Bender EDS460 User manual

Manual

EN

EDS460-490_D00085_01_M_XXEN/02.2016

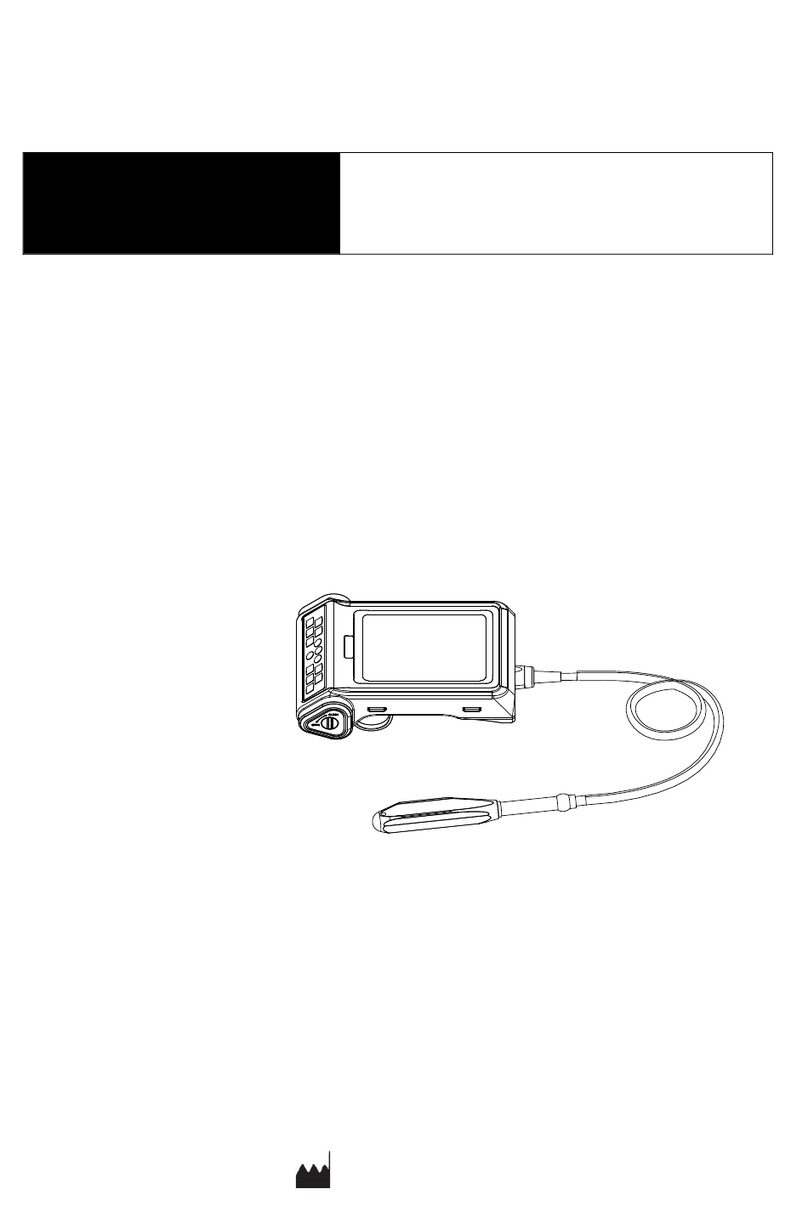

EDS460/490 and EDS461/491

Insulation fault locator

Software version: EDS4.0-D: D234 V3.1 / D256 V2.2

EDS4.0-L: D234 V3.1 / D216 V2.2

EDS4.1-D: D358 V3.1 / D256 V2.2

EDS4.1-L: D358 V3.1 / D216 V2.2

Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Gruenberg • Germany

Postfach 1161 • 35301 Gruenberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-Mail: [email protected]

Web: http://www.bender.de

©Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Photos: Bender archive

Table of contents

3

EDS460-490_D00085_01_M_XXEN/02.2016

1. Making effective use of this document ....................................................... 7

1.1 How to use this manual ................................................................................. 7

1.2 Explanation of symbols and notes ............................................................. 8

2. Safety instructions ........................................................................................... 9

2.1 Intended use ...................................................................................................... 9

