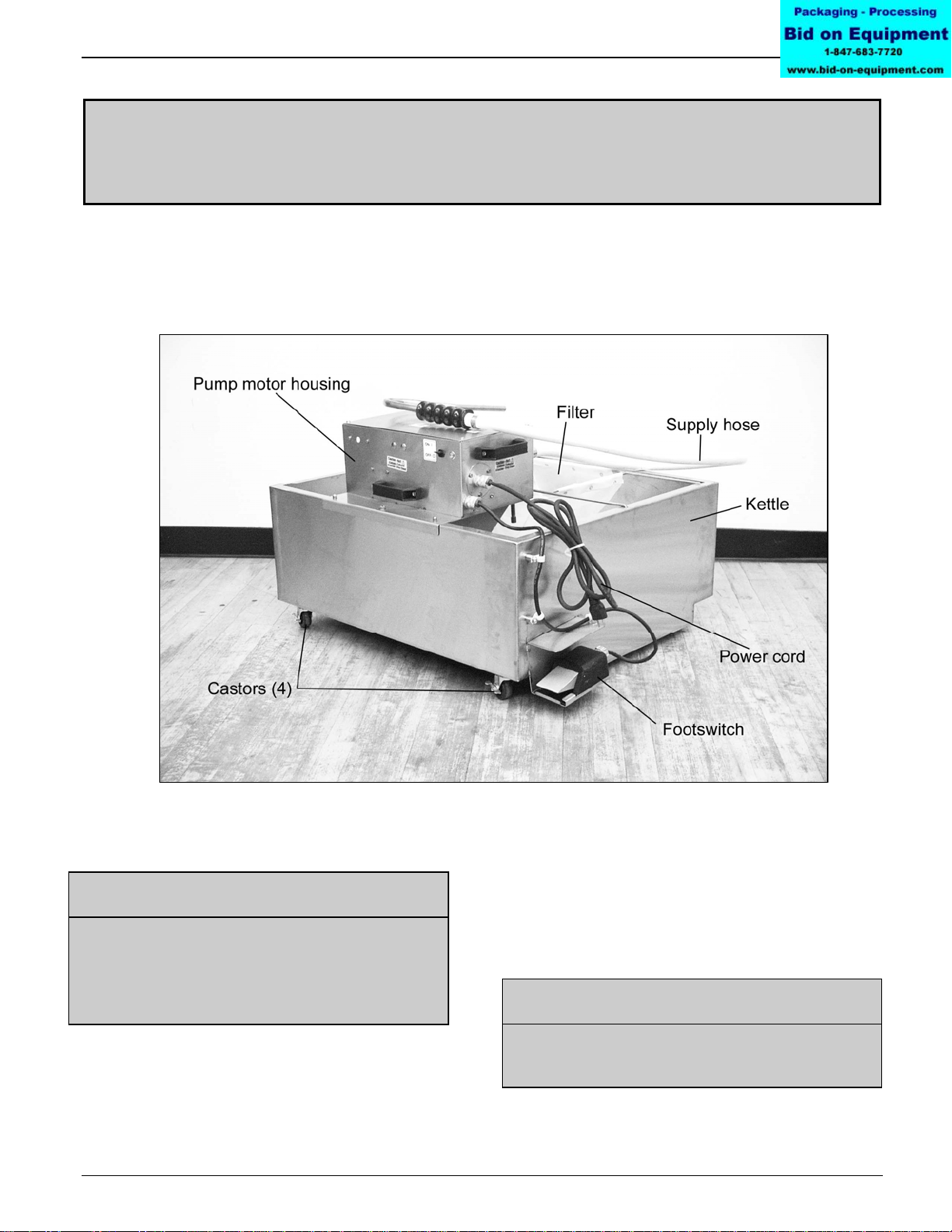

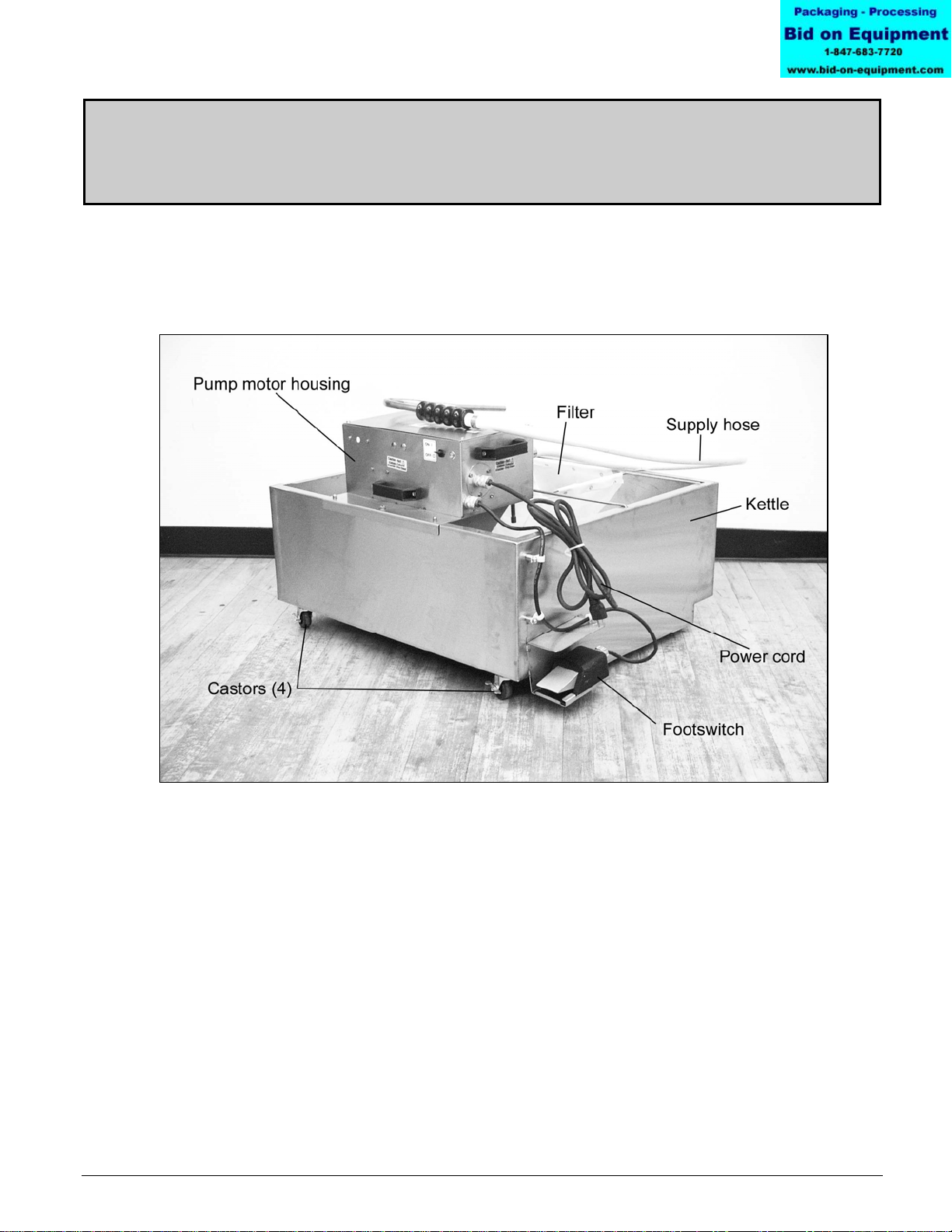

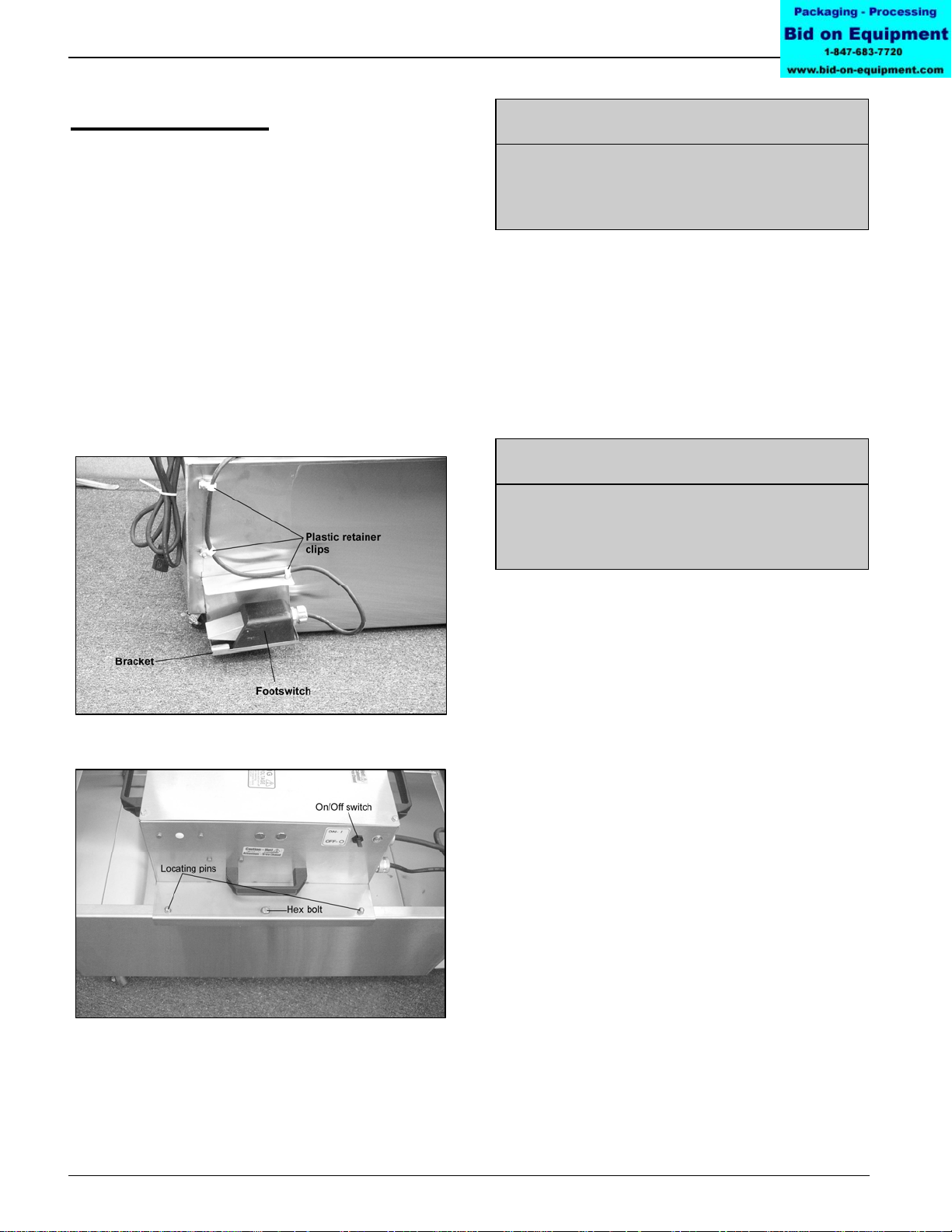

Belshaw Brothers SF18 User manual

This manual suits for next models

2

Other Belshaw Brothers Commercial Food Equipment manuals

Belshaw Brothers

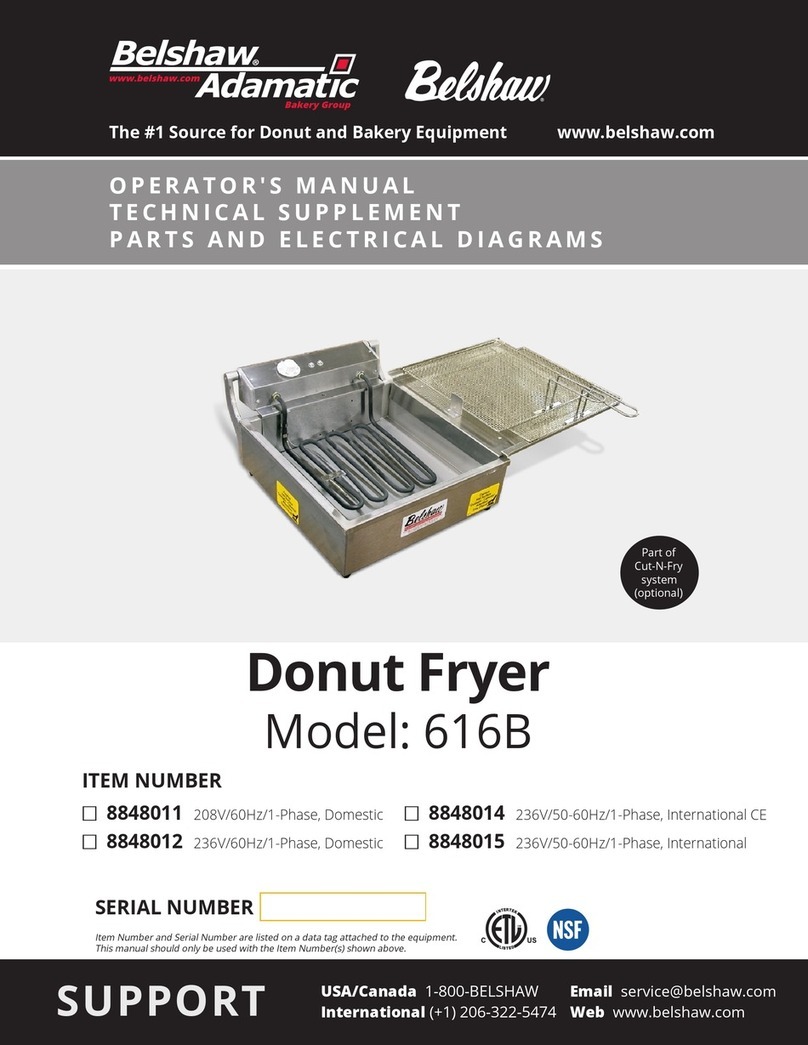

Belshaw Brothers 616B User manual

Belshaw Brothers

Belshaw Brothers H&I-2 Operation manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark II User manual

Belshaw Brothers

Belshaw Brothers 22587-20 User manual

Belshaw Brothers

Belshaw Brothers H18F User manual

Belshaw Brothers

Belshaw Brothers Type K Operation manual

Belshaw Brothers

Belshaw Brothers 22587-20 User manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark II User manual

Belshaw Brothers

Belshaw Brothers Adamatic HI18F User manual

Belshaw Brothers

Belshaw Brothers TZ6 User manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark VI User manual

Belshaw Brothers

Belshaw Brothers T User manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark II User manual

