Berthoud ALTO 300 User manual

1

82493 - ALTO

ALTO 300/400/600/800

82.493-A ENGLISH

To be read attentively

and kept for further reference

Safety, checks and maintenance of the sprayers: see manual 82.471

Tables of NOZAL nozzles: see manual 82.467

BERJUST 2: see manual 82.389

TLP 7 boom: see manual 82.232

RA boom: see manual 82.354

GC 9 boom: see manual 82.235

XR 12 boom: see manual 82.396

EC 9/12 boom: see manual 82.388

Hopper: see manual 82.413

© BERTHOUD Agricole 09/2010

82.471

82.467

82.389

82.235

82.396

82.354

82232

82388

282493 - ALTO

3

82493 - ALTO

Voir pages

- General and safety

(see manual No. 82.471)

. Technical specications - ALTO 300/400/600/800 ----------------- 6

. Sound measurements----------------------------------------------------- 7

. Dimensions ------------------------------------------------------------------ 7

. Descriptive plate ------------------------------------------------------------ 8

. Table of weights------------------------------------------------------------- 8

. Position of safety stickers - ALTO 300/400 -------------------------- 9

. Position of safety stickers - ALTO 600/800 -------------------------- 10

- Starting-up the sprayer

(see manual No. 82.471)

. Rinsing the sprayer before rst use------------------------------------ 12

.

Checks to be carried out every time before the sprayer is used

--- 12

. Calculating boom ow per minute-------------------------------------- 12

. Valves of options ----------------------------------------------------------- 13

- Choice of nozzles and tables of ow rates

(see manual No. 82.467)

- Using the sprayer - Constant pressure version

ALTO 300/400/600/800

.Filling -------------------------------------------------------------------------- 16

. Spraying ---------------------------------------------------------------------- 18

. Rinsing the equipment ---------------------------------------------------- 20

- Using the sprayer - D.P.M. version - ALTO 600/800

. Adjustment of the compensated return ------------------------------- 24

.Filling -------------------------------------------------------------------------- 26

. Spraying ---------------------------------------------------------------------- 28

. Rinsing the equipment ---------------------------------------------------- 30

- Other sprayer functions

. Incorporation hopper - ALTO 300/400/600/800 --------------------- 34

. Height of the boom--------------------------------------------------------- 36

. Stirring------------------------------------------------------------------------- 36

. Draining the tank ----------------------------------------------------------- 36

. Handwash tank ------------------------------------------------------------- 36

. Rinsing tank------------------------------------------------------------------ 36

.Rinsing cans ----------------------------------------------------------------- 38

. Rinsing the main tank (optional)---------------------------------------- 38

. Safety valve------------------------------------------------------------------ 38

. Suction lter------------------------------------------------------------------ 38

. Delivery lter----------------------------------------------------------------- 38

- Maintenance of the sprayer

(see manual No. 82.471)

. Practical recommendations for the servicing of your sprayer --- 42

. Checks before spray season -------------------------------------------- 42

. Foaming into the tank ----------------------------------------------------- 42

. Nozzles or lters dirty ----------------------------------------------------- 42

. Last lling operation ------------------------------------------------------- 43

. Maintenance after operation--------------------------------------------- 43

. Winter storage--------------------------------------------------------------- 43

. Protection against oxidising agents------------------------------------ 44

. Servicing the boom -------------------------------------------------------- 44

. Lubrication and greasing ------------------------------------------------- 45

- Maintenance diagram

. Spraying circuit-------------------------------------------------------------- 48/49

. Remember your parameters--------------------------------------------- 50

. Notes on the treatments carried out during the season ---------- 51

contents

482493 - ALTO

5

82493 - ALTO

General safety measures.

Hitching, unhitching.

Maintenance.

Adapting the PTO shaft.

Meaning of the safety stickers.

Acceptable use of the sprayer.

Counter indications.

Warning.

See "Safety, checks, maintenance of the Sprayers": manual No. 82.471.

