Bender PEM735 User manual

Other Bender Measuring Instrument manuals

Bender

Bender MK-BN User manual

Bender

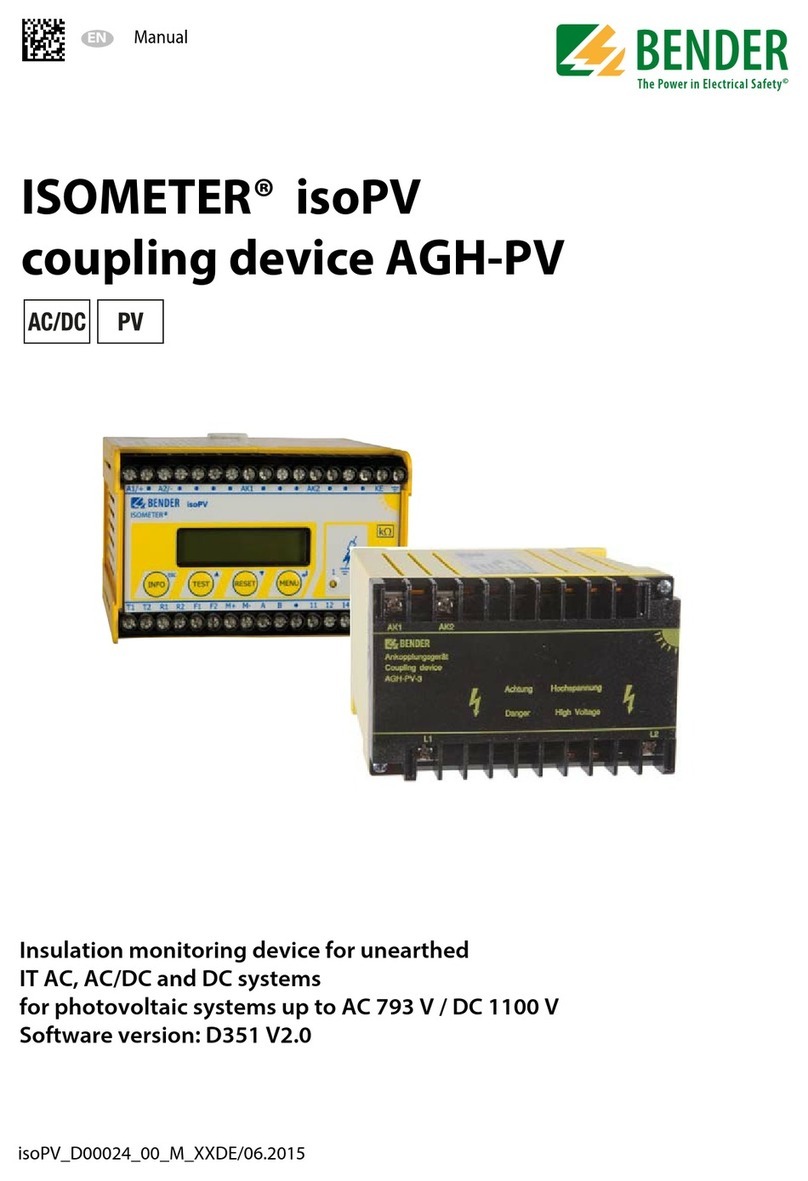

Bender ISOMETER isoPV with AGH-PV User manual

Bender

Bender ISOMETER isoHR1685DW-925 User manual

Bender

Bender RCMA420-DM User manual

Bender

Bender VME420 User manual

Bender

Bender RCMB104 User manual

Bender

Bender RCMA423 User manual

Bender

Bender ISOMETER isoGEN423 User manual

Bender

Bender iso685 User manual

Bender

Bender LINETRAXX CTBC series User manual

Bender

Bender VME420 User manual

Bender

Bender ISOMETER iso175 User manual

Bender

Bender ISOMETER IR1575PG1 User manual

Bender

Bender ISOMETER isoUG425 User manual

