Content

4 METPOINT®OCV

2 Content

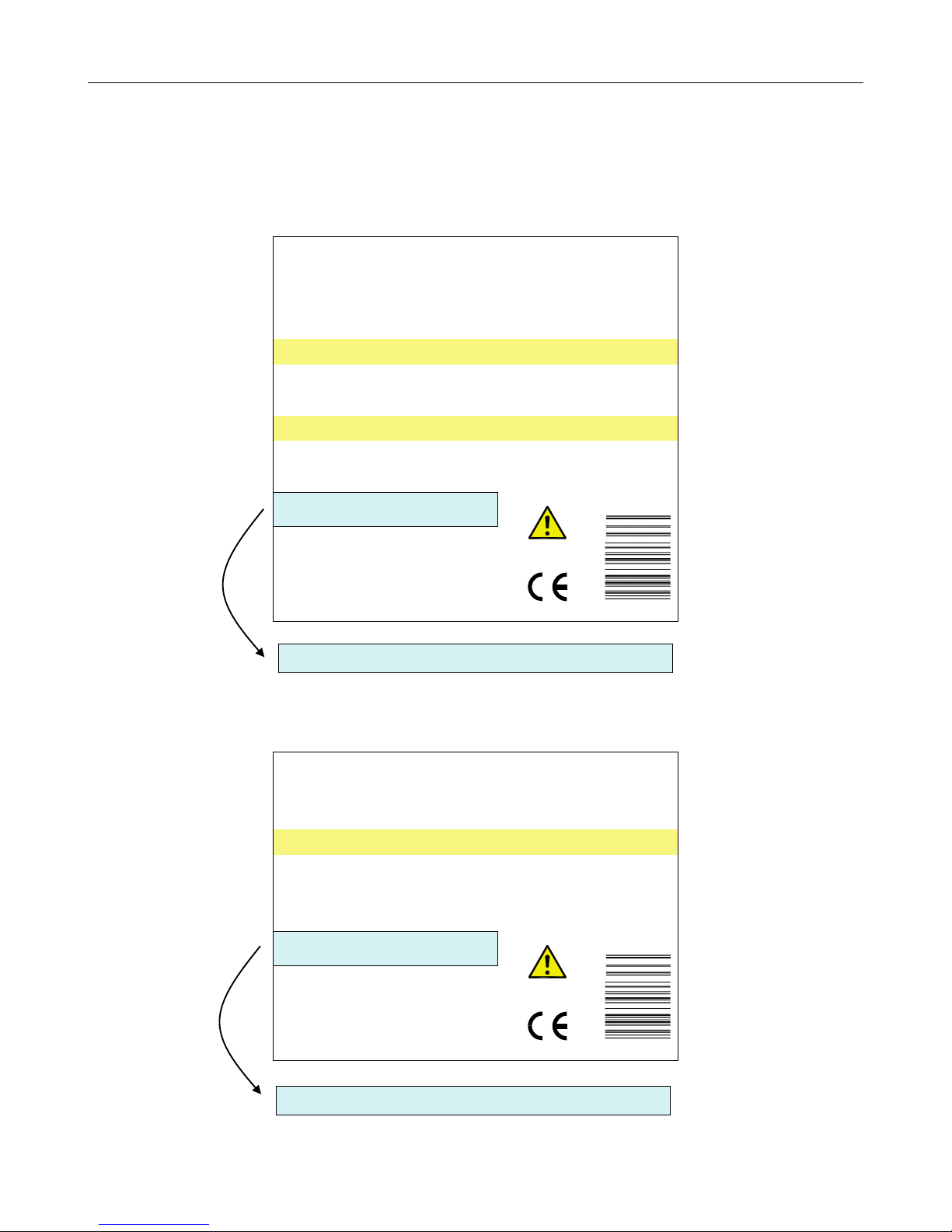

1Type plates ............................................................................................................................................ 3

1.1 Sensor unit............................................................................................................................................. 3

1.2 Evaluation unit with user interface (display)........................................................................................... 3

2Content .................................................................................................................................................. 4

3General advice....................................................................................................................................... 6

4Safety instructions.................................................................................................................................. 6

4.1 General safety instructions .................................................................................................................... 6

4.2 Special advice in accordance with the 97/23/EC Pressure Equipment Directive .................................. 9

4.3 Special safety instructions ..................................................................................................................... 9

4.4 Process-dependent hazards................................................................................................................ 10

5Field of application and proper use of the METPOINT®OCV ............................................................. 10

6Technical data ..................................................................................................................................... 12

6.1 METPOINT®OCV sensor unit............................................................................................................. 12

6.2 Evaluation unit with user interface (display)......................................................................................... 13

6.3 EU directives and harmonised standards applied ............................................................................... 13

6.4 Installation requirements...................................................................................................................... 14

6.4.1 Sensor unit........................................................................................................................................... 15

6.4.2 Evaluation unit with user interface ....................................................................................................... 15

6.5 Illustration of the device ....................................................................................................................... 16

6.6 Adjusted operating pressure................................................................................................................ 17

7System and functional description ....................................................................................................... 18

8Transport and storage ......................................................................................................................... 19

9Unpacking............................................................................................................................................ 19

10 Installation............................................................................................................................................ 20

10.1 Place of installation.............................................................................................................................. 20

10.2 Installation diagram METPOINT®OCV with activated carbon adsorber ............................................. 22

10.3 Installation diagram METPOINT®OCV with BEKOKAT ...................................................................... 23

10.4 Installation diagram METPOINT®OCV with oil-free compression ...................................................... 24

10.5 Installation of METPOINT®OCV downstream of an activated-carbon filter ........................................ 25

10.6 Installation diagram bypass installation for METPOINT®OCV............................................................ 26

10.7 Installation steps .................................................................................................................................. 27

11 Start-up ................................................................................................................................................ 35

11.1 General advice regarding the installation............................................................................................. 36

11.2 Procedure settings............................................................................................................................... 37

11.3 Procedure start measurement ............................................................................................................. 43

12 Removal from service and uninstalling................................................................................................ 48

13 Operation ............................................................................................................................................. 48

13.1 Control and display elements............................................................................................................... 49

13.2 General advice for the operation of the METPOINT®OCV ................................................................. 50

13.3 Trouble indications, service indications and note fields....................................................................... 51