Installation and operating manual EN

2 METPOINT®SF13

Content

1. Safety information.......................................................................................................................................... 4

1.1. Pictograms and symbols.......................................................................................................................... 4

1.1.1. In this documentation........................................................................................................................................................4

1.1.2. On the device.......................................................................................................................................................................4

1.2. Signal words ........................................................................................................................................... 4

1.3. Safety instructions.................................................................................................................................. 5

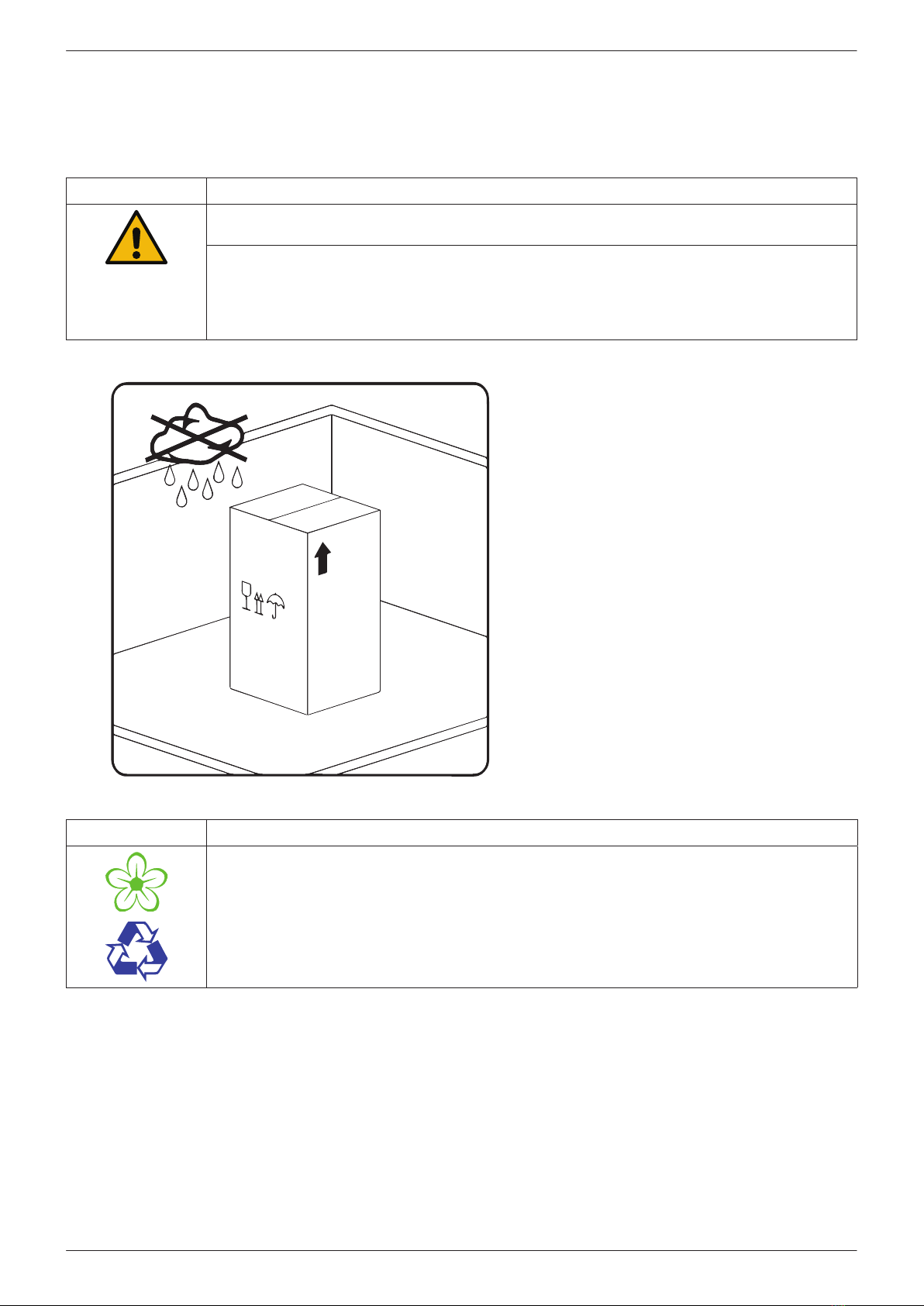

1.4. Transport and storage ............................................................................................................................. 6

1.5. Intended use........................................................................................................................................... 7

1.6. Warranty and liability ............................................................................................................................. 7

2. Product information ....................................................................................................................................... 8

2.1. Scope of delivery .................................................................................................................................... 8

2.2. Type plate............................................................................................................................................... 8

2.3. Product overview and description ........................................................................................................... 9

2.3.1. Identication based on product code.............................................................................................................................9

2.3.2. Product description ......................................................................................................................................................... 10

