Bender ATICS-2-ISO Series User manual

1

EN

Quick start "Installation and connection"

Automatic transfer switching devices with monitoring functions for unearthed safety power supplies

Software version: D333 V1.2x, D334 V1.2x, D335 V1.0x, D308 V1.2x

This reference guide does not replace the operating manual. You will find the operating manual on the download section of our homepage. Make

sure that the personnel has read this manual and understood all instructions relating to safety.

1. Safety instructions

Danger: Risk of fatal injury from electric shock

Parts of the system are live. During installation and connection:

►Do not touch parts of the system.

►Make sure that the power supply has been disconnected and the

system is dead.

►Switch the ATICS® to manual mode and to switch position "0".

►Lock the changeover device with a padlock to prevent it starting

accidently.

Warning: Risk of destruction if mains voltage incorrect

►The permissible mains voltage is indicated on the nameplate.

Caution: Avoiding incorrect insulation measurements

Only one insulation monitoring device may exist in an IT system to pre-

vent erroneous measurements. ATICS® includes an insulation monitor-

ing device.

►Do not connect additional insulation monitoring devices.

Danger: Risk of fatal injury from electric shock

Connecting wires can come loose and fall out if the ferrules being used

are too short, the wire ends are tinned or the connection screws have

not been tightened enough.

►Consider a stripping length of 20 mm and do not use ferrules

when connecting lines 1, 2 and 3.

►Use a torque wrench to tighten the terminal screws. Check all

the screws on a regular basis to make sure they are seated

tightly.

Warning: Risk of destruction when insulation and voltage

tests are being carried out

►Disconnect the device from the mains for the duration of the

test.

2. Scope of delivery 3. Other system components required

ATICS® transfer switching device

•including connectors, bridge and terminal covers

•Current transformers STW2 and STW3

Documentation

•You can find the ATICS® manual and the manuals of other sys-

tem components under:

http://www.bender.de > Service & support >

Download > Operating manuals

•Quick reference guides and checklist

•IT system transformer with temperature monitoring

•Alarm indicator and test combination MK… or/and alarm indi-

cator and operator panel TM…

•Bypass switch (recommended)

