Bently Nevada 3300/01 Series User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the GE / Bently Nevada 3300/01-01 at our website: Click HERE

3300/01

SYSTEM

MONITOR

OPERATION MANUAL

BENTLY re\

NEVADA

•

PART NO. 80175-01

System Monitor

NOTICE

80175-01

READ THE FOLLOWING BEFORE INSTALLING OR OPERATING EQUIPMENT

Bently Nevada Corporation has attempted to identify areas of risk created by improper installation

and/or operation of this product. These areas of information are noted as WARNING or CAUTION

for your protection and for the safe and effective operation of this equipment. Read all instructions

before installing or operating this product. Pay particular attention to those areas designated by the

following symbols.

WARNING

High Voltage present

Could cause shock, burns

or death.

Do Not touch exposed

wires or terminals.

CAUTION

Machine Protection

Will Be Lost

SYMBOLS

Special symbols are used in the manual to illustrate specifics in the step by step processes. For

example:

FLASHING CONNIECT D I SCONNECT OBSERVE

)

SCREWDPiVE

•

•

System Monitor 80175-01

FORWARD

This document is for control room personnel who operate the 3300 Monitoring System. The

information includes description, disassembly instructions, performance tests, recommended spare

parts, field changeable options, specifications and schematics. The procedures are presented in step-

by-step graphic format.

RELATED DOCUMENTS

3300 System Overview, 80177

3300 System Installation Instructions, 80172

3300 System Troubleshooting, 80173

3300/10 Power Supply, 80174

Dynamic Data Manager System, 46390-01

Transient Data Manager User Guide, 79206-01

Allen Bradley Communications Interface Module 1770-KF2 User's Manual

Modicon Modbus Protocol Reference Guide PI-MBUS-300 REV B

•

•

Keyphasor® is a registered trademark of Bently Nevada Corporation

Proximitor® is a registered trademark of Bently Nevada Corporation

PLC® is a registered trademark of Allen Bradley Company Inc.

Modbusa is a registered trademark of Modicon Inc.

TDC 3000® is a registered trademark of Honeywell Inc.

Document No. 80175 • First Printing: January 1988 • Revision A: November 1989

Copyright© 1989 Bently Nevada Corporation

All Rights reserved

No Part of this publication may be reproduced, transmitted, stored in a retrieval system nor translated into any human or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical, manual, or otherwise,

without the prior written permission of the copyright owner,

Bently Nevada Corporation

P. O . Box 157

Minden, Nevada 89423 USA

Telephone 800-227-5514 702-782-3611

Telemail/Telex 7400983 BNC UC

Fax 702-782-9253

Copyright infringement is a serious matter under

United States of America and Foreign Copyright Laws

III

System Monitor 80175-01

Blank Page

iv

•

•

•

System Monitor

SECTION

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

80175-01

CONTENTS

TITLE PAGE

System Monitor 1

Monitor Functions 3

Disassembly Procedure 5

Front Panel Assembly Removal 6

OK Relay Configuration 7

Communications Processor Interface 8,9

Performance Testing 10

Keyphasor Performance Test 11-16

-VT Jumper Configuration 17

Recommended Spare Parts 18

Specifications 19

Serial Interface Overview 20

Serial Interface Setup 22

Switch Settings 23

Jumper Settings 24

Cabling 25-27

Allen Bradley KF2 25

Allen Bradley KE Modules 26

Honeywell PLCG and DHP-II 27

15. Cable Diagrams 28,29

16. Protocol Specifications 30-49

Allen Bradley Protocol 30-37

Message Types 30,31

Data Addressing 32-35

Data Format 36

Message Response Times 36

Imbedded Responses 36

Exception Responses 37

Modbus Protocol 38-47

Message Types 38,39

Data Addressing 40-43

Data Format 44

Message Response Times 44

Exception Responses 45

Diagnostic Counters 46,47

Scan Rates 48

Modem Controls 49

17. Self Test 50

18. Schematics and Drawings 51

INDEX Index-1

System Monitor 80175-01

Blank Page

vi •

•System Monitor

1I SYSTEM MONITOR

•

•

(5) 3300/0i

",r,TE.MMONITOR

sUPPTILSOK

TRIPMULTIPLY

(1)

tki POINTADJUST 4'

h01

RESET

((5)

K02

33

6

80175-01

gga gg

JO

El .

(6(6

6 1_ 0 0

PR)K M TOR

—-

L_

K2 _

(TOP I CAI. )

'

1.ttLillAbc.,nc5g01Sc5C.,

LK 0

IRE:1A, 4)11 )\.1

c

C)

.1 I NG

RACK

HOST__

DVERr I SSMENT.

