Berthoud HERMES 800 User manual

HERMES 800 / 1000 / 1200

All regulations

82.526-A ENGLISH

Equipment designed for the treatment of cereal

and market garden crops

To be read carefully and kept for future reference

© BERTHOUD Agricole 06/2017

2 82.526 - HERMES

ADDITIONAL INFORMATION

Additional information is available in the following manuals:

Reference

Safety and control of sprayers Manual 82.471

Boom ALSR (15/16/18 m) Manual 82.525

NOZAL nozzles table Manual 82.467

Control units Manual 82.528

i

IMPORTANT:

Please read the manuals before using the equipment for the rst time, according to its conguration.

NOTE:

Depending on the conguration of your equipment, some manuals may not be available in your

documentation.

When this 'refer to' symbol is shown, please see the page indicated for further information.

82.526 - HERMES 3

CONTENTS

1. General ______________________________________________________________ 5

1.1. Technical characteristics 5

1.2. Overall dimensions 6

1.3. Weights table 6

1.4. Information plate 7

1.5. Noise measurements 7

1.6. Position of safety stickers 8

2. Presentation of the equipment _____________________________________ 9

2.1. Step 9

2.2. Direct reading oat gauge 9

2.3. Tape gauge (Option) 10

2.4. Boom height 10

2.5. Rinsingtank 10

2.6. Hand washtank 11

2.7. Main tank drain 11

2.8. Agitation 11

2.9. Rinsing balls 11

3. Starting-up the sprayer ___________________________________________ 12

3.1. Adapting the transmission shaft 12

3.2. Hitching the equipment to the tractor 12

3.3. Unhitching the sprayer 12

3.4. Rinsingbefore using for the rst time 13

3.5. Recommendations for use 13

4. Main sprayer functions with Gama 101 or Gama 130 pump _____ 14

4.1. Adjusting the valves 14

4.2. Filling the main tank 14

4.3. Induction hopper 15

4.4. Spraying functions Positions 1-10 16

4.5. Complete rinsing functions: Positions 11-15 17

4.6. Adjusting calibrated returns 17

4 82.526 - HERMES

5. Sprayer maintenance _____________________________________________ 18

5.1. Practical advice 18

5.2. Filters 18

5.3. Blocked nozzles 19

5.4. External washing option 19

5.5. Protection against oxidising agents 19

5.6. Checks prior to the spraying season 19

5.7. Periodic maintenance table 20

5.8. Winter Storage 20

6. Lubrication and greasing _________________________________________ 21

6.1. Gama 101 and Gama 130 pumps 21

6.2. Greasing 21

7. Spraying circuit ___________________________________________________ 22

8. Reminder of your parameters_____________________________________ 23

9. Notes on treatments applied during the season _________________ 24

82.526 - HERMES 5

1. GENERAL

1.1 TECHNICAL SPECIFICATIONS

HERMES Mounted Sprayer, regulation AUTOREGLEUR

Structure

Chassis

Single-piece chassis protected by UHR polyester paint

Stainless steel nuts and bolts

Retractable step for access to the manhole.

Boom lifting on mast with suspension on nitrogen ball

Hitching 3-point hitch

Fixed standing feet (with optional handling casters)

Tanks

Main tank High density polyethylene tank with large lling hole

Capacity: 800, 1000 or 1200 litres.

Rinsing tank 120-litre polyethylene rinsing tank

Handwash tank 18-litre polyethylene handwash tank.

Gauges Direct read oat gauge (main tank and rinsing tank).

Tape gauge (optional on main tank).

Regulation Pump Gama 101 3 piston volumetric pump (20 bar, 105 litres/minute).

Optional Gama 130 pump (20 bar, 130 litres/minute).

Regulation Self-adjuster Autoregleur, E.C.Control or E.C.Tronic.

Controls

Transmission Universal joint transmission

Electric valves Remote spraying control by electric check valves (ECV) with main cut-off on the

control box in the cab.

Electronic box Autoregleur Box, E.C.Control or E.C.Tronic.

Use BERLOGIC panel (manually controlled valve block). It contains all the equipment's

functions to make use easier.

Standards Road signals Complies with trafc regulations.

Approvals Environmental compliance

Functions

Filling

Filling via the manhole or via the hydro-ller.

Connection via 2" quick connector.

6m lling pipe with strainer.

