EN Installation and operating manual

METPOINT®BDL compact 3

9.6.9. Connection of PT 1000 ................................................................................................................................................... 31

9.6.9.1. Analogue - 4-wire, 0 … 10 V........................................................................................................................ 31

9.7. Connection of further sensors.................................................................................................................................................... 32

9.7.1. Analogue, 0/4 … 20 mA................................................................................................................................................... 32

9.7.1.1. Analogue - 2-wire 0/4 … 20 mA................................................................................................................. 32

9.7.1.2. Analogue - 3-wire 0/4 … 20 mA................................................................................................................. 32

9.7.1.3. Analogue - 4-wire 0/4 … 20 mA................................................................................................................. 33

9.7.2. Analogue, 0 … 1/10/30 V................................................................................................................................................ 33

9.7.2.1. Analogue - 3-wire, 0 … 1/10/30 V............................................................................................................. 33

9.7.2.2. Analogue - 4-wire, 0 … 1/10/30 V............................................................................................................. 34

9.7.3. Digital - SDI interface...................................................................................................................................................... 34

9.7.3.1. Digital - 3-wire SDI-interface ..................................................................................................................... 34

9.7.3.2. Digital - 4-wire SDI-interface ..................................................................................................................... 35

9.7.4. Digital - bidirectional RS485 bus system.................................................................................................................... 35

9.7.5. Analogue - galvanically isolated pulse sensors ......................................................................................................... 36

9.7.6. Resistance sensors........................................................................................................................................................... 37

9.7.6.1. 2-wire resistance sensors............................................................................................................................ 37

9.7.6.2. 3-wire resistance sensors............................................................................................................................ 37

9.7.6.3. 4-wire resistance sensors............................................................................................................................ 38

9.8. Connection of external displays (PLC / ZTL) ........................................................................................................................... 39

9.8.1. Analogue, 0/4 … 20 mA................................................................................................................................................... 39

9.8.1.1. Analogue - 2-wire 0/4 … 20 mA................................................................................................................. 39

9.8.1.2. Analogue - 3-wire 0/4 … 20 mA................................................................................................................. 39

9.8.1.3. Analogue - 4-wire 0/4 … 20 mA................................................................................................................. 40

9.8.2. Digital - SDI interface...................................................................................................................................................... 40

9.8.2.1. Digital - 3-wire SDI-interface ..................................................................................................................... 40

9.8.2.2. Digital - 4-wire SDI-interface ..................................................................................................................... 41

9.8.3. Digital - bidirectional RS485 bus system.................................................................................................................... 41