2.2 Qualified personnel ...................................................................................... 10

2.3 Safety information ........................................................................................ 11

2.4 Delivery conditions, guarantee, warranty and liability .................... 11

3. System description ........................................................................................ 13

3.1 Features ............................................................................................................ 13

3.1.1 Areas of application ...................................................................................... 13

3.1.2 Standards ......................................................................................................... 13

3.1.3 System versions ............................................................................................. 13

3.1.4 System features .............................................................................................. 13

3.2 Function of the EDS system ....................................................................... 14

3.2.1 Block diagram EDS system ......................................................................... 15

3.2.2 Test cycle .......................................................................................................... 16

3.2.3 Currents in the EDS system ........................................................................ 17

3.2.4 Requirements for reliable insulation fault location .......................... 18

4. Installation and connection ......................................................................... 21

4.1 Unpacking ........................................................................................................ 21

4.2 Fuses, max. voltage, cable lengths ......................................................... 22

4.3 Notes on mounting ...................................................................................... 22

4.3.1 Dimension diagram EDS460/461-D/-L .................................................. 23

4.3.2 Dimension diagram EDS490/491-D/-L .................................................. 23

Inhaltsverzeichnis

4EDS460-490_D00085_01_M_XXEN/02.2016

4.4 Connection ...................................................................................................... 24

4.4.1 Wiring diagram EDS460/461-D / -L ......................................................... 24

4.4.2 Wiring diagram EDS490/491-D / -L ......................................................... 26

4.4.3 Connection of W…, WR…, WS…-series measuring current

transformers .................................................................................................... 28

4.4.4 Connection example EDS standard system with FTC4…XET ....... 29

5. Commissioning .............................................................................................. 31

5.1 Before switching on ...................................................................................... 31

5.2 Switching on ................................................................................................... 32

6. Operation ........................................................................................................ 35

6.1 EDS…-D operating and display elements ............................................ 35

6.2 EDS…-L operating and display elements ............................................. 36

6.3 Working in operating mode ...................................................................... 37

6.3.1 Standard display ............................................................................................ 37

6.3.2 Alarms and their effects .............................................................................. 37

6.3.3 Carrying out a test ......................................................................................... 39

6.3.4 Resetting saved alarm messages (RESET) ............................................. 40

6.3.5 Displaying standard information ............................................................. 41

6.4 Setting the EDS…-L ...................................................................................... 42

6.5 Operating and setting the EDS…-D ....................................................... 42

6.5.1 Opening the main menu ............................................................................ 43

6.5.2 Menu overview diagram ............................................................................. 44

6.5.3 Main menu functions ................................................................................... 45

6.6 The main menu .............................................................................................. 46

6.6.1 Menu 1: Alarm/meas. values ..................................................................... 46

6.6.2 Menu 2: History .............................................................................................. 48

6.6.3 Menu 3: Settings ............................................................................................ 49

6.6.3.1 Settings menu 1: General ................................................................... 50

6.6.3.2 Settings menu 2: Channel .................................................................. 51

6.6.3.3 Settings menu 3: Relay ........................................................................ 55

6.6.3.4 Settings menu 4: History .................................................................... 56

Inhaltsverzeichnis

5

EDS460-490_D00085_01_M_XXEN/02.2016

6.6.3.5 Settings menu 5: Language .............................................................. 56

6.6.3.6 Settings menu 6: Interface ................................................................ 56

6.6.3.7 Settings menu 7: Alarm addresses ................................................. 57

6.6.3.8 Settings menu 8: Clock ....................................................................... 57

6.6.3.9 Settings menu 9: Password ............................................................... 58

6.6.3.10 Settings menu 10: Factory settings ................................................ 59

6.6.3.11 Settings menu 11: Service ................................................................. 59

6.6.4 Menu 4: Control ............................................................................................. 59

6.6.4.1 Control menu 1: TEST .......................................................................... 59

6.6.4.2 Control menu 2: RESET ....................................................................... 59

6.6.4.3 Control menu 3: Test communication .......................................... 59

6.6.5 Menu 5: External devices ............................................................................ 61

6.6.6 Menu 6: Info .................................................................................................... 64

7. Tests and service ........................................................................................... 65

7.1 Periodic tests ................................................................................................... 65

7.2 Maintenance ................................................................................................... 65

7.3 Service ............................................................................................................... 65

