Berthoud VANTAGE E.C.TRONIC 28-30 User manual

VANTAGE

E.C.TRONIC regulation

82.527-A ENGLISH

Machine intended for the treatment of

cereal and market-garden crops

To be read carefully and must be retained

© BERTHOUD Agricole 05/2017

82527 Vantage2

ADDITIONAL INFORMATION

Additional information is available in the following instruction notices:

Reference

Safety and sprayer controls Notice 82.471

AXIALE II boom (24/32m) Notice 82.486

KONDOR boom (32/38m) Notice 82.491

AXIALE 36 boom (36/38m) Notice 82.515

EKTAR B3 boom (36/38m) Notice 82.514

E.C.Tronic regulation Notice 82.510

Nivelec/Nivomatic Notice 82.494

Dualelec Notice 82.487

NOZAL nozzle tables Notice 82.467

Tracking axle Notice 82.485

Electrical diagrams Notice 589.493

IMPORTANT:

Please read the instruction notices before

rst use of the machine, according to its

conguration.

i

NOTE:

Depending on the conguration of your

machine, certain notices will not be

available in your documentation.

When this reference symbol appears,

please see the indicated page for more

information

82527 Vantage 3

CONTENTS

1. General points and safety 05/10

1.1 Technical characteristics 05

1.2 Table of weights 07

1.3 Dimensions 08

1.4 Nameplate 08

1.5 Tracks and dimensions 09

1.6 Noise measurements 09

1.7 Positions of the safety stickers 10

2. Overview of the sprayer 11/22

2.1 Overview of the E.C.Tronic control unit 11

2.2 Overview of the E-Pilot joystick 15

2.3 Overview of the DUALMATIC Berlogic 16

2.4 Characteristic of the Omega pump 16

2.5 Tracking axle 16

2.6 Adjustable boom 18

2.7 Manual strut 18

2.8 Hydraulic strut 19

2.9 Ribbon gauge 19

2.10 NIVELEC gauge 19

2.11 NIVOMATIC gauge 19

2.12 Rinse tank 20

2.13 Hand wash tank 20

2.14 Draining the tank 20

2.15 Mixing 21

2.16 Rinsing balls 21

2.17 Procedure for exterior washing 21

2.18 Height of the boom 21

2.19 Ladder 22

2.20 Doors, box, front bonnet 22

3. Commissioning the crop sprayer 23/26

3.1 Adaptation of the transmission shaft 23

3.2 Adjustment of the track 23

3.3 Service brake 24

3.4 Parking brake 25

3.5 Adjustment of the drawbar 25

3.6 Rinsing before the rst use 25

3.7 Usage advice 26

4. Use of the sprayer 27/33

4.1 Hitching the machine to the tractor 27

4.2 Filling the tank 27

4.3 Mixing hopper 28

4.4 Spraying / Agitation 29

4.5 Dilution of the residual liquid (Dilunet or Dilunet +) 30

4.6 Rinsing the machine in DUALMATIC 31

4.7 Rinsing the machine in DUALELEC 32

4.8 Exterior washing 33

4.8 Unhitching the sprayer 33

82527 Vantage4

5. Crop sprayer maintenance 34/38

5.1 Practical guidance 34

5.2 Filters 34

5.3 Clogged nozzles 35

5.4 Checks before the treatment season 35

5.6 Overwintering the sprayer 36

5.7 Protection against oxidising agents 36

5.8 Maintenance of the boom 36

5.9 Check the tightness of the nuts 36

5.10 Safety for changing a wheel 37

5.11 Lubrication and tightening 37

5.12 Hydraulic unit 38

6. Maintenance diagrams 39/41

6.1 E.C.TRONIC hydraulic circuit 39

6.2 E.C.TRONIC hydraulic circuit (option DILUNET) 40

6.3 E.C.TRONIC hydraulic circuit (option DILUNET +) 41

7. Reminder of your parameters 42/42

8. Notes concerning spraying carried out during the season 43/43

82527 Vantage 5

Trailed machine VANTAGE 28-30 / 35-37 / 43-46 / 55-60 / 67-71, E.C.TRONIC regulation.

1.1 TECHNICAL CHARACTERISTICS

1. GENERAL POINTS AND SAFETY

Structure

Chassis Steel chassis protected by U.H.R polyester paint with stainless steel bolts.

Protective plate.

Axle Axle with track adjustable from 1.50 to 2.25 m, according to the machine.

ACTIFLEX 2 axle suspension.

Tracking axle Tracking axle with track adjustable from 1.80 to 2.25 m, according to the machine

(option).

Brake Mechanical parking brake. Hydraulic service brake.

Optional pneumatic brake.

Fixed drawbar

"France ring" (ring Ø 50), "Ball coupling" (sphere Ø80), "Germany ring" (ring Ø40),

"Italy ring" (rotating ring Ø76).

Height adjustment (2 positions).

Suspended drawbar Flexia drawbar on 55-60 and 67-71 (option in 28-30, 35-37, 43-46).

Fixed adjustable boom "France ring" (ring Ø 50), "Ball coupling" (sphere Ø80), "Germany ring" (ring Ø40), "Italy

ring" (rotating ring Ø76), only in ED version (option).

Suspended adjustable

boom

Flexia drawbar with "France ring" (ring Ø 50), "Ball coupling" (sphere Ø80), "Germany

ring" (ring Ø40), "Italy ring" (rotating ring Ø76), (option).