10. Connecting the METPOINT®BDL compact with a PC....................................................... 42

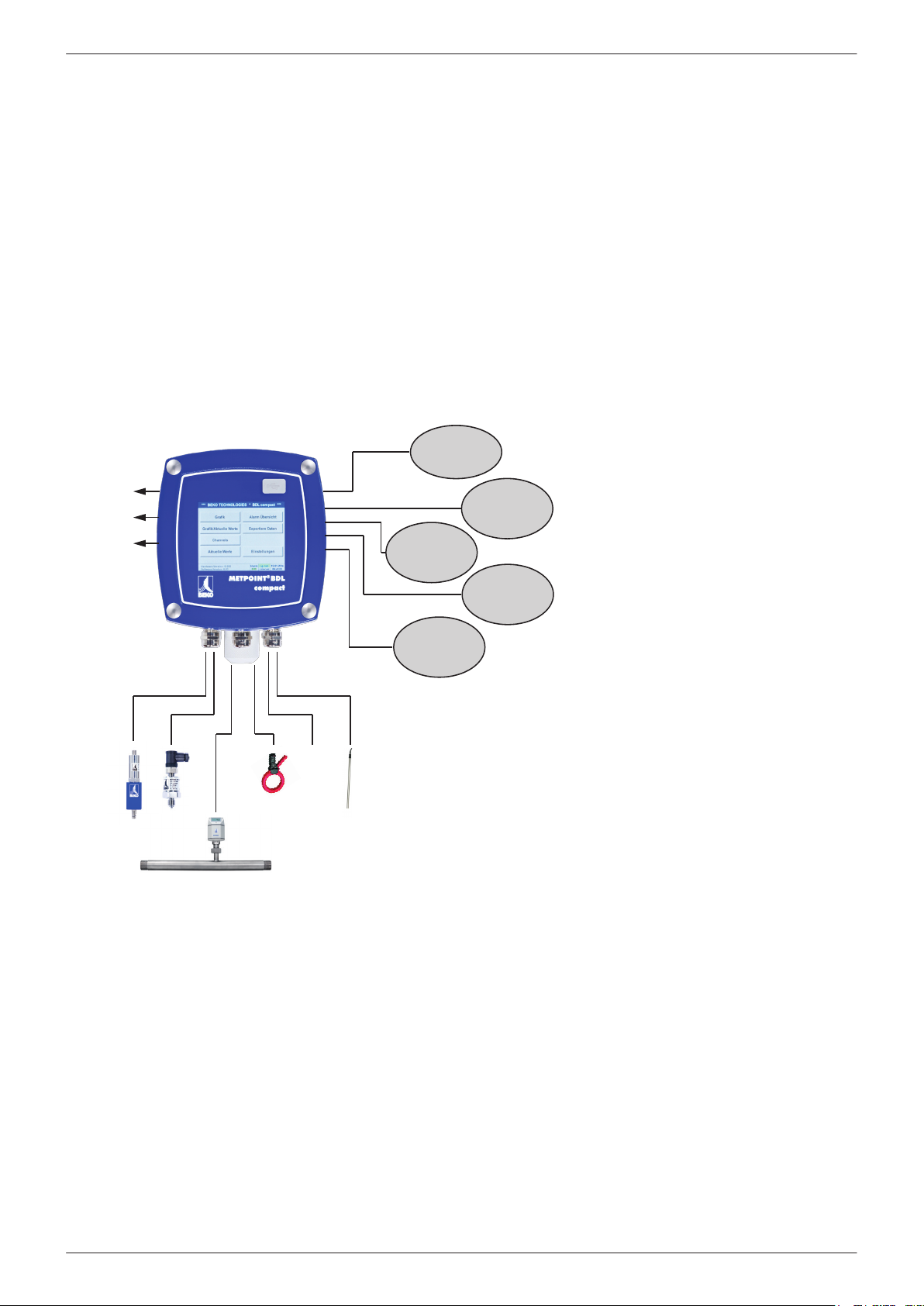

11. Operation of METPOINT®BDL compact ......................................................................... 43

11.1. Home (Main Menu)..................................................................................................................................................................... 43

11.1.1. Initialisation .................................................................................................................................................................... 43

11.1.2. Home after switching-on ............................................................................................................................................. 44

11.2. Settings .......................................................................................................................................................................................... 44

11.2.1. Password.......................................................................................................................................................................... 45

11.2.2. Sensor settings ............................................................................................................................................................... 45

11.2.2.1. Selecting sensor type (example: BEKO Digital sensor) ..................................................................... 46

11.2.2.2. Labelling measurements and dening resolution (decimals).......................................................... 48

11.2.2.3. Recording measuring data ....................................................................................................................... 49

11.2.2.4. Alarm settings ............................................................................................................................................. 49

11.2.2.5. Advanced settings (scaling of analog output)..................................................................................... 51

11.2.2.6. BEKO Digital dew point sensor............................................................................................................... 52

11.2.2.7. Labelling and conguring text elds...................................................................................................... 53

11.2.2.8. Conguring analog sensors...................................................................................................................... 56

11.2.2.9. Type "Pulse".................................................................................................................................................. 58

11.2.2.10. Type "Modbus".......................................................................................................................................... 61

11.2.3. Device settings ............................................................................................................................................................... 66

11.2.3.1. Language ...................................................................................................................................................... 67

11.2.3.2. Date and time.............................................................................................................................................. 67

11.2.3.3. Network settings........................................................................................................................................ 68

11.2.3.4. Modbus (Slave) ........................................................................................................................................... 69

11.2.3.5. Relay settings .............................................................................................................................................. 70

11.2.3.6. SD card ......................................................................................................................................................... 70

11.2.3.7. System........................................................................................................................................................... 71

11.2.3.8. Calibrating touch screen........................................................................................................................... 75