7.4 Troubleshooting ............................................................................................ 66

7.4.1 Display device error ...................................................................................... 66

7.4.2 Device error display (channel-related) .................................................. 67

7.4.3 CT connection fault display (channel-related) ................................... 68

7.4.4 Display "peak" ................................................................................................. 68

7.4.5 External alarm ................................................................................................. 68

8. Data .................................................................................................................. 69

8.1 Standards ......................................................................................................... 69

8.2 Approvals and certifications ..................................................................... 69

8.3 Technical data EDS460/490/EDS461/491 ............................................. 70

8.4 Response sensitivity characteristics ....................................................... 74

8.4.1 Characteristic curves EDS460/490 .......................................................... 77

8.4.1.1 EDS460/490 characteristics for 3AC systems .............................. 77

8.4.1.2 EDS460/490 characteristics for AC systems ................................ 80

Inhaltsverzeichnis

6

EDS460-490_D00085_01_M_XXEN/02.2016

8.4.1.3 EDS460/490 characteristics for DC systems ................................ 82

8.4.2 Characteristic curves EDS461/491 .......................................................... 84

8.4.2.1 EDS461/491 characteristics for AC systems ................................ 84

8.4.2.2 EDS461/491characteristics for DC systems ................................. 87

8.5 Ordering information .................................................................................. 89

INDEX ..................................................................................................................... 97

Making effective use of this document

7

EDS460-490_D00085_01_M_XXEN/02.2016

1. Making effective use of this document

1.1 How to use this manual

This operating manual describes EDS460/490 resp. EDS461/491 insulation

fault locators. It is designed for skilled persons working in electrical enginee-

ring and electronics and in particular for those designing, installing and ope-

rating electrical systems.

Before using the equipment, please read this operating manual, the supple-

ment entitled "Important safety instructions for Bender products", the "BMS

bus" instruction leaflet, as well as the instruction leaflets supplied with the in-

dividual system components. Please keep this documentation close at hand

near to the equipment.

Should you have any questions, please do not hesitate to contact our techni-

cal sales team. We are also happy to provide on-site services. Please contact

our Service Department for more information.

Service-Hotline: 0700-BenderHelp (Telephone and Fax)

Carl-Benz-Straße 8 • 35305 Grünberg • Germany

Tel: +49 6401 807-760 • Fax: +49 6401 807-629

E-Mail: info@bender-service.com • www.bender.de

Although great care has been taken in the drafting of this operating manual,

it may nevertheless contain error and mistakes. The Bender group cannot

accept any liability for injury to persons or damage to property resulting from

errors or mistakes in this manual.

Making effective use of this document

8EDS460-490_D00085_01_M_XXEN/02.2016

1.2 Explanation of symbols and notes

The following terms and symbols are used to denote hazards and instructions

in Bender documentation:

This signal word indicates that there is a high risk of

danger that will result in electrocution or serious injury if

not avoided.

This signal word indicates a potential risk of danger.

Failure to observe the associated instructions and take

appropriate precautions may result in death, serious

physical injury or substantial damage to property

This signal word indicates a low level risk that can result in

minor or moderate injury or damage to property if not

avoided.

This symbol denotes important information intended to

assist the user in making optimum use of the product.

DANGER

WARNING

CAUTION

9

EDS460-490_D00085_01_M_XXEN/02.2016

2. Safety instructions

2.1 Intended use

EDS… insulation fault locators are used for localisation of insulation faults in

unearthed DC, AC and three-phase power supply systems

(IT systems). Alternating and three-phase systems in the range of AC 24 to 690

V and DC systems in the range of DC 24 to 500 V can be monitored. The ope-

rating frequency is optionally DC, 50, 60 or 400 Hz. The nominal system volta-

ge varies with the type of locating current injector (PGH47., IRDH575).

An EDS system consists of the insulation fault locators EDS460/490 or EDS461/

491 and either the A-ISOMETER® IRDH575 or locating current injector PGH.

Using measuring current transformers, EDS460/490 or EDS461/491 insulation

fault locators detect locating current signals generated by the IRDH575 insu-

lation monitoring device or PGH… locating current injector and evaluate

them.

If the locating current is too high, IRDH575 or PGH… may

damage sensitive loads (e.g. in control circuits) or may

accidentally activate switching operations. Therefore, it is

recommended to use a PGH… with a low locating current

or to set a low locating current at the IRDH575. The

response sensitivity of EDS461/491 insulation fault locators

is higher and hence they are capable of evaluating this low

locating current.