Strut

Manual strut in 28-30, 35-37, 43-46 with Axiale boom.

Hydraulic strut on 43-46 with Ektar and Kondor boom.

Hydraulic strut on 55-60 and 67-71, any boom.

Mudguard Series mudguard.

Wheel See table on following page.

Tanks

Tank

Tank made of high-density polyethylene, with large lling hole and two rinsing balls.

Vantage 28-30: Nominal capacity 2800 litres.

Vantage 35-37: Nominal capacity 3500 litres.

Vantage 43-46: Nominal capacity 4300 litres.

Vantage 55-60: Nominal capacity 5500 litres.

Vantage 67-71: Nominal capacity 6700 litres.

Rinse tank

Polyethylene rinse tank equipped with a oat gauge.

380 litres for Vantage 28-30 and 35-37.

580 litres for Vantage 43-46 and 55-60.

720 litres for Vantage 67-71.

Hand wash tank 20 L hand wash tank, with support for liquid soap.

Ribbon gauge Silk-screen printed ribbon gauge.

NIVELEC / NIVOMATIC

gauge Electric gauge with reading on screen, sound alarm and automatic stop (option).

Regulation

OMEGA pump OMEGA pump, twin turbine centrifuge (550 l/mn at 8 bars).

E.C.Tronic D.P.A.E regulation, equipped with a backed-up memory.

Plot management, treatment congurations, user mode.

82527 Vantage6

Controls

Transmission Transmission with double constant-speed universal joints with 6 splines (optional

hydraulic pump drive).

Motorised valves Spraying remote controlled by motorised valves with general cut-off on the control unit

in the cab and congured to cut off sections by GPS.

Continuous ow The pneumatic anti-drip devices immediately open and close the spraying (option).

Electronic unit E.C.Tronic with multi-pin connection sockets (regulation, boom control, spray control).

DUALMATIC Display of the positions of valves enabling the various functions (manual).

DUALELEC DUALELEC provides the simplicity of all-electric during use. Electrical control for

agitation, rinsing the tank and the boom (option).

BOOM CONTROL Automatic management of ground monitoring (option).

ACS

Two functionalities:

1) The ACS can unfold and fold the boom automatically at the beginning of the eld.

2) It can also cut the spray and raise the boom at the end of the eld (option).

Standards

Road signalling Compliant with the highway code.

Approvals Road (DREAL).

Environmental compliance.

Functions

Filling

Direct lling with the quick connection Ø 50mm.

Isolation valve for the circuit and 6m lling tube with strainer.

Retractable mixing hopper with rinsing of drums, the circuit and anti-return valve.

Filtration Sieve (lling, mesh 8/10).

Discharge lter (lter 1/4 turn with mesh of 4/10).

Mixing Hydraulic mixing by returning non-sprayed liquid to the tank.

Dilunet or Dilunet + Optional dilution of the residual liquid, by return to the tank or rinsing balls (option).

External washing Equipment for externally washing the machine (option).

Casing Secured access to the manhole.

Storage compartments Storage for safety equipment.

Lighting pack Lighting pack with working lights, lighting at the control position and support for ashing

light (option).

End nozzle End nozzle with manual or electric closure (option).

Type

of

tyre

270/95 R48 300/95 R46 300/95 R52 340/85 R48 380/90 R46

Standard Option Option Option Option

Type

of

tyre

420/85 R38 460/85 R38 520/85 R38 520/85 R42 520/85 R46

Option Option Option Option Option

NOTE:

Depending on the capacity of your machine,

certain types of tyres will not be available.

