Bently Nevada 3300/15 User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the GE / Bently Nevada 3300/15-03-01-00-00-00-00 at our website: Click HERE

3300/15

DUAL VIBRATION

MONITOR

OPERATION MANUAL

DOCUMENT NO. 80176-01

REV DATE

11 28APR89

00

IBENTLY

NEVADA

•

NOTICE

READ THE FOLLOWING BEFORE INSTALLING OR OPERATING EQUIPMENT.

Bently Nevada Corporation has attempted to identify areas of risk created

by improper installation and/or operation of this product. These areas of in—

formation are noted as WARNING or CAUTION for your protection and for the

safe and effective operation of this equipment. Read all instructions before

installing or operating this product. Pay particular attention to those areas

designated by the following symbols.

WARNING

High voltage present

could cause shock

burns or death

Do not touch exposed

wires or terminals

cn,,,Truo

Machine Protection Could

Be Discontinued

IN THIS DOCUMENT PROCEDURES ARE GIVEN ONLY FOR CHANNEL A.

PROCEDURES FOR CHANNEL B ARE SIMILAR EXCEPT FOR THE

OBVIOUS SUBSTITUTION OF CORRESPONDING SWITCHES, TERMINALS,

AND INDICA TORS.

SYMBOLS

Special symbols are used in the manual to illustrate specifics in the step--by--

step process. For example:

PRESS FLASHING OBSERVE SCREWDRIVER

Dual Vibration Monitor Operation 80176-01

•••••••.

FOREWORD

Tins document is for control room personnel who operate the 3300 Monitoring System .The procedures arc

presented in step-by-step graphic format.

RELATED DOCUMENTS

•3300 System Overview, 80171.

.3300 System Installation Instructions, 80172

•3300 System Troubleshooting, 80173

•3300 Power Supply, 80174

•3300 System Monitor, 80175

•3300 Dual Vibration Monitor Maintenance , 80177-01

.Dynamic Data Manager System, 46390-01

Keyphasor® is a registered trademark of Bently Nevada Corporation

IDProximitor® is aregistered trademark of Bently Nevada Corporation

Document No. 80176 • First Printing: Janurary 1988

Copyright © 1987 Bently Nevada Corporation

All Rights Reserved

No part of this publication may be reproduced, transmitted, stored in a retrieval system nor translated into any human

or computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical, manual, or

otherwise, without the prior written permission of the copyright owner,

Bently Nevada Corporation

P. O . Box 157

Minden, Nevada 89423 USA

Telephone : 702-782-3611

Telex: 7400983 BNC UC

Fax: 702-782-9253

Copyright infringement is a serious matter under

United States of America and Foreign Copyright Laws

Iii

80176-01 Dual Vibration Monitor Operation

Blank Page

iv

Dual Vibration Monitor Operation 80176-01

•CONTENTS

TITLE SECTION

DUAL VIBRATION MONITOR SYSTEM 1

MONITOR FUNCTIONS

MONITOR OPTIONS 3

PROGRAMMABLE OPTIONS 4

()K 5

BYPASS

ALERT 7

DANGER 8

MONITOR RANGES 9

READ CHANNEL VIBRATION II)

•READ GAP VOLTAGE 11

READ ALERT SETPOINT LEVELS 12

READ DANGER SETPOINT LEVELS 13

SELF TEST 14

•

80176-01 Dual Vibration Monitor Operation

Blank Page

vi

Dual Vibration Monitor Operation 80176-01

•1DUALVIBRATIONMONITORSYSTEM

3300/15

VIBRATIONMONITOR

OK 0

DANGER 0

ALERT 0B

BYPASS 0

DANGER ALERT

)GAP 6)

BUFFEREDTRANSDUCERS

6666oi

o

80 0 0 0

ICI

0:10

5300 HACK

1

CHANNEL A

RECORDER

OUTPUT

ALER1

RELAY

CONTACTS

PROXIMITOR

0

PROXIMITOR

(7,

um won

IP

II

INAV111.AY MINIS

NO

PC

uoI

IC

O

11571

ret•

n

I•

CHANNEL [3

RECORDER

OUTPUT

„DANCER

RELAY

CONTACTS

SIGNAL INPUT RELAY

MODULE

(PEAR HACK )

CHANNFI A

PROBE

.1-1(

CHANNEL 11

PROBE

VMO

1

80176-01 Dual Vibration Monitor Operation

2MONITORFUNCTIONS

RADIAL VIBRATION - Radial vibration is defined as shaft dynamic motion in a direction perpendicular to the shaft

centerline. The Dual Vibration Monitor displays vibration values for two channels (Channels A. and B).