25-litre retractable induction hopper with cans and circuit rinsing system.

Filtration

On lling (main tank):

- Strainer, 8/10 mesh.

On suction (main tank and rinsing tank):

- Filter, 6/10 mesh.

On delivery:

- Filter, 4/10 mesh.

Agitation Agitation by Hydromax with intensity adjustment on BERLOGIC panel.

Rinsing Cleaning the main tank with rinsing balls (Lav'ton).

Rinsing the boom without return to the main tank.

6 82.526 - HERMES

1.2 OVERALL DIMENSIONS

01

B

CA

BOOMS

ALSR 15 ALSR 16 ALSR 18

HERMES

A2.450 m 2.450 m 2.450 m

B2.615 m 3.150 m 3.150 m

C1.665 m 1.665 m 1.665 m

The height should be understood with the equipment on its support on the ground (without wheels).

1.3 WEIGHTS TABLE

The data below relates to France only (see DREAL document).

EQUIPMENT HERMES 800 HERMES 1000 HERMES 1200

BOOM ALSR 15 ALSR 16 ALSR 18 ALSR 15 ALSR 16 ALSR 18 ALSR 15 ALSR 16 ALSR 18

Kerb weight 915 kg 925 kg 930 kg 925 kg 935 kg 940 kg 930 kg 940 kg 945 kg

Max. gross

vehicle weight 2015 kg 2115 kg 2120 kg 2440 kg 2450 kg 2455 kg 2720 kg 2730 kg 2735 kg

These weights are to be understood in the equipment's heaviest conguration (options, settings, suspensions).

NOTE:

Before you hitch the equipment, it is recommended that you check the maximum permissible load

on your tractor coupling.

This information will be provided by your tractor supplier in the technical handbook of your tractor..

82.526 - HERMES 7

1.4 INFORMATION PLATE

The position of the information plate on your equipment is shown on page 8.

The "Type Berthoud " box contains letters and gures.

- Example: HER R 12 LR 18

HER = HERMES equipment

R = Autoregleur regulation

12 = Nominal capacity 1200 litres (08 = 800 litres, 10 = 1000 litres)

LR = ALSR boom

18 = Width 18 metres (15 = 15 metres, 16 = 16 metres)

The "PV" (kerb weight) and "PTAC"

(max. gross vehicle weight) boxes

contain information from the table

below.

1.5 NOISE MEASUREMENTS

ATMOSPHERIC NOISE EMITTED BY: HERMES carried equipment, self-adjusting regulation

Tractor and sprayer

when working

Tractor,

PTO disengaged,

sprayer at rest

•Maximum sound pressure level:

- From the induction hopper 78 dB(A) 73.5 dB(A)

- From the tractor driver's seat 76 kW 72 dB(A) 70 dB(A)

•Maximum sound pressure level:

- Tractor only = 99.1 dB(A)

- Tractor + sprayer = 101.2 dB(A)

i

IMPORTANT:

The legislation in force must be complied with and ear protectors should be worn if necessary.

8 82.526 - HERMES

1.6 POSITIONS OF SAFETY STICKERS

417.572 417.580417.593

417.597

418.630

401.362

417.576

417.576

417.465

455.278

443.250

417.590

426.484

ATTENTION : Lors de l’accrochage ou du décro-

charge de l’appareil assurez-vous que la surface

portante du sol est stable et horizontale.

ATTENTION : When hitching or dismounting

sprayer from tractor linkage make sure that its

base is stable and horizontal with the ground.

VORSICHT : Beim An-Und Abbau des Geraetes

bitte prüfen Sie vor, dass die Grundfläche stabil

und horizontal ist.

ATENCIÓN : Para enganchar y desenganchar la

maquina asegurarse que el suelo sea llano y

estable. 467.289 C

467.289

417.587

417.579

400.382

401.429

401.428

02

- HERMES -

i

IMPORTANT:

It is important to keep safety stickers in place and in good condition. Indeed, they draw your

attention to potential hazards and refer to the user manual.

Check their location on the sprayer and see their meaning in the manual No. 82471 (sprayer

safety, checks and maintenance).

82.526 - HERMES 9

2. PRESENTATION OF THE EQUIPMENT

2.1 STEP

A non-slip step (1), housed in the hopper, provides safe access to the manhole (hopper in closed position).

To remove the step from its housing:

• Pull the step towards you (1) and pull it out all the way.

