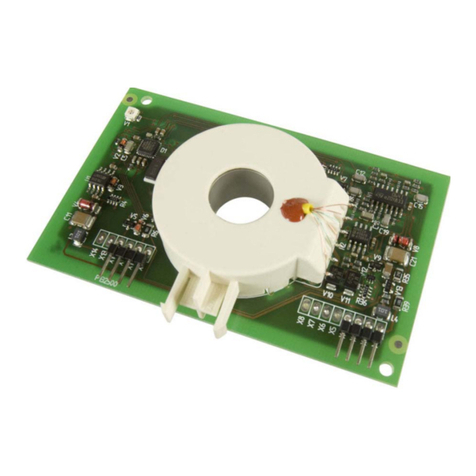

Installation instructions of measuring CT

I Caution! Device damage due to high induction

currents! High currents can be induced into the

conductor loop due to the AC/DC sensitive meas-

uring technology used. Do not route protective

conductors and low-resistance conductor loops

through the measuring current transformer!

I Caution!Device damage due to interference

pulses! The connecting cable (supply, analogue

interface ...) must not be routed directly past the

current transformer core.

I Caution!Risk of injury due to accessible live

conductors! The measuring current transform-

er must be connected to the corresponding

evaluator before the first use and before com-

missioning of the monitored system.

i

Application in railway vehicles / DIN EN

45545-2:2016: If the horizontal or vertical dis-

tance to adjacent components which do not

meet the requirements in table 2 of DIN EN

45545-2 is less than 20 mm or less than 200 mm

respectively, they are to be regarded as grouped.

Refer to DIN EN 45545-2 chapter 4.3 Grouping

rules.

i

Do not route any shielded cables through the

measuring current transformer.

The measuring current transformer must be connec-

ted to the corresponding evaluator before the first

use and before commissioning of the monitored sys-

tem.

All current-carrying cables must be routed through the meas-

uring current transformer. Never route an existing protective

conductor through the measuring curre nt transformer.

L1

L2

L3

N

The cables must be aligned with the centre of the measuring

current transformer.

*

The primary conductors may only be bent from the specified

minimum distance. The minimum bending radius specified by

the manufacturers for the conductors used must be observed.

Distance to 90° angle = 2 x outside diameter

Technical data

Measuring circuit

Internal diameter measuring CTs ......... see dimension diagrams

Rated current I.............................................................................

CTBC20 when IΔn = 30 mA ...............................................40 A

CTBC20 when IΔn = 300 mA .............................................63 A

CTBC20P...........................................................................80 A

CTBC35 when IΔn = 30 mA ...............................................80 A

CTBC35 when IΔn = 300 mA ...........................................125 A

CTBC35P.........................................................................160 A

CTBC60 when IΔn = 30 mA .............................................160 A

CTBC60 when IΔn = 300 mA ...........................................250 A

CTBC60P.........................................................................320 A

CTBC120 when IΔn = 100 mA .........................................330 A

CTBC120P when IΔn = 100 mA .......................................630 A

CTBC210 when IΔn = 300 mA .........................................630 A

CTBC210P when IΔn = 100 mA .......................................630 A

CTBC210P when IΔn = 300 mA .....................................1000 A

Measurement accuracy.......................................................±1 %

Test winding.......................................................................... yes

Rated continuous thermal current Icth ...................................30 A

Rated short-time thermal current Ith............................ 2.4 kA/1 s

Rated dynamic current Idyn .........................................6 kA/40 ms

LINETRAXX® CTBC series

CTBC-series_D00336_02_M_XXEN/09.2020 3