PROBE GAP VOLTAGE - Probe gap is measured as a negative dc voltage that is directly proportional to the gap

distance between the face of a proximity probe and the surface being monitored. Probe gap voltage for each chan-

nel is displayed on the front panel meter by pressing the GAP switch.

OK - When the Proximitor output voltage is within its upper/lower OK voltage limits, the transducer is defined as

()K. The OK detection circuit controls the channel OK LED and the monitor relay drive to the OK relay.

OK RELAY - The OK Relay is located on the Power Input Module. Every channel in the rack must be OK or

bypassed to energize the OK Relay.

TIMED OK/CHANNEL DEFEAT - Timed OK/Channel Defeat minimizes faulty transducer wiring from causing

false alarms. If the robe input signal level on a given channel is not within upper/lower limits, that channel OK.

LED goes off, the BYPASS LED goes on, the channel is disabled, and the OK Relay dcenergizes. If the channel

input signal level is restored within the upper/lower OK limits for 30 seconds, the channel- OK LED will start

flashing at 1 Hz to indicate the OK state is restored, the BYPASS LED goes off, and monitoring is enabled. The

RESET switch on the front panel of the System Monitor must be pressed to stop the OK LED from flashing (it

remains on). If the channel remains in the NOT OK state, a Channel Bypass switch on the monitor circuit board can

be set to put the channel "out of service". The monitor can then be operated as a single-channel monitor. Without

this feature, the OK Relay could not be reactivated. In the Timed OK/Defeat and Channel Bypass modes, there is

no recorder output and the meter registers zero.

ALARM - Pressing the ALERT or DANGER switch on the front panel of the monitor causes the corresponding

Alert (first-level alarm) or Danger (second-level alarm) alarm setpoints on each channel to be displayed on the front

panel meter. ALERT and DANGER LEDs light when the vibration signal level exceeds preset levels for the

selected time delay, and appropriate Alert and Danger alarm relay contacts are activated. Voting logic options

determine when the Danger alarm relay contacts are activated.

FIRST OUT - Separate First Out circuits exist for Alert and Danger alarms. A monitor with First Out Option

selected flashes a channel alarm LED if that channel was the first channel in the rack to go into alarm. Pressing the

RESET switch acknowledges the First Out condition. This allows the next channel in the rack that goes from non-

alarm-to-alarm condition to indicate First Out by flashing its alarm LED.

ALARM RELAYS - Monitor alarms can be programmed for either latching or nonlatching mode. In the nonlatching

mode, the alarm resets automatically when the alarm no longer exists. In the latching mode, the alarm condition

must be reset manually by pressing the RESET switch on the front panel of the System Monitor (or by closing

external Reset contacts). The alarm will not reset if the alarm condition still exists.

DANGER BYPASS - For maintenance functions, a DANGER BYPASS switch on the monitor circuit board is set to

inhibit the Danger relay drive. This function turns on the BYPASS LEDs. Other front panel functions are not

effected. This function can be disabled using a jumper within the monitor.

BUFFERED OUTPUT - The Channels A and B coaxial cable connectors on the front panel of the monitor and

terminals on the Signal Input Relay Module provide buffered signals from the respective channel transducers.

These connectors can be used for connection of external equipment.

TRIP MULTIPLY - The Trip Multiply function multiplies set points by 2X or 3X in response to an external contact

closure through terminals on the Power Input Module. The front panel meter and recorder outputs could saturate

in this mode.

RECORDER OUTPUTS - Depending on the option selected, the recorder output levels proportional to measured

vibration are either 0 to -10 Vdc, +1 to +5 Vdc, or +4 to +20 mA.

SELF TEST - The monitor has three categories of self test: cyclic, power up, and user invoked.

