mA, 3-wire .............................................................................................................................. 21

4.2.3. MBus.................................................................................................................................................................................... 21

4.2.4. Galvanically isolated pulse output............................................................................................................................... 22

4.3. Connection of METPOINT® BDL............................................................................................................. 23

4.3.1. Bidirectional RS485 bus system.................................................................................................................................... 23

4.3.2. Current output 4 ... 20 mA, 3-wire ............................................................................................................................... 24

4.3.3. Galvanically isolated pulse output............................................................................................................................... 24

4.4. Connection to METPOINT® BDL compact............................................................................................... 25

4.4.1. Bidirectional RS485 bus system.................................................................................................................................... 25

4.4.2. Current output 4 ... 20 mA, 3-wire ............................................................................................................................... 25

4.4.3. Galvanically isolated pulse output............................................................................................................................... 26

4.5. Modbus end termination....................................................................................................................... 26