• Turn it clockwise until it is horizontal.

•Lower the riser (2).

To return the step to its housing:

•Fold up the riser (2).

• Turn the step (1) anti-clockwise into the vertical.

• Push it home until it locks.

i

IMPORTANT:

Whenever the sprayer is in motion, the step (1) must be locked in its housing.

1

1

2

03

2.2 DIRECT READ FLOAT GAUGE

A direct read oat gauge (1), highly visible from inside

the tractor cab and at control station (BERLOGIC) is

positioned on the front left of the equipment. It shows

the volume contained in the main tank.

1

04

10 82.526 - HERMES

2.3 TAPE GAUGE (Option)

A tape gauge (1), rhighly visible from inside the tractor

cab and at control station (BERLOGIC) is positioned

on the top of the equipment. It shows the volume

contained in the main tank.

1

05

2.4 BOOM HEIGHT

A working height (H) between 50 and 60cm above

the surface to be treated is recommended. It is dened

by the nozzle spraying angle and spacing.

There is a risk of drift with a greater height.

H

06

2.5 RINSING TANK

A 120-litre clean water tank (2) is used to rinse

the sprayer.

The rinsing tank (2) is positioned under the right

hand side of the main tank.

Its lling level can be seen from the tractor cab and

at the control station via a direct read oat gauge (3).

IMPORTANT:

The rinsing tank MUST be lled with

clean water, not under pressure:

•Via the cover (1).

•Or via the connector (4) situated

on the control station. To ll, open

valve (D).

07

1

4

D

2

3

82.526 - HERMES 11

2.6 HANDWASH TANK

08

3

21

For hygiene and convenience: An 18-litre clean water

tank (2), separate from the rinse tank is provided for

washing your hands and all body parts (face, eyes,

etc.) contaminated by the product.

The tank is on the left of the main tank; the tap (3)

is accessed under the control wheel on the control

station.

To wash your hands, open the tap (3) to the

desired ow.

WARNING:

The handwash tank MUST be lled

with clean, unpressurised water, via

the cover (1).

2.7 DRAINING THE MAIN TANK

Turn the valve (1) on the control station to

position (gure 09).

Recover the liquid from the tank in a container

suitable for phytosanitary residues.

09

1

2.8 AGITATION

Hydraulic agitation produces a uniform product mixture in the tank, before and during the spraying operation

( 4.4, page 16 for the position of the valves).

2.9 RINSING BALLS

The balls (1) on the gauge tube inside the main tank

provide the rinsing function ( 4.4, page 16 or 4.5,

page 17 for the various rinsing phases).

NOTE:

With a direct read external gauge, there

is one rinsing ball.

With a tape gauge, there are two rinsing

balls

10

1

1

12 82.526 - HERMES

3. READYING THE SPRAYER FOR USE

3.1 ADAPTING THE TRANSMISSION SHAFT

i

IMPORTANT:

This operation must be carried out with the aim of achieving the shortest possible length.

shafts 20 mm longer than their guards when in

their position ready for use.

• For your safety, the two half-shafts must overlap by

a minimum of 300 mm.

• Re-t the transmission shaft ready for use.

L

L

10 mm mini.

L

10 mm mini.

L

11

The length of the transmission shaft can mean

that an adjustment is necessary, depending on the

tractor used.

This is the procedure to follow, once the sprayer

is hitched:

• Align the jaw on the universal joint on the tractor's

power take-off shaft.

• Separate the two half-shafts, connect them to the

corresponding shaft by tting the female guard on

the side of the tractor.

• Present the two half-shafts side by side.

• Mark and cut if necessary, ensuring that you leave

10 mm clearance between the end of the tube and

the heel of the jaw.

• Carefully de-burr both tubes.

• Grease the contact surfaces.

• Cut the guards to the same size as the half-shafts,

using a hacksaw, taking care to leave the half-

3.2 HITCHING THE EQUIPMENT TO THE TRACTOR

• Attach the 3-point hitch on the equipment to the

hitching hook on the tractor. The equipment must

be horizontal.

• Fix the end of the transmission to the power

take-off.

• Attach the transmission shaft guard chain in the

location provided.

• Attach the hydraulic connectors.

• Make the electrical connections.

NOTE:

• Ensure that the guards on the

transmission shaft are in good

condition.