•Power up self test is performed automatically each time the monitor power is turmed on. A series of basic

tests and transducer OK tests are performed. upon completion of the tests, if no errors, the monitor will

performtimcd OK channel defeat and monitoring will resume in 30 seconds.

• Cyclic self tests is performed automatically during monitor operation. Errors encountered during cyclic tests

disable the monitor, and flash a led bargraph error code. Should the error be intermittent the monitor will

return to operation, but the error codes are stored for retrieval during user-invoked self tests. ;:j)red error

codes are indicated by OK LED's flashing at 5 HZ provided that the channel is OK

• User invoked test performs power up self test and allows error messages stored during cyclic tests to be read

and cleared. stored errors arc annunciated by flashing the OK LEDs at 5 HZ and displaying the error codes

on the front panel LCD bargraph.

2

Dual Vibration Monitor Operation 80176-01

•

•

•

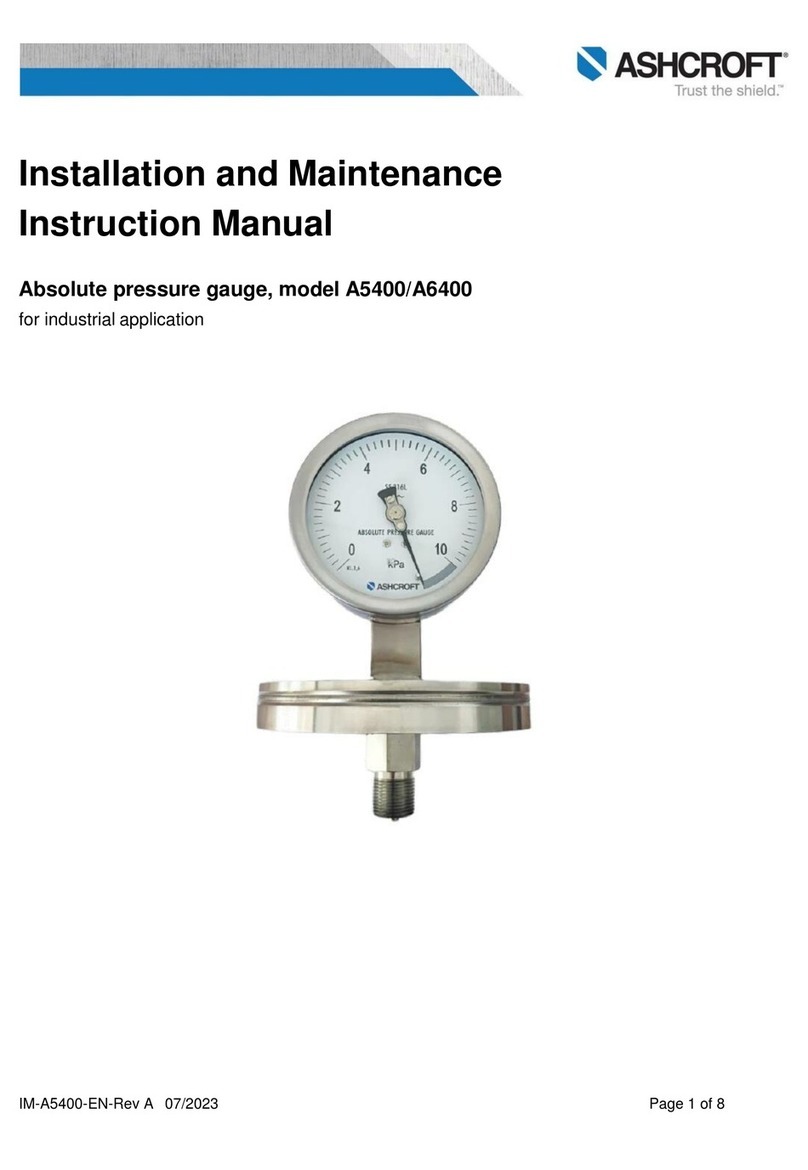

3MONITOROPTIONS

DUAL VIBkATION MONITOR

PART NUMBER FULL SCALE RANGE0

3T00/15 AA

01=0-3 MILS pk--pk

02=0-5 MILS pk-pk

03=0-10 MILS pk-pk

05=0-20 MILS pk-pk

11=0-100 MICROMETRES pk- pk

12=0-150 MICROME1RES pk- pk

13=0-200 MICROMETRES pk pk

14=0-400 MICROMETRES pk-pk

1Az=0-500 MICROMETRES pk - ph

TRANSDUCER INPUT 0 AL ARM RELAY

-BB CC

01=7200 PROVMITOR

200 rriV/MIL

02=3000 PROXIMI TOR

200 mV/MIL (MUST

BE USED WITH POWER

SUPPLY PROGRAMMED

TO -18Vdc)

