2009/06 – Subject to change 3

Internet: www.festo.com/catalogue/...

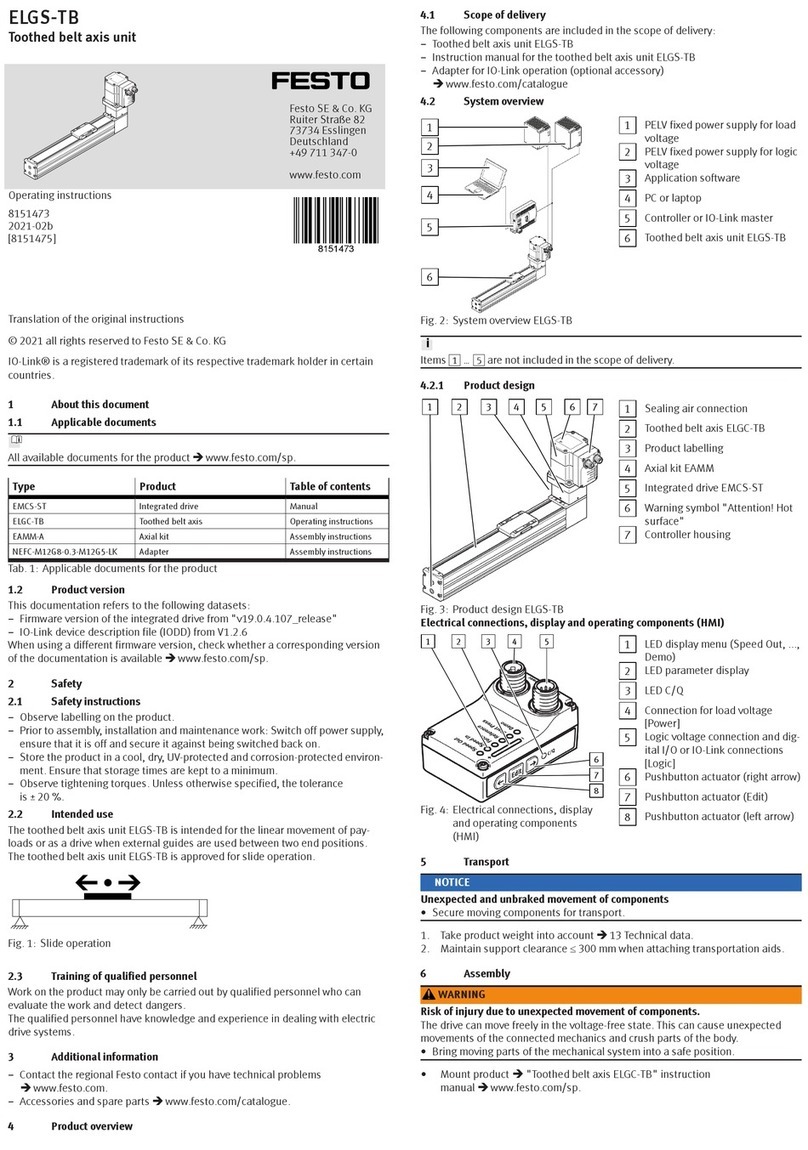

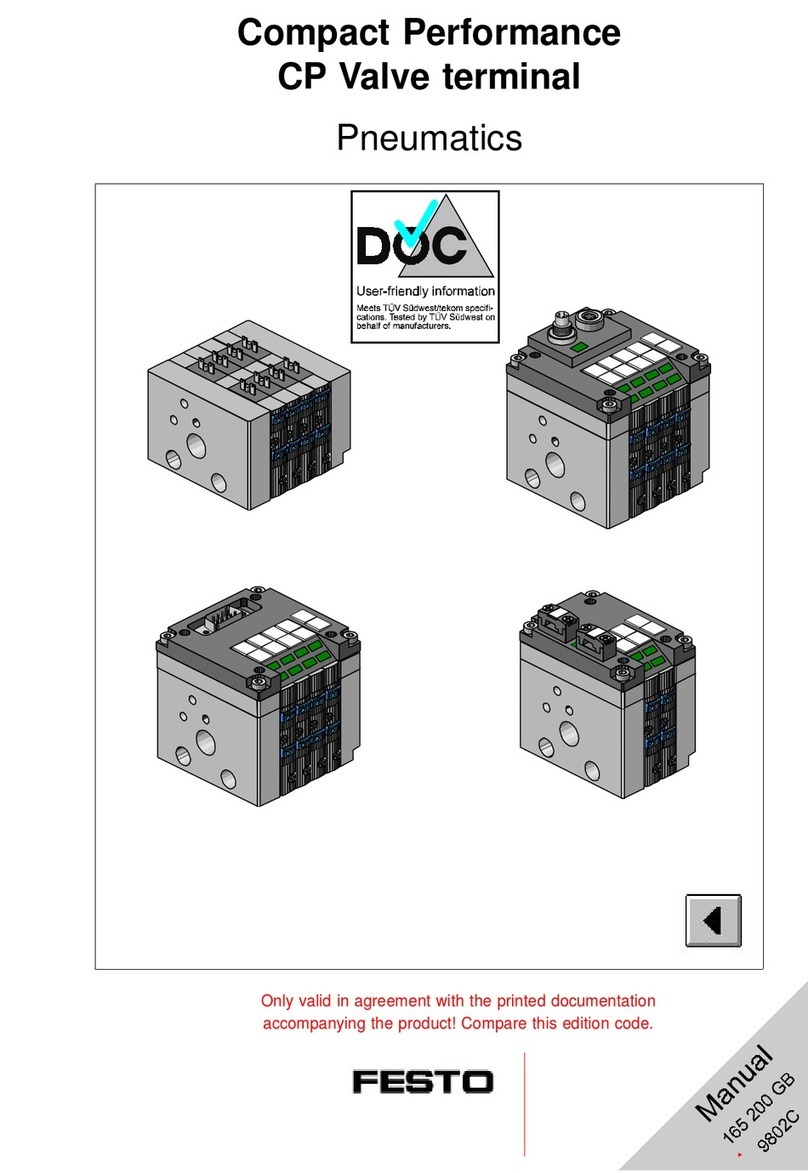

Valve terminals type 32 MPA

Key features

Reduced downtimes:

Two-colour LED diagnostics on site

Reliable operation:

Manual override non-detenting/detenting or with cover

Width 10 mm and 20 mm

Safe:

Operating voltage connection ±25%, outputs

and valves can be disconnected separately

Compact:

Slim valves and flat plate silencers

Flexible:

– 64 valve positions/128 solenoid coils (FB)

– 24 valve positions/24 solenoid coils (MP)

Functional:

Sturdy metal thread or pre-assembled QS

fittings

Wide range of valve functions

Practical:

Large inscription labels

Quick mounting:

Directly using screws or on a H-rail,

automatic earthing

CPX diagnostic interface for hand-

held devices (channel-oriented diag-

nostics down to the individual valve)

Pneumatic interface to CPX

Straightforward electrical onnections

– Multi-pin plug connection

– Fieldbus connection

– Control block

–AS-interface

–CPI

Modular:

Supply plates facilitate the creation of

multiplepressurezonesaswellasnumer-

ous additional exhaust and supply ports

Equipment options

Valve functions

•5/2-way valve, single solenoid

•5/2-way valve, double solenoid

•2x 3/2-way valve,

normally open

•2x 3/2-way valve,

normally closed

•2x 3/2-way valve,

1x normally open,

1x normally closed

•5/3-way valve,

mid-position pressurised

•5/3-way valve,

mid-position closed

•5/3-way valve,

mid-position exhausted

•2x 2/2-way valve,

1x normally closed,

1x normally closed, reversible

•2x 2/2-way valve,

normally closed

•1x 3/2-way valve,

normally closed,

external compressed air supply

•1x 3/2-way valve,

normally open,

external compressed air supply

•Manual pressure regulators

•Proportional pressure regulators

•Pressure sensor

All valves have the same compact

dimensions with an overall length of

107 mm and a width of 10.5 mm or

21 mm. A height of 55 mm makes

them a perfect match for the electrical

peripherals CPX.

