8 • 909A & 919A OWNER/OPERATOR MANUAL

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456789012

1

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456789012

4. USDA authorized Berkel oil is available in 2-oz (P/N 4675-00182), 16-oz (P/N 4675-00183) and

one-gallon (P/N 4675-00184) containers.

5. To store the pusher at the top of the product table, simply pull the product pusher to the top of the

table and allow the nylon button to fall behind the catch plate at the top of the product table.

TESTING PRIOR TO OPERATION

WARNING

SHARPKNIFE

TOAVOIDSERIOUSPERSONALINJURY:

1. NEVER touch rotating knife.

2. Keep HANDS CLEAR of all MOVING PARTS. Use PRODUCT TABLE HANDLE—

not your hand.

3. Always TURN OFF slicer when NOT IN USE.

4. Always TURN thickness control knob as far to the right as possible when NOT IN USE.

5. TURN OFF and UNPLUG machine before CLEANING or SERVICING.

GENERAL

1. Make sure the machine is unplugged.

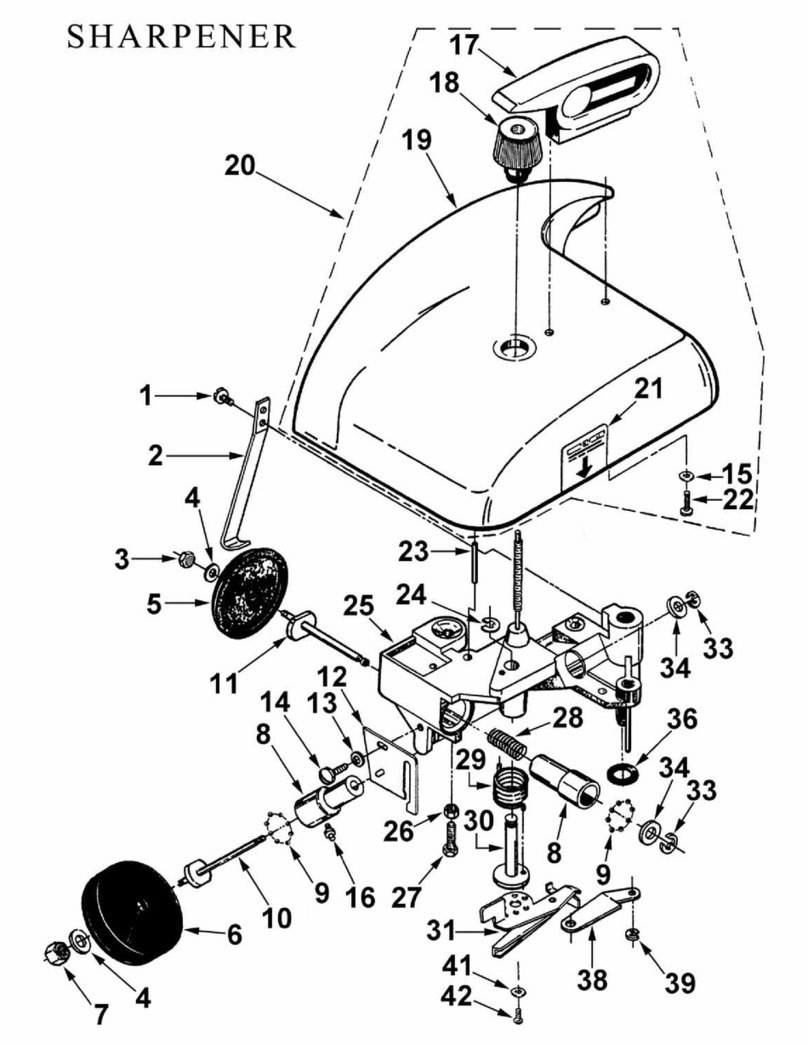

2. Check to see that the center plate, product table and sharpener assembly are in proper position.

3. Turnthicknesscontrolknobasfartotheright aspossible.Thispositionsthegaugeplate so that the

knife is not exposed during testing.

4. Plug the power cord into a GROUNDED, APPROVED electrical outlet, using the plug that is

provided with the machine. The pilot light should be solid and constant. If it is blinking, then one

of the following conditions applies:

One blink - The center plate is not installed properly.

Twoblinks - The meat table is not installed properly.

Threeblinks - If the slicer has a lift, then the lift is not completely down.

Fourblinks - The motor overload sensor has been tripped.

Ifyoucannotsatisfytheconditioncausingtheblinkinglight,thencallyounearestDesignatedBerkel

Service Location.