00-NONE

p1.--5A EPDXY

SEALED

02=5A HERMETI-

CALIY SEALED

03= QUAD RELAYS

EPDXY SEALED

APPROVALS

DD

00=N ONE

01=r, SA

0= BASED: A

03=CI FY OF LA

BARRIERS USED

-FE:

00=NO

DI- YES

IMP MULTIPLY

FL

00 -NONE

01z CX [PIP MULTF-OT"

02 'MP F401.11111'

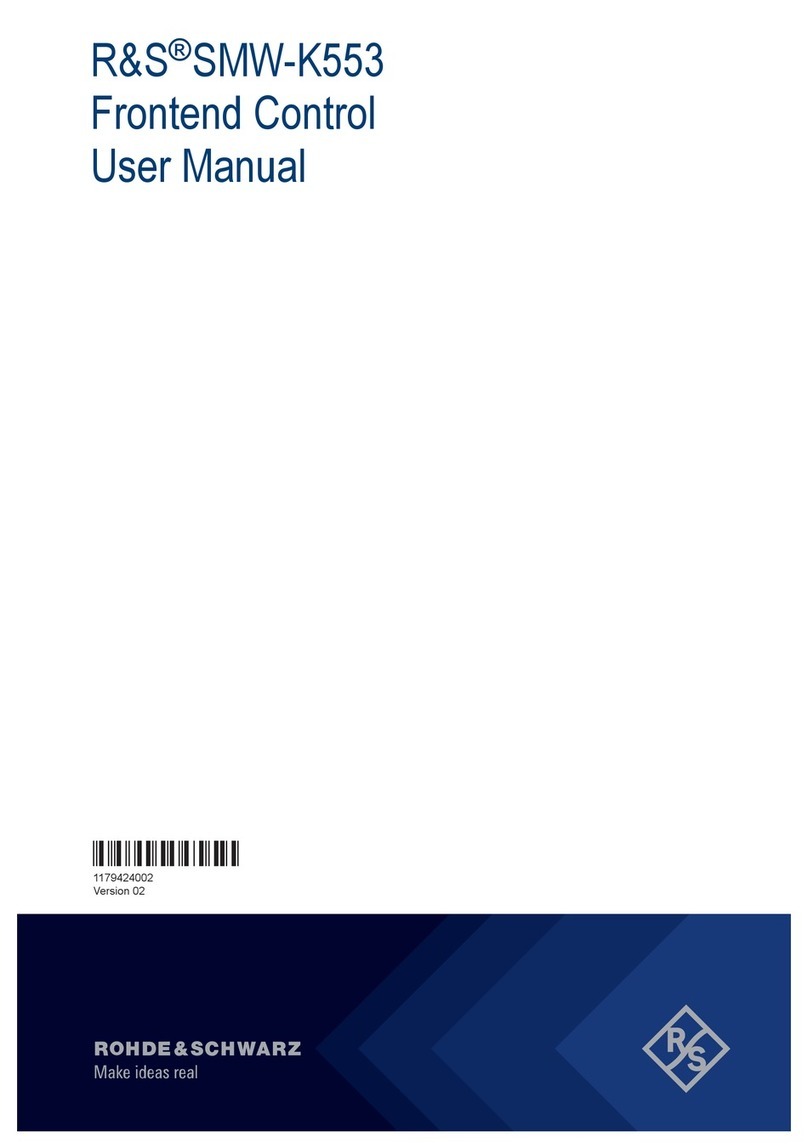

4PROGRAMMABLEOPTIONS

AMMABLE OPTIONS

FIRST OUT ,ENABLED.

eDISABLED

ALARM DELAYS o i `,ECOND

,1 SECOND

o3 SECOND', •

o

1PEG-ENS)

Pr ',E,4451

_.