82527 Vantage 7

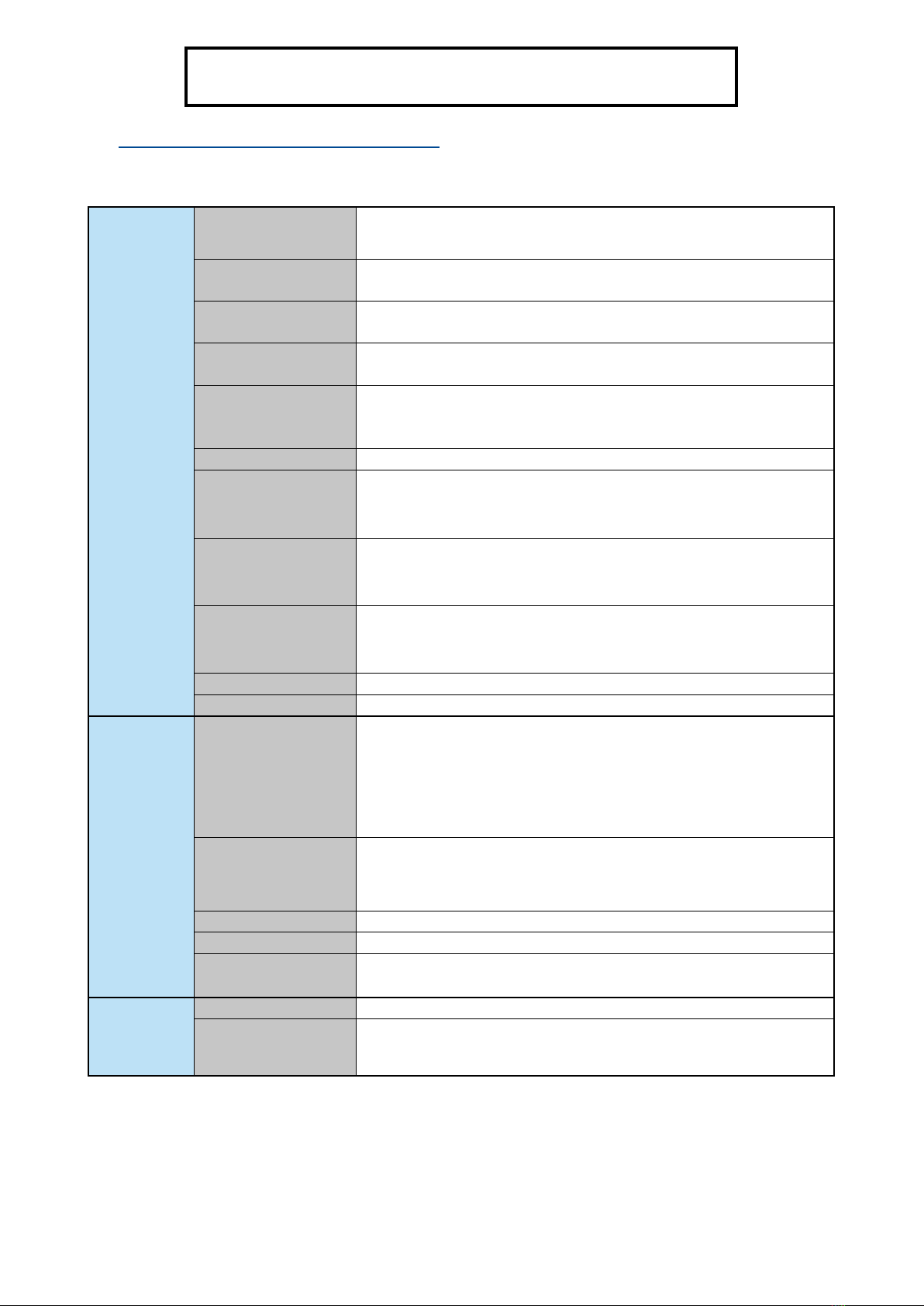

1.2 TABLE OF WEIGHTS

These weights are understood as being in the

heaviest conguration of the machine (options, tyres,

regulation and suspension).

The data below concerns France only (see the DREAL document).

BOOMS

MACHINES Axiale II Axiale 36 Kondor Ektar B2 Ektar B3

VANTAGE

28-30

Weight without

boom 4000 kg - - - -

G.V.W.R. 7270 kg - - - -

G.V.W.R. Axle 5614 kg - - - -

G.V.W.R. Drawbar 1656 kg - - - -

VANTAGE

35-37

Weight without

boom 4400 kg - - - -

G.V.W.R. 8215 kg - - - -

G.V.W.R. Axle 6577 kg - - - -

G.V.W.R. Drawbar 1638 kg - - - -

VANTAGE

43-46

Weight without

boom 4480 kg 5030 kg 4960 kg 5100 kg 5000 kg

G.V.W.R. 9239 kg 9789 kg 9830 kg 9860 kg 9860 kg

G.V.W.R. Axle 7032 kg 7272 kg 7840 kg 7272 kg 7660 kg

G.V.W.R. Drawbar 2207 kg 2517 kg 2050 kg 2597 kg 2200 kg

VANTAGE

55-60

Weight without

boom 4700 kg 5250 kg 5180 kg 5320 kg 5750 kg

G.V.W.R. 11020 kg 11570 kg 11500 kg 11640 kg 12070 kg

G.V.W.R. Axle 8370 kg 8610 kg 9050 kg 8610 kg 9300 kg

G.V.W.R. Drawbar 2650 kg 2960 kg 2510 kg 3000 kg 2810 kg

VANTAGE

67-71

Weight without

boom 5050 kg 5600 kg 5330 kg 5670 kg 5900 kg

G.V.W.R. 12450 kg 12920 kg 12850 kg 12920 kg 13340 kg

G.V.W.R. Axle 9230 kg 10170 kg 10110 kg 10170 kg 10400 kg

G.V.W.R. Drawbar 2920 kg 2750 kg 2740 kg 2780 kg 2950 kg

NOTE:

Before hitching your machine, we

recommend checking the maximum load

acceptable by your tractor's drawbar

coupling.

This information is communicated to you by

your tractor manufacturer in the technical

data for your machine.