Belshaw Brothers

Belshaw Brothers HG18EZ User manual

Belshaw Brothers

Belshaw Brothers EZMelt 18 User manual

Belshaw Brothers

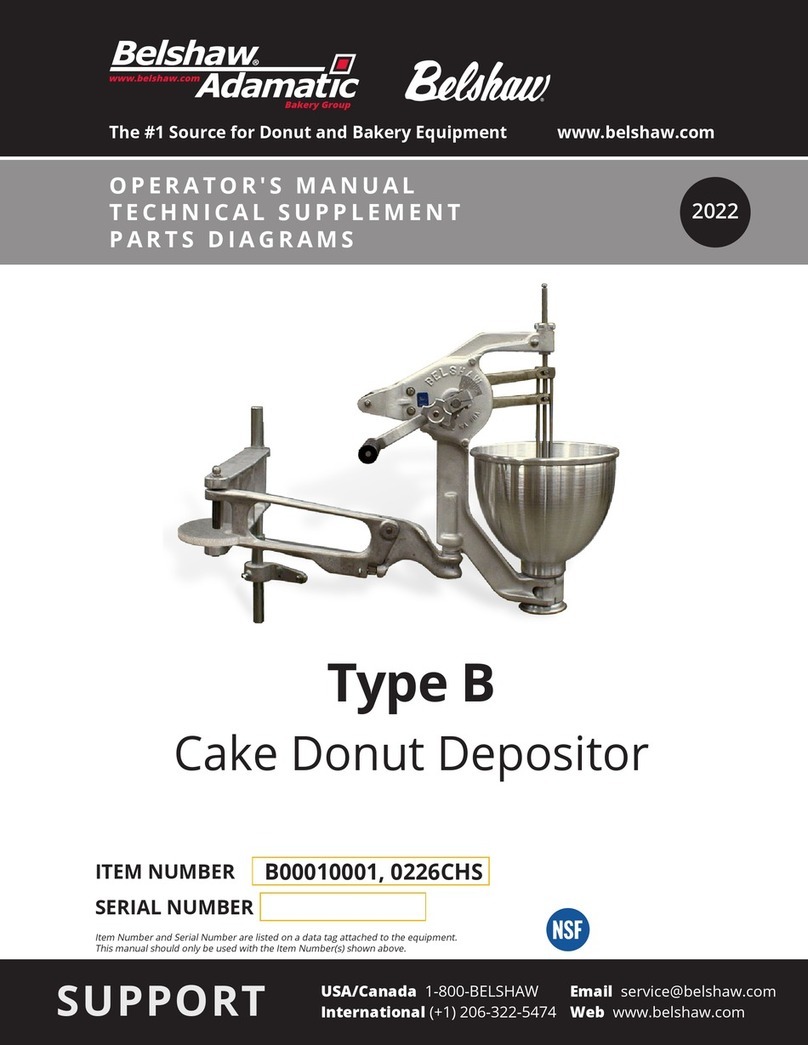

Belshaw Brothers B00010001 User manual