Al T RT M001

2.15-240,F.F00 RPM.

oa0 ,36,000 PPM

oI AKIIINT. •

III IN LATCHING

SHIPPED WITH OR7101: INSTALLED

DANCER MODE o LATCHING*

oNON-LATCHING

pf.COPDFR OUTPUTS E4 TO I 20 roA.

O1 10 IS `,/d/-

o0 In-10 \01,-

1JANGER. VOTING

DAFFEE LI IT 'WAY,

;WITCH

o 11It VU I iNG I Tilt HF.1 Al(*NI •

oAND VOTING I OP PE ()RIVE

NAI31 I

DIF,AH1 1 •

21, ',NI

3

80176-01

HL[) n'')PLAY

AB

COTiC

NDI OK REL.A.r'

DRIVE*

ny

•• CHANNEL A AND B IN OPERA ONO

RANGE.

RANGE.

,,,) ( ik. • HEsrrrliVE CHANNEL A OR B

•NR 0 IRAWSDIJCLR IN NO1 OK C(iNDITION,

OH HYPA'7-A..D.

Or r i,

Mk:!-!I TOR IN SE- LF 11'7,1, liR B(_' 111

c,.) ) (. 11::A11`..:HHCLR',.; WI- OK OR By - OF I.- -

PAS'..:;ED.4

..-- ELASHING AT 5 Hz ERROR EN-- (fir.,

(*), , 4,

\.-:,4...)/ ' c:omTEPED LURING CYCLIC TEST.

,.\..-: PL AP ERROR ME- .(::::.A.GE. (SEE P 1 I

,...--,-..•:>

t*)))) (k* ii'•:-.:HIN(.; Al 1 Fir — TRAN'DUCER

,..— -*---- —

..,e.,.., IIA'7) BEEN NOT 01K qNCE LAST RE- cm

(4.,#) oK 0 !....i- 1

•OKii457))

Dual Vibration Monitor Operation

5OK

o— =

•OK •

0DAKR 0

AC) ALERT 08

0irms

NOTE, LAO i CHANNEL IN THE ',3r3-11.M CONTROLS THE. OK RELAY. THEREFORE, AN

CHANNEL CAN CAUSE A NO I OK RELAY CONDITION (DENERCIIED RELAY).

11/ds',11,11 I (1\1,1 lif I() RI I. A! ()I. I !)1,11)1110i.r,

4

•

LID D SPAY

AB COND TION

0BynASQ) 0

oMONITOR IN DANGER BYPASS MODE

oSYSTEM IN POWER UP MODE

oUSER INVOKED SEE F TEST IN

PROGRESS

oTIMED OK CHANNEL! DEFEAT

o[30TH CI IANNLL BYPASS

0BYPASS

•BYPASS

0

—

0

oCHANNEL A OR B BYPASSED

oTIMED OK CHANNEL. DEFEAT

oi-BYPASS

.._.)

n)o)

.P__-,:y BYPASS

•BYPASS

:_.,'

*)

•--:,--

•

c( 1j)

t_..)

TRIP MULTIPLY ACTIVA FED. FLASHING

OVERRIDDEN BY:

oCHANNEL BYPASS

oTIMED OK CHANNEL DEFEA I

oDANGER BYPASS

Dual Vibration Monitor Operation 80176-01

6BYPASS

O

O

AO

•

_4

0_.4)

OK 0

DANCER 0

MIRE 011

BYPASS •

5

80176-01

0OK 0

0DANGER 0

A• ALERT 011

0BYPASS 0

LED DISPLAY

AB CONDI.TIO N

ALERT

RELAY DRIVEL

•ALER i. 0 F_ITHER CHANNEL A OR B OR

BOTH) HAS EXCEEDED ALARM

iEVE". (SEE ill)

ON

ON

(,..) ALER1 •

_ —

•ALERT • ON

„---;.:-,--,,,\

(..) III. E. R L rfofi

:-..../

--

_._. _...

..

(2, -----., _ ....„

IC ALE. p1 ( .)