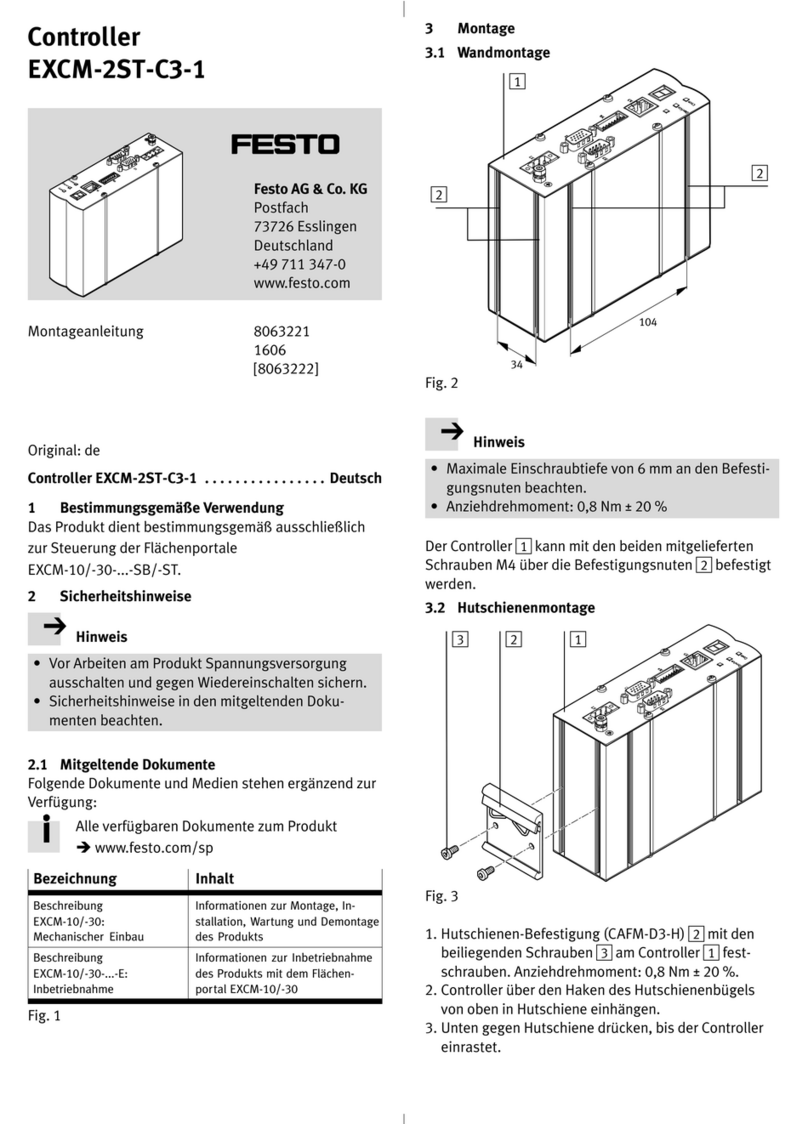

Special features

Multi-pin terminal

•Max. 24 valve positions/

max. 24 solenoid coils

•Parallel modular valve linking via

circuit boards

•Electronics module with integrated

holding current reduction

•Any compressed air supply

•Creation of pressure zones

Fieldbus terminal/control block

•Max. 64 valve positions/

max. 128 solenoid coils

•Internal CPX bus system for valve

actuation

•Module for electrical valve actua-

tion, via separate voltage supply or

without electrical isolation

•Any compressed air supply

•Creation of pressure zones

Individual valve

•Electrical M8 connection, 4-pin

with screw connection

•Detachable electronics module with

integrated holding current

reduction

AS-interface

•2 to 8 valves, freely configurable

(max. 8 solenoid coils) with input

feedback

CPI interface

•Max. 32 valve positions/

max. 32 solenoid coils

Combinable

•MPA1 flow rates up to 360 l/min

•MPA2 flow rates up to 700 l/min

•MPA1 and MPA2 can be combined

on one valve terminal

Electrical supply plate

•Increases the maximum number of

valve positions possible to 64, with

max. 128 solenoid coils

•Creation of isolated, individually

disconnectable electrical circuits

(voltage zones)

•Greater economy thanks to the

higher number of valves/solenoid

coils per valve terminal

•Greater safety through individual

disconnection of valve groups, for

example for EMERGENCY-STOP

functions

-H- Note

The electrical supply plate is

available with either an M18 or

7/8” connection.