ENGLISH

UM - CODE N4 N5 N6 N10 - REV 0.3

5

Contents

1. Premise

1.1. Purpose of the manual ................................................................................................................................................................................................ 6

1.2. Keeping the manual ................................................................................................................................................................................................... 6

1.3. Use of the machine .................................................................................................................................................................................................... 6

2. General information

2.1. Machine limits, safety regulations ................................................................................................................................................................................ 7

2.2. Guarantee and maker’s responsibility .......................................................................................................................................................................... 7

2.3. The user’s obligations ................................................................................................................................................................................................. 8

2.4. Marking-plates ........................................................................................................................................................................................................... 8

3. Technical characteristics

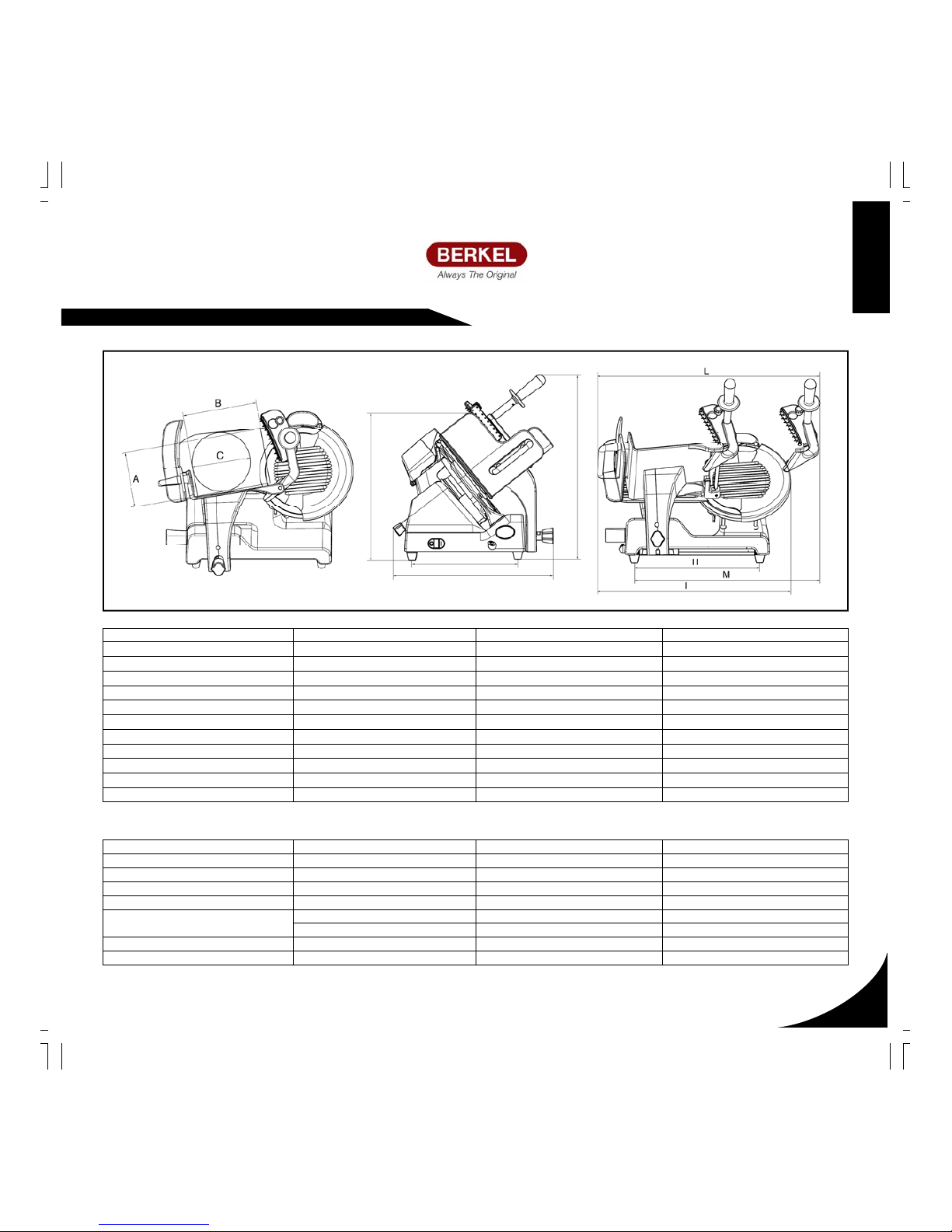

3.1. Dimensions, BSPG series ........................................................................................................................................................................................... 9

3.2. Specifications, BSPG series ....................................................................................................................................................................................... 9