.:-.i

I- 'PST OUT L.ONDI [ION FOP

14:.,P{: 1.11VF A (.)k H cHAN[JH

[HAI HAS EXCEEDI'D ALARM

!L VI-.L. IVO) L.I-1 AN N F_I. (..) MA)

INDICA IL I- IR'. I ( t_i i r Cu OwING

'Ll r II.IS.1 4

ON

ON

Dual Vibration Monitor Operation

7ALERT

_

4FT;P'.1 OUT RESOLUTION IS BETTER -THAN 50 MILLISECONDS. IF TWO ALARMS

OCCUR WI THIN 50 MILLISE_Cnt--.InS OR IT-7,S, THEY COULD CAUSE HOTH LEE'S

Fi ASI I.

S7hi

6

•

LI D DISH_ AY

AB CON D TI ON

DANCER

DpivL

OR VOTING

DE L i% '7

AND VOIINOI,

•DANCER 0

EITHER CHANNEL A OR B (OR

BOTH) HAS EXCEEDED ALARM

LEVEL. (SEE [1.3 )

ON OF

-

OPL,EIGEP 0

•DANCER •

ON

ON

OFT

ON

—.

UDANCER (.9.01

_.,2

FIRST II E CONDI HON EOR

RE SPEC IVE A OR E-3 CHANNEL_

THAT HAS EXCEEDED ALARM

LEVEL. TWO CHANNELS MAX

INDICATE F=IRST ONT FOLLOWINGF.

SETT iLST.40

ON OF

(%---.1 ,- , , (---,

Ic.c0ATicr E '

-Ts-L--7-_-

)N

•

Dual Vibration Monitor Operation 80176-01

8DANGER

0- -0

0OK 0

DANGER

A0 REDO 0B

C) BYPASS (

Ir

iLE ETHER CHANNEL IS BYPASSED, ALARM RELAY IS ACTIVA LED IE NONPTYPA

CHANNEL IS IN ALARM.

*ITIRST OUT RESOLU [ION BL TIER THAN 50 MILL1ST COWS IF TWO ALARMS

OCCUR WITHIN 50 MILLISECONDS OR LE'S,S: OF EACH OTHER THEY COULD

CAUSE BOTH LEE)c; TO LEASH.

•2SE'D1

7

80176-01 Dual Vibration Monitor Operation

9MONITORRANGES

L300/1 E

FULL SCALE CANOE

•3 MILS pk-pk:

(IJE-0 5 MILS pk-pk

0-10 MILS Hz.- pk.

04-0-15 MILS pk-

05-v--0-20 pk.

100 MICROML IRF S pk-pk

12r- 150 MICROML 1-, --pk

0--?00 MICRUME NC pl pk.

14 N - 400 MICROMF IR! Hpl< - pk

EL, 0 000 MICR( )MI

I

3—

S2—

A

A

-

-3

-2

P

-E

-A

-

0— - o - —0

L_

1007 -100

--12 -

P- 7 - P

A40- -40

r-

P= P

r?fi—

r

-LO

ESAMPLES OF METER SC AL

2S9D1

8

•

•

Dual Vibration Monitor Operation 80176-01

10 READCHANNELVIBRATION

MONITOR CONTINUOUSLY INDICATES MEASURED VIBRATION VALUES FOR CHANNELS A AND

VIBRATION

11, 2Siof)

9

80176-01 Dual Vibration Monitor Operation

11 READGAPVOLTAGE

PRESS GAP SWITCH AND READ GAP VOL. LACE FOR BOTH CHANNEL. A AND

cHANNEL B ON ML [I lrINIC; (INTER MEIER`:,CALF..

(,) ALERT 0

BYPASS 0

BANGER AL

GAP 6)

HUETRANSDUCERS

SHAFT

CHANNEL A SHAFI

CHANNLL R

3S1 I DI

10

Dual Vibration Monitor Operation 80176-01

•

•

•

12 READALERTSETPOINTLEVELS

CHESSALERT SWITCH AND READ ALERT SETPOINTS (FOR BOTH CHANNEL

P) ON METER SCALE.

0BYPASS 0

MdR

U

ALERT

A

BUFFEREDTRANSDUCERS

0

—

s2—

P—

—

A_

111—

—- 25

-P

—A

—K

P

A

13 READDANGERSETPOINTLEVELS

ENESSDANGER SWITCH AND READ DANGER SEA-POINTS (FOR BOTH CHANNEL

ANL E3) ON METER SCALE.