POKER I NnuT MOH h

,/,‘H ort-

EL J1 ( l()

(:OMM(JJ\ I I f rj•I'S Pfs)(d ' ()F-'

HEE [14 f FOR 1? I AL ifilisH

Or lEr T I CI

-0

S

--(TT)

-REEL

INH I B

TRIP

MULI PI

CE.HTI

JOC11SL

IN'S>TOLLSU

1

System Monitor

1f SYSTEM MONITOR

80175-01

1•

Two types of Power Input Modules (PIM) can be used with the System Monitor. The PIM shown

below on the left is supplied when the Serial Interface option is specified. It includes the two

additional 25-pin serial connectors. The PIM on the right is the standard input module, Whenever

the PIM is referenced pictorially in this document, the figure shown is the Serial Interface option

PIM. In all these figures, the standard PIM may be substituted for the Serial Interface PIM. All

connections to either PIM are the same, only the style of the connectors have been altered.

r— -i

t.f.,..»

41,....

.;; g i;.-s. 6 ::' 6 :.1 - A IF

1r -Ae..,J.:,i;:licii::; i .!a!ii5LT::,ifi

1.1.--.'--;7 -; ,-,-:,:7,-,:::-7. :::!---,-;5711

(il

Ai

11

1.1[1111C-)17:

_ill.* .1

•

(.1 ) 1(Ai;l•

W1 1',10

ADVERT I SSMEIA

STATIC

V

I; 75 ?'.,(TY

SPARE 101 IA 1;"(V SN

!!!, (,.1 SE'•

()

USECOPPERCONOVEFORSONL1

(

•'

t• —1 -ii

liNli

It+ii...._.__

(li

'sn1.0 !!!

HiV(k Pkiiik In MPVILENG 4:

cD:Pre L Ai 'FMNTAT AVAN; !EPICURE IE 01- petwilif

1!!114 R1 NilSEEP IES 111S;611

Serial Interface option

PIM

SPAPI IL...it,

SPARE

j

DI

EON

IM

COM

r,1. 1_

!!IIN

DDI;111 In$1!1_111V, EIRCUll IS 114 UNL1'.:

REIN I', INiVN ;ii

AVERTISSEMENi RiSOUEDEXPLOSION

NE ercericieeAUEUNCONDU(.ICUR IANI Off tECIRCUITEST SEC

TE-c:55 7,AS PIFIAEEMENEESTDES1GNECOMMENUN CAKERIN

LL

KEY ?I

U

rrei fi

aril?

ERR

(PM Ell

kEY 02 i}i 1I

11:14T.

USECOPPERCONDUCTORSONIY I

LINE !

LINO

NEU;

',NP

110 26VAC 10/15ANR

r)SC-GOHZ

PIS!ONNELI (1;0i. LP.A 10SERVICINGDRREPLACINGFUSES

CO111';R L ILIIEWANONAVAN1 S!EFEEEIEUR DEPANNAGE

F(.(111 /,`.1R ! ;

Standard PIM

2

•

•

e

•

•

System Monitor 80175-01

I2 I MONITOR FUNCTIONS I

SYSTEM POWER-UP INHIBIT

The System Monitor provides a Power-up Inhibit function that allows each monitor to inhibit its

alarms during power-up, or whenever a system supply voltage falls below its operating level. After

power-up, the inhibit function remains active for approximately 2 seconds. The inhibit function can

also be activated by contact closure through terminals on the Power Input Module at the rear of

the rack.

SUPPLY VOLTAGES OK

Seven LEDs located behind the front panel of the System Monitor are ON to indicate when supply

voltages are functioning. The supply voltages are +VRH, +VRL, +7.5V, +5V REF, -7.5V, and -

VT. A green LED on the front panel (SUPPLIES OK), when ON, indicates that all supply voltages

are functional.

SYSTEM RESET

The System Monitor provides System Reset capability that is activated by either external contact

closure through terminals on the Power Input Module, or by pressing the RESET switch on the

front panel.

TRIP MULTIPLY

The System Monitor provides a trip multiply control that is activated by contact closure through

terminals on the Power Input Module. When activated, trip multiply allows the alarm setpoints to

be multiplied by a factor preset on monitors with Trip Multiply options installed. The Trip Multiply

function is indicated by a red LED on the front panel.