82527 Vantage8

1.3 DIMENSIONS

Dimensions

in metres

Axiale II 24 - 28

Axiale II 30 - 33

Kondor 32 - 33

Kondor 36 - 38

Ektar B2 36 - 38

Axiale 36 - 38

Ektar B2 40 - 42

Ektar B3 36 - 38

Ektar B3 39 - 44

VANTAGE

A

(mini) 6.9 7.9 7.3 7.3

9.6 10.6

7.5 8

A

(maxi) 8.4 9.4 8.3 8.3 8.3 8.5

B

(mini) 2.5 2.5 2.5 2.5 3 3 2.5 2.7

C

(mini) 3.8 3.8

3.8 3.8

3.8 4

3.9

3.8

C

(maxi) 4 4 4.3 4.4 4.3

A

C

B

1

1.4 NAMEPLATE

ZI Bois Baron - 1 rue de l’industrie Pulvérisateurs – Sprayers – Spritzgeräte

69220 BELLEVILLE s/SAÔNE – France Pulverizadores – Polverizzatorri

Homologation - Approval Poids - Weight

N° Identification PTAC - Laden weight - Zul.Gesamtgewicht - MMA kg

kg

kg

Réceptionné le - Regist.Date ar - By

N° Série Berthoud PV - Curb weight - Stutzlast - Tara kg

Type Berthoud Année fabrication - Manufacturing year

20

Agricole

TVV - Type approval

N° Dossier - N° File

Poids/essieu - Axle Weight - Zul. Achslast - MMA eje

Poids/anneau - Ring Weight - Zul. Zugöse - MMA anillo

The empty weight and G.V.W.R.

(Gross Vehicle Weight Rating)

boxes use the data from the table

below.

The location of your machine's nameplate is given in

paragraph 1.4.

The Type box contains letters and gures.

Example: VAN C 35 AX 24

VAN = Machine VANTAGE

C= Regulation E.C.Tronic

35 = Nominal capacity 3500 litres

AX = Boom Axiale (A2 = Axiale 36, E2 = Ektar B2, E3

= Ektar B3, KD = Kondor)

24 = Width 24 metres (28 = 28 metres...)

82527 Vantage 9

1.6 NOISE MEASUREMENTS

AIRBORNE NOISE EMITTED BY: Trailed sprayer

VANTAGE E.C.Tronic.

Acoustic pressure at driving position LPA in dB(A):

- Tractor alone = 69.4

- Tractor + sprayer = 70.5

Acoustic pressure peak value:

- Tractor alone = 92.8

- Tractor + sprayer = 95.3

LWA acoustic power:

- Tractor alone = 104.4

- Tractor + sprayer = 107.3

IMPORTANT:

Comply with the legislation in force and,

when necessary, use hearing protection.

i

Adjustable track (1.50 to 1.90m) Standard adjustable track (1.80 to 2.25m)

Interior rim offset (1) Exterior rim offset (2) Interior rim offset (1) Exterior rim offset (2)

270/95R48

1.50 to 1.70

1.70 to 1.90

1.80 to 2.00 2.00 to 2.25

300/95R46

300/95R52

340/85R48 1.55 to 1.70

380/90R46 1.60 to 1.70

420/85R38 1.65 to 1.70

460/85R38

520/85R38 1.75 to 1.90

520/85R42 1.80 to 1.90

520/85R46 1.85 to 1.90

1.5 TRACKS AND DIMENSIONS

2 3

1

32

3

Interior rim offset

Track

1

3

Exterior rim offset

2

82527 Vantage10

417.590

417.576

418.630

418.629

401.362

417.572

417.465

417.597

417.588 417.575 417.580

417.581 417.586

426.484

1 7 POSITIONS OF THE SAFETY STICKERS

It is very important to keep the safety stickers in place and in good condition. They attract your attention

to the possible dangers and refer to the user manual.

Check their location on the crop sprayer and see their meaning in manual No. 82.471 (safety, controls,

crop sprayer maintenance).

Additional stickers are used concerning the pneumatic braking on the 40 km/h machines.

They provide you with information on the adjustments to be made 3.3.