GENERAL

AND

SAFETY

682493 - ALTO

• CHASSIS:

- Steel chassis protected by polyurethane paint.

• HITCHING:

- 2-point hitching on ALTO 300/400.

- 3-point hitching on ALTO 600/800.

• Universal PTO SHAFT.

• TANKS:

- Spraying: 300/400/600/800 litres high-density

polyethylene tank with large ll opening.

- Rinsing tank: 40 litres (ALTO 300/400) or 80 litres

(ALTO 600/800).

- 15-litre handwash tank.

• DIAPHRAGM PISTON PUMP:

- BP 60/20 (20 bar - 60 l/min) for constant pressure

version.

-

BP 105/20 (20 bar - 105 l/min) for D.P.M. version.

• FILLING AND FILTRATION:

- Filling by manhole or external suction (optional).

- Filtration:

▪ Suction lter (lter cartridge, mesh 6/10),

▪ lling lter (lter, mesh 8/10),

▪ delivery lter (lter cartridge, mesh 4/10).

• STIRRING: hydraulic by no-sprayed liquid return to

tank.

• CONTROL:

- Constant pressure version:

▪ ALTO 300/400/600/800.

- D.P.M. version:

▪ ALTO 600/800.

• DISTRIBUTION:

BERTHOUD distribution manual control unit,

including:

- Glycerine pressure gauge, 0-25 bar, diameter 63 mm.

- Constant pressure version:

▪ 1 general quarter turn shutoff valve,

▪ 1 manual regulating valve,

▪ 2 or 3 supply shutters of the spraying boom's

sections (depending on boom).

- D.P.M. version:

▪ 1 general quarter turn shutoff valve,

▪ 1 manual regulating valve,

▪ 3 supply shutters of the spraying boom's sections

with multireturn units.

• BOOMS:

-

TLP 7 metres (see manual 82.232).

- GC 9 metres (

see manual

82.235).

- XRT/XRS 12 metres (

see manual

82.396).

- RA 12 metres (

see manual

82.354).

- ECO 9/12 metres (

see manual

82.388).

• OPTIONS:

- Hose reels.

- 0.60 m gun with 10 m of hose.

- Filling with hydro-injector.

- 6 metres ller hose with strainer.

- Independent lling hopper.

- Rinsing ball.

- Berjust 2 (in-cab display monitor showing speed

and volume/hectare).

- Rinsing cans.

- 1 main shutoff electric valve

- Large diameter manometer (Ø 80).

- RA 12 to RA 15 boom extension kit.

TECHNICAL SPECIFICATIONS

ALTO 300/400/600/800

7

82493 - ALTO

DIMENSIONS

ALTO without boom (in mm):

SPRAYERS A BC

ALTO 300 780 1,640 740

ALTO 400 930 1,640 1,080

ALTO 600 1,300 1,640 1,350

ALTO 800 1,650 1,640 1,530

ALTO with boom (in mm):

SPRAYERS BOOMS > TLP 7 GC 9 XRT 12

XRS 12 RA 12 ECO 9 ECO 12

ALTO 300

ALTO 400

Overall width 2,600

Overall length 1,600

Overall height 1,630

ALTO 600

ALTO 800

Overall width 2,610 2,700

Overall length 1,730 2,150

Overall height 2,200 2,540

C

B

A

SOUND MEASUREMENTS

Atmospheric noise emitted by: Mounted sprayer ALTO with BP 60 or BP 105 pump

Comply with the legislation in force and use ear-protectors if necessary.