•For screw mounting only: mounting screws M5

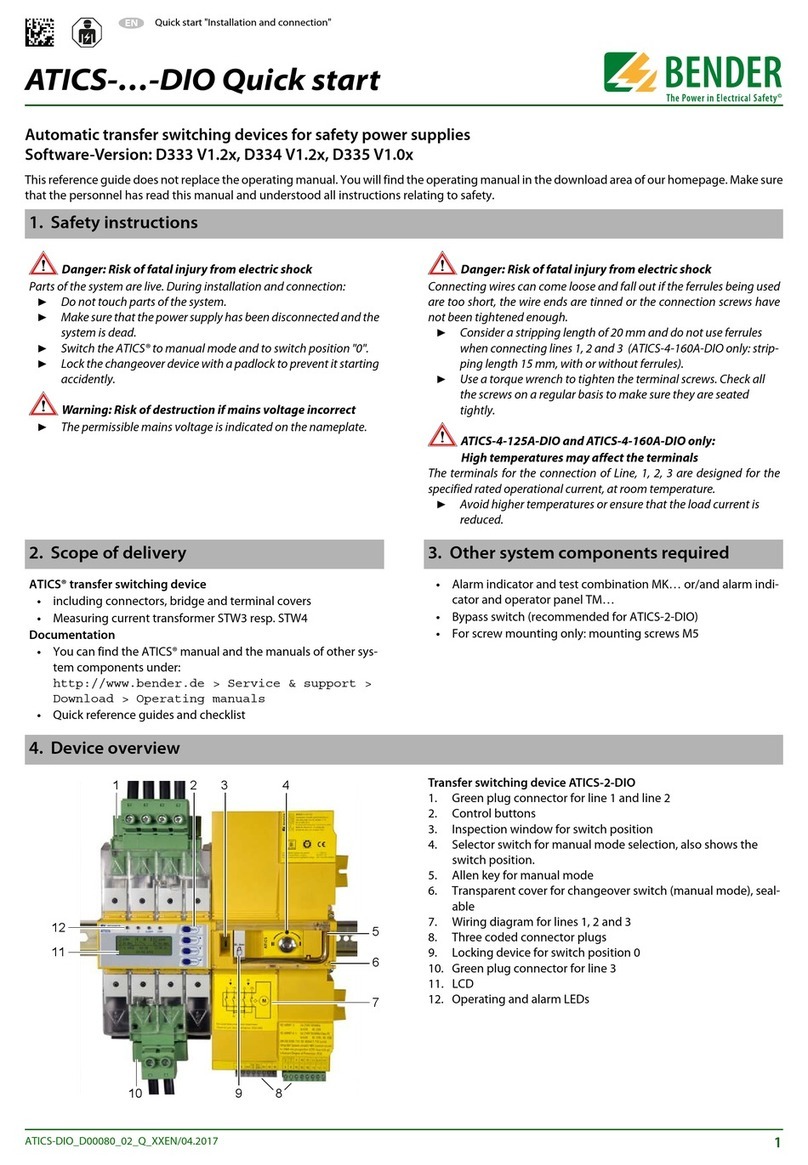

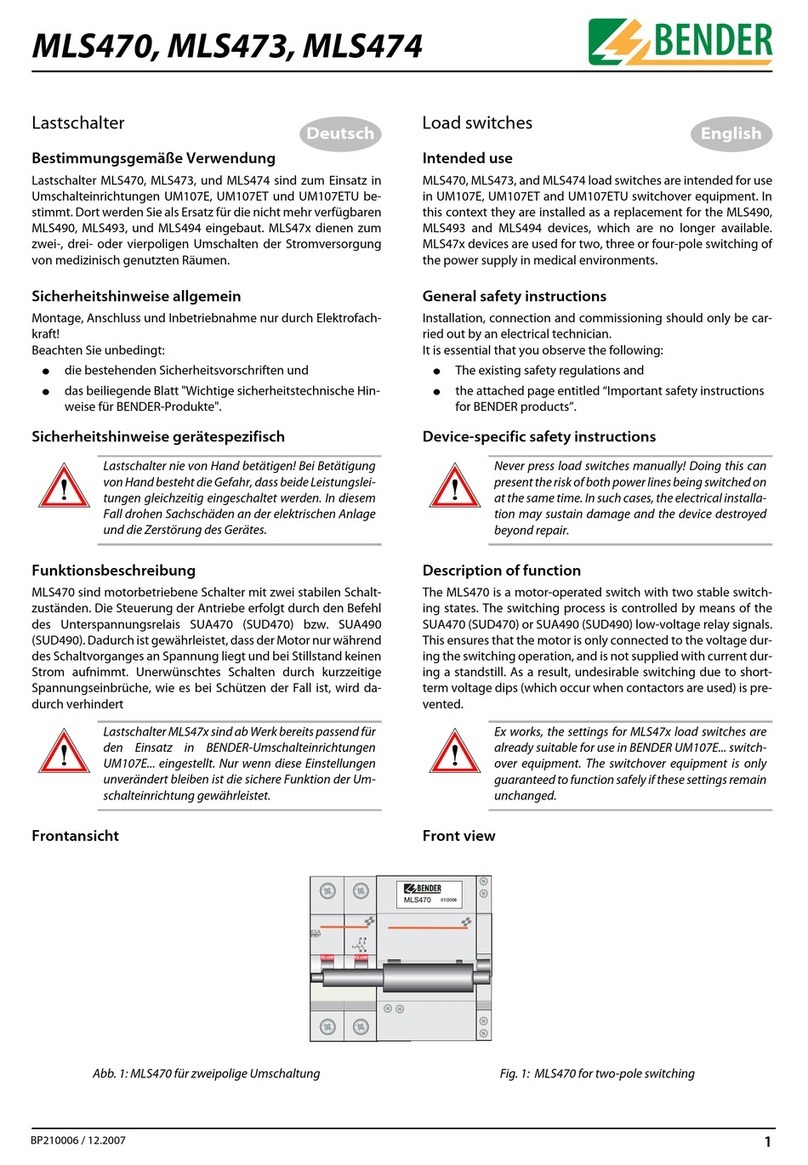

4. Device overview

1. Green plug device for Line 1 and Line 2

2. Control buttons

3. Inspection window for switch position

4. Selector switch for manual mode selection, also shows the

switch position.