- VANTAGE -

ZI Bois Baron - 1 rue de l’industrie Pulvérisateurs – Sprayers – Spritzgeräte

69220 BELLEVILLE s/SAÔNE – France Pulverizadores– Polverizzatorri

Homologation - Approval Poids - Weight

N° Identification PTAC - Laden weight - Zul.Gesamtgewicht - MMA kg

kg

kg

Réceptionné le - Regist.Date ar - By

N° Série Berthoud PV - Curb weight - Stutzlast - Tara kg

Type Berthoud Année fabrication - Manufacturing year

20

Agricole

TVV - Type approval

N° Dossier - N° File

Poids/essieu - Axle Weight - Zul. Achslast - MMA eje

Poids/anneau - Ring Weight - Zul. Zugöse - MMA anillo

At the front right of the chassis

On the control unit

for the spray boom

4

82527 Vantage 11

5

R

5780 L

50%

1

2

3

4

5

678

13

12

11

10

9

14

15

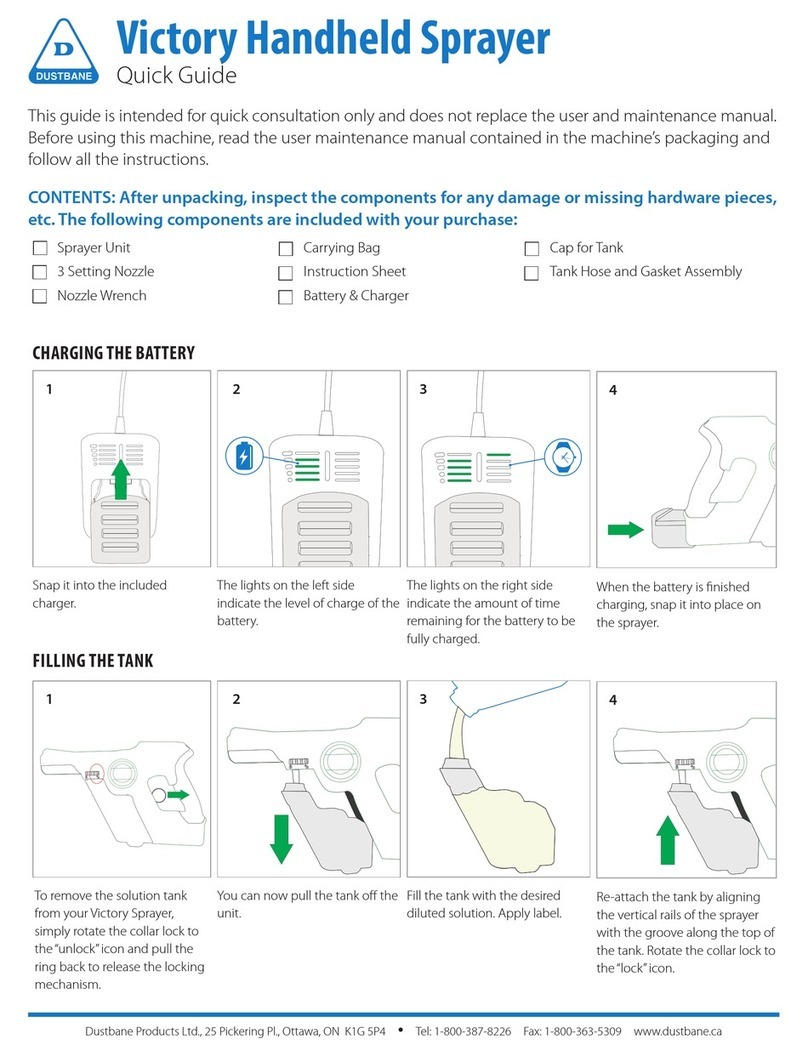

OVERVIEW OF THE BUTTONS ON THE UNIT:

"Back" button.

"Settings" button.

"Information" button.

"Change icon page" button

DUALELEC safety system button.

"Start control unit" button

Buttons for changing volume/ha or pressure

Switches for individual control of sections

Section status.

OK button.

2.1 OVERVIEW OF THE E.C.TRONIC CONTROL UNIT

Navigation buttons.

Action buttons.

"DUALELEC" button to control sprayer functions

"Program" button to access vol/ha setting, change

of plot, etc.

"Totals" button

1

2

3

4

5

6

7

12

8

14

11

9

10

13

2. OVERVIEW OF THE SPRAYER

15

ButtonMenu Access Number of pulses

Settings

Select the language.

short x 1

Adjust screen brightness.

Pair joystick.

-PILOT

Troubleshooting help.

Calibration.

long x 1

Parameters.

Troubleshooting help.

Information

Information on current treatment:

Volume/ha – Nozzle – Product. short x 1

Weather information:

Ambient temperature - Humidity. short x 2

Machine information: Circumference/Pulses

Boom width - Number of sections.

- long x 1

Change

icon page Next icon page. short x 1

82527 Vantage12

ButtonMenu Access Number of pulses

Back Back to working screen without taking

unsaved values into account. short x 1

Totals

Management

of plots

activated

Totals per plot:

Distance covered, surface treated,

volume applied since the last reset to zero.

short x 1

Totals per user. short x 2

Totals per machine. short x 3

Totals

Management

of plots

deactivated

Totals per user. short x 1

Totals per machine. short x 2

Totals Reset to zero (except machine). long x 1

Programme

Management

of plots

activated

List of plots. short x 1

Change of volume/ha or pressure

in a treatment record.short x 2

List of treatment records. short x 3

Programme

Management

of plots

deactivated

Change of volume/ha or pressure

in a treatment record.short x 1

List of treatment records. short x 2

Programme

General configuration, select or create

a machine.long x 1

Select or create a user. long x 2

DUALELEC

(optional) Quick access to the most used functions. short x 1

>

DUALELEC

(optional)

List of 13 functions.

short x 1

> short x 1

Automatic variation agitation.

short x 1

> short x 2

Mask a function.

short x 1

> long x 1

DUALELEC

(optional) Secure the DUALELEC. short x 1

ON / OFF

Start or stop the control unit.C-TRONIC short x 1

Turn off the control unit

after confirmation request.

C-TRONIC long x 1

82527 Vantage 13

ButtonMenu Access Number of pulses

PLUS

Allows you to increase the volume/ha

during treatment in steps of 5% or

the pressure in steps of 0.1 bar.

short x 1

Activation of the Zoom mode. long x 1

MINUS

Allows you to decrease the volume/ha

during treatment in steps of 5% or

the pressure in steps of 0.1 bar.

short x 1

Deactivation of the Zoom mode. long x 1

Move up in the screen.

Move right in the screen.

Move down in the screen.

Move left in the screen.

Confirm.

OVERVIEW OF FUNCTION ICONS:

Movements of booms

Icon Description Icon Description

Axiale bolt open. Axiale bolt closed.

Pendulum bolt open. Pendulum bolt closed.

Raise/lower the boom. Open / close the main arms.

Opening for left main arm

(ULYS or AX decoupled).

Opening for right main arm

(ULYS or AX decoupled).

Opening / closure of left

intermediate arm (2 arm boom).

Opening / closure of right

intermediate arm (2 arm boom).

Opening / closure of left end

arm (3 arm boom).