Belshaw Brothers

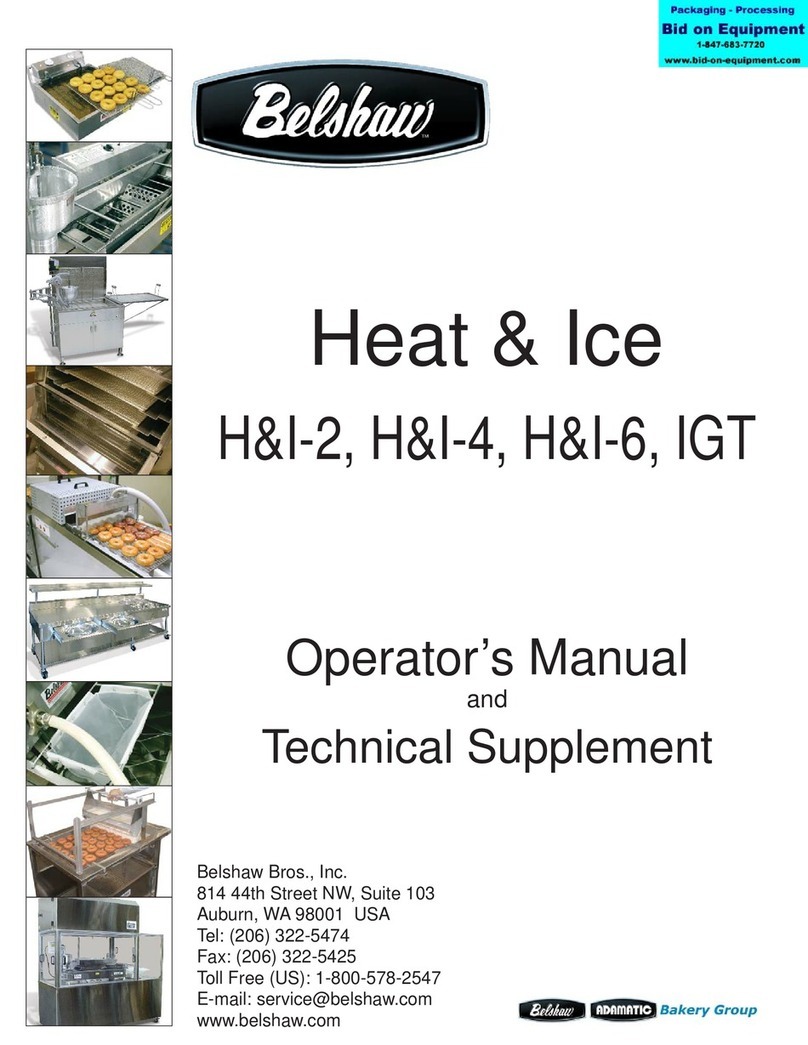

Belshaw Brothers Heat & Ice H&I-2 User manual

Belshaw Brothers

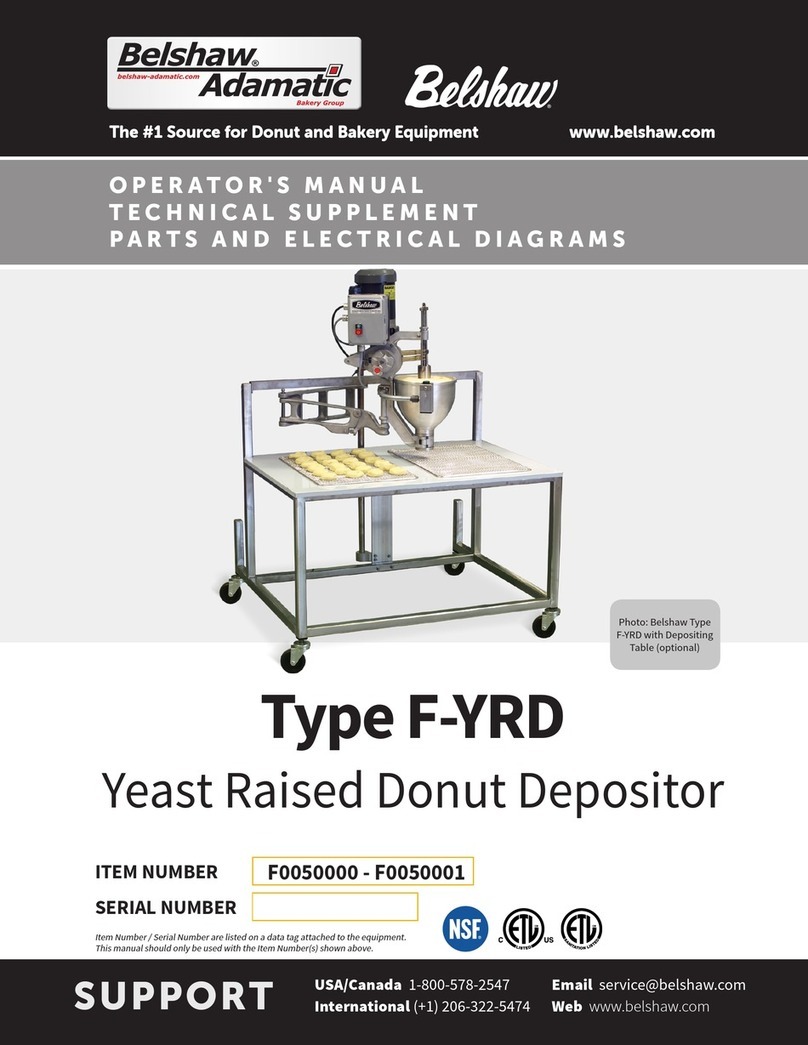

Belshaw Brothers F-YRD F0050000 User manual

