4

EXCLUSIVE

b Under the safety valve, install a water collecting funnel with the

corresponding discharge in the event of leaks due to the overpressure

of the heating system. The domestic hot water circuit does not need a

safety valve, but make sure that the pressure of waterworks does not

exceed 6 bar. In case of doubts, install a pressure reducer.

b Prior to ignition, make sure that the boiler is designed to operate

with the gas available; this can be checked by the wording on the

packaging and by the adhesive label indicating the gas type.

b It is very important to highlight that in some cases the ues are under

pressure, so the joints of the various elements must be airtight.

3.2 Installation regulations

The installation must be carried out by qualied personnel, in compliance

with the following reference standards:

- UNI 7129-7131

- CEI 64-8.

Always comply with local standards of the Fire Department, the Gas

Company and with possible municipal dispositions.

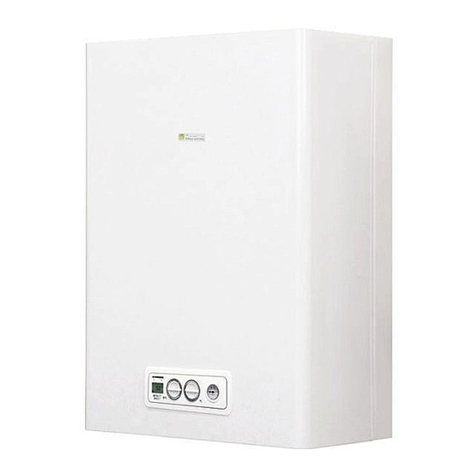

POSITION

EXCLUSIVE is a wall-hung boiler for heating and for the production of hot

water. There are two categories, depending on the type of installation:

- B23P-B53P boiler type - forced open installation, with ue gas discharge

pipe and pick-up of combustion air from the installation area. If the

boiler is not installed outdoors, the air intake in the installation area is

compulsory;

- C13,C13x; C33,C33x; C43,C43x; C53,C53x; C63,C63x; C83,C83x,

C93,C93x type boiler: appliance with airtight chamber, with ue gas

discharge pipe and pick-up of combustion air from outside.

It does not require an air intake point in the installation area.

This type MUST be installed using concentric pipes, or other types of

discharge designed for condensing boilers with an airtight chamber.

MINIMUM DISTANCES (g. 6-6a)

To ensure access to the boiler for normal maintenance operations, respect

the minimum installation clearances envisaged.

For correct appliance positioning, bear in mind that:

- it must not be placed above a cooker or other cooking device

- it is forbidden to leave inammable products in the room where the boiler

is installed

- heat-sensitive walls (e.g. wooden walls) must be protected with proper

insulation.

b In case of installation it is ESSENTIAL to provide the necessary

space for the introduction of the instrument for the combustion

analysis check. In g. 6a is shown a sample drawing where the

distances between boiler and cabinet/niche were obtained using a

300mm length tool.

Longer lengths of tools require more space.

3.3 Elimination of air from the heating circuit and

from the boiler - g. 7

During the initial installation phase, or in the event of extraordinary

maintenance, you are advised to perform the following sequence of

operations:

1. Open by two or three turns the automatic relief valve cap (A) and leave

it open.

2. Open the system lling tap located on the water unit.

3. Switch on the electricity supply to the boiler, leaving the gas tap turned

off.

4. Activate a heat request via the room thermostat or the remote control

panel, so that the 3-way valve goes into heating mode.

5. Activate a request for DHW as follows: open a tap for 30” per minute so

that the three-way valve cycles from heating to DHW and vice versa for

about ten times (in this situation, the boiler will go into alarm due to lack

of gas, therefore reset it whenever this is proposed).

6. Continue the sequence until no more air is felt coming from the air vent

valve.

7. Check the system pressure level is correct (the ideal level is 1 bar).

8. Turn off the system lling tap.

9. Turn on the gas tap and ignite the boiler.

3.4 Positioning the wall-mounted boiler and hydraulic

connections - g. 8-9

The boiler comes as standard with a boiler support plate. The position and

dimension of hydraulic ttings are shown in the detail drawing.

For the assembly, proceed as follows:

- fasten the boiler support plate (F) to the wall and use a spirit level to

make sure it is perfectly horizontal

- mark the 4 holes (ø 6 mm) envisaged for securing the boiler support

plate (F)

- make sure that all measurements are exact, then drill the wall using drill

tips with the diameters indicated above

- x the plate with the built-in template to the wall

- carry out the hydraulic connections.

3.5 Electrical wiring - g. 10-11

Low voltage connections

Carry out the low voltage connections as follows:

- use the external cable box supplied as standard

- unscrew the xing screws of the cover (V)

- carry out the connections as shown in g. 11

b It is recommended to use wires with section not exceeding

0,5mm2.

b In case of TA or TBT connection, remove the respective shunts

(g. 12).

- close the box with the screws that were previously removed

- press the two tabs on the sides of the box to place it correctly in its

housing in the boiler sliding upward within the guide rails

- tighten the safety screw (V1).

b If the low voltage electrical connection box is not connected the

boiler does not ignite.

High voltage connections

The connection to the mains supply must be made via a separation device

with an omnipolar opening of at least 3.5 mm (EN 60335/1 - category 3).

The appliance works with alternating current at 230 Volt/50 Hz, and is in

compliance with Standard EN 60335-1.

It is obligatory to make the connection with a safe ground/earth, in

compliance with current directives.

b It is the responsibility of the installer to provide suitable grounding

for the appliance; the manufacturer will not be liable for any damage

resulting from an incorrect or absent earth connection.

b It is also recommended to uphold the phase-neutral connection (L-N).

b The earth conductor must be a couple of cm longer than the others.

The boiler can operate with a phase-neutral or phase-phase supply.

For power supplies that are not earthed, it is necessary to use an isolating

transformer with earth-anchored secondary.

It is forbidden to use gas and/or water pipes to earth electrical appliances.

Use the power cable supplied to connect the boiler to the mains power

supply.

If the power cable has to be replaced, use a HAR H05V2V2-F cable, 3 x

0.75mm2, Ø max external 7 mm.

3.6 Gas connection

The connection of the gas supply must be carried out in compliance with

current installation standards.

Before carrying out the connection, check that the type of gas is that for

which the appliance is set up.

3.7 Removing the casing

To access the components inside, remove the casing as indicated below:

- locate and unscrew the 2 screws (A - g. 13) that x the casing to the

boiler

- by leveraging the xing clips (C - g. 13), unhook the lower part of the

casing

- lift the casing upwards to release it from the top tabs (B - g. 13), then

remove it.

WARNING

b The possible damage of the frontal panel involves the replacement

of the same.

b The noise absorbing panels inside the front and side walls ensure

the airtight seal for the air supply duct in the installation environment.

b It is therefore ESSENTIAL after the dismantling operations to

correctly reposition the components so as not to compromise the

boiler’s operation.

3.8 Flue gas exhaust and combustion air suction

To evacuate the combustion products, refer to UNI 7129-7131. Always

comply with local standards of the Fire Department, the Gas Company and

with possible municipal dispositions.

The release of combustion products is assured by a centrifugal fan and the

control board constantly checks that it is operating correctly. It is essential

for evacuating fumes and adduction boiler combustion air that only original

pipes are used and that the connection is made correctly as shown in the

instructions provided with the ue gas accessories.

A single ue can be connected to several appliances provided that every

appliance is the condensing type.