SY(2...9)U230-SR/MF-T actuator

SY(2...5)U24-SR/MF/MP-T modulating actuator

Circuit Board Set Up

Wiring diagram

Note: 1) Power supply Com/Neutral and control signal " - " wiring

to a common is prohibited.

Incorrect wiring will damage the actuator!

2) 75% duty cycle

Auxilary Switches

(SPDT Relays)

SY(2...5)U24-SR/MF/MP-T

SY(2...9)U230-SR/MF-T

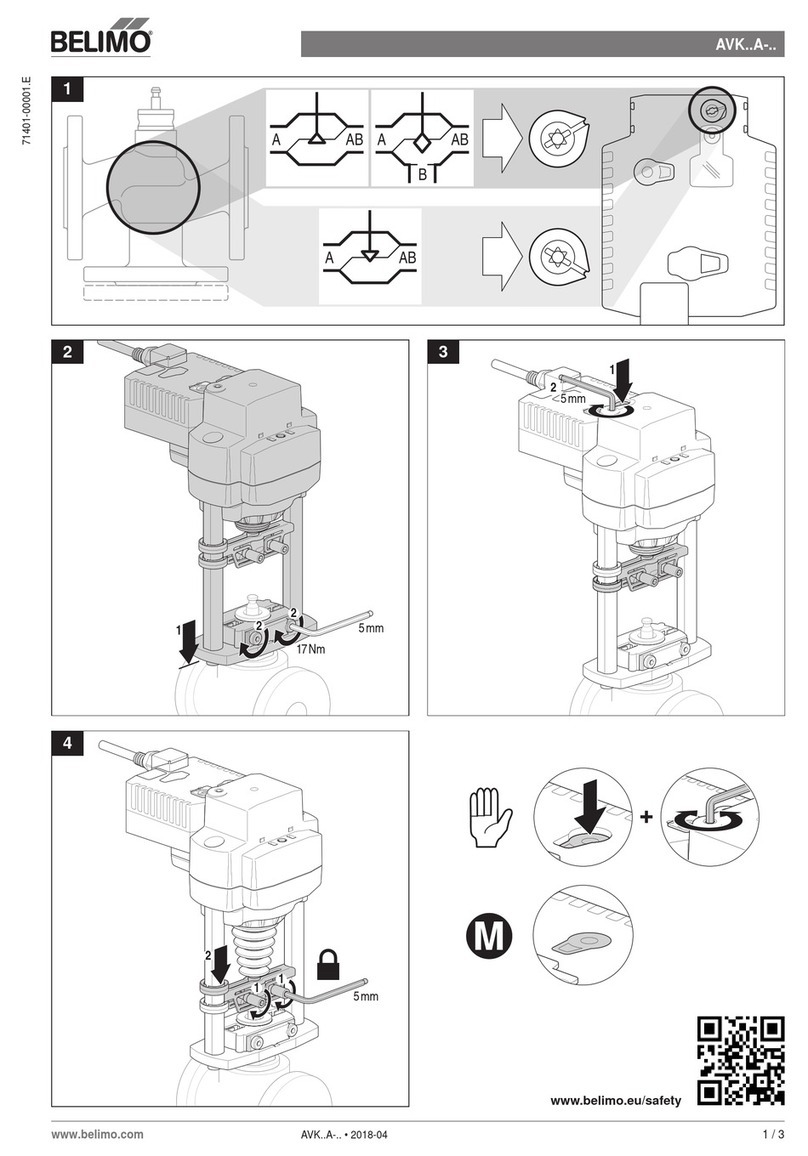

Install to butterfly valve

Manual operate the actuator

to the similar open position

of the valve, which can be

judged by the valve disc or

the red line on the valve top

stem.

Fit coupling on the top stem

of the valve.

Mount the actuator onto the

coupling, manual operate

the actuator to align the holes

of valve top flange and actu-

ator bottom; then tighten the

bolts by wrench in diagonal

sequence.

Uncover the actuator, wire

according to the wiring diag-

ram, check the DIP switch

setting.

Power on to test run the

actuator, check its stroke

and feedback position, do

some adjustment if necessary.

Put the cover on and tighen

the bolts for it.

1).

2).

3).

4).

5).

6).

!

Auxiliary switch for closed

Auxiliary switch for open

(factory setting 3°)

(factory setting 87°)

The line indicates

the position of the

valve's disc

Before power on, make sure the input signal and voltage wiring are

in accordance with the actuator nameplate.