Opening / closure of right end arm

(3 arm boom).

82527 Vantage14

Icon Description Icon Description

Simultaneous opening / closure of

end arms for 2 arm booms or the

2 main arms of 3 arm booms.

BEs

Simultaneous opening / closure

of the end arms of 3 arm booms.

Slope corrector.

Reset the slope corrector to zero

(the icon shows that the slope

corrector is used).

Reset the slope corrector to zero

(the icon shows that the slope

corrector is centred).

Slope non-centred.

Left geometry. Right geometry.

Reset the variable geometries to

zero (the icon shows that one of

the variable geometries is used).

Reset the variable geometries

to zero (the icon shows that the

variable geometries are centred).

Variable geometries not horizontal.

Icon Description Icon Description

General spraying open. General spraying closed.

Icon Description Icon Description

Spraying in automatic mode

Short

Spraying in auto-manual mode

General spraying open.

General spraying open.

General spraying closed.

General spraying closed. General spraying with open and

closed sections.

R Spraying in automatic mode

Long

Spraying in auto-manual mode

General spraying open (option to

have open and closed sections).

Spraying closed.

Spraying, without GPS-controlled section shut-off

Spraying,with GPS-controlled section shut-off

82527 Vantage 15

5780 L

50%

0.0

Km/h

0

L/ha

2.00

bar

utilisateur_1 32.00 Ha herbicide

05-PULVERISATION

1

2

3

4

5

6

789

Information on the current treatment record.

Information on the working pressure.

Information on the Volume/hectare applied.

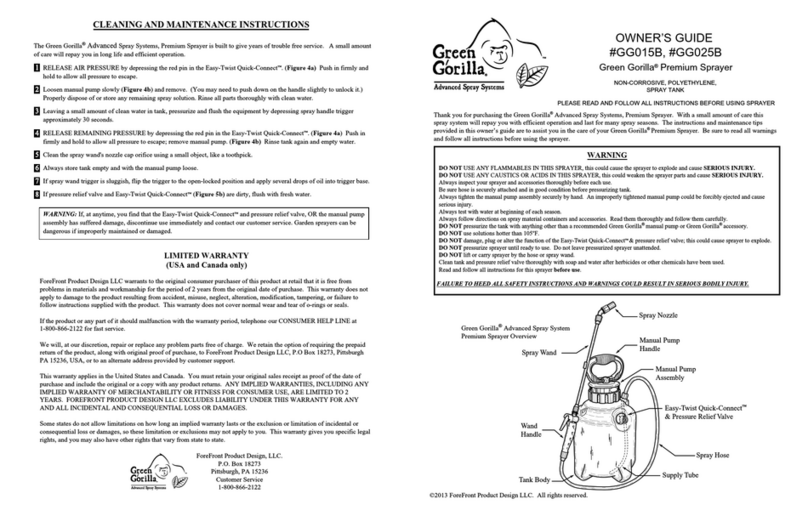

OVERVIEW OF THE WORKING SCREEN

Pseudonym of the current user.

Information on the forward speed.

Information on the spray function.

Information on the agitation percentage.

Icons for boom movements and other functions

Information on the volume remaining in the tank.

1

2

3

4

5

6

7

8

9

6

MULTIFUNCTION JOYSTICK:

Control of all sprayer and spraying functions in

sequential mode.

Wireless joystick: range of over 50 m. Operates with

R 06 (AAA) batteries, power supply 3 Volt.

Ergonomic and adaptable: most buttons can be

congured depending on the user (except sequential

spraying).

When the joystick is detached from its base, you must

press the red "Dead Man” (5) button on the back of

the joystick to activate the keypad.

The second button (6) on the back of the joystick

duplicates certain functions.

Example: with the "Slope correction" buttons, we can

also control the adjustable boom.

Buttons to control spraying in sequential mode

and the general spraying.

Boom bolts + duplication with the blue button

located to the rear.

Buttons for boom controls:

- Raise / lower

- Slope correction

- Geometries

- Reset to zero

2.2 OVERVIEW OF THE E-PILOT JOYSTICK

7

8

3

1

2

4

56

Free buttons or tracker or boom

"Dead man" button

Duplicate function button

1

2

3

4

5

6

82527 Vantage16

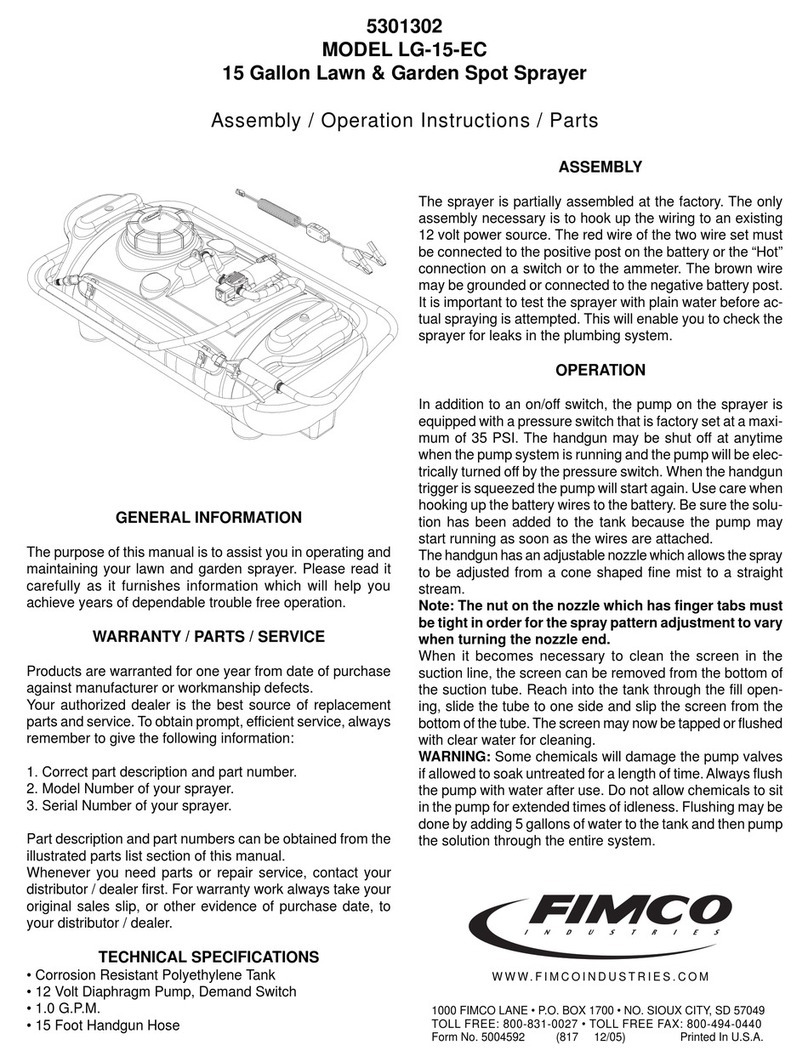

2.4 CHARACTERISTIC OF THE OMEGA PUMP

Frame made of machined cast iron.

Driven by oil-bath gearbox.

Rotation speed of the double turbine:

3900 rpm for 540 rpm at power take-off.

Double liquid output: low and medium pressure.

The pressure of the OMEGA pump varies according

to the ow/minute.

0

500

1000

0 5 10

Pressure (Bars)

Spraying with mixing

Mixing

Spraying without mixing

3 bars

550 l/min

Characteristic curve

10

2.3 OVERVIEW OF THE DUALMATIC BERLOGIC

The main functions of the Berlogic panel are listed on

the diagram below (1).

To obtain the desired position, place the indexes (2),

(3) and (5) opposite the booms corresponding to the

numbers of the functions in the list (1).

To put the index in position (5):

Turn the index using one of the two controllers.

To put the index in position (3):

Press the two controllers in, then turn.

To put the index in position (2):

Pull the two controllers towards yourself, then turn.

The diagram (4) represents the hopper and the two

positions of the control lever for the incorporation

valve 4.3.

11

11

11

2

5

3

4

789

1

2

3

4

6

6

4

5

5

10

3

2

2

14

9

8

8

931

10 7

7

10

6

11 EXTERIOR SUCTION

2 INCORPORATION WATER MAIN TANK

3 INCORPORATION WATER EXTERIOR SUCTION

4 INCORPORATION WATER RINSING TANK

5 SPRAYING

6 CLEANING TANK WITH RINSE TANK

7 RINSING BOOM WITH RINSE TANK

8 TRANSFER

9 CLEANING FILTER

10 AUXILIARY SUCTION OPTION

11 EXTERIOR WASHING OPTION

9

1

2

3

5

4

2.5 TRACKING AXLE

Pictogramme Description Pictogramme Description

Suiveur verrouillé. Remise à zéro du suiveur.

Suiveur désactivé. Suiveur en fonctionnement.

Suiveur activé. Commande manuelle des roues du

suiveur.

Alternance OFF/ON.

Suiveur en mode "Pause".

82527 Vantage 17

NOTE:

From "Pause" to "Activated" mode or

conversely, the wheels are automatically

re-centred during 8 seconds.

Give 1 long press on the button located next to

the icon to unlock the tracker and move into

"Pause" mode.

In "Pause" mode, the icons and ash

alternately.

1 long press on the button located next to the

icons or during the "Pause" mode,

OR when the tracker is activated (mode ), it can

lock the tracker (mode ).

1 long press on the button located next to the

icons or during the "Pause" mode, deac-

tivates tracking the tractor tracks (mode ).

1 new long press on the button re-establishes

the "Pause" mode (the icons and ash

again alternately).

Give 1 short press on the button or on the

button located next to the icon to activate

tracking the tractor tracks.

Give 1 short press on the button or on the

button located next to the icon to deactivate

tracking the tractor tracks.

Tracking the tractor tracks goes into "Pause" mode

(the icons and ash alternately).

To stop the automatic mode, give 1 long press on

the button located next to the icons or

to move from "Pause" into mode (track-

ing the tractor tracks deactivated).

AUTOMATIC MODE:

5780 L

25%

utilisateur_1 herbicide32.00 Ha

05-PULVERISATION

0.0

Km/h

0

L/ha

3.00

bar

5780 L

25%

utilisateur_1 herbicide32.00 Ha

05-PULVERISATION

0.0

Km/h

0

L/ha

3.00

bar

5780 L

25%

utilisateur_1herbicide32.00 Ha

05-PULVERISATION

0.0

Km/h

0

L/ha

3.00

bar

11

12

13

MANUAL MODE:

Ground monitoring is in mode .