3' .11,D I

11

80176-01 Dual Vibration Monitor Operation

14 SELFTEST

THE MONITOR HAS THREE LEVELS OF SELF TESTS:

o POWER UP TEST: PERFORMED ONLY WHEN MONO OR IS TURNED ON.

oCYCLIC TEST: PERFORMED CONTINUOUSLY.

oUSER INVOKED -11.S1: PERFORMED ONLY WHEN INITIA TED E3Y USER.

03300/15

VIBRATIONMONITOR

37 -3

..-

-Nef as—

.zoc.

•OK n

ODANGER 0

A0 ALERT GB

•BYPASS 0

(7»--

AB

PUFFEPLDTRANSDUCERS

0

IF ERRORS ARE DETECTED DURING CYCLIC SELF

TESTS:

o MONITORING IS ADOPTED UNTIL THE ERROR

IS RESOLVED.

o ERROR CODE STORED IN MEMORY AND

FLASHED ON LCD BARGRAPH DISPLAY.

oBYPASS LED GOES ON ANDOK LED FLASHE.`.3

AT 5 HZ.

oIF ERROR IS INTERMITTENT AND DISAP—

PEARS. MONITORING IS RESUMED AND OK

LED FL ASHES AT 5 HZ.

o ERROR CODE STORED, USER INVOKED

ntsr,LA..., AND I....L_FARc) F PROP.

IF ERROR5:, ARE DETECTED DURING POWER UP

OR USER INVOKED LEST:

oMONITORING IS ABORTED UNTIL USER—ACTION

RESOLVES PROBLEM.

TEST CAN Pr. RERUN WITH MONITOR POWER

UP OR USER INVOKED TEST.

35143)1

12

•

•

•

Dual Vibration Monitor Operation 80-176-01

14 SELFTESTECONT]

,INIT IATE USER INVOKED TEST BY SHORTING ACROSS TWO S l F.-- TES 1. (S fl PINS.

/r2k_11`1 1©

MACHINE PROTECTION WILL E3F.

LOST FOR DURATION OF TEST

oAT COMPLETION OF USER INVOKED TEST MONITOR WILL RECAt L STORED FRROR

CODES, IF ANY. THESE ERROR CODES MUST BE READ AND CLEARED WITH USER

INTERACTION TO ALLOW MONITORING TO CONTINUE. TIMED nv CHANNEL DEEE-A

SAC TIVE FOR APPROXIMATE l.. Y 30 SECOND`:. FOIL °M r: IFII S Ac 1 ION.

(N) 0 5300/15

MONI1OR

(")

C) DAVtP

A(i) Alf41

RYPASS

eiii!F°F0IRMISDIJCEPS

O

;B

NOTE

ALTHOUGH BOTH COLUMNS ON

BARGRAPH FLASH, ERROR CODE

IS ONLY THE SUM OF BARGRAPH

SEGMEN-IS DISPLAYED IN ONE

COLUMN. EXAMPLE SHOWS ERROR

CODE 6.

oREAD CODE S ON LIST; S 1E5" IHROUC,E1 EACH I

CODE ON 11ST BY PRESSING AND HOLDINGALERT

SWITCH f OR APPROXIMATELY 1 SLCUND.

oAT THE END OF LIST, LCD BARGRAPH DISPLAYS L

SEGMENTS. TO REREAD LIST PRESSALERT SWLI TO

CLEAR LIST FROM MEMORY, PRESS AND HOLDDANGER

SWITCH FOR APPROXIMATELY 1 SECOND.

.1f

13

Other manuals for 3300/15

1

This manual suits for next models

8

Table of contents

Other Bently Nevada Measuring Instrument manuals

Bently Nevada

Bently Nevada Ranger Pro 70M300 User manual

Bently Nevada

Bently Nevada 3300/20 User manual

Bently Nevada

Bently Nevada Velomitor Sensor User manual

Bently Nevada

Bently Nevada 3300/48 User manual

Bently Nevada

Bently Nevada 3300/01 Series User manual

Bently Nevada

Bently Nevada 3300/70 User manual

Bently Nevada

Bently Nevada 3300/50 User manual

Bently Nevada

Bently Nevada 3300/40 User manual

Bently Nevada

Bently Nevada 3300/15 User manual