• Ensure that there are no foreign

bodies in the tank.

• Check the oil and greasing levels on

the various parts.

• Check that the lters are clean.

3.3 UNHITCHING THE SPRAYER

• Take up a position on a rm, at surface.

• Place the sprayer in its storage position.

• Disconnect the electrical connections.

• Disconnect the hydraulic connections.

• Rest the hydraulic pipes on the supports of the

sprayer, provided for the purpose.

• Disconnect the transmission shaft from the tractor.

• Unhitch the sprayer.

IMPORTANT:

The sprayer must only be unhitched

with the tanks completely empty.

82.526 - HERMES 13

3.4 RINSING THE EQUIPMENT BEFORE USING IT FOR THE FIRST TIME

WARNING:

Before using your sprayer with phytosanitary products for the rst time (herbicide,

insecticide or other), the equipment must be ushed completely.

• Remove the nozzles if they are tted.

• Unscrew the end caps from the pipes.

• Fill the tank to 1/5 with water.

• Spray ( 4.4, page 16).

• Remove and clean the lters.

• Replace the end caps on the pipes.

• Fit the nozzles.

NOTE:

This will eliminate any foreign particles

that might be in the spraying circuit and

which could otherwise block nozzle

orices.

3.5 RECOMMENDATIONS FOR USE

When starting up:

• Start the tractor engine.

• Power up the controls.

• Engage the power take-off.

Always check:

• Run the ow from the nozzles at a pressure of 3 bars for 1 minute before starting the spraying session,

• If the ow is 10% higher than the initial value, the nozzles should be replaced.

WARNING:

All operations on valves must be done with the power take-off stationary.

