1. INTRODUCTION

1.1.Purpose of the manual

................................

................................

................................

2. GENERAL INFORMATION

2.1.

Machine limits, general safety regulations

2.2.Guarantee and manufacturer’s responsibility

2.3.User’s obligations

................................

................................

2.4.Plates

................................

................................

3. TECHNICAL CHARACTERISTICS

3.1.Overall size

................................

................................

................................

3.3.Products that can be sliced

................................

3.4.Products that cannot be sliced

................................

4. DESCRIPTION

4.1.Unpacking

................................

................................

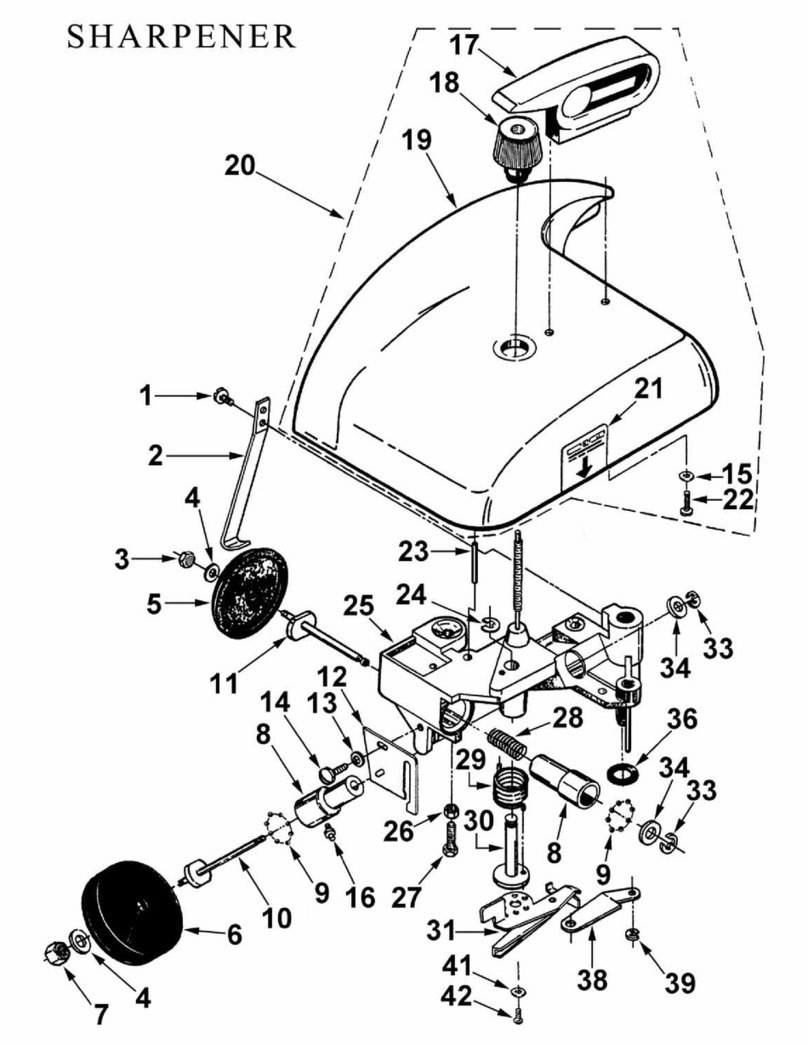

4.2.Main components

................................

................................

................................

5. INSTALLATION

5.1.Installing the machine

................................

................................

6. USING THE SLICING MACHINE

6.1.Loading the goods

................................

6.2.Cutting the goods

................................

................................

6.3.Cleaning the slicing machine

................................

7. MAINTENANCE AND REPAIRS

7.1.General information

................................

................................

7.3.Lubricating the guide bars and overplay

................................

8. DISMANTLING THE SLICING MACHINE

The manual is made progressively numbered pages.

The contents are divided into progressively numbered paragraphs, if in any doubt about the contents and for any

further explanation contact the manufacturer or the authorised technical assistance, stating the paragraph

number of the pertinent subject.