5. Allen key for manual mode

6. Transparent cover for changeover switch (manual mode), seal-

able

7. Wiring diagram for lines 1, 2 and 3

8. Three coded connector plugs

9. Locking device for switch position 0

10. Green plug device for Line 3

11. LCD

12. Operating and alarm LEDs

1234

10

7

6

11

5

98

12

ATICS-2…-ISO Quick start

ATICS-2-ISO_D00046_02_Q_XXEN/09.2016

2ATICS-2-ISO_D00046_02_Q_XXEN/09.2016

ATICS-2…-ISO Quick start

5. Dimensions

6. Tools required

►We recommend to use the following tools for connecting the

power section and the control cables:

•Torx® screwdriver T20 or 6.5 x 1.2 mm

•Screwdriver 2.5 x 0.4 mm

•Allen key 4 mm

7. Removing the terminal covers

1. Push back the locking hook (B) in the middle of the top and

bottom terminal (A) cover by using a screwdriver.

2. Remove the terminal cover.

234

176

115,3 14,7

52

220

263

132

132

245

M5

18

46

73,5

52

45

222

47

*

**

***

***

Caution: Risk of destruction by plastering

Liquid plaster may run into the device and the device

may jam.

►Do not seal the device with plaster.

ATICS® is suitable for DIN rail mounting or screw

mounting on plate. To guarantee the protection

against accidental contact, it is to be installed be-

hind a plastic cover.

* Additional space required for the auxiliary con-

tact when using a bypass switch

** Adapt the cutout to the terminal cover

*** Dimensions for screw mounting on mounting

plate

A

B

A

B

3

ATICS-2-ISO_D00046_02_Q_XXEN/09.2016

ATICS-2…-ISO Quick start

8. Mounting the ATICS® on DIN rail

1. Place the ATICS® on the top edge of the rail.

2. Use a screwdriver to pull down the lower yellow slide lock (C)

and snap the ATICS® into place with slight pressure. Check that

the slide lock is properly snapped into position by pulling

slightly the lower part of the enclosure.

3. Secure all terminals including the unused terminals with Allen

screws.

Tightening torque: 5 Nm.

4. Fasten the terminal covers.

Tighten the mounting screws (D) (PZ1, 8.8 lb-in, 1 Nm).

Caution: If the screws are not tightened, ATICS can be damaged

by the vibrations of the switch-over.

9. Mounting the ATICS® on mounting plate

Warning: Screw heads or washers reduce voltage clearance

Provide for sufficient clearance to live conductors (voltage clearance) by using mounting screws with flat screw heads and flat washers. If mounted on

electrically conductive material: the mounting plate has to be earthed and the area under the terminals has to be covered with insulating material. It is

the responsibility of the mounting staff to select the appropriate mounting plate and mounting screws and to keep the prescribed torque setting.

1. Undo the Allen screws of the terminals (C).

2. Remove the green connectors (D) top and bottom

3. Remove the black bridge (E) bottom

4. Fasten the ATICS® to the mounting plate with M5 (22 lb-in, 2.5

Nm) mounting screws (see dimension diagram).

5. Insert the black bridge (E), bottom

6. Plug in the green plug connectors (D) top and bottom

7. Tighten the Allen screws on the terminals (C).All terminals,

including the unused terminals must be fully tightened.

Tightening torque: 5 Nm.

8. Fasten the terminal covers.

10. Fastening, inserting and securing connections

Connect the terminals according to the wiring diagram to the plug

connectors (A, B) and the three connector plugs (C).

