Belief 4W2002 12C21 Manual

Air parking heater

Technical description, installation, operation

and maintenance instructions.

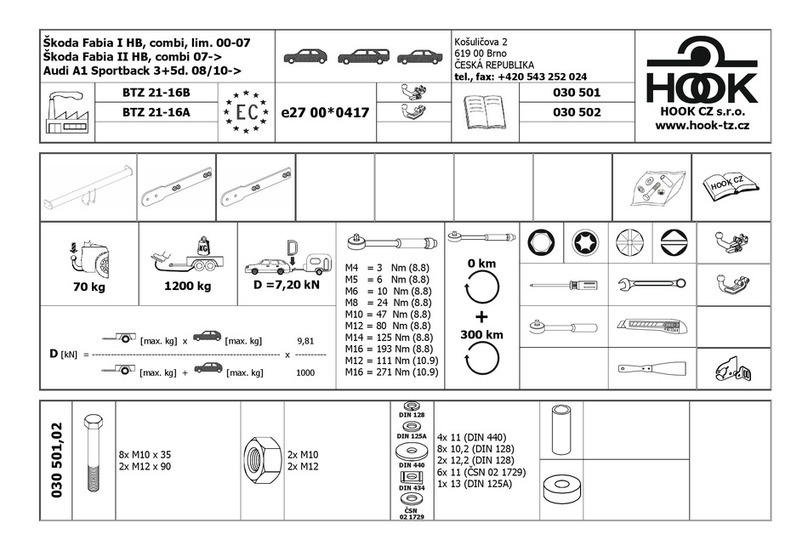

Product type Order No.

Diesel 12V 4W2002 12C21

Diesel 24V 4W2002 24C21

Jan. 25th,2022

Air heater for operating independently of the engine.

Preface

Thank you for choosing 2KW air parking heater.

This instruction book describes the structures, working principles, installation

and operation of the parking heater. For correct use of the heater, please read this

instruction book carefully before installation and use. The instruction book shall be

saved in a convenient place for later reference.

Attention:

●This instruction book is subject to revision without notice, but the instruction

book is in conformity to the purchased product.

●Our effort is to explain all questions the users may have through this instruction

book. If you have any doubts or find anything incorrect in this instruction book,

please contact our company directly.

●At first unpacking, please check the heater and its accessories against the

packing list. Please contact the dealer immediately if any problem is found.

●If any trouble arises during application, please contact the Department of

Marketing of our company or other customer service stations authorized by our

company. We shall do our best to provide service to you.

Note:

Comply with the operational manual for installation and use

to ensure that the heaters can work for a long time.

Plateau version

1

1 Introduction

The main equipment of Model 2KW

air parking heater (hereinafter

referred to as the heater) is a small fuel

furnace controlled by a single-chip

micro- processor. Its furnace body (the

heat exchanger) is located in the

hood-shape case, which serves as

independent air passage. Cold air is

sucked into the air passage by the heat

supplying fan and blown out when it

becomes hot, so as to form another

heating system that is

independent to the original heating

system of the vehicles. In such a way,

heat can be supplied by the heater to

driver’s cab and passengers’ compartment no

matter the engine is working or not working.

The schematic diagram is shown in Fig. 1.

The heater is fully automatically controlled. It features in compact structure, easy

installation, energy-saving, environmental protection, safety and reliability, easy

maintenance, etc.

2 Main Technical Specifications

Please refer to Table 1 for main technical specifications.

Table 1

Heat Power (W)

2000

Fuel

Gasoline

Diesel

Rated Voltage

12V

12V/24V

Fuel Consumption

0.14~0.27

0.12~0.24

Rated Power Consumption

(W)

14~29

Working (Environment)

Temperature

-40℃~+20℃

Working height above sea

level

≤5000m

Weight of Main Heater (kg)

2.6

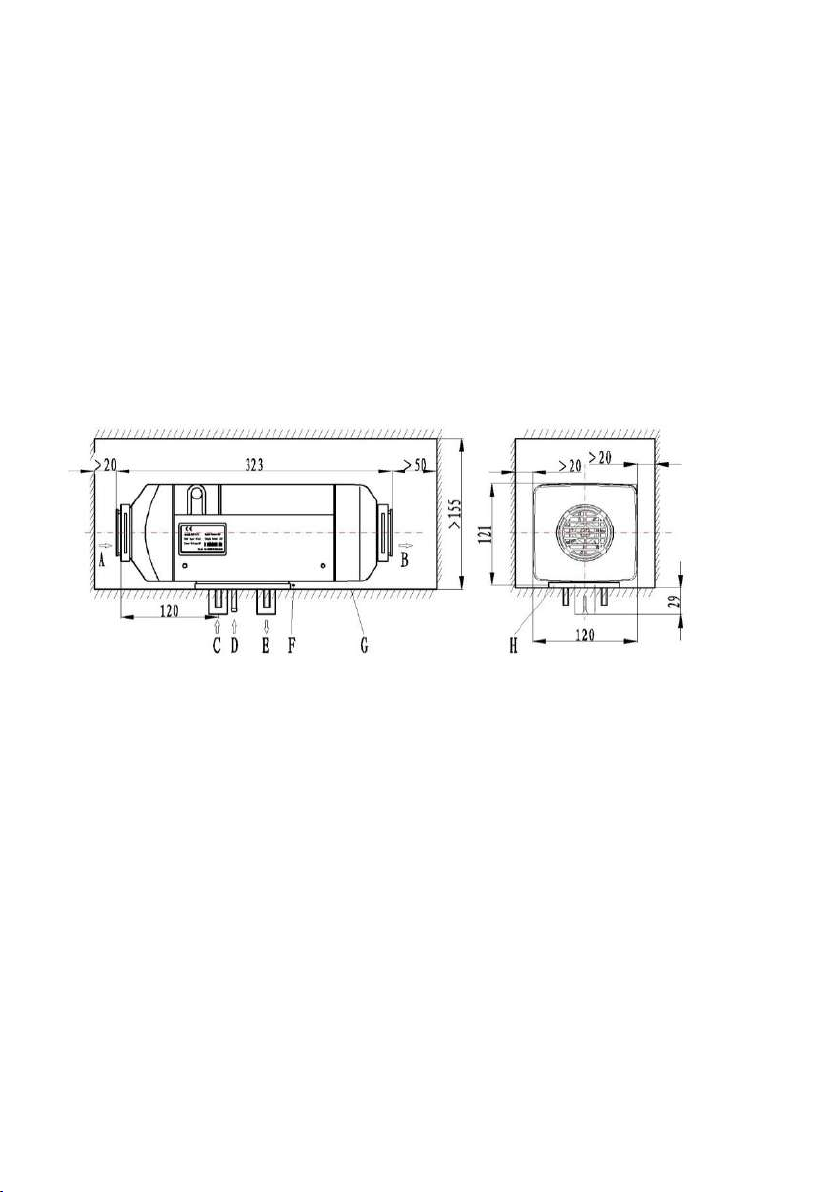

Dimensions (mm)

Length323±2 width 120±1 height121±1

Mobile phone control

(Optional)

No limitation(GSM network coverage)