STATIC DATA BUS BUFFER

The System Monitor multiplexes signals from the Communications Processor to select static data

from the monitors. Static data signals from the monitor are buffered before being sent to the

Communications Processor. If the Serial Interface option is installed, the position and data select

signals from the Communications Processor are intercepted in the interface. If no Communications

Processor is connected the Serial Interface takes over control of the position select and data

select signals to gather data.

OK RELAY

The System Monitor drives an OK Relay that is located on the Power Input Module. The single-

pole, double-throw (SPDT) relay is used to indicate that the 3300 rack is in an OK condition. The

OK Relay is set normally energized. The OK Relay is deactivated either by the system power-up

inhibit signal (from System Monitor), or by a not OK signal from the monitors.

3

I2 I MONITOR FUNCTIONS

ALARM SETPOINT ADJUST

System Monitor 80175-01

I110

The System Monitor has two switches on the front panel that adjust alarm setpoint levels on each

monitor. One switch is for upscale adjustments and the other is for downscale adjustments.

KEYPHASORS

The System Monitor receives input from two Keyphasor transducers through terminals on the

power input module and buffers the input for use by the monitors. Buffered Keyphasor signals are

also available from the coaxial connectors on the front panel. The System Monitor also provides

short-circuit protected Keyphasor power.

SERIAL INTERFACE OPTION

When installed in the System Monitor, the Serial Interface option provides a communications

interface via defined protocols for the transmission of static data from the 3300 rack. The Serial

Interface option can operate concurrently with a connected Data Manager Communications

Processor.