14 82.526 - HERMES

4. MAIN SPRAYER FUNCTIONS

WITH A GAMA 101 OR GAMA 130 PUMP

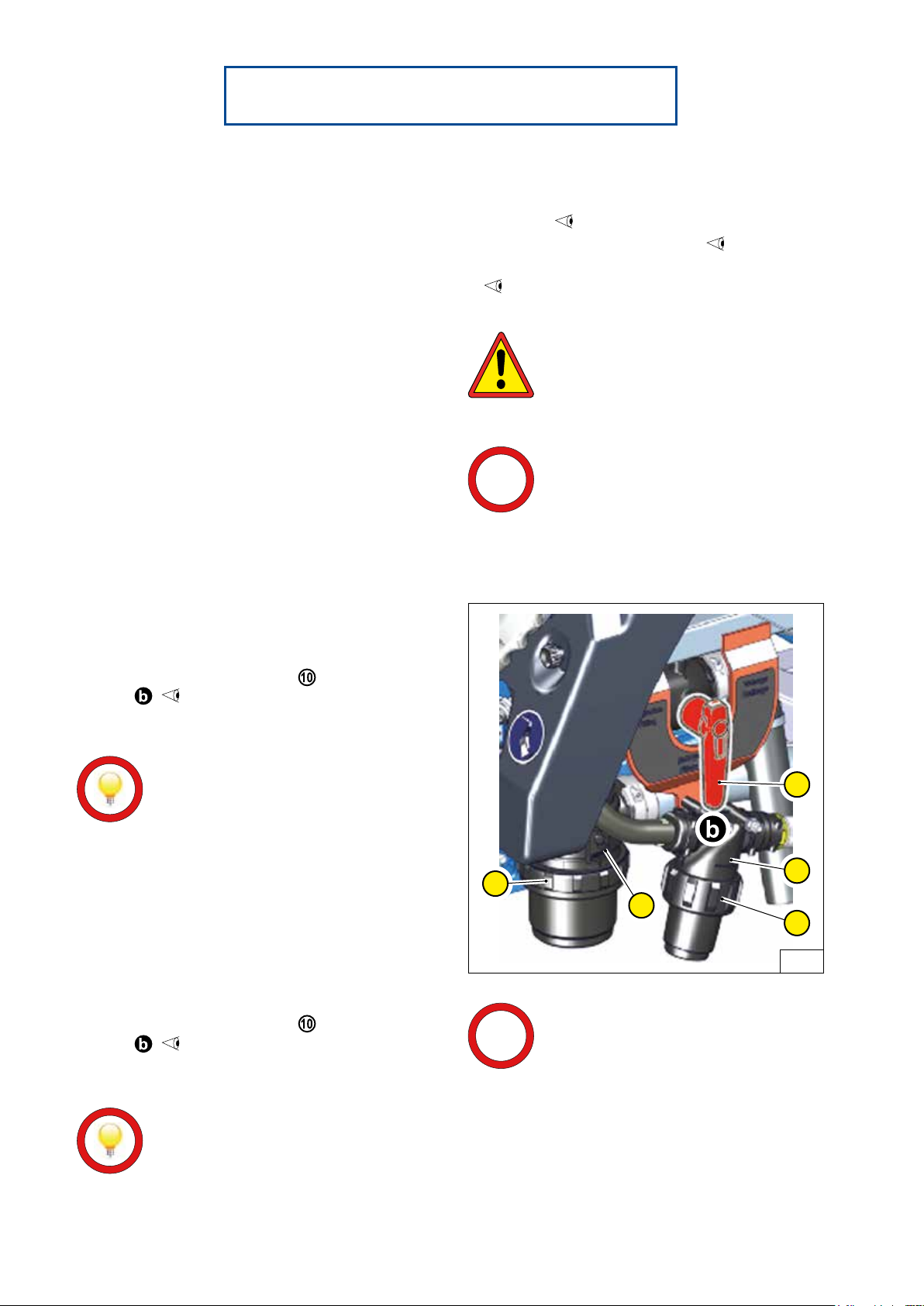

4.1 ADJUSTING THE VALVES

The main functions are shown on the BERLOGIC

(list (1), gure 12).

To obtain the desired position, pull the indexing palette

(6) towards you and turn the wheel (4) to position the

index (3) opposite the desired function on the disc (2)

and then release the indexing palette (6).

The white numbers on the disc (2) from to refer

to the main functions.

The blue numbers on the disc (2) from to refer

to the complete rinsing functions.

NOTE:

•For access to functions to , set

the index (3) to position on the

disc (2) and move the palette (5)

to the right.

•to return to functions to , set the

index (3) to position on the disc (2)

and move the palette (5) to the left. 12

5

6

3

4

2

15

WARNING:

All operations on valves must be done with the power take-off stationary.

4.2 FILLING THE MAIN TANK

Via the manhole (gravity):

• Open the cover on the top of the tank.

Via the external suction device without using

the hopper:

There should be a quantity of water in the main tank

before you start. This water can be poured through

the manhole or be drawn in from the rinsing tank

( 4.4, page 16).

• Attach the lling pipe to the quick connector (1)

(gure 13).

• Set the index on the steering wheel in position .

• Valve (A) in position .

• Valve (B) in position .

• Lever (C) in position .

• Valve (D) in position .

• Dip the lling pipe into the water to be pumped.

• Engage the tractor's power take-off and bring it to

540 rpm.

• When the lling operation is complete, set the lever

(C) to position .

• Remove the lling pipe and replace the cap on the

quick connector (1).