To align the wheels:

Maintain pressure on the button or the button

located next to the icon until the icon

appears.

To orient the wheels manually:

Press the button located next to the icon

to turn to the left.

5780 L

25%

utilisateur_1 herbicide32.00 Ha

05-PULVERISATION

0.0

Km/h

0

L/ha

3.00

bar

14

WARNING:

On the road, locking the tracking axle

is mandatory.

Press the button located next to the icon

to turn to the right.

82527 Vantage18

2.7 MANUAL STRUT

The strut (1) is hinged on the drawbar. When the ma-

chine is unhitched, the shoe (3) rests on the ground

and the axle (2) is placed in one of the 2 positions P.

Use the handle (5) to raise or lower the drawbar. This

handle is also used for the parking brake.

Store the handle away after use.

Folding the strut:

When the machine is hitched to the tractor, it is imper-

ative to fold the strut.

To do so:

Raise the strut (1) using the handle (5) until the

mechanism is fully folded.

Hold the handle (4) before withdrawing the axle (2).

Place the strut (1) against the drawbar using the

handle (4) (align the holes T1 and T2) then immobi-

lise with the axle (2).

16

4 T13 52

1

P

Unfolding the strut:

Hold the handle (4) before withdrawing the axle (2),

then:

Lower the strut (1) using the handle (5) until the

mechanism enables the axle (2) to be inserted in

one of the two positions P.

Finish using the handle (5) so that the shoe (3) has

a good seat on the ground.

T2

Transition from the road to the eld:

Align the tractor and the sprayer.

Remove the pin (1).

Transition from the eld to the road:

Align the tractor and the sprayer.

Place the pin (1).

To orient the boom manually:

Press the button located next to the icon

to turn to the left.

Press the button located next to the icon

to turn to the right.

Reset the boom to zero:

Maintain pressure on the button or the button

located next to the icon until the icon

appears.

2.6 ADJUSTABLE BOOM

15

WARNING:

On the road, it is mandatory to lock the

adjustable boom (pin 1).

1

82527 Vantage 19

2.8 HYDRAULIC STRUT

The strut (1) is articulated on the drawbar by the cyl-

inder (2). When the machine is unhitched, the shoe

(3) rests on the ground.

Use a solenoid valve on the tractor to raise or lower

the drawbar.

17

2

3

1

2.10 NIVELEC GAUGE

The NIVELEC (1) unit gives a digital display of the

volume in the tank.

The NIVELEC gauge is visible from inside the tractor's

cab (on the EC-TRONIC unit) and the work position

(on the remote unit (1)) (Berlogic).

19

1

2.11 NIVOMATIC GAUGE

The NIVOMATIC unit (1) not only gives the digital

display of the volume in the tank, but also enables you

to programme the ll volume. Combined with a control

unit, it can trigger a sound alarm or the automatic cut-

off of the lling as soon as the programmed volume

is reached, thereby preventing accidental overows.

The NIVOMATIC gauge is visible from inside the

tractor's cab (on the EC-TRONIC unit) and the work

position (on the remote unit (1)) (Berlogic).

20

1

2.9 RIBBON GAUGE

A ribbon gauge (1), readable inside the tractor's cab

and from the work position (Berlogic), is placed on

the top of the machine's tank.

0

18

1

82527 Vantage20

2.13 HAND WASH TANK

Hygiene and comfort: the tank (1) of 20 litres of fresh

water is for washing the hands or any part of the body

(face, eyes,…) contaminated by the product.

The tap (3) is easily accessible by opening the door.

To wash the hands, open the tap (3) to a greater or

lesser extent, depending on the desired ow.

WARNING:

The rinsing tank must MANDATORILY be

lled with fresh water, under no pressure,

via the plug (1) or under pressure via the

"GARDENA" connection (2)

22-2

2.14 DRAINING THE TANK

The draining system is controlled at the top of the

machine's tank.

You must pull the handle after having removed the

safety pin.

Recover the liquid coming out of the tank in a container

adapted to the management of phytosanitary

residues.

NOTE:

On all the machines, a nut has been

added under the tank, which must rst be

removed.

2.12 RINSING TANK

A tank (2) of 380 to 720 litres of fresh water enables

the sprayer to be rinsed.

The rinsing tank (1) is placed in front of the main tank.

Its lling level is visible from the tractor's cab via a

oat gauge.

WARNING:

The rinsing tank must MANDATORILY

be filled with fresh water, under no

pressure, via the cover (1). 21

1

2

22-1

23-2

23-1

1

2

1

2

(1) valve closed - (2) valve open

3

This manual suits for next models

3

Table of contents

Other Berthoud Paint Sprayer manuals

Berthoud

Berthoud HERMES 800 User manual

Berthoud

Berthoud ELYTE 2 VITON User manual

Berthoud

Berthoud ULV User manual

Berthoud

Berthoud RAPTOR 2540 User manual

Berthoud

Berthoud VERMOREL 3000 ELECTRIC User manual

Berthoud

Berthoud ELYTE 2 360 EPDM User manual

Berthoud

Berthoud PULVASOL 200 User manual

Berthoud

Berthoud ELYTE Series Installation and operation manual

Berthoud

Berthoud MAXAIR 240 User manual

Berthoud

Berthoud COSMOS 18 PRO User manual