4

System Monitor 80175-01

W3 I DISASSEMBLY PROCEDURES

•

00y,j, jLAS SIC) CULT_

6,

c: REMOVE =_,IDE COvrR B

PiNCHING PHTHUDINO

ON EACH CAL , cli\NDflP4-

-5 REMOVE SERIAL IMLBPACE

OPJION 8'[ C,ENII PPyWG

OPIION CIRCUIT HOARD AviAy

FROM UNDFRI (F NC CIRCUIT BOARD

AT MATING CONNECTOR AND r,

sTANDCFBS

FOR DETAIL Or FRONT

PANEL ASSEMBLY SEE [41

ILM MONI1oH u111 I ILCM kA(Th

6, (0 (6

AA

6'E,

[

DIPB

J

OTPli

131-1,161-#7

OrP,OTPE,

0

O

a

0

SI Ai....11)0E-f

CC. INECTORS

VIEW A

SYSTEM MONITOR

SIDE

cf,l) /DP

SE=R AL INTERFACE

flPTION

BACIKPI. ANE

5

System Monitor 80175-01

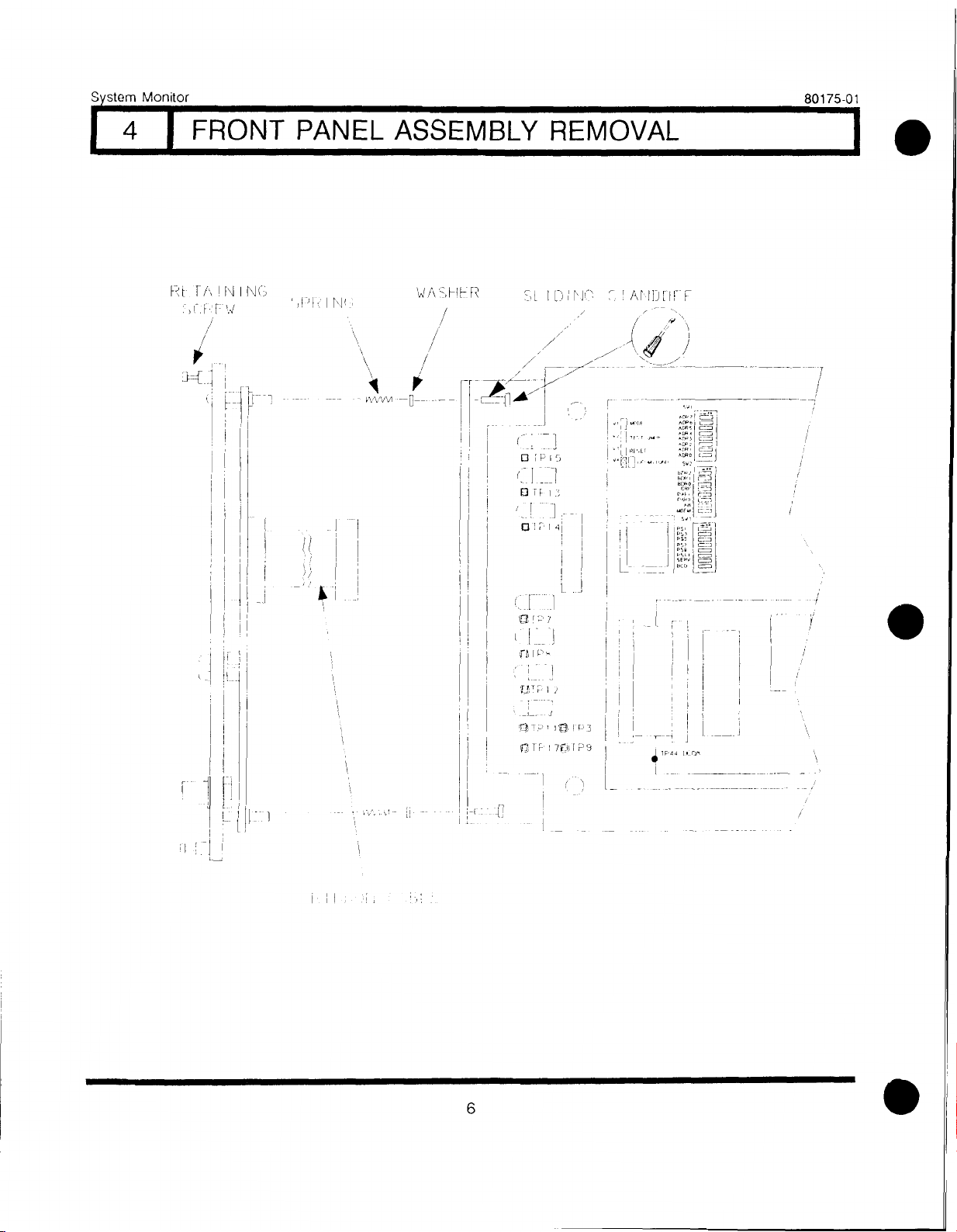

4I FRONT PANEL ASSEMBLY REMOVAL

Rr FA!NINIC3 !Pk I Nti:

I!

IDIGL I Aril-J[1r F

I•

•

frP

53TP ,131-p3

171 TF- I7th1P9

II

6

System Monitor 80175-01

5I OK RELAY CONFIGURATION

THE FOLLOWING DIAGRAM SHOWS THE FUNCTIONAL CONCEPT or THE OK RBLAI

FOR MOPE DETAIL __r FR TO SCHFMATIC ISEE

•

•

MONITOR

OK RELA

DRIVE

MONI1OR

ON RPLAY

DRIVE

MONITOR

N

OK RELAY

DRIVE

PEL A r r.:(DN ,

0- fk I1.1,

.4.YM

NO (2,K,

ARM STATE

NC

OK BUS

INHIBIT

CONTACT

CLOSURE

ROWER UP

INHIBIT

POWER

_J INPUI

MODULE

1No

1(- AkM

ICH

_LI \7 I

uK HFLA

NORMALLY ENERGIZED)

S'ESTEM

MOUITOR

NOTE -A\

RELAY CONTACTS

IN NO! Ce

ci-)HPITION

r,r

7

System Monitor 80175-01

6I COMMUNICATIONS PROCESSOR INTERFACE I

i,0

iit? phi

„ci

4,144420

Communications processor systems used with 3300 systems should all

operate from the same power source. If they do not and if the 3300 system

power goes off, the computer screen will indicate system OK and displayed

meter values will be approximately 7% of full scale.

4JG.' 03 o f hAM C SIGNAL

PoWFP NPU I

MoD.

B

w)

I

!)-(NAM I C DA 79._ m/...:ACE:=--

OMMUN ICAr 101%15

PPOCE F,OR

7pi-IT=IIENT DATA MAV.;'"-JER

ii_:, 1.1 1 'I "

p.1.11.1,...1..:,..p.ir.,,!i,,,rmyirri

i:„.ip,....i,,lidLikiHill ........_....

:M. p LPMPMEP

TO NEXT

RACK i tl

DAISY

CHAIN

CEE13)

1•

KETPHAfy.:•p

8

•

•

•

•

•

System Monitor 80175-01

6I COMMUNICATIONS PROCESSOR INTERFACE I

MONITOR/1

4 A

MONITOR#2 MONITOR#N

*CONNECTIONS TYPICAL ON AL:_ MONITORS

POSITION ENABLE - 4

BUFFERED DATA SELECT

BAPKPLANf

SYSTEM

MONITOR

STATIC DATA OUT

BUFFERED TRANSDUCER CED

BUFFERED TRAN'T,DErhE CR2

BUFFERED STATIC DATA

DATA SEl EAT

mON1 TOf FIFCS

COMMUNICATION'T,

PROCESSOR

▶

9

System Monitor 80175-01

71 PERFORMANCE TESTING

L

!RIP WI !III I

t!!POINT Afl.PiSl'ir

r---1

SYSTEM

MON I Ti)k

-------

ADVEhT 15`All.N

flyNAmiL

1.