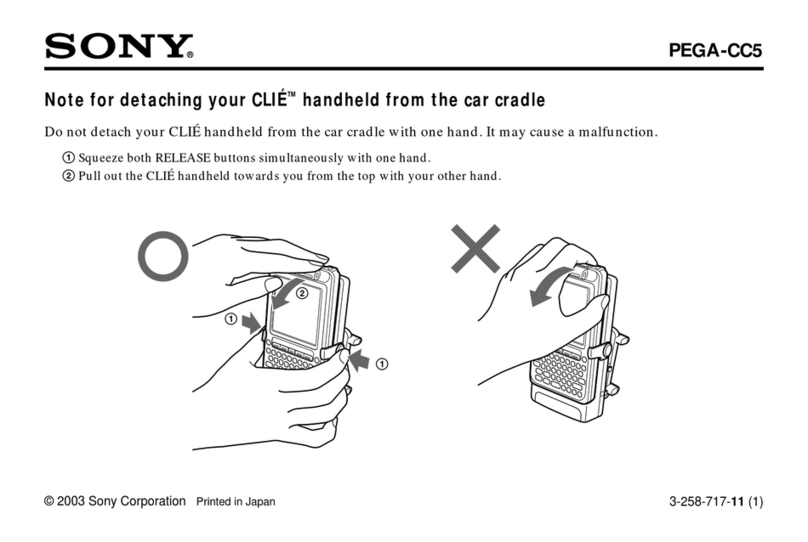

Fig. 1

1-Control switch 2- Heater

3- Fuel pump 4- Reducing T

2

3 Structures and Working Principles

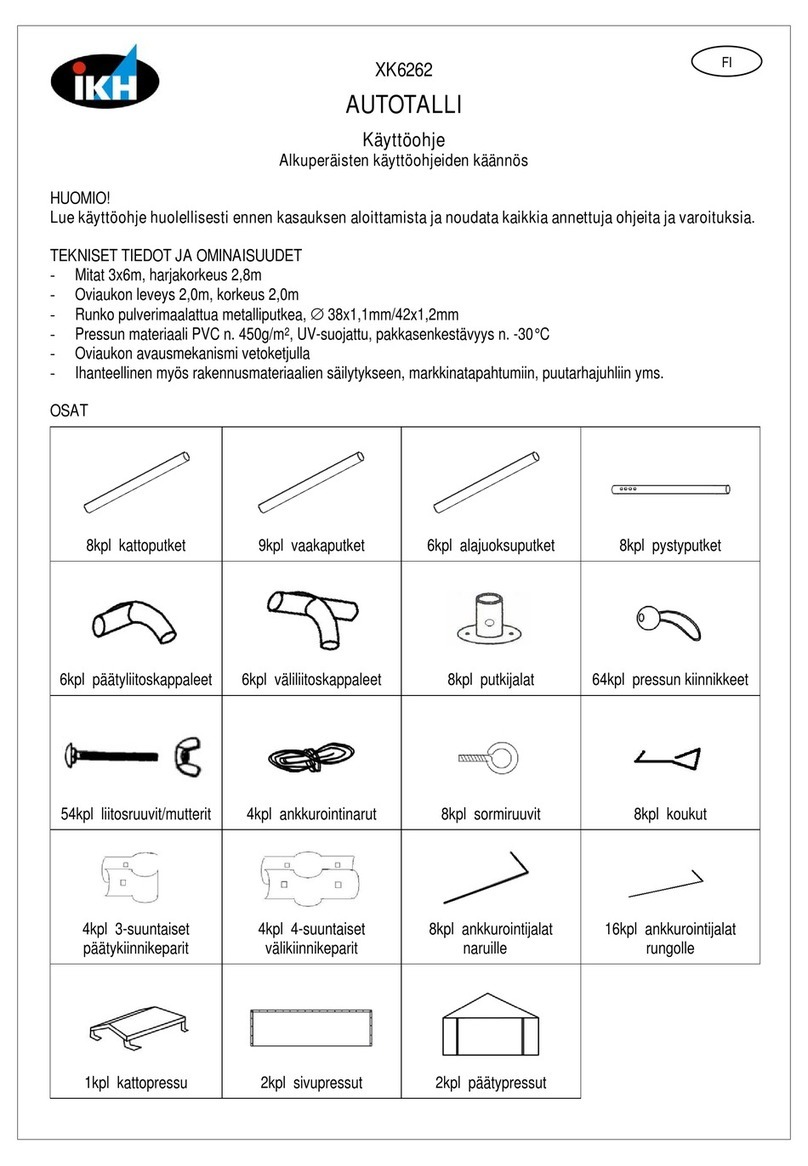

The structures of the main heater are shown in Fig. 2

3.1 Heater

Fig.3 is the diagram for structure of the

heater.

Heat exchanger 1 is the combustion furnace

body, made of die-casting aluminum, with

radiating fins around and at the rear end.

Combustion pipe 3 is installed in the inner cavity.

The front of the combustion pipe insert the

combustor 4, Fuel comes to the combustor core

through the fuel pipe 13 and is ignited by the

glow plug 14 after atomization. The flame enters

the gap between the inner walls of the furnace body through the rear-end guide pipe of the

combustion pipe, The exhaust is discharged through exhaust pipe vent 15.

The fresh air for supporting combustion of the furnace comes from the

supporting air inlet port 12 and is sent to the combustion pipe by the combustion

supporting air blades 6 of the fan motor.

Burner is quick-wear part which should be

replaced after every 800 hours

1-Heat exchanger 2-Gasket 3-Combustion pipe 4-Burner 5-Gasket

6-Combustion supporting fan blades 7-Bracket for fan motor 8-Fan motor

9-Controller 10-Blade wheel of heating fan 11-Fuel pump leading wire

12-Inlet of combustion supporting air 13-Fuel inlet pipe 14-Glow plug

15-Exhaust pipe vent 16-Overheat sensor 17-Insulating mat

Fig.3

3

3.2 Hood-Shape Case

Fig. 4

The structure of the hood-shape case is shown in Fig. 4. It consists of the top

cover 2 (The junction box cover 1 can be fixed on 2), bottom cover 4, air inlet hood 6,

air inlet of heater 5 and hot air outlet 3. They form an air heating passage. Blade

wheel of heating fan (Fig.3-10) on the fan motor (the same for supporting combustion

fan) sucks in cold air from the air inlet. The air is heated by the heat exchanger and

sent out from the hot air outlet.

3.3 Controller

The controller (Fig. 3-9) is at the front of the heater and the back of the blade

wheel of heating fan. This controller main including collect the circuit and exam the

temperature circuit of the signal of a single-chip、drive circuit、frequency、rotational

speed、voltage. Have the function of heating process automation、system surveillance

automation、breakdown handling automation.

3.3.1 Control of Working Procedures

Adjustment and control on operational status are performed during the whole

working cycle (start-operation-stop) of heater in terms of the rotation speed of fan

motor, the frequencies of fuel pump, on-off of glow plug, to given time sequence and

in consideration of the preset value and measured value of the temperature of the

temperature control point, rotation speed of fan motor feedback signal、frequency of

fuel pump, surface temperature of the heat exchanger and other random parameters.

3.3.2 Locking Due to Troubles

When the heater cannot be ignited normally, or cannot sustain normal

combustion after ignition, or broken circuit or short-circuit occurs to the glow plug,

fan motor, fuel pump, or various sensors and components, or in case of overheating or

1-Junction box cover

2-Top hood-shape cover

3-Hot air outlet

4-Bottom hood-shape cover

5-Air inlet of heater

6-Air inlet/exhaust hood

4

excessive temperature of heat exchanger, abnormal of power voltage and speed of fan

motor when heater operation, the heater will turn off and enter into locked status

(not working of glow plug, fuel pump and fan motor, LED light flashing on control

switch) for protection.