In case of doubt, please contact a Bender product manager.

CAUTION

Safety instructions

10 EDS460-490_D00085_01_M_XXEN/02.2016

Up to 12 measuring current transformers can be connected to one EDS…. Up

to 90 EDS… insulation fault locators can be connected via a BMS bus (RS-485

interface with BMS protocol), thereby up to 1080 measuring channels (sub-cir-

cuits) can be monitored. The scanning time for all channels is

– for EDS460/EDS490 approx. 8…24 s

– for EDS461/EDS491 approx. 14…30 s

The individual parameterisation, necessary to adjust the insulation fault loca-

tor to the existing system and utilisation conditions, must be carried out at the

place of utilisation in order to meet the requirements laid down in the stan-

dards.

Please take note of the limits for the application area specified in the technical

data. Any other use, or use which goes beyond the foregoing is deemed to be

use other than for the intended purpose.

Use for the intended purpose also includes:

The observation of all information in this operating manual.

and the compliance with test intervals.

2.2 Qualified personnel

Only skilled persons may work on Bender devices. Personnel who are familiar

with the assembly, commissioning and operation of the equipment and have

undergone appropriate training are considered qualified. Such personnel

must have read this manual and understood all instructions relating to safety.

Safety instructions

11

EDS460-490_D00085_01_M_XXEN/02.2016

2.3 Safety information

Bender devices are built in accordance with the state of the art and accepted

rules in respect of technical safety. Nevertheless, the use of such devices may

introduce risks to the life and limb of the user or third parties and/or result in

damage to Bender devices or other property.

Only use Bender devices:

– for the purpose for which it is intended;

– when it is in perfect condition as far as safety is concerned;

– in compliance with the accident prevention regulations and guide-

lines applicable in the location of use.

Any faults which may impair safety must be eliminated immediately.

Do not make any unauthorised changes and only use replacement

parts and optional accessories purchased from or recommended by

the manufacturer of the equipment. Failure to observe this require-

ment can result in fire, electric shock and injury.

Warning signs must always be easily legible. Damaged or illegible signs

must be replaced immediately.

2.4 Delivery conditions, guarantee, warranty and liability

The conditions of sale and delivery set out by Bender shall apply. Conditions

of sale and delivery can be obtained from Bender in printed or electronic for-

mat.

13

EDS460-490_D00085_01_M_XXEN/02.2016

3. System description

3.1 Features

3.1.1 Areas of application

Insulation fault location in AC, AC / DC and DC IT systems

Main and control circuits in industrial installations and ships

Diode-decoupled DC IT systems in power stations

Systems for medical locations

3.1.2 Standards

The standard for unearthed power supply systems (IT systems) IEC 60364-4-41

requires that a first fault is to be eliminated with the shortest practicable delay.

Fast insulation fault location is possible with EDS systems.

3.1.3 System versions

EDS460, EDS461, EDS490 or EDS491 insulation fault locators differ in their re-

sponse sensitivity and/or number of alarm relays.

3.1.4 System features

Universal system concept;

Modular design, hence easily adaptable to the individual conditions of

the system;

Measuring current transformers in various sizes and types of construc-

tion;

Communication between the components via BMS bus (two-wire);

All measuring current transformers are scanned simultaneously;

Central indication of faulty sub-circuits;

Various setting options allow individual adjustments;

Connection to higher level control and visualisation systems can easily

be established.

System description

14 EDS460-490_D00085_01_M_XXEN/02.2016

3.2 Function of the EDS system

When an insulation fault is detected by the insulation monitoring device in

the IT system, the insulation fault location process will be started.

On the occurrence of a first insulation fault, a fault current essentially determi-

ned by the system leakage capacitances flows in the IT system. The funda-

mental idea in fault location is therefore to close the fault current loop for a

short period via a defined resistance. As a result of this principle, the system

voltage itself drives a locating current containing a signal that can be evalua-

ted.

The locating current signals are generated periodically by the IRDH575 res-

pectively the PGH… . The locating current is limited in amplitude and time. As

this happens, the system conductors are connected alternately to earth via a

defined resistance. The locating current generated in this manner depends on

the magnitude of the present insulation fault and the system voltage. It is li-

mited according to the setting of the IRDH575 respectively the PGH… . For pl-

anning purposes, it should be noted that no system components are present

in which this locating current can bring about a damaging reaction, even in

unfavourable cases.