("Fa

?1,4 •

•

I.CO (.4.1

TEP

2

Vr JUMPE I H l EM MON I T OF< ALJ1)

POWER SUPPL MU •`) I BE SETT TO F.AW.

VOLTAGE (-i8 VDC OR -24 VDC) OR

SUPPLIES OK LED WILL NOT GO ON.

I. -1.- REFER To POWEP

sur2,pt_ !AL

II () / 2 2 () Vt.(

10

System Monitor 80175-01

•1

•

•

8I KEYPHASOR PERFORMANCE TEST

NOTES: 1 THE FOLLOWING PROCEDURE FOR TESFIN(.; KE-(PHASOR 1 IS TYPICAL

FOR TESTING KEYPHASOR 2

2. MACHINE ASSOCIATED WITH KEYPHASOR UNDER TEST SHOULD BE

RUNNING DURING THIS PROCEDURE. IF MACHINE IS NOT TURNING.

SIMULATE RUNNING MACHINE INPUT FROM FUNCTION GENERATOR OR

TK3 TEST KIT.

MEASURE KEYPHASOR 1 POWER AT POWER INPUT MODULE Ket POWER TERMINAL.

TOLERANCE IS -23.7 ! 0 t; VDC

(-17.85 I 0.45 VDC FOR 3000 PROSIMI1OR,

Igmaalf&vit__

IVOLTAGF HI

/\ TOLERANrI

•••., ! /

,.//

VOL1AGE OU1 -

OF fOLERANCE

MP. tlo To

STEP 5

11

-• -

System Monitor 80175-01

8I KEYPHASOR PERFORMANCE TEST

DICONNECI WIRE: FROM K01 POWER /ND MEASURE VOLTAGE AT

POWER II\PJT MODULE TERMINAL. MCASUPFMENT SHOULD MEET

-HA FRANCE SPE:CH:ILL) IN 1.

_, _.... .

t!gt p iq

l

-,--.e5.:7,c,cc,c41

OK fr

i-CEL4Y ,6 00110 11( .r.)I

vf)LIA6L

OU1 OF

toLERANCE

VOL. 1 ACE

IN TnLERANCE

1110.- 60 TO STEP 4

LOO',FH 1.:H, PULL POWER INPUT MODULE._ Our FkOM

OF- I-/AMINF CABLIM6 AND (.0NNECIION-'=, 7!EiWEEN

MODULI PACL

MlihJllt ID MC,

WARNING

HIGH VOLTAGE LEVELS ARE

PRESENT THAT COULD CAUSE

SERIOUS INJURY.

i'")WL i INPUI MOWLE

CAI3L INO

DEFECTIVE REPAIR/REPLACE I

CABLE OR

CONNECTION

1•

12

•

•

Sstem Monitor

8

80175-01

KEYPHASOR PERFORMANCE TEST

RECONNECT WIRE AT KOI POWER TERMINAL. DISCONNECT WIRE AT -VT

(-18 vDC OR -24 VDC) TERMINAL OF PROXIMITOR AND MEASURE VOLTAGE

AT WIRE_ VOLTAGE SHOULD MEET TOLERANCE LISTED IN STEP I

REPAIR FAULTY

FIELD WIRING

VOLTAGE

OUT OF

TOLERANCE

4

0

VOLTAGE. IN -------------

-\TOLERANCE REPLACE

.1) PROXIMITOR

13

This manual suits for next models

1

Table of contents

Other Bently Nevada Measuring Instrument manuals

Bently Nevada

Bently Nevada 3300/50 User manual

Bently Nevada

Bently Nevada 3300/20 User manual

Bently Nevada

Bently Nevada 3300/15 User manual

Bently Nevada

Bently Nevada Velomitor Sensor User manual

Bently Nevada

Bently Nevada 3300/48 User manual

Bently Nevada

Bently Nevada Ranger Pro 70M300 User manual

Bently Nevada

Bently Nevada 3300/15 User manual

Bently Nevada

Bently Nevada 3300/40 User manual

Bently Nevada

Bently Nevada 3300/70 User manual