3.3.3 Display of Troubles

For convenience of maintenance and repair, troubles of the heater can be

displayed by the corresponding indicators of the control switch.

In trouble status, indicator light will flash circularly, each cycle consists of a long

extinguishing (2 seconds) and several slow flashes ( interval of about 0.5

seconds ).During the period between two long extinguishing, the times of slow flashes

represent the types of troubles, as shown in Table 2.

Table 2

Times of

flashes of LED

Cause of trouble

1

Failure of second start

2

Termination of the third time of combustion

3

Power voltage out of specified range

4

Furnace temperature over high during self-check period

6

Broken circuit or short-circuit of temperature sensor

7

Broken circuit or short-circuit of fuel pump

8

Broken circuit, short-circuit, or rotation clogging of fan motor

9

Broken circuit or short-circuit of glow plug

10

Ambient temperature over high before starting or furnace body

temperature over high during heating process

11

Broken circuit or short-circuit of overheating sensor

12

Broken circuit or short-circuit of control switch

13

Maintenance reminder:More than 800 hours of work time

14

Failure of controller

12V Heater operating voltage range:

10.5V~16V

24V Heater operating voltage range:

21V~32V

5

3.3.4 Circuit Interfaces

The following circuit interfaces can

be found on the controller case:

Socket X1 for fan motor,

Socket X2 for glow plug,

Socket X3 for overheating sensor,

Socket X4 for the leads to fuel pump

Socket X6 for the main wire bundle.

Please refer to Fig. 5 for their locations.

The connection parts are designed with such structures that wrong connection is

made impossible.

3.4 Sensors and Safety Protection

3.4.1 Overheating Sensor

The overheating sensor (Fig.3-16) is installed on the back outer wall of the heat

exchanger. If the temperature here becomes higher than upper limit , the fuel pump

circuit will be cut off by the controller and supply of fuel is stopped and then the heater is

turned off for purpose of overheating protection.

3.4.2 Temperature Sensor

The inside temperature sensor(in the controller) is installed on the air inlet of

heater ,it measures the air temperature at the air inlet ,according to the temperature

change the working state of the furnace and adjust the output of the thermal power.

The outside temperature sensor is

optional part which require extra

configuration and can be put those

heating places you want. Same working

principle as inside temperature sensor.

3.5 Control Switches

The control switch is shown in Fig. 6.

It is used for the following operations:

turning on or off of the heater;

regulate the heating temperature

or the heater power;

eliminating locking of the heater due

to trouble interrupt;

converting working mode through the

mode conversion button;