The locating current pulse flows from the locating current injector via the live

parts, taking the shortest path to the location of the insulation fault. From the-

re, it flows via the insulation fault and the PE back to the IRDH575 respectively

PGH… . This locating current pulse is then detected by the measuring current

transformers located in the insulation fault path, and is signalled by the con-

nected insulation fault locator.

Additional information is available in the data sheet "Technical issues affec-

ting the use of insulation fault location systems".

System description

15

EDS460-490_D00085_01_M_XXEN/02.2016

3.2.1 Block diagram EDS system

Legend

EDS… Insulation fault locator

PGH… Locating current injector

IRDH575

A-ISOMETER® IRDH575 with integrated locating current injector

UsCurrent source IT system

W Measuring current transformer

V Electrical load

RFd Insulation fault downstream of the measuring current trans-

former

PE Protective conductor respectively equipotential bonding

conductor

BMS BMS bus

System description

16 EDS460-490_D00085_01_M_XXEN/02.2016

3.2.2 Test cycle

The duration of a locating current pulse cycle is 6 seconds. The IRDH575 or

PGH… alternatively sends positive or negative locating current pulses. The

test cycle of the IRDH575 or PGH… is shown in different switch positions

(1,2,3) in the block diagram below, („Block diagram EDS system“ on page 15).

EDS start

Position

PGH... 12331

2 sec 4 sec 2 sec 4 sec

System description

17

EDS460-490_D00085_01_M_XXEN/02.2016

3.2.3 Currents in the EDS system

In addition to the block diagram on page 15, the path of the residual currents

and the locating current is shown in the diagram below:

Legend

............. Locating current loop I∆s

.. .. .. .. Residual currents I∆(example)

CLu Upstream capacitances, system leakage capacitances

upstream the measuring current transformer.

CLd Downstream capacitances, system leakage capacitances

downstream the measuring current transformer.

RFu Insulation fault upstream the measuring current transformer.

RFd Insulation fault downstream the measuring current transfor-

mer.

System description

18 EDS460-490_D00085_01_M_XXEN/02.2016

The following residual currents flow through the measuring current transfor-

mer of the EDS… :

The locating current I∆scaused by the insulation fault RFd

Residual currents I∆flowing through the system leakage capacitances

CLu, and CLd, respectively which are caused by RFu and RFd

Transient leakage currents caused by switching and control activities in

the system

Low-frequency leakage currents caused by the use of converters

3.2.4 Requirements for reliable insulation fault location

The EDS… is intended to locate insulation faults downstream of the measu-

ring current transformer RFd. For this purpose, the locating current caused by

the insulation fault has to be detected reliably, subject to the condition that:

The locating current I∆sfor the EDS460/490 is more than 1.5 mA and

less than 50 mA.

The locating current I∆sfor the EDS461/491 is more than 0.15 mA and

less than 5 mA.

The upstream capacitances CLu must be at least as large as the down-

stream capacitances CLd.

The system leakage capacitance does not have to be too large (see

„Response sensitivity characteristics“ on page 74).

The total residual current through the measuring current transformer

(locating current and residual currents etc.) may be a maximum of 10 A

(EDS460/490) respectively 1 A (EDS461/491).

Not only does the amplitude influence the reliable detection of the

locating current but also the residual current frequency. This effect is

illustrated in the following fault curve.

System description

19

EDS460-490_D00085_01_M_XXEN/02.2016

Fault curve

Safe insulation fault location is only possible in the grey-shaded area.

A measuring channel where insulation fault location is not possible is marked

with "peak" in the "Alarm/meas. values" menu.

Example: A residual current of 2 A/20 Hz (marked with a point (•) in the dia-

gram) would be outside the permissible range.

Symmetrical insulation faults downstream of the

measuring current transformer are not recognised under

certain circumstances.

Low-frequency residual currents (caused by converters, for

example) may have the effect that insulation faults cannot

be found when their frequency is equal or nearly equal the

test cycle frequency of the IRDH575 respectively PGH… .

Other manuals for EDS460

1

This manual suits for next models

35

Table of contents

Other Bender Diagnostic Equipment manuals