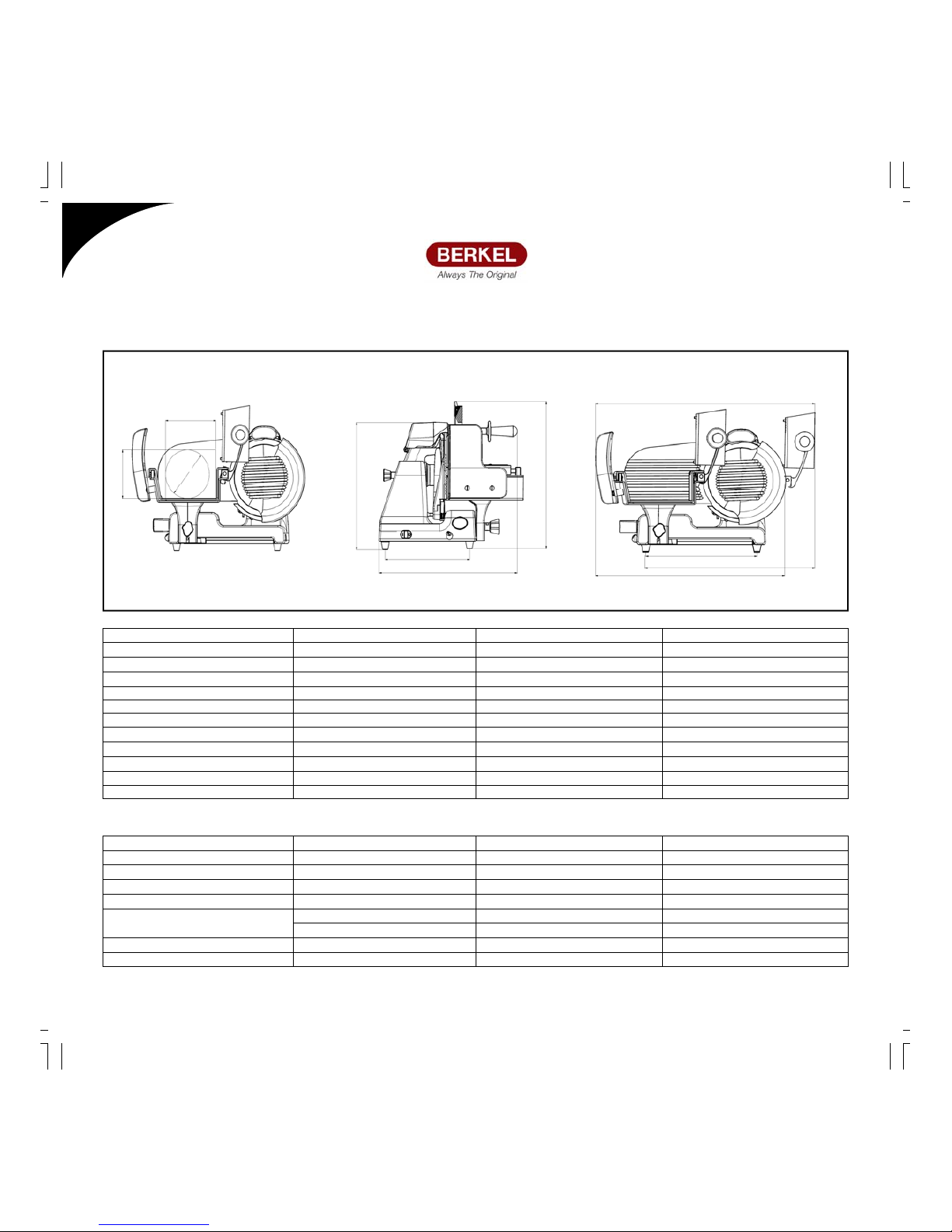

3.3. Dimensions, BSPM series ......................................................................................................................................................................................... 10

3.4. Specifications, BSPM series ..................................................................................................................................................................................... 10

3.5. Dimensions, BSPS series ......................................................................................................................................................................................... 11

3.6. Specifications, BSPS series ...................................................................................................................................................................................... 11

3.7. Dimensions, BSPT series........................................................................................................................................................................................... 12

3.8. Specifications, BSPT series ....................................................................................................................................................................................... 12

3.9. Furnished items and accessories .............................................................................................................................................................................. 13

3.10. Products that can be sliced .................................................................................................................................................................................... 13

3.11. Products that cannot be sliced ................................................................................................................................................................................ 13

4. Description

4.1. Unpacking ............................................................................................................................................................................................................... 13

4.2. Main components .................................................................................................................................................................................................... 15

4.3. General description .................................................................................................................................................................................................. 19

5. Installation

5.1. Installing the machine ............................................................................................................................................................................................... 20

5.2. Command description .............................................................................................................................................................................................. 20

5.3. Electrical connection ................................................................................................................................................................................................. 20

5.4. Checking direction of rotation of the blade (only for machines with three-phase motors) ............................................................................................... 20

6. Using the machine

6.1. Loading the goods on the plate and cutting ............................................................................................................................................................... 21

6.2. Cleaning the slicing machine ..................................................................................................................................................................................... 26

7. Maintenance and repairs

7.1. General information .................................................................................................................................................................................................. 31

7.2. Sharpening the blade ............................................................................................................................................................................................... 31

7.3. Lubricating the guide bars of the carriage with arm and food plate support .................................................................................................................. 33

7.4. Lubricating the transversal guide rod/s of the plate and food press ............................................................................................................................. 33

8. Locating and eliminating failures .................................................................................................................................................................................... 34

9 . Electrical diagram .......................................................................................................................................................................................................... 35

10. Dismantling the slicing machine .................................................................................................................................................................................... 37