Fig.5

1-Control Knob Fig.6

2- Heating (constant power) mode button

3-Heating (constant power) indication light

4-Air conditioner (constant temperature) indication light

5- Air conditioner (constant temperature) mode button

6- Ventilation mode button 7-Ventilation indicating light

6

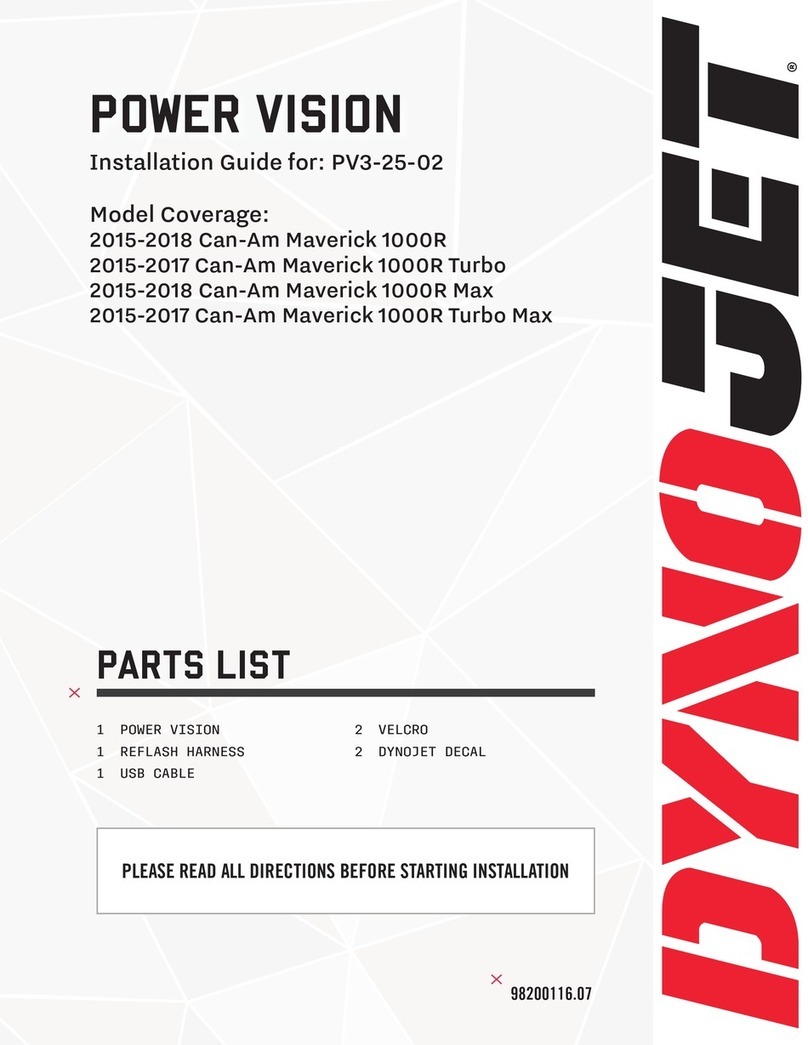

3.6 LCD control switch (Optional device, see Fig.7)

Display set temperature

Set heat starting time

Set heat time

Display fault information

Eliminate fault code

Digital display power level

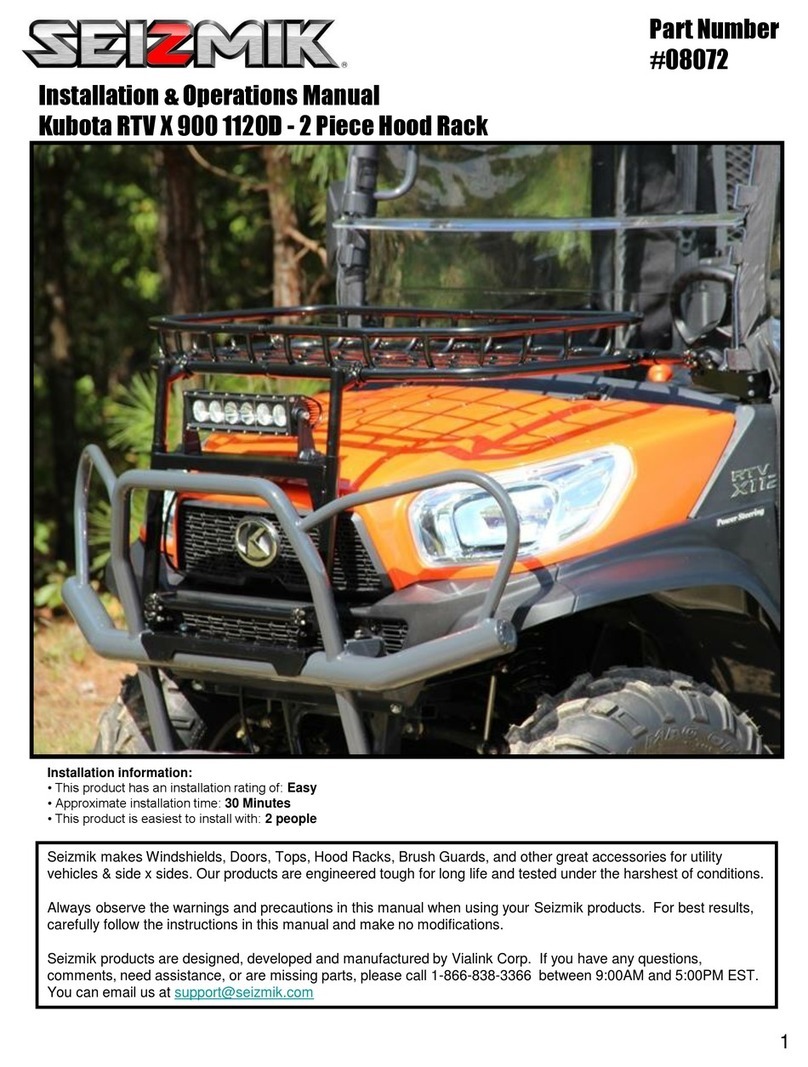

3.7 GSM remote controller (Optional device, see Fig.8)

GSM remote controller is an extended

function device of parking heaters which can be

started and stopped through calling or sending

message to the number of SIM card in the GSM

remote controller by phones or cellphones.

Control ways include voice and short message.

It can start and power off heater immediately.

Operation methods for LCD control switch and GSM controller ( Both of

the parts are optional ) please see relevant instructions.

3.8 Power Supply

Heater power leads (positive and negative line) must be connected to the 12V/24V

batteries directly. Battery more than 2 years which lack of electric frequently should

be changed a new one in order to ensure normal use of the heater.

3.9 Fuel Supply

The fuel for the heater can be from the fuel tank in the car or from optional 5L

independent fuel tank. The fuel pump is used for transmission of fuel and

regulation of supply quantity of fuel.

3.10 Fuel standard

Gasoline should accord with standard DIN EN288

Diesel should accord with standard DIN EN590

Note: Fuel brand which used should meet the requirements of low temperature in

winter. Biofuel is forbidden!

Fig.7

Fig.8

7

A Connect with battery

B Connect with external

temperature sensor

C Connect with fuel tank

DConnect with heater

E Connect engine

1-Control switch

2- Fuse

3- Heater

4- Gasket

5- Air inlet pipe

4 Installations

Only special-purpose parts can be used for installation of the heater. Fig. 9 is the

diagram for installation. The positions and ways of fixing of various parts may vary

from one automobile model to another, but the general principles must be followed in

conformity with the requirements of this chapter. Otherwise the heater may not work

normally or safety problems may occur.

4.1 Requirements for Installation and Places of Application of the Heater

4.1.1 It is not allowed to use the heater in locations with inflammable or explosive

substances such as flammable gas or flammable dust.

4.1.2 It is not allowed to use the heater in closed space (such as garage or

maintenance workshop without air ventilation) to avoid danger of poisoning due to

exhaust from burning.

Attention: Under either of the above circumstances, it is not allowed to use the heater

even at the stand-by state.

4.1.3 It is not allowed to install and use the heater in bedrooms.

4.1.4 If the heater is installed in special-purpose vehicles (such as vehicles for dangerous

6- Fuel pipe

7- Air filter (optional)

8- Exhaust pipe

9-Tank(optional)

10- Tubing joint(optional)11- Fuel suction pipe

12- Filter 13- Fuel pump 14- Damper 15- Non-return value

Fig. 9

8

goods), special rules must be followed in installing the heater.

4.1.5 Never place fuel tank, compression tank, fire extinguisher, clothes, paper,

etc. near the heater or opposite to the hot air vent.

4.2 Installation of the Main Heater

4.2.1The main heater can be installed inside the vehicle or outside the vehicle. But

when it is installed outside the vehicle a shield which can be prevent the damage

(splash of stones)of external force(supplied by retailers).The heater can’t be soaked in

the water or in the rain for a long time(heater should be shut off).The heater should be

operated after it is completely dried if the heater is corroded by rain and water.

4.2.2 For convenience of heating air flow and installation, maintenance of the main

heater, enough space must be provided for installation. Please refer to the scope of

double dot line for the space for installation, as shown in Fig. 10.

A-Inlet of heating air B-Outlet of heated air C-Inlet of combustion air

D- Fuel inlet E-Exhaust outlet F- Non-interference area

G-Installation surface H-Gasket

Fig. 10

Please make sure that there are not any interference objects in the gap

between the bottom surface of the main heater and the installation surface of the

vehicle (Fig. 8-F).

4.2.3 Good sealing is necessary between the main heater and the installation surface

on the vehicle. A special gasket (as shown in Fig. 10) supplied by the manufacturer must

inserted in between during installation. The installation surface must be smooth and steady

enough. Its parts at the installation bases of the main heater shall have unevenness of less

than 1mm. After drilling installation holes, evenness must be improved according to this

requirement. At installation, please rotate the four M6 nuts, which provided by the

manufacturer should be tighten. The torque for tightening shall be 6Nm+1Nm.

Please refer to Fig. 11 for positions of installation holes.

9

4.2.4 If the sickness of the installation panel<1.5mm a mounting plate may need.

Between mounting plate and the car body must also be sealed (use glass glue(Fig.12).

Attention: For re-installation of the heater ,

a new gasket must be used to replace the old one.

4.2.5Direction for installation of the heater is shown in Fig. 13. Attention must be

paid to that the inclination angle shall

not exceed the limit, or normal

operation will be affected.

