Table of Contents

4TGH1445en/04.2011

4.1 Installing the device ..................................................................................... 16

4.1.1 DIN rail mounting: ......................................................................................... 16

4.1.2 Screw mounting ............................................................................................ 16

4.2 Wiring of the device ..................................................................................... 17

4.3 Commissioning / factory setting ............................................................. 19

5. Operation and setting .................................................................................. 21

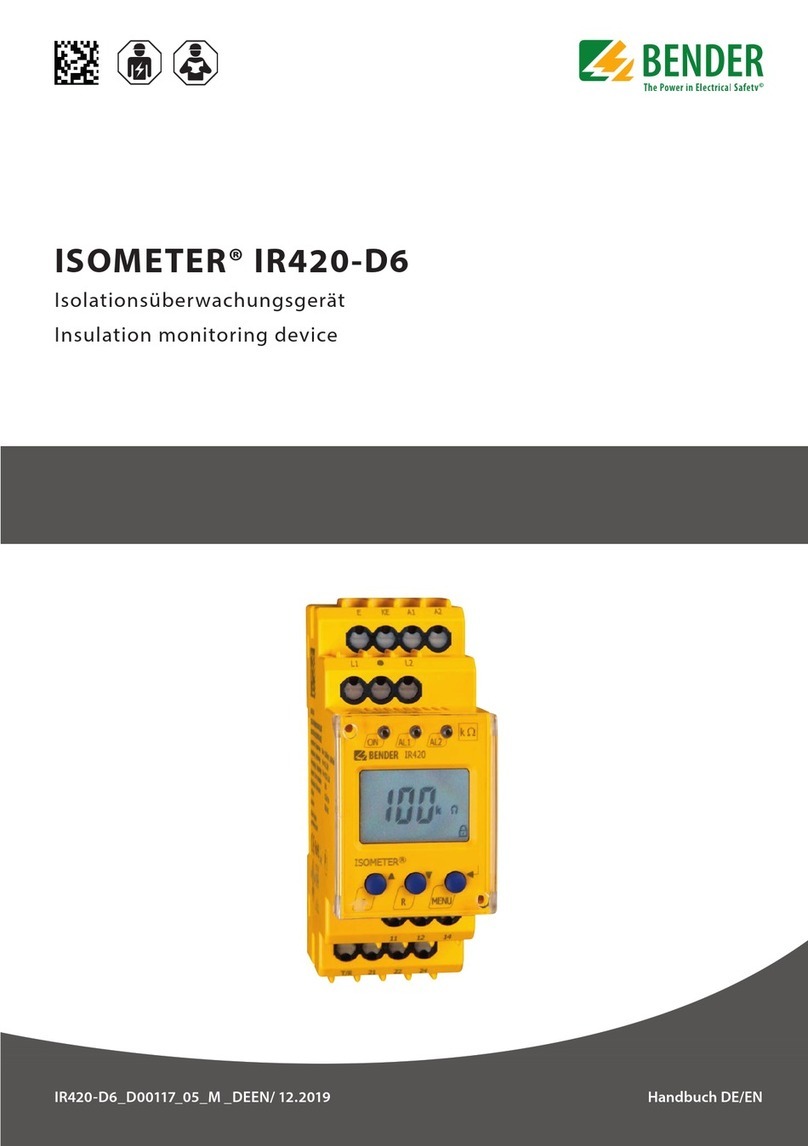

5.1 Getting to know the user interface ......................................................... 21

5.2 Understanding standard display indications ...................................... 23

5.3 Getting to know keys and key functions .............................................. 24

5.4 Querying values ............................................................................................. 25

5.5 Starting the self test manually .................................................................. 27

5.6 Clearing the fault memory ......................................................................... 27

5.7 Calling up or leaving the menu ................................................................ 27

5.8 Carrying out settings in the menu .......................................................... 27

5.8.1 Password protection .................................................................................... 27

5.8.2 Selecting menu items .................................................................................. 29

5.8.3 Carrying out settings in the menu item AL .......................................... 31

5.8.4 Carrying out settings in the menu item out ........................................ 35

5.8.5 Carrying out settings in the menu item t ............................................. 41

5.8.6 Carrying out settings in the menu item SEt ......................................... 42

5.8.7 Querying information in menu item INF .............................................. 44

5.8.8 Querying and clearing fault memory in the menu item HIS ......... 45

6. Technical data ................................................................................................ 47

6.1 Data in tabular form ..................................................................................... 47

6.2 Standards, approvals and certifications ................................................ 50

6.3 Ordering information ................................................................................... 51

6.4 Label for modified versions ....................................................................... 51

INDEX .................................................................................................................... 53