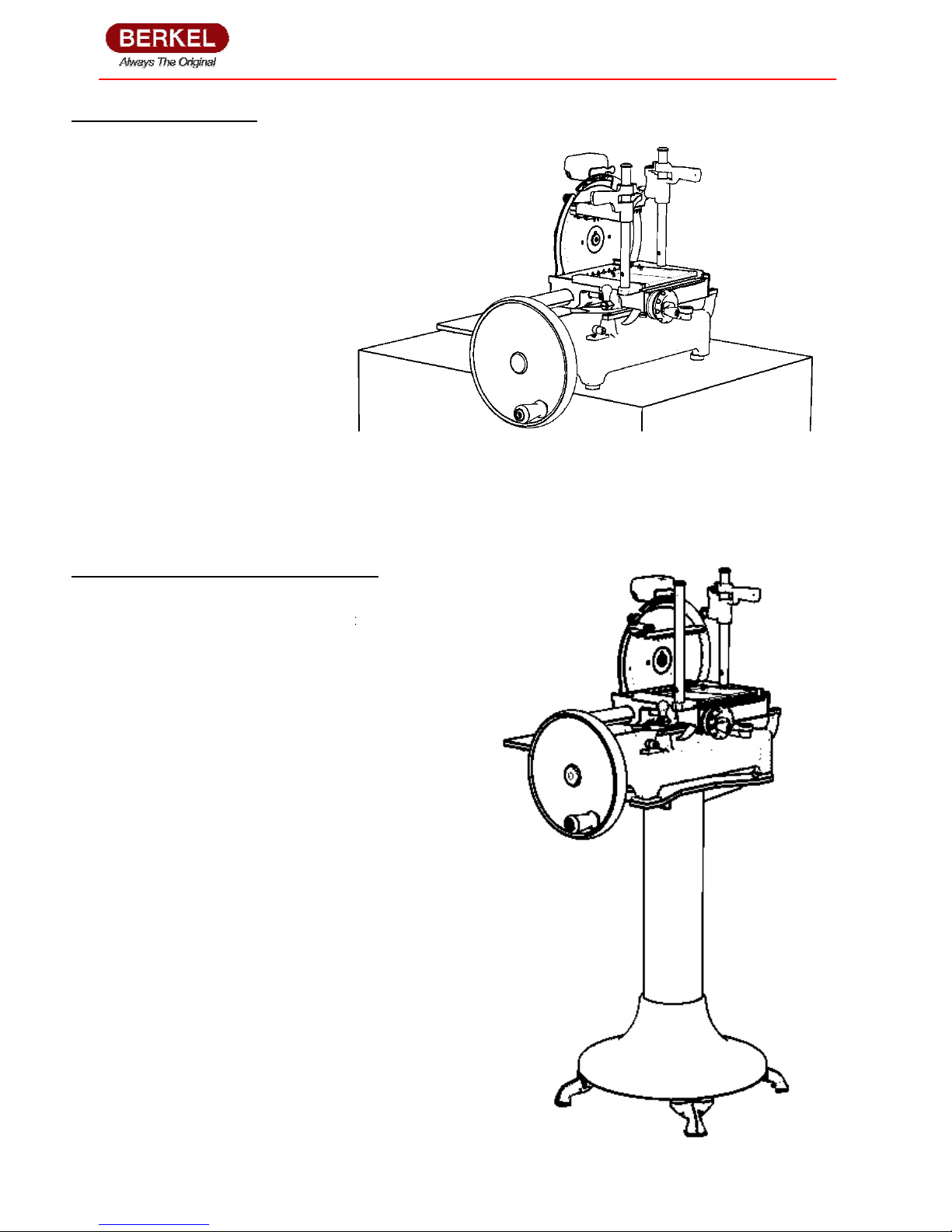

P15 Series

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

Machine limits, general safety regulations

................................................................

................................

2.2.Guarantee and manufacturer’s responsibility

................................................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................

................................

................................

................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................

................................

8. DISMANTLING THE SLICING MACHINE

................................................................

................................

The manual is made progressively numbered pages.

The contents are divided into progressively numbered paragraphs, if in any doubt about the contents and for any

further explanation contact the manufacturer or the authorised technical assistance, stating the paragraph

................................

................................

................................

................................

................................

................................

................................

............................

6

................................

................................

................................

............................

8

................................

.......................

8

................................

................................

................................

................................

................................

................................

................................

................................

........................

15

................................

................................

................................

................................

The contents are divided into progressively numbered paragraphs, if in any doubt about the contents and for any

further explanation contact the manufacturer or the authorised technical assistance, stating the paragraph

07 UM – CodeF2 - Rev. 0.1