4.2.6 After installation of the main

heater, please check and make sure

that there is not any contact or

friction between the blade wheel of

fan and other nearby parts to avoid

unsmooth operation

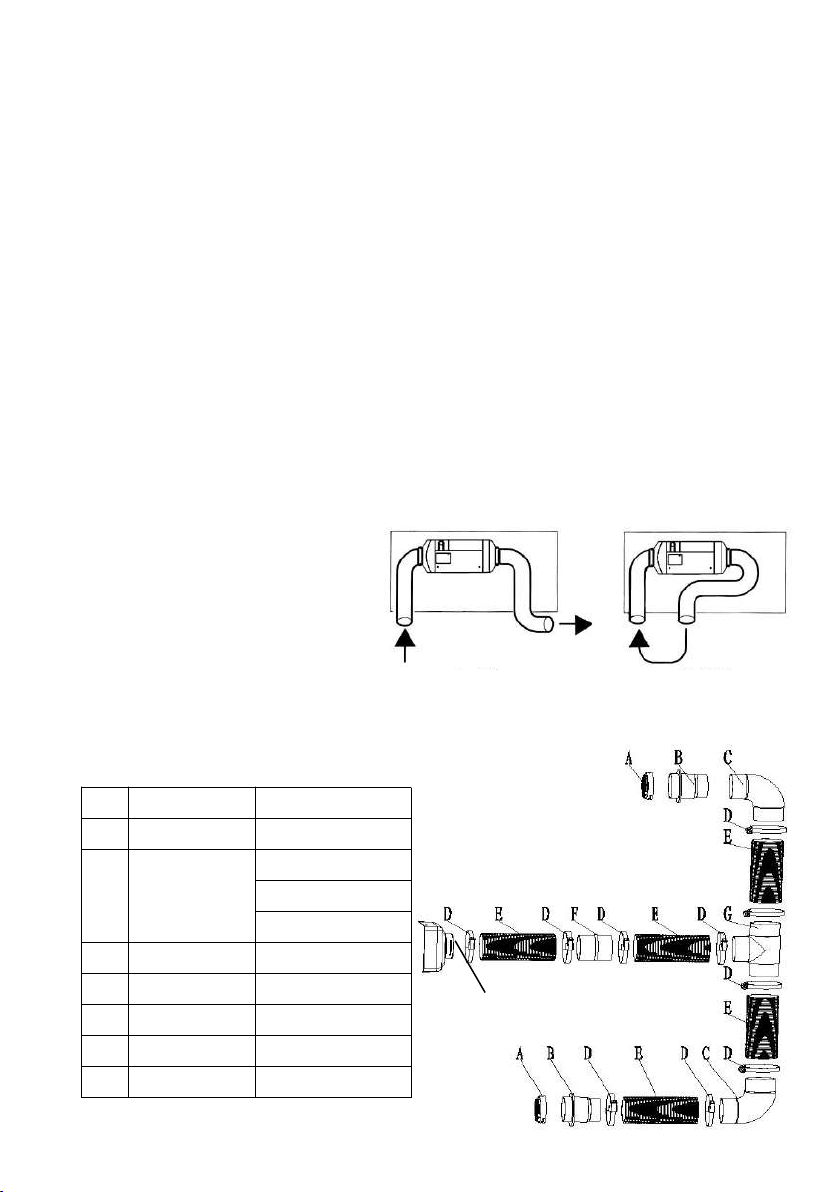

4.3 Installation of Air Heating System

4.3.1The independent outer circulation or inner circulation mode of heater can be

recommended. If the air heating system of the heater have to be connected with the

air duct of the vehicle, in order to ensure the air duct unobstructed the connection way

should be analyzed by the professionals.

4.3.2 When an external heating air pipe is attached to the heater, the pipe diameter

Fig 12

Fig 11

Fig.13

10

shall not be smaller than 60mm. Its material shall be capable to resist temperature of

130℃.

4.3.3 The maximum pressure drop between the air inlet side and air outlet side of the

air heating system shall not be greater than 0.15kPa.

4.3.4 The hot air from the heating system shall not erupt onto such parts that are

unable to resist heat. In case of passenger vehicles, measures shall be taken to avoid

blocking of the hot air vent by passengers. A self-provided protective net can be

installed if necessary.

4.3.5 For heater working in external circulation mode, the position of air inlet port

shall be proper to guaranteed that under normal operation no splash of water can enter.

No water can be sucked into the heater and no exhaust from the engine can be sucked

in.

4.3.6 For heater working in internal circulation, measures shall be taken to avoid

re-entering of the supplied hot air into the air inlet port (as shown in Fig. 14). If no air inlet

pipe is attached in this mode, an air inlet hood with grids (Fig3. 4-6) must be installed at

the air inlet port of the main heater. The inlet air shall be drawn from the cold area of the

compartment, such as under the seats or berths.

4.3.7 The optional air duct fittings

Users can choose the air duct fittings according to the situation. Please refer to

Fig.15.

No

Name

Specification

A

Grill

φ90

B

Diameter

changes

joint

φ60

φ90/60

φ56/60

C

Elbow

φ60/90。

D

Clamp

φ50~70

E

Ducting

φ60/φ64

F

Connector

φ60-φ60

G

Reducing T

φ60

a) Correct b) Wrong

Fig. 15

Warm air outlet

Table 3

Fig 14

11

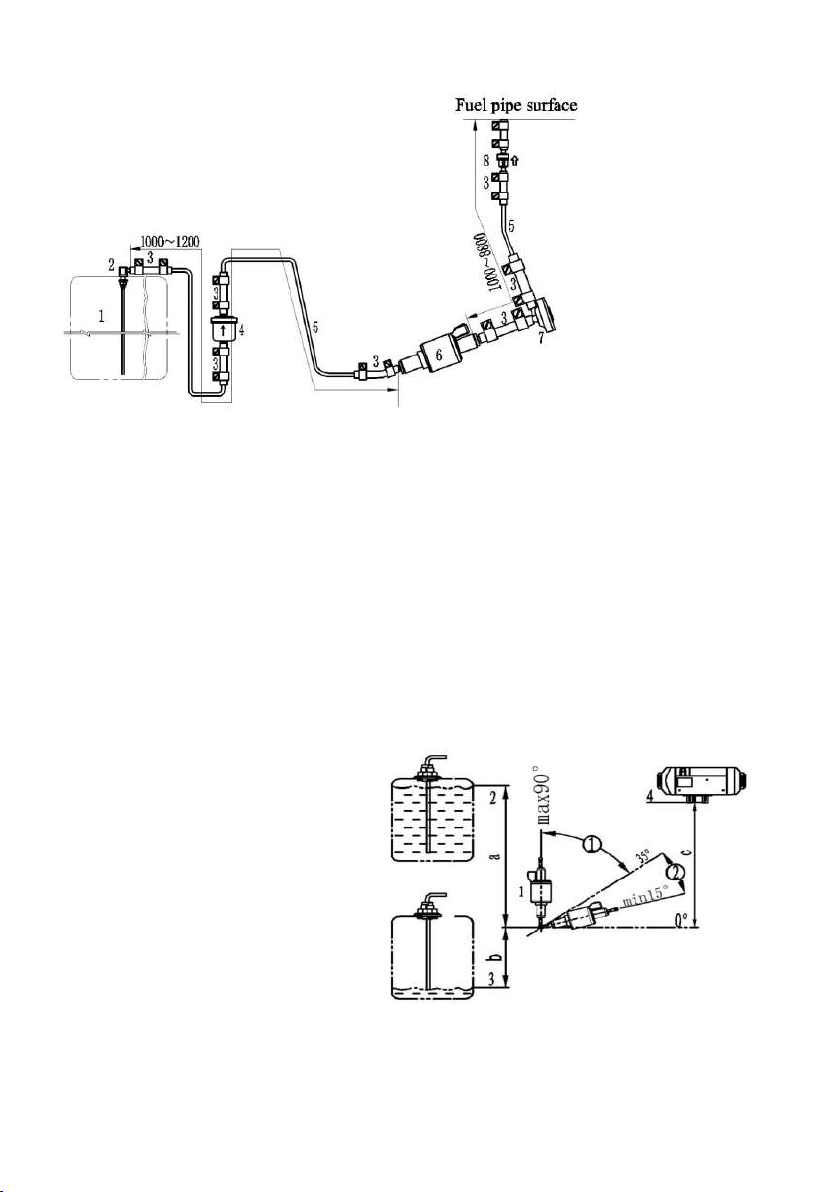

4.4 Installation of Fuel Supply System

The fuel supply system for the heater

is as shown in Fig. 16.