Tractor and sprayer

running

Tractor P.T.O. disengaged,

sprayer at rest

Maximum sound pressure:

- at product mixer level 80 dB (A) 73.5 dB (A)

- at the tractor driver’s cabin,76 kW 72 dB (A) 70 dB (A)

Maximum sound power:

- Tractor alone = 99.1 dB (A)

- Tractor + sprayer = 99.8 dB (A)

882493 - ALTO

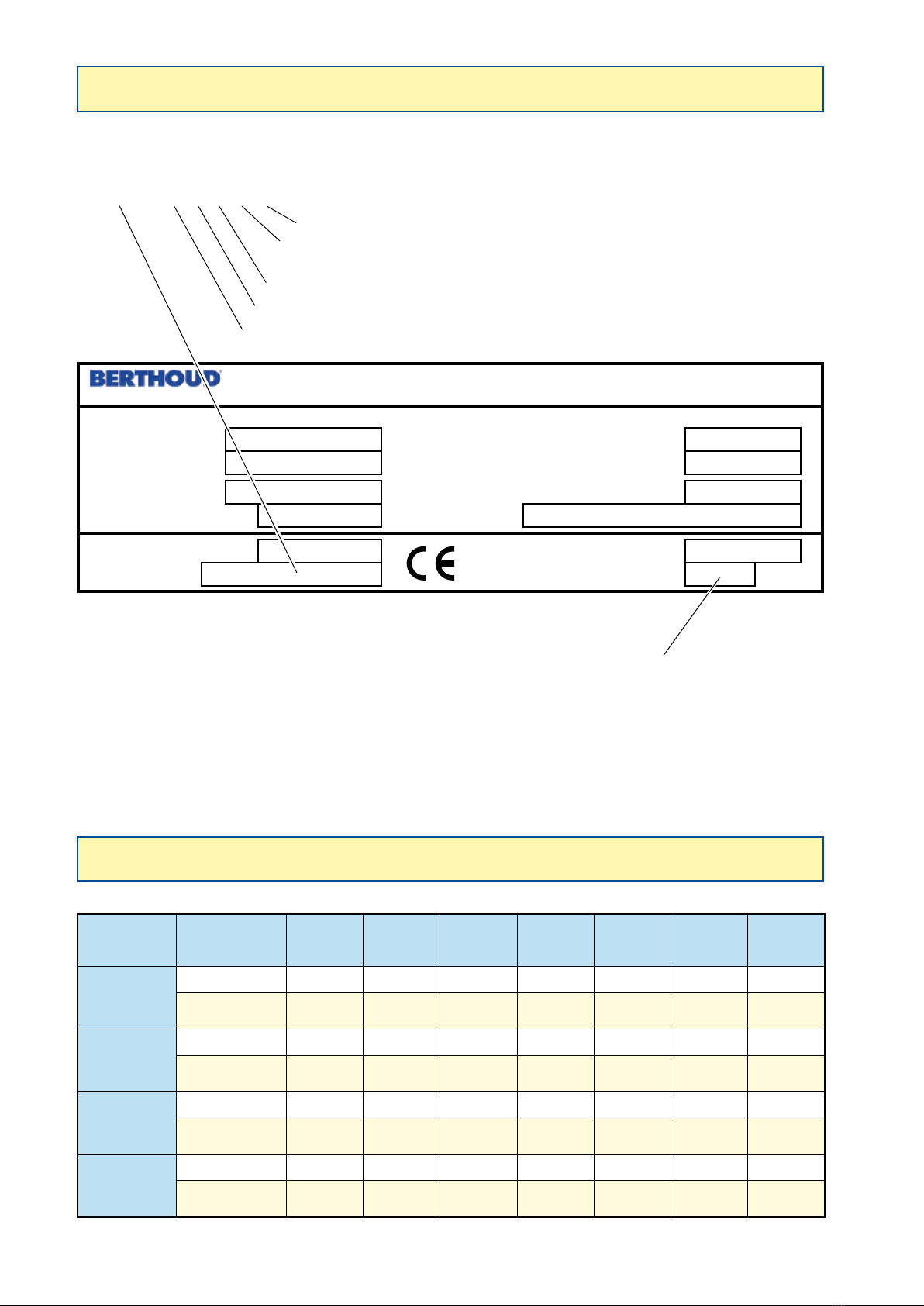

ZI Bois Baron - 1 rue de l’industrie Pulvérisateurs – Sprayers – Spritzgeräte

69220 BELLEVILLE s/SAÔNE – France Pulverizadores – Polverizzatorri

Homologation - Approval Poids - Weight

N° Identification PTAC - Laden weight - Zul.Gesamtgewicht - MMA kg

kg

kg

Réceptionné le - Regist.Date Par - By

N° Série Berthoud PV - Curb weight - Stutzlast - Tara kg

Type Berthoud Année fabrication - Manufacturing year 20

Agricole

TVV - Type approval

N° Dossier - N° File

Poids/essieu - Axle Weight - Zul. Achslast - MMA eje

Poids/anneau - Ring Weight - Zul. Zugöse - MMA anillo

The sprayer's identication plate is located on the chassis (see pages 9 and 10).

- The box "Type Berthoud" is made up of letters and gures.

- Example: ALT M 06 XR 12

12 = width 12 metres

XR = XRT 12 and XRS 12 boom

(TL = TLP 7, GC = GC 9, RA = RA 12, EC = ECO 9-12)

06 = Rated capacity 600 litres (03 = 300 litres, 04 = 400 litres, 08 = 800 litres)

M = Manual regulation (R = Autoregleur regulation, E = Electric regulation)

ALT = ALTO

DESCRIPTIVE PLATE

TABLE OF WEIGHTS

Year and month of manufacture

SPRAYERS BOOMS >TLP 7 GC 9 XRT 12

XRS 12 RA 12 ECO 9 ECO 12 Without

boom

ALTO 300

Kerb weight (kg)

Gross vehicle

weight (kg)

ALTO 400

Kerb weight (kg) 135

Gross vehicle

weight (kg) 635

ALTO 600

Kerb weight (kg)

Gross vehicle

weight (kg)