•Connect the lines 1, 2 and 3 to the plug connectors (A, B) with

a Torx® screwdriver T20 or a slotted screwdriver 6.5 x 1.2 mm.

Consider a stripping length of 20 mm and do not use ferrules.

Tightening torque: 2.5 Nm (≤ 25 mm²) or 4.5 Nm (≥ 25 mm²).

The connecting wires must be laid so that they are short-cir-

cuit and earth-fault proof!

•Connect the connector plugs (C) with a slotted screwdriver of

2.5 x 0.4 mm. Stripping length: 7 mm. Tightening torque:

0.22…0.25 Nm.

1. Insert bottom green plug connector (B) and secure with

mounting screws. After that, insert top green plug connector

(A) and secure with mounting screws.

2. Insert the other three connector plugs (C).

3. ATICS…400 only: Connect connector plug on the top of the

housing (opposite side of (C)).

C

D

E

D

C

C

AB

4ATICS-2-ISO_D00046_02_Q_XXEN/09.2016

ATICS-2…-ISO Quick start

Alle Rechte vorbehalten. Nachdruck und Vervielfältigung nur mit

Genehmigung des Herausgebers. Änderungen vorbehalten!

©Bender GmbH & Co. KG

All rights reserved. Reprinting and duplicating only with

permission of the publisher. Subject to change!

©Bender GmbH & Co. KG

Fotos: Bender Archiv. Photos: Bender archives.

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Gruenberg • Germany

Londorfer Strasse 65 • 35305 Gruenberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

BENDER Group

11. Connection example basic configuration

Terminal Meaning

1, 3 Connection for Line 1 (input line) L, N

5, 7 Connection for Line 2 (input line) L, N

4, 6 Connection for Line 3 (output line) N, L

l, k Connection measuring current transformer T3 (STW3) for monitoring the load current downstream the transfer switching device

(short-circuit monitoring)

GND, En/Ex Connection must not be used. These terminals are solely intended for future extensions!

IN1/GND, IN1 Digital input, configurable, for example, for monitoring the switch position of the transfer switching device

NC not used

L1/IT, L2/IT Connection to the IT system. Monitoring the insulation resistance. When there are insulation faults: Locating current fed in for

insulation fault location. Bipolar protection via 6 A back-up fuse.

E, KE Connection of E and KE to two separate PE lines.

The terminals labelled GND must not be connected to PE.

Z1, Z2 Temperature monitoring for the IT system transformer

k/IT, l/IT

Connection for measuring current transformer STW2 to monitor the load current downstream of the IT system transformer (overload monitoring)

A, B BMS bus connection

NC not used

14, 12, 11 Alarm relay, programmable function

1

EN

Quick start "Commissioning and operation"

Automatic transfer switching devices with monitoring functions for unearthed safety power supplies

Software version: D333 V1.2x/D334 V1.2x, D335 V1.0x/D308 V1.2x

This reference guide does not replace the operating manual. You will find the operating manual on the download section of our homepage. Make

sure that the personnel has read this manual and understood all instructions relating to safety.

1. Safety instructions

Caution: Missing or false messages on the MK…, TM… or

COM460IP because of out-dated software.

►Replace or update older operating software of MK…, TM…,

FTC… or COM460IP

►Update TMK-SET configuration software.

Note: Configure MK… resp. TM… in a meaningful way.

►In addition to the message, configure a short remark of what

needs to be done and who is to be informed.

The attached checklist includes both the factory defaults and installation-specific settings for the ATICS® transfer switching device. Please carry

out all the work outlined in the list and log each test step.

Keep the checklist with this manual in the vicinity of the device.

2. Enabling manual mode 5. Operating and display elements

3. Configure MK… resp. TM…

MK… resp. TM… must display at least the following faults detected

by the ATICS®:

•Failure Line 1, failure Line 2

•Device error, device failure ATICS®

•Failure of the other MK… or TM…

•Insulation fault, overload, overtemperature

•Optional: EDS channels with circuit and/or room designation

•Device error with complete text or error code

4. Minimum parameter settings

The following minimum default settings have to be carried out:

•BMS bus address (see "Settings menu 9: Interface" in the oper-

ating manual)

•Load current according to the connected IT-System trans-

former (see "Settings menu 4: IT System" in the operating man-

ual)

•Delay times (see chapter "Setting and testing according to the

checklist" in the operating manual)

By default, there is no password set on the ATICS®.