4.4.1 The fuel pump shall be fixed in automobile with a fuel pump clamp with

protective rubber cover. The outlet of the fuel pump shall tilt upwards. The tilt angle

can be selected from the range of 15°~ 35°(as shown in Fig. 17). When conditions

permit, the fuel pipe between the fuel pump and the heater shall go up gradually.

4.4.2 Damper installation should be according to the practical situation. If the packing

list doesn’t include the damper then it is should not be used temporarily.

4.4.3 Difference in elevation between the level of fuel and the fuel pump as well as

the difference in elevation between the fuel pump and the fuel inlet of the heater can

produce pressure (or suction) in the fuel pipeline(See Fig.17).So, these dimensions

shall conform to the requirements as follows:

a≤3m b≤0.5m (Avoid of negative pressure may be produced in sealed fuel tank.

In such case, b≤0.15m) c≤2m.

Note:

1.Please check the vent on the fuel tank when doing installation.

2.Fuel pipe after clipping(must use blade, Scissors or pliers are forbidden)

should ensure not affect fuel flow amount.

Fig.16

1-Fuel pump

2-Max.fuel level

3-Min.fuel level

4-Fuel inlet level

①Allowable installation angle

②Optimum installation angle

1-Fuel tank

2-Fuel extractor

3-Fuel pipe connector

4-Filter

5-Fuel pipe

6-Fuel pump

7-Damper

8- Non-return value

Fig.17

12

4.4.4 Installation of Fuel Filter

A fuel filter shall be installed before the fuel inlet port.

Please make sure that the fuel flow is correctly followed.

Its position shall be in conformity with Fig. 18.

Fuel filter should be changed after 2 years, fuel pipe joints

and clamps should also be changed.

4.4.5 Installation of Fuel Pipe

4.4.5.1 Only the flexible nylon pipe, which has good

light-resistance and thermal stability, supplied with the heater can

be used as the fuel pipe. The inner diameter of the pipe is Φ2mm.

4.4.5.2 The place for installation of fuel pipe shall be resistant against flying stones

and shall be away from any heat emitting parts of the vehicle. Protective device can

be installed if necessary.

4.4.5.3 The fuel pipe from the fuel pump to the main heater shall be in any directions

other than downward direction. The fuel pipe shall be tied in some proper location to

make it fixed. The distance between two ties shall be less than 50cm.

4.4.5.4 The fuel pipe fittings supplied with the heater shall be used for connections

between fuel pipe and fuel pump, fuel pipe and heater, fuel pipe and sucking pipe of

fuel tank and fuel pipe and reducing T. The fuel pipe shall ties with fuel pipe clamps.

Bubbles shall be eliminated from the connecting places (Fig. 19).

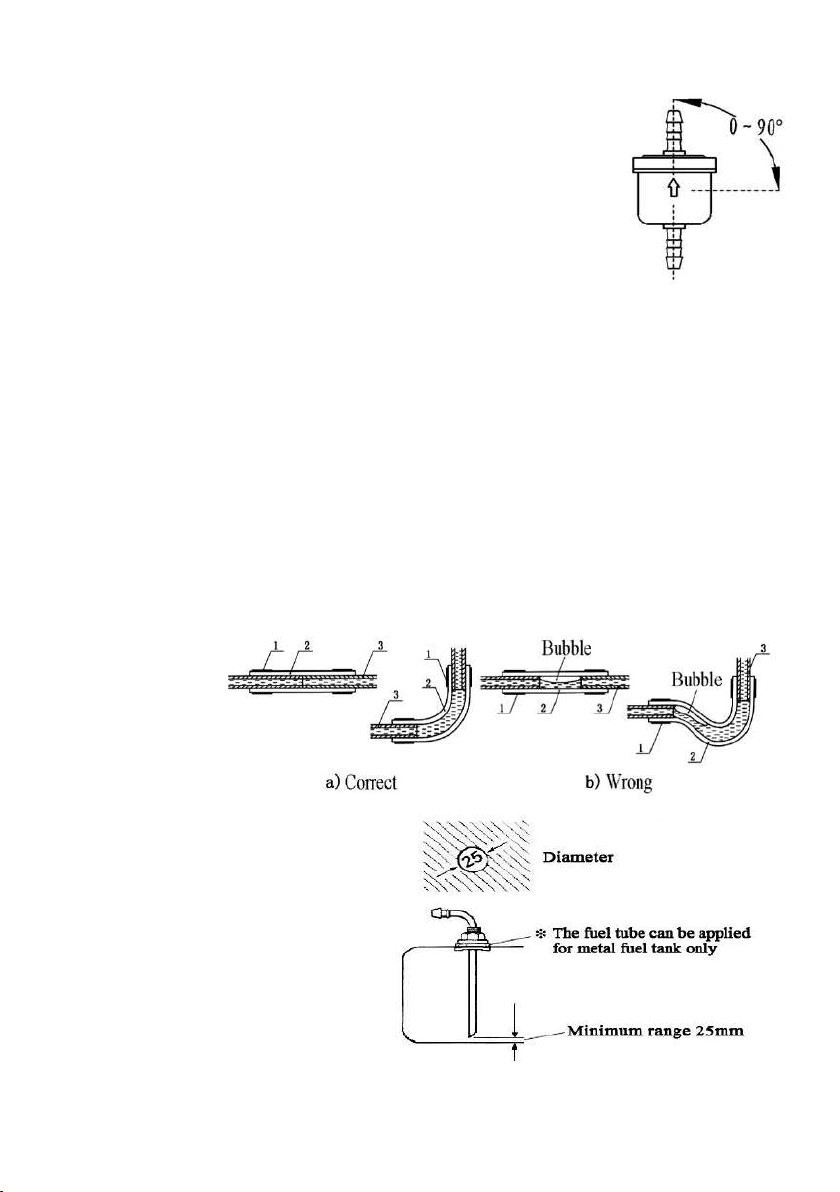

4.4.6 Installation of Fuel Sucking Device (Fig.20)

4.4.6.1When fuel is sucked from the

vehicle fuel tank or from an independent

fuel tank, a sucking pipe shall be used.

Attention shall be paid to that the openings

on the fuel tank (or tank cover) for

installation shall be size φ25±0.2,

with trimmed brim and with good

evenness around the opening. Good

sealing is necessary for the base of the

fuel sucking pipe. The bottom end of the fuel sucking pipe shall be 30mm-40mm

from the bottom of fuel tank to suck enough fuel and at the same time to avoid

Fig.18

1-Fuel pipe clamp;

2-Fuel pipe fitting;

3-Fuel pipe

Fig.19

Fig.20

13

From fuel tank

Reducing T

To fuel filter,

vehicle

Fuel pump

and engine

To fuel pump of heater

sucking in impurities sediment on the bottom of fuel tank.