Bender

Bender LINETRAXX RCM410R-1 User manual

Bender

Bender RCMA421H-DCB User manual

Bender

Bender ISOMETER isoPV425 with AGH420 User manual

Bender

Bender ISOMETER isoHR685W Series User manual

Bender

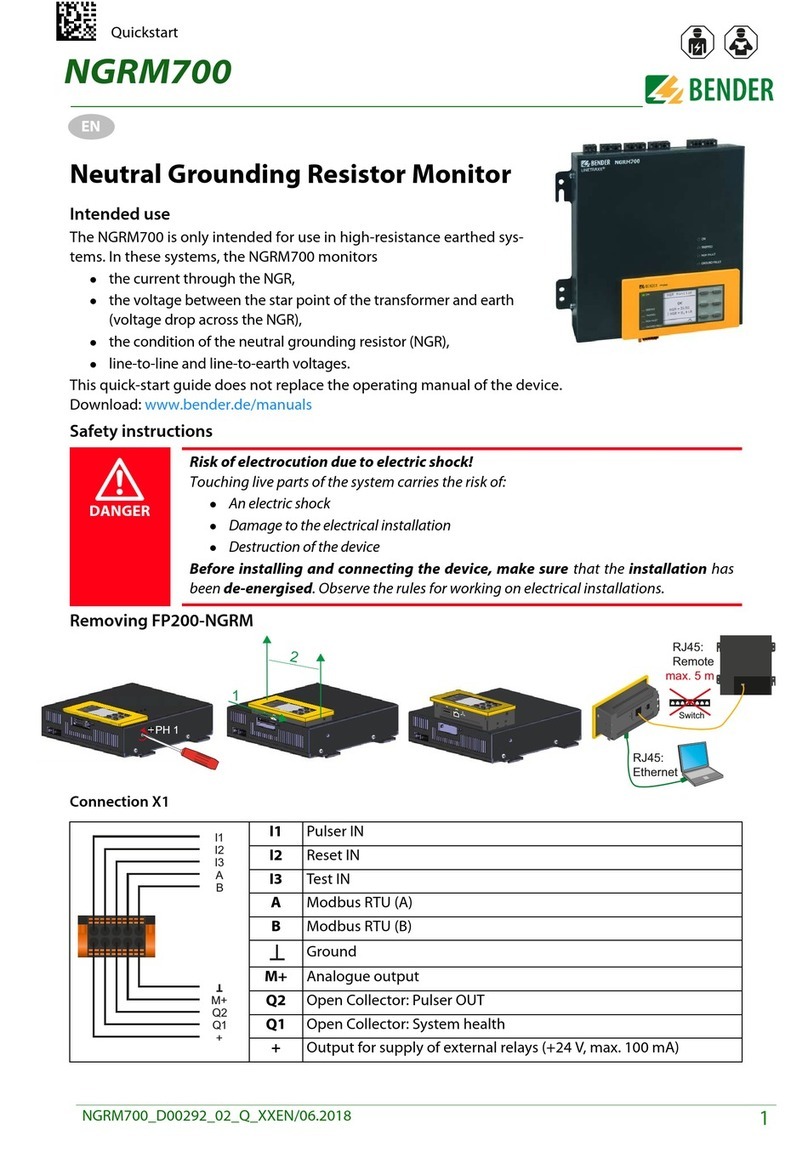

Bender NGRM700 User manual

Bender

Bender NGRM700 User manual

Popular Measuring Instrument manuals by other brands

Takachiho Sangyo

Takachiho Sangyo VerifierG2 MPL-H10S Operation manual

SATO KEIRYOKI

SATO KEIRYOKI SK-660PH Series instruction manual

Niigata seiki

Niigata seiki BEVEL BOX instruction manual

OHAUS

OHAUS MB35 instruction manual

Agilent Technologies

Agilent Technologies HP E5574A user guide

Omega

Omega DPF500 Series user guide