Subject to technical changes

F

ECBA

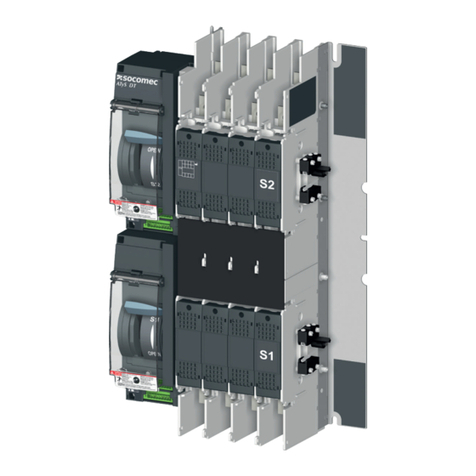

S1 100% S2 0%

D

TC2/TC4 (CW)

TC2/TC4 (CCW)

TC1/TC3 (CCW)

TC1/TC3 (CW)

Current position

Required position

1. How to adjust the travel cam

Perform an adaption after changing

the position of the travel cam.

1.1

Loosen the cam to be adjusted

with a 2.5 mm allen key;

1.2 By turning the key rotate and

adjust the cam as shown in

the right diagram;

1.3

Commission;

1.4

Tighten the cam after succes-

sful

adjustment.

LS4

LS3

LS2

LS1

TC4

TC3

TC2

TC1

shaft

Limiting of manual rotation with stop screws

SY quarter-turn actuator is provided with a limiting of manual rotation

device to avoid over-travel with the handwheel going beyond the 1/4-turn

rotation.

The actuator is supplied and tested for 90°electrical operation, and -2°

...92° limiting of manual rotation.

The limiting of manual rotation is realized by the stop screws 1and 2

( max. ± 2° which corresponding to 1 turn of the stop screw).

SY(2...5)U24-SR/MF/MP-T

SY(2...9)U230-SR/MF-T

Open

Adaption button

Close

If it's necessary to change the following settings, only

authorized and trained persons are allowed to do that.

!

Limit switches LS.. with travel cams TC..

The TC.. cams operating the LS.. limit switches rotate with the shaft.

Clockwise movement of the shaft closes the actuator, counterclockwise

opens the actuator.

There are 4 cams included , marked with two colors : blue for open,

silver for close; each cam can be set independently.

(factory setting 0°)

(factory setting 90°)

Closed switch

Open switch

!Connect via safety

isolating transformer

1

2

3

1- Stop screw for manual OPEN limit

2- Stop screw for manual CLOSED limit

3- Handwheel connection

(Note: SY1 without the device)

The stop screws must be sec-

ured with the lock nut after any

adjustment. (by both a allen key

and a wrench)

The 90° travel must always be

limited by the travel limit sw-

it

ches so they must be set to

trip just BEFORE stop screw's

contact. To achieve this, loose

stop screws by 2 1/2 turns. Then,

after travel limit switch setting is

terminated, (see paragraph

Limit switches LS.. with travel cams TC..), operate the actuator elect-

rically to

closed position. Now rotate the stop screw 2to closed position,

re-loose 1 turn, and secure by lock nut. Proceed in the same way for stop

screw 1in open position.

It is emphasized that the limiting of manual rotation device is only a design

feature to prevent over-travel when the actuator is being operated manually,

not a safety function to prevent over-travel in the event of travel limit

switch failure.

2. Closed position (0%) setting

2.1

2.2 Power on.

The actuator will stop

.

2.3

Adjust travel cam TC2 in the closed position.

Check whether

LS2 switch trips prior to manual operation stop.

(The fanshaped cam which connected with the potentiometer need

to be loosed firstly, then retightened after the

travel limit switches

setting is

terminated.)

(

So when motor stops at fully closed position, it should be

possible to further operate the handwheel CW 1/2...3/4 turn.

Otherwise the stop screw for close need to be adjusted.)

Proceed in the similar way for TC1 in open position.

± 1°

T T

AC 24 V AC 230 V

-

Y1U5 C1C22

+-

+

~

T

~

T

N L

Direction switch

Direction switch

Y2 standard

Y2 standard

SY(2...5)U24-SR/MF/MP-T

SY(2...9)U230-SR/MF-T

71102-00001.A