ALTO 800

Kerb weight (kg) 400

Gross vehicle

weight (kg) 1,365

9

82493 - ALTO

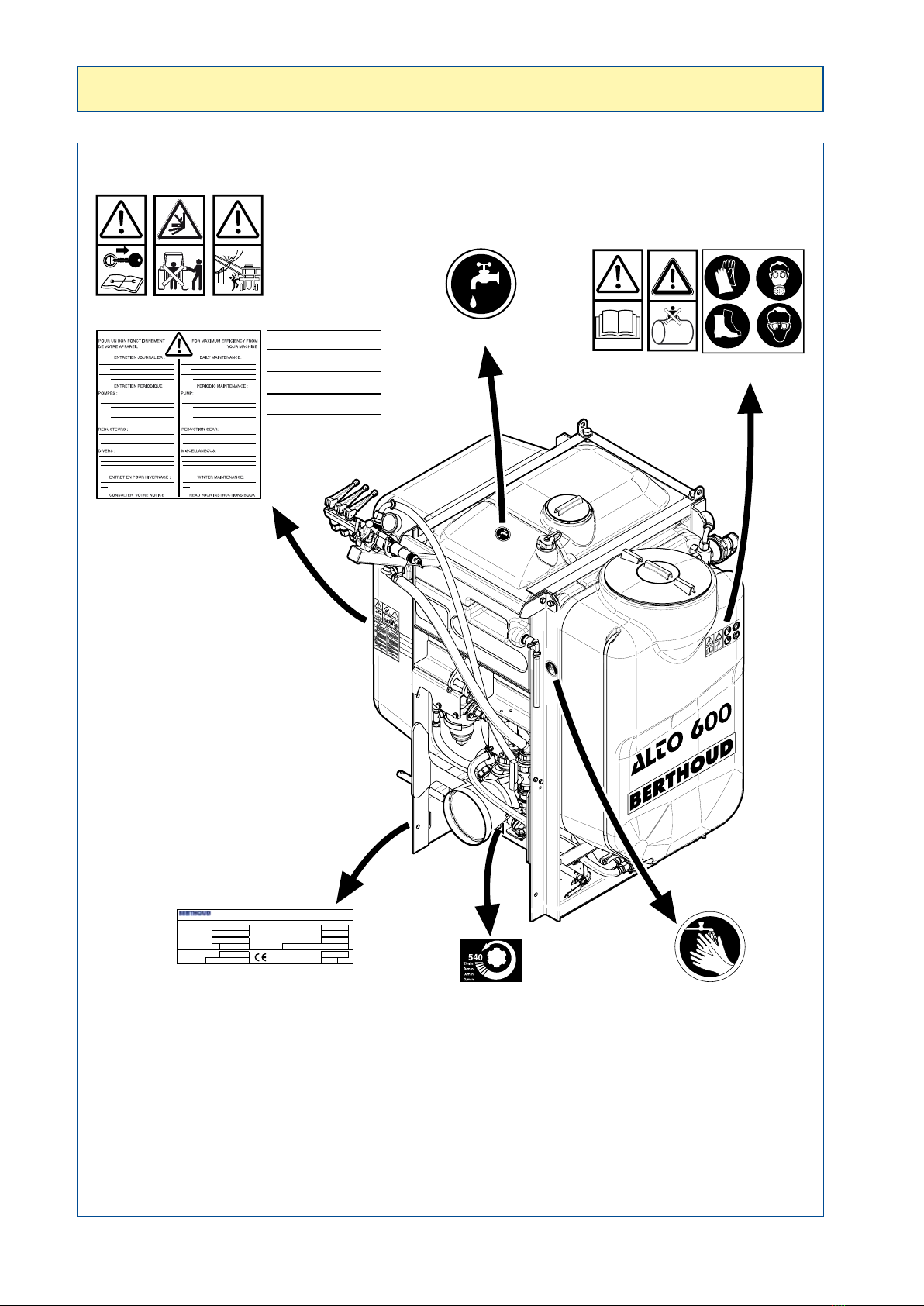

It is very important to keep the safety stickers in location and in good condition as they draw your attention

to possible dangers and refer to the operator's manual.

Check their location on the sprayer and see their meaning in manual 82.471 (Safety, checks and

maintenance of the sprayers).

POSITION OF SAFETY STICKERS - ALTO 300/400

ATTENTION

ATTENTION

VORSICHT

ATENCION

417.576

417.465

417.572 417.597 418.630

418.629

417.575 417.579

417.586

417.289

ATTENTION

ATTENTION

VORSICHT

ATENCION

ZI Bois Baron - 1 rue de l’industrie Pulvérisateurs – Sprayers – Spritzgeräte

69220 BELLEVILLE s/SAÔNE – France Pulverizadores – Polverizzatorri

Homologation - Approval Poids - Weight

N° Identification PTAC - Laden weight - Zul.Gesamtgewicht - MMA kg

kg

kg

Réceptionné le - Regist.Date Par - By

N° Série Berthoud PV - Curb weight - Stutzlast - Tara kg

Type Berthoud Année fabrication - Manufacturing year 20

Agricole

TVV - Type approval

N° Dossier - N° File

Poids/essieu - Axle Weight - Zul. Achslast - MMA eje

Poids/anneau - Ring Weight - Zul. Zugöse - MMA anillo

417.590

10 82493 - ALTO

It is very important to keep the safety stickers in location and in good condition as they draw your attention

to possible dangers and refer to the operator's manual.

Check their location on the sprayer and see their meaning in manual 82.471 (Safety, checks and

maintenance of the sprayers).