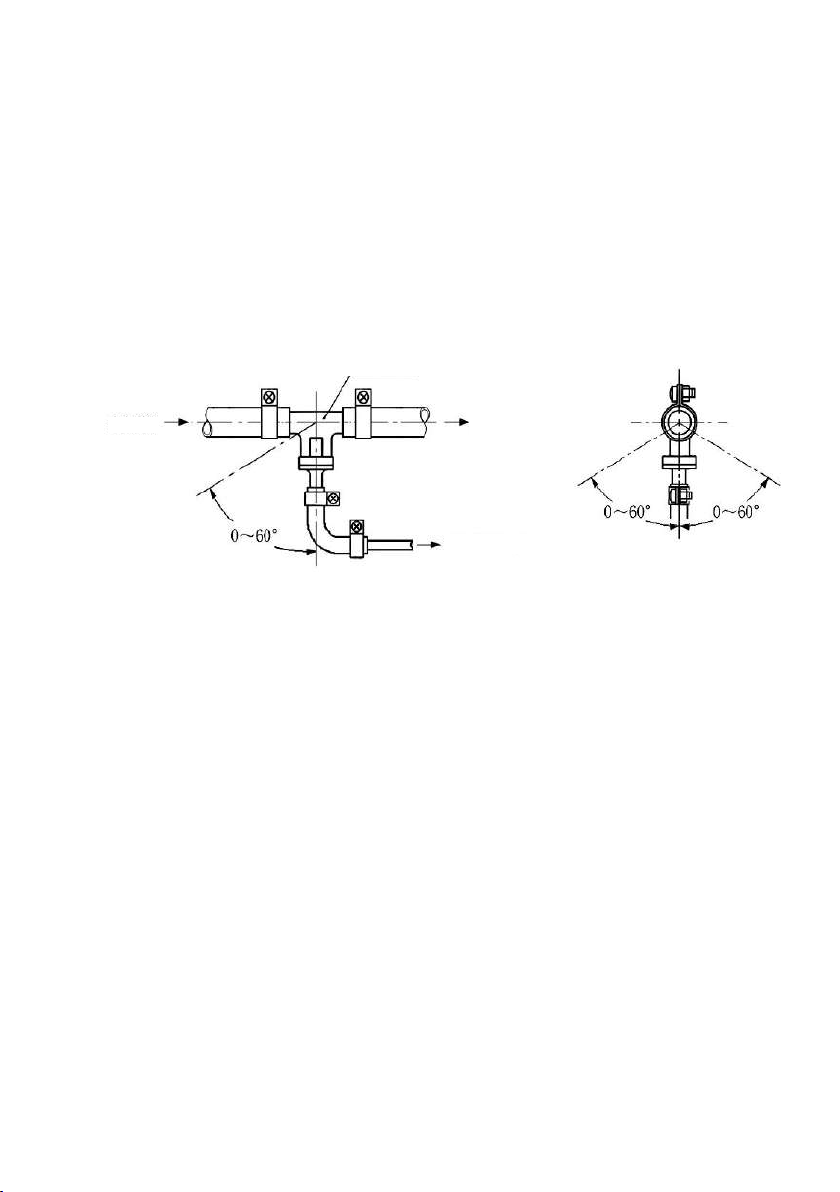

4.4.6.2 If fuel is sucked from the fuel pipe to the engine, the fuel pipe from

the fuel tank to the fuel filter shall be disconnected and re-connected with the thicker

pipes of the reducing T and the thinner pipe of the reducing T shall connect the fuel

pump of the heater via oil pipe fitting and fuel pipe. Must ensure fuel extraction

without any pressure and extract the fuel smoothly when the car is stopping. The

angle for installation must in conformity with Fig. 21, or normal work of the heater

will be affected.

After installation, the vehicle engine shall be started and then turned off after one

minute’s work to eliminate air trapped in the fuel sucking pipe.

4.5 Installation of Electrical System

4.5.1 The wiring diagram for the heater is shown in Fig. 22. The wires of the main

heater for connection to outside circuits have been made into wire bundles. They can

be laid according to the positions of various components and shall be fixed in some

proper locations. The distance between two fixing points shall not exceed 30cm.

Attention: Any exposed wire bundle out of the vehicle body or out of the wiring

groove must be protected by corrugated pipe.

4.5.2 Connection of the main wire bundle with the heater: Use a blunt tool to pry the

places marked “ ○

Q”of Fig.4 gently to remove the junction box cover (Fig. 4-1).

Connect the 18-wire connector X6 of the wire bundle to the controller socket. The

wire bundle can come out from either the right

side or the left side of the heater. Then replace the junction box cover. Make sure to

have good sealing between the junction box cover and upper cover and between the

junction cover box and the wire bundle sealing mat to avoid any thermal malfunction

due to leak of air from the hood-shape case.

4.5.3 Straighten the fuel pump leads (two 0.6mm2black wires and not distinguish

positive and negative) with their protective pipes, which is made a coil inside the

combustion supporting air inlet port , and put them through the opening on the wall of

the air inlet pipe. Connect the insert of fuel pump connector with fuel pump(Insert the

right position).Cutting fuel pump leads is forbidden.

4.5.4 Use four self-tapping screws to fix the control switch in a position for

convenient operation and the arrangement shall make easy observation on the

Fig.21

14

15

indicator on the case, so as to identify the working conditions (operation/stop) of the

heater easily. The plugs on the leads from the control switch shall be connected to the

main wire bundle and make self-locking mechanism. Note to remove the knob firstly,

then install the knob after fixing the screw.

4.5.5 Insert sheet fuse into fuse holder F and replace the upper cover tightly. Use

screws to fix it in a proper location in the vehicle.

4.5.6 Connect the 2.5mm2red wire and the 2.5 brown wire in the wire bundle to the

hole terminals with springs and therefore connect to the “+” and “-” terminals of the

vehicle battery.

The length and cross-sectional area of the power line shall ensure that the allowable

voltage drop is not greater than 0.5V and 1.0V when the voltage is 12V and 24V. It is

recommended to configure the power cord according to the following table.

4.6 Installation of combustion supporting air sucking pipe and exhaust discharge pipe

4.6.1 The combustion supporting air must be sucked in from external fresh

air outside the vehicle. The exhaust from combustion must be discharged into the air

through exhaust pipe. Measures must be taken to avoid the exhaust from re-entering

the vehicle.

The pipes go through the outer wall or holes on the bottom of vehicle.Measures

must be taken to prevent entering of splash water. The pipes must be protected and

can resist shock permanently.

4.6.2 Only the air inlet pipe and exhaust pipe provided with the heater can be used. The

air inlet pipe is a corrugated pipe made of a aluminum pipe that it’s surface is covered by

plastic and paper;The exhaust pipe is corrugated stainless steel pipe. Please identify air

inlet pipe and exhaust pipe and do not make mistake at installation. To connect them with

the heater, please use the supplied clamps to fix them tightly

on the combustion. The protective hood on the vents of the

air inlet pipe and exhaust pipe must be kept in good condition.

Do not damage them or remove them.

In order to meet the dust environment, an

optional air filter is a good choice(Fig.23).

A length of air filter can be cut in order to

meet different thickness of air inlet pipes.