13

B

1

D

C

A

82.526 - HERMES 15

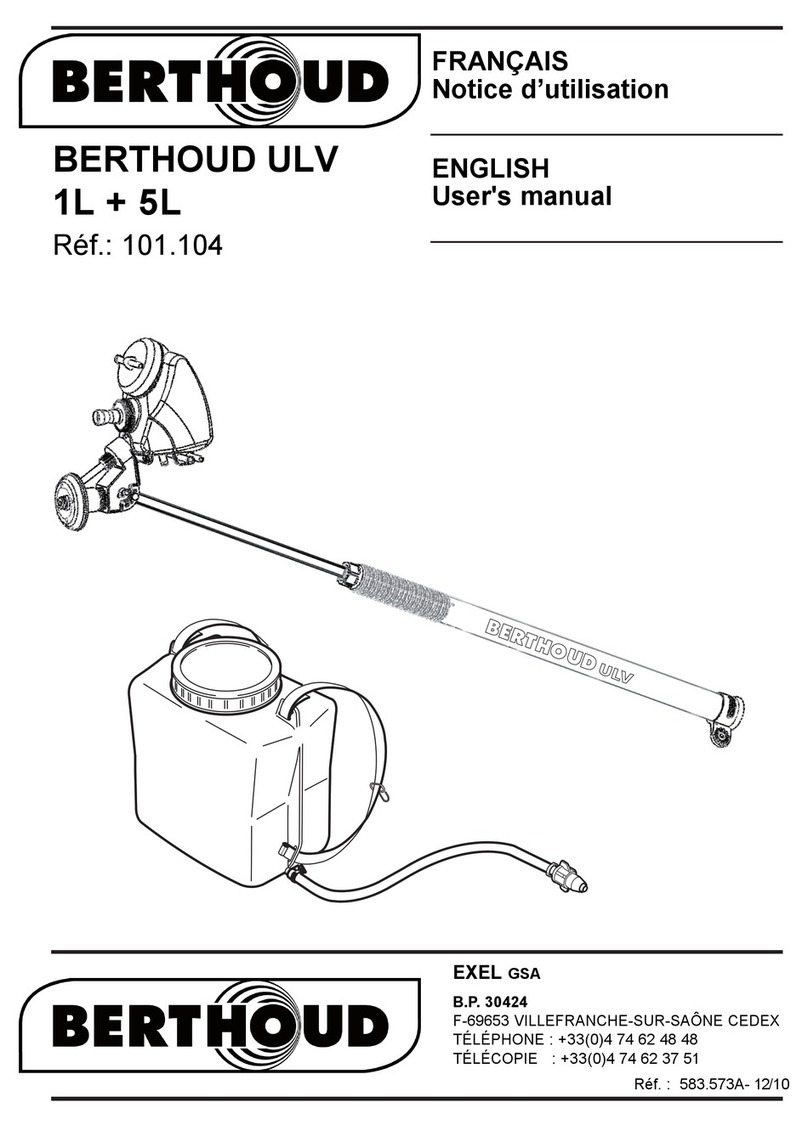

4.3 INDUCTION HOPPER

The Induction hopper is used to mix phytosanitary

powders and liquids while the main tank is being lled.

This feature ensures that the product is mixed

perfectly with the water and makes the work easier

at the same time.

There are three different ways of mixing:

1 - By drawing liquid from the main tank.

2 - By drawing liquid from the rinsing tank.

3 - By drawing it in from outside.

NOTE:

When the lever (C) is in position ,

drawing in from outside is cut off.

In case 2, drawing in clean water has several

advantages:

• Beingable to rinse accessories, cans and the

hopper with clean water.

• Being able to clean the induction hopper circuit

immediately after use.

NOTE:

It is necessary to partly ll the main

tank ( 4.2) before incorporating in the

hopper.

Position of the index on the wheel

in each case:

Suction point

Position of

the index on

the wheel

Power

take-off

speed

1 - Main tank 540 rpm

2 - rinsing tank 540 rpm

3 - External 540 rpm

OperatiOn Of the hOpper

• Set the wheel to the desired position (see table

above).

• Press the pedal (1) and pull the hopper towards

you to lower it.

• Unlock the lid and open it.

• Pour the phytosanitary product into the hopper.

• Valve (A) in position .

• Valve (B) in position .

• Lever (C) in position .

• Valve (D) in position .

• Engage the tractor's power take-off.

• To empty the hopper:

- Replace the cover and lock it.

The product is incorporated and mixed in the

sprayer's main tank.

• To rinse the induction hopper:

- Set the index on the wheel in position .

- Open valve (A) in position (gure 14);

it actuates the rinsing manifold in the hopper.

- After this operation, close valve (A) in position .

NOTE:

Close valve (A), position , as soon

as the hopper is empty, so as not to

produce foam in the main tank.

rinsing cans

• Valve (A) in position (gure 14).

• Put the product can on the part (1) (gure 15)

and press.

14

B

1

D

A

C

1

15

16 82.526 - HERMES

4.4 SPRAYING FUNCTIONS: POSITIONS 1-10

NOTE:

The rinsing functions allow partial rinsing if there is no change of products but not a complete

rinsing of the circuit (for that, 4.5).

FUNCTIONS

Position of the

index on the

wheel

Position of the valves State of the

sections

Power

take-off

A B C D

Priming / Filling the main tank from

outside Closed 540 rpm

Mixing the product via the hopper using

the rinsing tank Closed 540 rpm

Filling the main tank from outside Closed 540 rpm

Mixing the product via the hopper using

the main tank Closed 540 rpm

Spraying

Without agitation

Open 540 rpmWith 50% agitation

Between and

With 100 % agitation

Rinsing the boom using the rinsing tank

(clean water) Open 300 rpm

Rinsing the main tank using the rinsing

tank (clean water) Closed 300 rpm

Rinsing the main tank using the main tank Closed 300 rpm

External washing option Closed 300 rpm

Isolating the circuit (cleaning the lters) Closed 0 rpm

WARNING

All operations on valves must be done with the power take-off stationary.