POSITION OF SAFETY STICKERS - ALTO 600/800

417.576

417.590 417.465

417.572 417.597 418.630

418.629

417.575 417.579

417.586

417.289

ATTENTION

ATTENTION

VORSICHT

ATENCION

ATTENTION

ATTENTION

VORSICHT

ATENCION

ZI Bois Baron - 1 rue de l’industrie Pulvérisateurs – Sprayers – Spritzgeräte

69220 BELLEVILLE s/SAÔNE – France Pulverizadores – Polverizzatorri

Homologation - Approval Poids - Weight

N° Identification PTAC - Laden weight - Zul.Gesamtgewicht - MMA kg

kg

kg

Réceptionné le - Regist.Date Par - By

N° Série Berthoud PV - Curb weight - Stutzlast - Tara kg

Type Berthoud Année fabrication - Manufacturing year 20

Agricole

TVV - Type approval

N° Dossier - N° File

Poids/essieu - Axle Weight - Zul. Achslast - MMA eje

Poids/anneau - Ring Weight - Zul. Zugöse - MMA anillo

11

82493 - ALTO

Checking power take-off speed.

Checking tractor advance speed.

Checking engine speed.

Checking ow/hectare.

Checking tractor wheel circumference.

See "Safety, checks, maintenance of the Sprayers": manual No. 82.471.

STARTING-UP

THE

SPRAYER

12 82493 - ALTO

- Remove the nozzles if they are tted.

- Undo the end plugs on the pipes.

- Fill 1/5th of the volume of the tank with water.

- Spray (Refer to the OPERATION chapter of the pump).

- Remove and clean the lters.

- Retighten the pipe end plugs.

- Fit the nozzles.

NOTE: Any foreign particles which may be in the spraying circuit will thus be eliminated and there will be no

risk of them blocking the holes in the nozzles.

RINSING THE SPRAYER BEFORE FIRST USE

Rinse the sprayer completely with clean water, before using phytosanitary products

(weed killers, insecticide or other product) in your sprayer for the rst time.

CHECKS TO BE CARRIED OUT EVERY TIME BEFORE

THE MACHINE IS USED

- Check the condition of the protectors on the drive shafts.

- Make sure that there is no foreign matter into the tank.

- Check the condition of the hoist as well as the boom's lifting rope.

- Check the oil levels and the greasing of the various elements (see "Lubrication and greasing" section).

- Check the cleanness of the lters:

▪ Suction,

▪ delivery.

CALCULATING BOOM FLOW PER MINUTE

- To obtain the desired boom ow per minute, the traditional formula is used:

Boom ow = Volume/hectare x width treated x Advance speed

600

Example: We wish to spray 500 litres/hectare with a 9 metres boom and at a calibrated

tractor speed of 6.8 km/h.

We obtain: Boom ow per minute = 500 x 9 x 6.8 = 51 litres/minute

600

- It is most important that maximum pump ow should satisfy the demands made on it for the desired spraying

conditions (advance speed, volume/hectare, width treated).

- The boom ow per minute should be 10 % less than maximum pump ow to ensure liquid return to the tank

and thus hydraulic agitation.