Belshaw Brothers

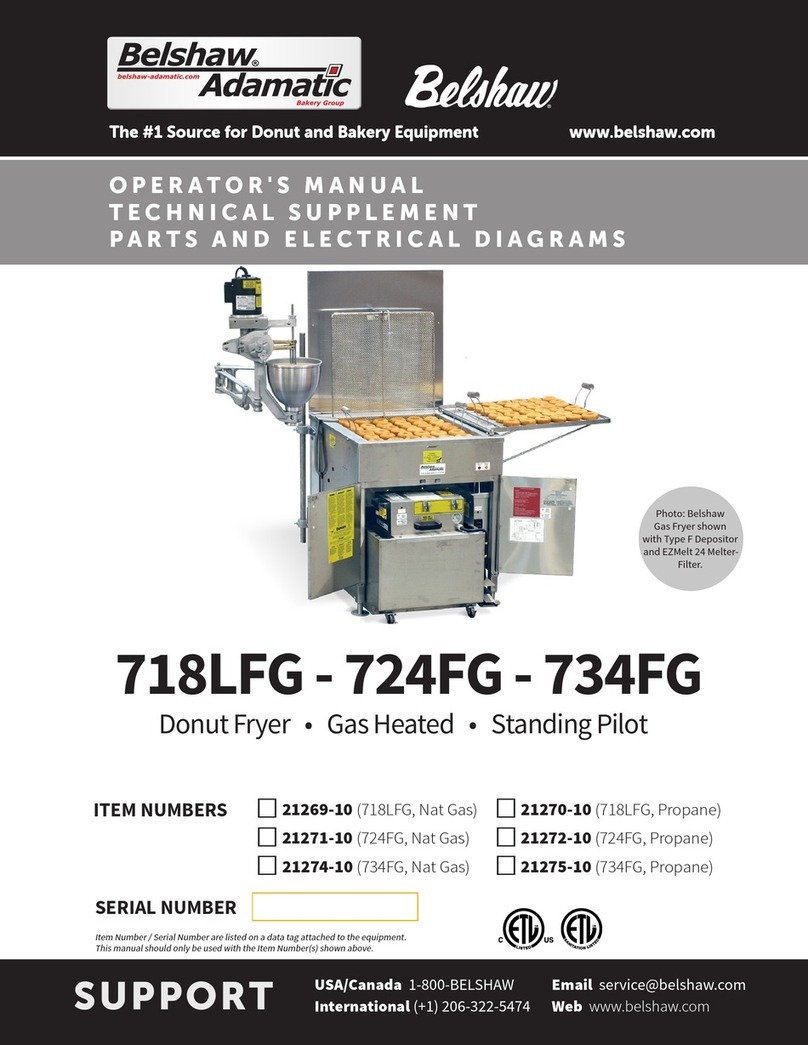

Belshaw Brothers 718LFG User manual

Belshaw Brothers

Belshaw Brothers TG 50 User manual

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use