16

B

D

C

A

82.526 - HERMES 17

4.5 COMPLETE RINSING FUNCTIONS: POSITIONS 11-15

The rinsing cycle provides thorough rinsing at the end of the day or when there is a change of product.

FUNCTIONS

Position of

the wheel

index

Position of the valves State

of the

sections

Power

take-off Time

A B C D

Rinsing the boom using the rinsing

tank (clean water) Open 300 rpm 15 s

Rinsing the main tank using the

rinsing tank Closed 300 rpm 15 s

Rinsing the boom and the agitation

circuit with the rinsing tank Open 300 rpm 15 s

Rinsing the product mixing circuit via

the hopper using the mixing tank Closed 300 rpm 15 s

Spraying the bottom of the main tank Open 300 rpm 15 s

17

B

D

C

A

4.6 ADJUSTING CALIBRATED RETURNS

The distributor unit consists of electric check valves (V.E.C.) (2) for each boom section.

These valves supply lling each boom section in the "open" position (spraying) and the return to tank in the

"closed" position.

calibrated return adjustment

• The tank return is calibrated by means of a

micrometer screw (3).

• Adjust the screw (3) to obtain the same pressure on

the pressure gauge (1) in both positions "closed"

and "open" (spraying). Carry out this operation for

each electric check valve.

• Use the electric switches on the control box to start

and stop spraying. 18

3

1

2

18 82.526 - HERMES

5. SPRAYER MAINTENANCE

5.1 PRACTICAL ADVICE

regular maintenance

By cleaning your sprayer regularly during and at the

end of spraying programs:

• You will avoid spreading phytosanitary residues on

crops,

• You will ensure a good distribution of the product

by avoiding clogged nozzles,

• You will extend the life of your sprayer.

fOam fOrming in the tank

If this occurs, reduce the motor speed to below

540 rpm or add an anti-foaming additive to the tank

contents during lling.

final fill:

When lling the tank for the last time, add only the

amount of water and product necessary to spray the

remaining area of eld.

maintenance at the end Of treatment:

The whole of the equipment should be rinsed internally

(including tanks, booms and nozzles) by following the

procedures ( 4.5, page 17).

• Wash the outside of the sprayer ( 5.4, page 19).

• Check the cleanliness of the nozzles and lters

(5.2 and 5.3).

• Put the sprayer away.

WARNING:

Carry out sprayer maintenance

operations with the tractor engine

switched off, the ignition off and the

power take-off disengaged.

i

IMPORTANT:

Do not add fuel oil to the spraying

mixture as an anti-foaming agent.

5.2 FILTERS

main tank suctiOn filter

The suction lter (2) is located in the control station.

To clean the lter cartridge, you must position the

index on the wheel on function and valve (B) in

position ( 4.4, page 16).

To remove the lter cartridge, unscrew nut (1) from

the lter.

NOTE:

6/10 mesh lter cartridge tted as

original equipment (10/10 available as

a replacement for liquid fertiliser).

rinsing tank suctiOn filter

The suction lter is located between the tank outlet

connector and the non-return valve.

delivery filter

The delivery lter (3) is located in the control station.

It provides additional ltering.

To clean the filter cartridge, you must place the

index on the wheel on function and valve (B) in

position ( 4.4, page 16).

To remove the lter cartridge, unscrew nut (4) from

the lter.

NOTE:

4/10 mesh lter cartridge tted as

original equipment (8/10 available as a

replacement for liquid fertiliser).

19

1

4

3

B

2

i

IMPORTANT:

The lter cartridge must be cleaned

after every application. Grease seals.

82.526 - HERMES 19

5.3 CLOGGED NOZZLES

Clean with a brush and rinse clogged nozzles with water.

For this, use the brush/wrench (BERTHOUD reference

779.354).

WARNING:

Never blow into a nozzle.

5.4 EXTERNAL WASHING OPTION

• Unclip the brush..

• Attach it to the quick connector on the unwinder.

•

S

et the index on the wheel to function

( 4.4, page 16)

and then proceed with cleaning.

• When washing is complete, put the brush back

in its place.