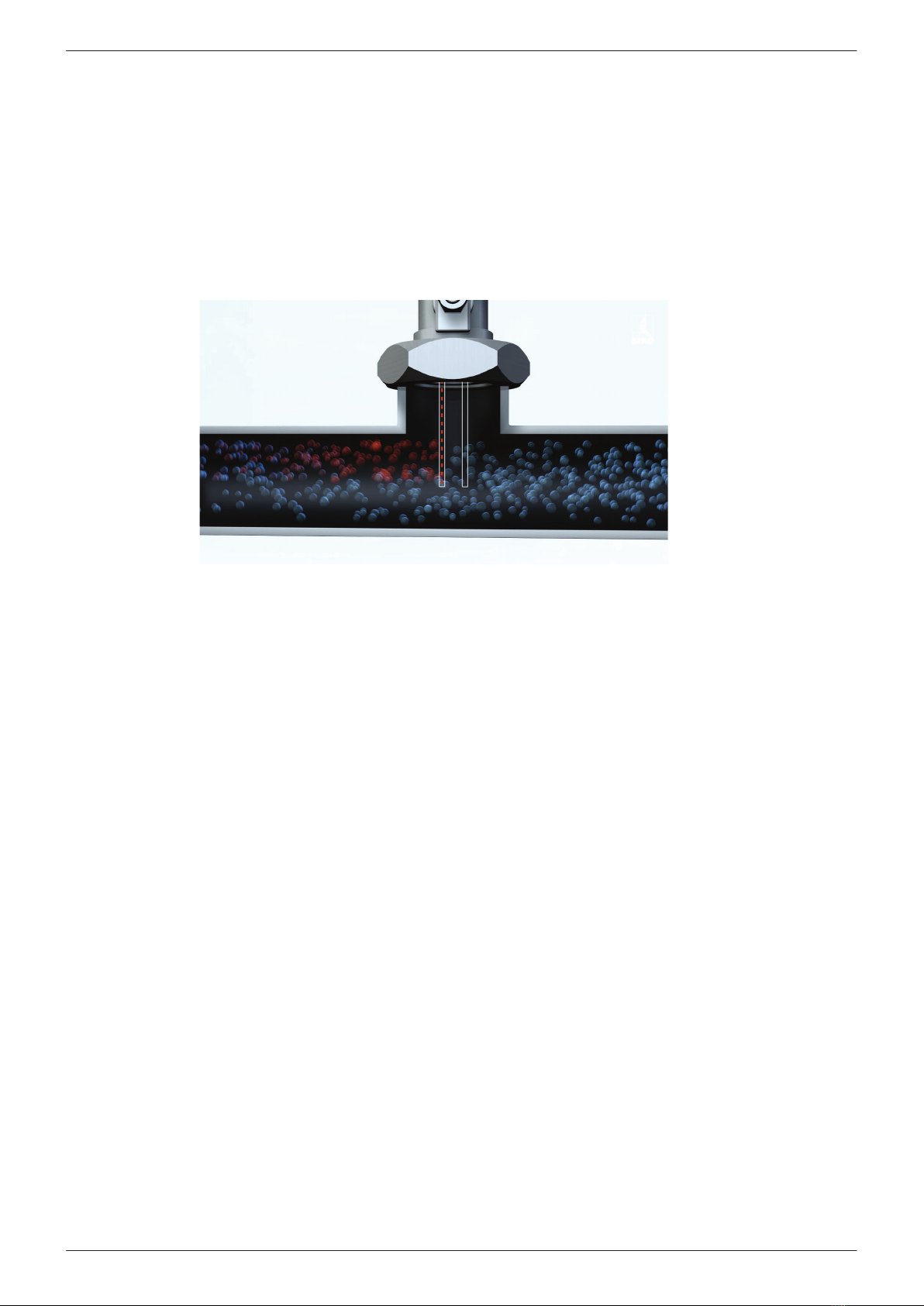

2.3.3. Operating principle.......................................................................................................................................................... 10

2.4. Control and display elements ................................................................................................................ 11

2.4.1. Version with display......................................................................................................................................................... 11

2.4.2. Version with LED .............................................................................................................................................................. 11

2.4.3. Direction of ow............................................................................................................................................................... 12

2.5. Dimensions........................................................................................................................................... 13

2.6. Technical data....................................................................................................................................... 14

2.7. Measuring ranges ................................................................................................................................. 15

2.7.1. For air .................................................................................................................................................................................. 15

2.7.2. For other gases.................................................................................................................................................................. 15

3. Installation................................................................................................................................................... 16

3.1. Warning................................................................................................................................................ 16

3.1.1. Requirements for piping................................................................................................................................................. 16

3.1.2. Requirements for inlet/outlet sections....................................................................................................................... 16

3.1.3. Turning housing ................................................................................................................................................................ 17

4. Electrical installation .................................................................................................................................... 18

4.1. Pin assignment of plug-type connectors ................................................................................................ 18

4.2. Connection options............................................................................................................................... 18

4.2.1. Bidirectional RS485 bus system.................................................................................................................................... 18

4.2.2. Current output 4 ... 20 mA, 3-wire .............................................................................................................................. 19

4.2.3. Mbus (optional) ................................................................................................................................................................ 19

4.2.4. Galvanically isolated pulse output............................................................................................................................... 20

4.3. Connection of METPOINT® BDL............................................................................................................. 20

4.3.1. Bidirectional RS485 bus system.................................................................................................................................... 20

4.3.2. Current output 4 ... 20 mA, 3-wire ............................................................................................................................... 21

4.3.3. Galvanically isolated pulse output............................................................................................................................... 21

4.4. Connection to METPOINT® BDL compact............................................................................................... 22

4.4.1. Bidirectional RS485 bus system.................................................................................................................................... 22

4.4.2. Current output 4 ... 20 mA, 3-wire ............................................................................................................................... 22

4.4.3. Galvanically isolated pulse output............................................................................................................................... 23

4.5. Modbus termination ............................................................................................................................. 23