►For operation of the device, it is absolutely essential to enter

and enable a password (see "Settings menu 11: password" in

the operating manual).

►Open the transparent

cover of the automatic

transfer switching device.

The display shows "Man-

ual mode".

1 2 ALARM COM

1 2 543

9

8

7

6

Pos. LED/Button Meaning

1 LC graphical dis-

play

2 LED "1" lights up when Line 1 is ready

3 LED "2" lights up when Line 2 is ready

4 LED "ALARM" lights up when there is an alarm

message

5 LED "COM" flashes during communication via the

BMS bus

6"INFO"

"ESC"

Calls up standard information

Exits the menu function without chang-

ing parameters

7"TEST"

Up button

Calls up test menu

Parameter changes, scrolling

8 Taste "RESET“

Down button

Resets alarm and fault messages,

unlocks switching back interlocking

function

Parameter changes, scrolling

9 "MENU" button

Enter button

Toggles between the standard display,

alarm display and the "MENU"

Confirms parameter changes

ATICS-2…-ISO Quick start

ATICS-2-ISO_D00046_02_Q_XXEN/09.2016

2ATICS-2-ISO_D00046_02_Q_XXEN/09.2016

ATICS-2…-ISO Quick start

6. Enabling automatic mode

►In order to enable automatic mode, close the transparent

cover of the automatic transfer switching device and seal it, if

necessary.

7. Display in error-free operation

There is no alarm message. Standard display:

Alternate displays in the bottom line of the display

The device displays alarm messages in the bottom line of the dis-

play. Also shown there are: switching back interlocking function,

manual mode, countdown timer for return transfer time

8. Display during fault condition

There is an alarm message:

•The yellow LED "Alarm" lights up.

•Information about the message appears on the display in the bottom line.

Example: Line 2 has no voltage

►

Press the "

↵

" button to display the current alarm.

The alarm message consists of:

– Line 1: Alarm

xx = Serial number of the displayed alarm

yy = Number of pending messages

– Use the arrow buttons to select the previous or next mes-

sage.

– Line 2: Alarm status and alarm text

– Line 3: Measured value

– Line 4: Address and channel of device triggering message.

►If no button is pressed for a few seconds, the standard dis-

play reappears.

►Press the Enter button again, then the main menu will

appear.

9. Menu mode: Operation and configuration

►Press the "MENU" button to open the main menu.

– Use the arrow buttons to go up resp. down one menu level.

– Press the "↵" button to confirm the selected menu item.

– Press the "ESC" button to leave the menu.

10. Menu overview

Main menu Meaning Submenu: Meaning/Setting

Exit Exit menu mode

228V

50.0Hz

1 0 2 231V

50.0Hz

160kΩ14:11 35 %

12.10.2010

213

654

Pos. Meaning

1Line 1: Measured values of mains voltage and frequency

2 Switch position of the automatic transfer switching device

3Line 2: Measured values of mains voltage and frequency

4 Display of the load in the IT system in %. The maximum load

current is adjustable.

5 Date and time

6 Measured value of insulation resistance

The device shows the alarm status for each measured value:

No alarm

Alarm

ALARM xx/yy

Undervoltage

0V

Addr.:3 Chan.:2

228V

50.0Hz

1 0 2

0.00V

0.00Hz

160k

Ω

14:11 35 %

Undervoltage

3

ATICS-2-ISO_D00046_02_Q_XXEN/09.2016

ATICS-2…-ISO Quick start

1. Alarm/meas. values

Displays current status messages, alarm messages and measured values

2. Changeover Displays information on the changeover function (number, test)

3. History/Logger Displays logger information 1. History Alarm messages of this device and tests which have been

performed: value and time

2. Data logger Displays the history of measured values: Line 1, Line 2, posi-

tion, load current in the TN system I(3), insulation, trans-

former load

3. Config. Logger Shows the history of the "Settings" menu: value and time

4. Test logger Displays the history of the tests of the changeover switch

carried out

5. Service logger Displays the history of the service activities carried out

4. Settings Various settings for this device 1. Changeover Setting the date and time, system, switching back interlock-

ing function, preferred supply, generator, test and service

interval

2. Voltage Delay times, voltage ranges, hysteresis

3. Current Short-circuit detection

4. IT system Response values insulation, transformer load, temperature,

fault location

5. Relay Mode of operation and relay mode

6. Digital input Mode of operation, function, delay

7. Data logger Modify, overwrite, delete

8. Language Deutsch, English, Francais

9. Interface Setting the BMS bus address of this device.

Allow the settings to be changed via the interface.

Allow a test to be run via interface.

10. Clock Set date format and date and time

11. Password Enable resp. set password for settings and test

12. Service Reserved for settings to be made by authorised Bender

Service personnel.

5. Control Run TEST and RESET for this device 1. TEST

Isometer, changeover, last changeover saved as a test, generator

2. RESET Reset alarm messages, cancel the switching back

interlocking function, change the alarm value for the max.

permissible number of changeover operations performed

and the max. permissible number of operating hours

6. Digital input Display voltage level of the digital input

7. Info Display information on device type and firmware versions

11. Troubleshooting

If a fault occurs,

proceed as follows:

1. Activate manual mode, if necessary.

2. Make a note of what happened prior to the fault: operator

inputs, device error messages, ambient conditions, etc.

3. Keep the device type and device serial number to hand.

4. Speak to Bender Service, describe the type of fault

and quote the three-digit error code.

Fault/message Description Remedy

Failure Line xx

(xx stands for: 1, 2, AV, SV, UPS,

BSV), undervoltage or overvoltage

Voltage is no longer available on Line 1 or Line 2

(Channel 1 = Line 1,

Channel 2 = Line 2)

→Measure voltage on Line xx.

→Check cause.

→Eliminate fault on the system.

→Check the setting for voltage and hysteresis.

Failure line 2 Generator deliveres no voltage within the set time t(GenMax)

Insulation fault IT system has insulation fault →Look for insulation fault.

→Eliminate fault on the system.

Overload Current consumption too high →Check setting for transformer load current.

→Switch off any loads which are not urgently needed.

Overtemperature Temperature on the IT system transformer is too high →

Switch off any loads which are not urgently needed.

CT connection

CT short-circuit

Generator delivers no voltage within the set time. Short circuit or

interruption of the connection cable was detected: Measuring

current transformer STW2 (T4), isolating transformer load, channel 10.

→Check connecting wire of measuring current trans-

former

Main menu Meaning Submenu: Meaning/Setting

4ATICS-2-ISO_D00046_02_Q_XXEN/09.2016

ATICS-2…-ISO Quick start

Alle Rechte vorbehalten. Nachdruck und Vervielfältigung nur mit

Genehmigung des Herausgebers. Änderungen vorbehalten!

©Bender GmbH & Co. KG

All rights reserved. Reprinting and duplicating only with

permission of the publisher. Subject to change!

©Bender GmbH & Co. KG

Fotos: Bender Archiv. Photos: Bender archives.

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Gruenberg • Germany

Londorfer Strasse 65 • 35305 Gruenberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

BENDER Group

Fault/message Description Remedy

Mains power connection Connection to the IT system interrupted or voltage in the system

being monitored below 150 V

→Check connection of ports L1/IT, L2/IT to the IT system.

Check voltage in the IT system.

Earth connection Connection to PE interrupted →Check that the E and KE are connected to the protec-

tive earth conductor by two separate lines on.

Device error + Errorcode For details about actions to be taken refer to table section "Error code/service code“. The message is on channel 6 of the BMS bus.