The use of a detergent is recommended to facilitate

cleaning:

- All Clean (5 l) BERTHOUD reference 788.796.

- All Clean Extra NF (5 l) BERTHOUD reference

788.792.

i

WARNING:

We recommend that you wash the

outside of the sprayer, once rinsing is

complete ( 4.5, page 17) to avoid

contaminating the outside again.

5.5 PROTECTION AGAINST OXIDISING AGENTS.

• Prior to treatments using liquid fertiliser, it is desirable to protect the equipment and boom completely

by spraying with an oily product, so as to prevent any attack by rust or deterioration of the paintwork.

• Rinsing with a pressure jet after treatment will remove any trace of dust and the oily product

5.6 CHECK BEFORE THE SPRAYING SEASON STARTS

Filters: Make sure that the suction and delivery lters are clean and in good condition.

Pipes: Look for any leaks. Check for kinks in the pipes.

Seals and connectors: Check that connection nuts are tightened and change seals if necessary.

Pump, reduction gear, angle transmission: Check the oil levels.

Nozzles: Change the nozzles once per year or if their ow rate is 10% to 15% greater than their initial ow rate.

For this use FLOW TEST, BERTHOUD reference 765.241 or FLOW COMPARATOR, BERTHOUD reference

778.887.

Tank: Check that there is no foreign matter in the tank.

20 82.526 - HERMES

5.7 PERIODIC MAINTENANCE TABLE

Inspection points Every

treatment Monthly After winter

storage

Before winter

storage

Rinse the tank X X

Rinse the spraying circuit X X X

Clean the suction lter X X

Clean the delivery lter X X

Clean the nozzles X

Check the road signals X

Apply moisture repellent product to electrical connectors X X X

Clean and grease transmissions (universal joint) X(or max. 50h) X X

Condition of cables X X

Condition of safety devices X X

Alignment of nozzle carriers and nozzles X X

Alignment of the boom arms X X

Grease friction parts X X

Grease mechanical joints X

Oil level in pump X

Clean the drip preventer X

Clean the outside X

Check the ow through nozzles X

Check the drip preventer X

Drain the pump X

Check the pressure in the nitrogen lifting bulb (depending

on boom) X

5.8 WINTER STORAGE OF THE SPRAYER

• The sprayer must be clean before winter storage.

• Rinse the entire circuit thoroughly (with the cleaning

product)

(

4.5, page 17

)

.

• Drain the tank.

• Rinse with clean water.

• Completely drain the uid circuit, making sure that

the pump is not operated for too long without water

(2 minutes maximum).

• Protect from frost by adding the necessary quantity

of anti-freeze to provide the level of protection

required.

• When adding anti-freeze, take into consideration

the residual volume in the circuit pipework.

• Run the pump at idling speed.

• Operate all valves in all positions, so as to protect

the pump valves, regulator, lters and pipes.

• Open the sprayer to let anti-freeze into the boom.

When the anti-freeze reaches the nozzles, stop

spraying and disengage the power take-off.

• Check the level of protection using an anti-freeze

tester, by taking a sample and adjusting the

dosage, if necessary.

• Grease or oil metal parts and moving parts where

rust can occur.

• Remove oxidation from contacts on electrical

connectors (BERTHOUD reference 765.065,

aerosol KF F2).

• Clean the outside of the equipment

( 5.4, page 19), re-paint any bare mechanical

parts (BERTHOUD reference 769.077 for the

blue paint aerosol or 778.890 for the green paint

aerosol).

• Store the equipment out of the sun and sheltered

from bad weather on at, rm ground.

This manual suits for next models

2

Table of contents

Other Berthoud Paint Sprayer manuals

Berthoud

Berthoud ULV User manual

Berthoud

Berthoud PULVASOL 200 User manual

Berthoud

Berthoud VERMOREL 3000 ELECTRIC User manual

Berthoud

Berthoud ELYTE 2 360 EPDM User manual

Berthoud

Berthoud COSMOS 18 PRO User manual

Berthoud

Berthoud VANTAGE E.C.TRONIC 28-30 User manual

Berthoud

Berthoud ALTO 300 User manual

Berthoud

Berthoud RAPTOR 2540 User manual

Berthoud

Berthoud ELYTE 2 VITON User manual

Berthoud

Berthoud VERMOREL 3000 ELECTRIC User manual