Plus cable + minus cable

cross section

<8m

2.5mm2

8~12m

4mm2

12~16m

6mm2

Fig.23

16

a) Correct

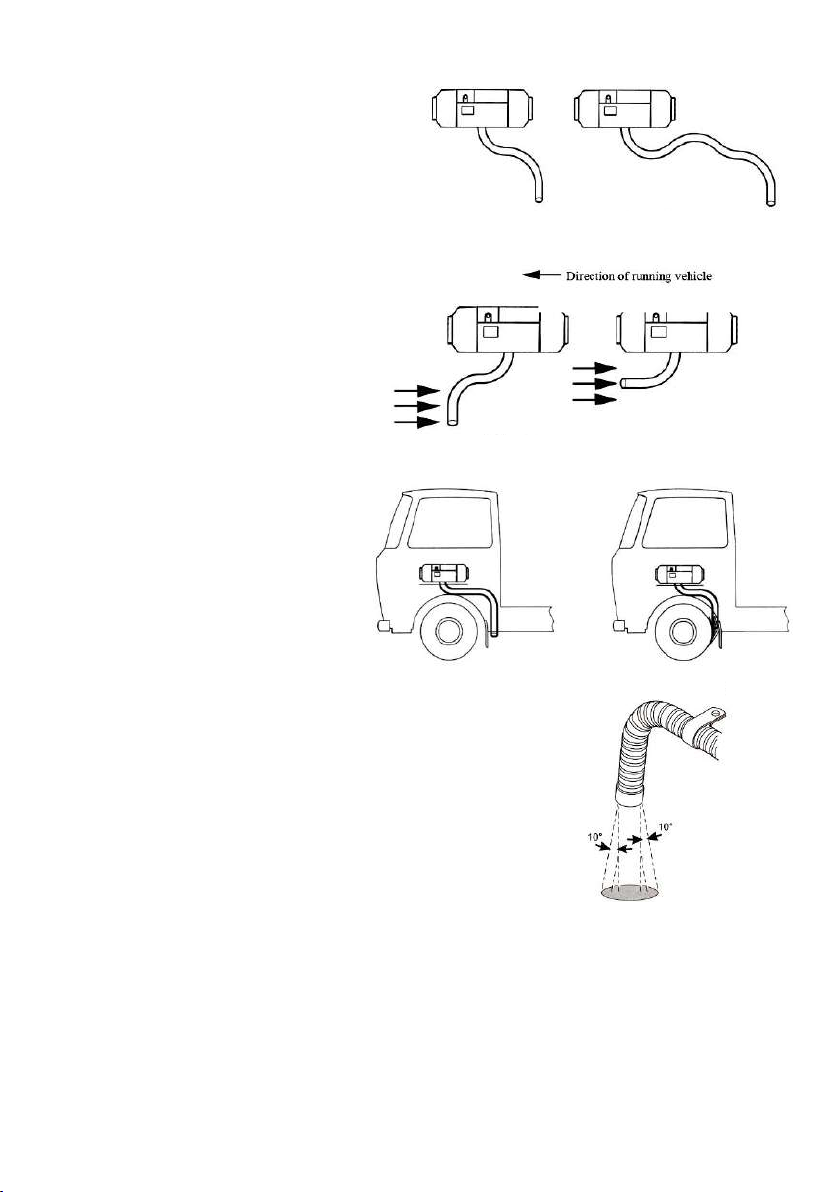

4.6.3 Both the air inlet pipe and exhaust

pipe shall come outwards and

downwards from the heater (Fig. 24),

otherwise a Φ4mm hole shall be

prepared at the bottom of the pipe for

discharge of condensation water.

If the pipe need curve, the radius cannot

be smaller than 50mm.Also, the sum of

all curve angles for each pipe shall not

exceed 270°.

4.6.4 The openings of the pipes

shall not be opposite to the direction

of the running vehicle. (Fig. 25)

4.6.5 Arrangement of the

pipes shall protect the pipe

openings from blocking by

slurry, rain and snow or

other dirt. (Fig. 26)

4.6.6 When the heat is working, the exhaust pipe is at high

temperature. In installation, make sure to install it in far

distance from plastic parts or other objects with poor

thermal resistance of the vehicle body. The exhaust

pipe shall be properly fixed. The exhaust vent shall

be downwards, perpendicular to road surface with an

angle of 90°±10°. To ensure such an angle, the fixing

clamp for the exhaust pipe shall be within 150mm from the pipe end. (Fig. 27)

Warning: Violation against the above requirements may cause fire.

Any consequences caused by not installing according our requirement we don’t afford any

responsibility.

4.6.7 If the section of the exhaust pipe inside the vehicle may be touched by passenger,

a protective cover has to be installed to prevent human contact and scald.

Fig.27

a) Correct b) Wrong

Fig.26

Fig.24

b) Wrong

Fig.25

b) Wrong

a) Correct

Direction of running vehicle

17

5 Methods of Operation

5.1 The heater control with three ways.

(1) Use the control switch(normal configuration).

(2) Use LCD control switch(optional choice).

(3) Use GSM mobile phone controller(optional choice).

5.2 Use the control switch

5.2.1Power on

Push air conditioner(constant temperature)button or heating(constant power) button,

then the indicator light of air conditioner(constant temperature)or heating(constant

power) flash 0.3S, then lit, said controller has started work, enter the corresponding

working mode. The heater comes to the start stage. The controller will run heating

program according to the temperature control target set by the control knob. In the

start stage, the time delay from switch-on to fuel supply to the fuel pump is 65

seconds.

5.2.2 Power control

After the combustor is ignited, if you want to regulate the heating temperature or

the heater power, you can turn the control knob according to the arc mark around the

control switch.

5.2.2.1 Air conditioner(constant temperature) mode

The air conditioner(constant temperature) mode indicating light is illuminated

after pressing air conditioner (constant temperature)button. If you want to adjust the

heating temperature(adjustable continuously from 5℃to 35℃),press the curve sign on

the control switch and turn the control knob.

5.2.2.2 Constant power mode

The heating(constant power) mode indicating light is illuminated after pressing

heating (constant power)button. If you want to adjust the heating power(adjustable

continuously between 1KW and 2KW), press the curve sign on the control switch and

turn the control knob.

5.2.3 Ventilation mode

You can only enter the ventilation mode when you press the ventilation mode key

to start the heater. The ventilation indicating light turns green after pressing

ventilation button. Heater can only circulating air without any heating. The wind

capacity can be continuously regulated with the control knob.

5.2.4 Shutdown

If you want to turn off the heater manually, press the button which is lighting on then

work indicator goes out. If the fuel pump is at work before the heater is turned off, the

pump will shut down immediately. But the fan will continue to run for 180 seconds.

18

5.2.5 Use any other way shut off the heater (cut off the power) directly is not

allowable.

6 Treatment of Usual Troubles

6.1 During use, the heater may become unable to start normally or die out after start.

Such troubles may lead to locking state. In such case, you can press the button which is

lighting on then work indicator goes out. Turn off the heater and keep it in such state for

at least 5 seconds. Then, restart the heater.

6.2 Circuit troubles may be caused by different reasons, such as corrosion of

connectors, poor contact of connectors, wrong connection of wires, corrosion of wires

or fuse, corrosion and looseness of battery poles, etc. Users need to check and prevent

such troubles and offer good maintenance.

6.3 The reasons for the troubles to the heater can be indicated by the green LED on

the control switch (see Section 3.3.3 for details). When the following troubles occur,

users can take measures to solve:

(a)Failure to turn on the heater and the indicator light is not illuminating, the

reason is open circuit of fuse or wrong connection of wires.

(b)The heater runs idly and no start process occurs after the heater is powered on,

this indicates that the temperature of air inlet (or the ambient temperature around the

external temperature sensor) is higher than the set heating temperature, or called hot

start. In such case, you need to turn the control switch knob clockwise to have a

higher set temperature.

(c)When the LED flashes once, troubleshooting can be solved by the methods list in

table 4.

This manual suits for next models

1