Short-circuit distribution board

Short-circuit detected →Eliminate short-circuit

Failure distribution board No voltage on Line 3, contact of the changeover switch defective →Replace the ATICS®.

Overcurrent I(3) Short circuit or interruption of the connection cable was detected:

Measuring current transformer STW3 (T3), channel 7

→Eliminate the cause of overcurrent.

→Eliminate any damage.

CT connection

CT short-circuit

Measuring current transformer STW3 (T3), channel 7 →Check connecting wire of measuring current trans-

former

No MASTER There is no device with master function available on the RS-485

interface

→Check BMS bus connection cable.

→Check whether master has failed or whether its ad-

dress has changed. If the device is operated without

BMS bus, the "Failure monitoring" must be switched

off (setting menu 8: interface).

Service: __ (date) Reminder for next service →Agree date with Bender Service

Test: __ (date) Reminder for next test →Plan date for test.

→Carry out test.

Manual mode

Message "Manual mode" although manual mode has not been activated

→Check the connections of the digital input.

Error during the changeover

process

When the test set-ups do not supply enough current for switching

the coils of the ATICS. →Only use test set-ups that provide the necessary peak

current of 17 A.

Error code/Service code Description Remedy

1.xx, 4.xx, 9.xx Fault message from the internal memory monitoring →Contact Bender Service.

3.11 Max. number of hours exceeded →Plan device replacement

3.12 Max. number of changeovers exceeded →Plan device replacement

3.13 Changeover due to overcurrent or shortcircuit detected. These

changeovers reduce the life of the device. Currents which are

measured in excess of 130 A are evaluated as overcurrents or short-

circuit currents.

→Have personnel assess the short-circuit load.

→Contact Bender Service.

3.5 Service has been carried out.

This is not a fault message. Display only on service logger.

→No action required

6.xx, 7.xx, 8.1x

Device error. The internal self monitoring of the device has detected a

fault which could impair the safe operation of the device.

→Replace the device immediately.

8.21 … 8.30

Fault Isometer or transformer monitoring

→Reset, then execute test of the IT system

→Check that the current firmware is installed.

→When no fault is being displayed: OK. Otherwise re-

place the device.

→Check that the bridge on the output side is properly in-

stalled.

8.22

Temperature sensor faulty or earth potential tainted.

→Disconnect the temperature sensor (Z1/Z2). If no error

is displayed: replace temperature sensor or correct its

wiring.

8.51 … 8.52

Fault internal power supply unit.

→RESET -> execute alarm, then test the changeover

function.

→If fault persists: device replacement.

→Only use test set-ups that can supply the necessary

peak current

8.61 … 8.66 Fault during changeover process.

Occurs when the voltage on the new line fails during the

changeover.

Also occurs when the test set-ups do not supply sufficient current for

switching the coils of the ATICS.

→RESET -> execute alarm, then test the changeover

function.

→

If fault persists: replace the device.

→

Only use test set-ups that provide the necessary peak

current of 17 A.

→

In the settings menu 1: Select changeover t(0)≥160 ms.

Other manuals for ATICS-2-ISO Series

1

Table of contents

Other Bender Switch manuals

Bender

Bender ATICS DIO Series User manual

Bender

Bender ATICS-BP-3 Series User manual

Bender

Bender ATICS-2-63A-ISO User manual

Bender

Bender ATICS-2-63A-DIO User manual

Bender

Bender ATICS DIO Series User manual

Bender

Bender ATICS-2-63A-ISO User manual

Bender

Bender ATICS-BP-2 SET Series User manual

Bender

Bender MLS470 User manual

Bender

Bender ATICS-2-63A-DIO User manual

Popular Switch manuals by other brands

HBM

HBM SOMAT XR EX23-R quick start guide

CAMBRIONIX

CAMBRIONIX ThunderSync3-16 user guide

Upsite

Upsite HOTLOK Switchfix SF001-PR3 installation guide

HP

HP Procurve Series 4100GL Management and configuration guide

Siemens

Siemens SCALANCE XB-200 Web based management

D-Link

D-Link DGS-1008G Quick install guide