Pump Maximum pump ow Maximum boom ow Minimum return ow to tank

BP 60/20 60 l/min 54 l/min 6 l/min

BP 105/20 100 l/min 90 l/min 10 l/min

13

82493 - ALTO

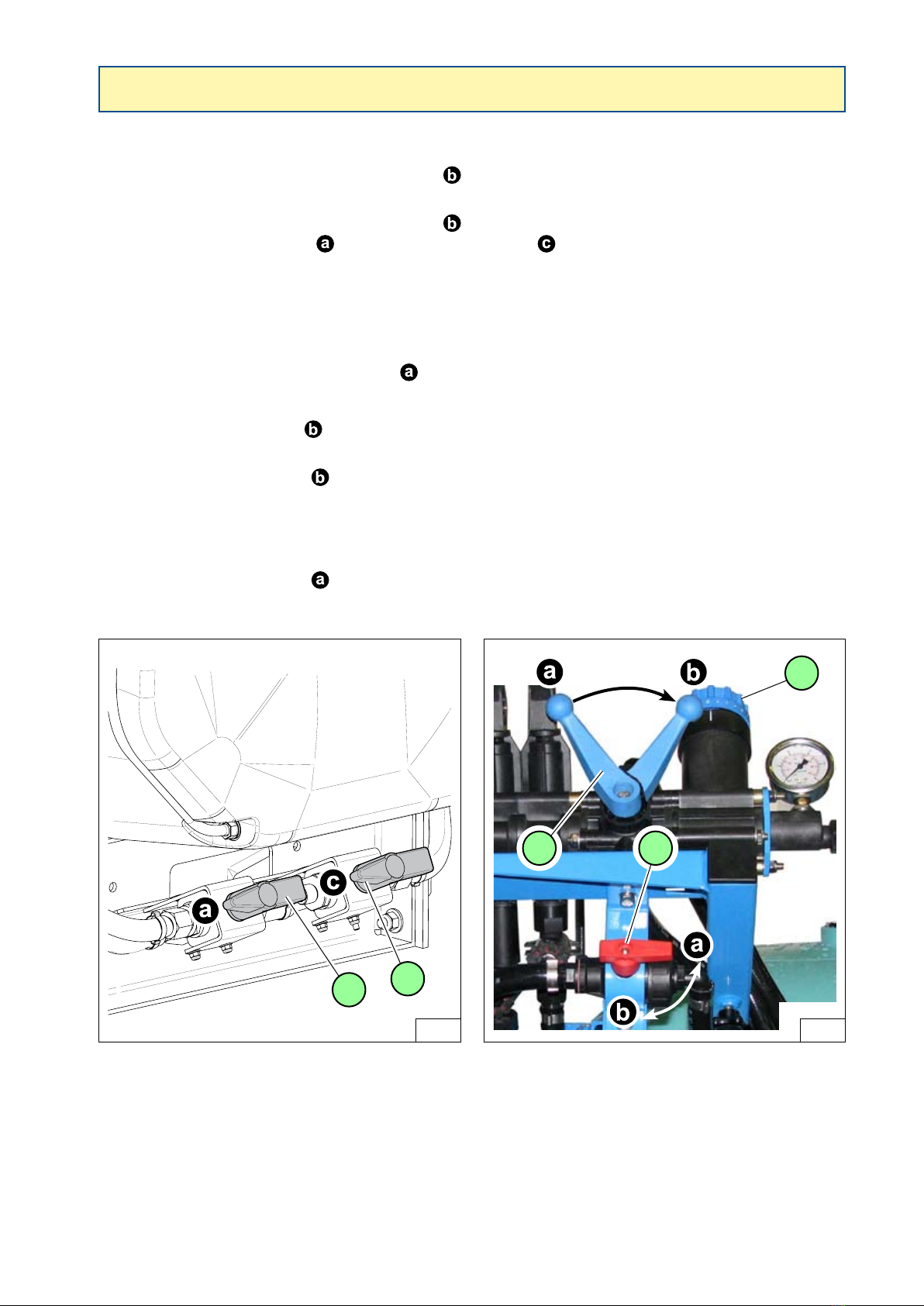

With one option on the equipment:

- Put the handle of the main valve (V2) in position (gure 7, page 19).

With several options:

- Put the handle of the main valve (V2) in position (gure 7, page 19).

- Put the valve (1) in position or the valve (2) in position (see gure 1) according to the selected

options.

WITH THE VALVES OF OPTIONS (gure 2)

In spraying mode:

- The valve (V3) must always be in position (opened).

In option mode:

- The valve (V2) is in position .

- Adjust the regulator (1) at position 1 (mini pressure).

- Put the valve (V3) in position (closed).

- Adjust the regulator (1) to obtain the desired pressure.

To exit the option mode:

- Adjust the regulator (1) at position 1 (mini pressure).

- Put the valve (V3) in position (opened).

VALVES OF OPTIONS

2

V3V2

1

12

1

14 82493 - ALTO

15

82493 - ALTO

CHOICE OF NOZZLES

AND

TABLES OF FLOW RATES

See "NOZAL nozzles"

Manual No. 82.467

USING THE SPRAYER

CONSTANT PRESSURE VERSION

ALTO 300/400/600/800

Berjust 2 monitor option,

see manual No. 82.389

16 82493 - ALTO

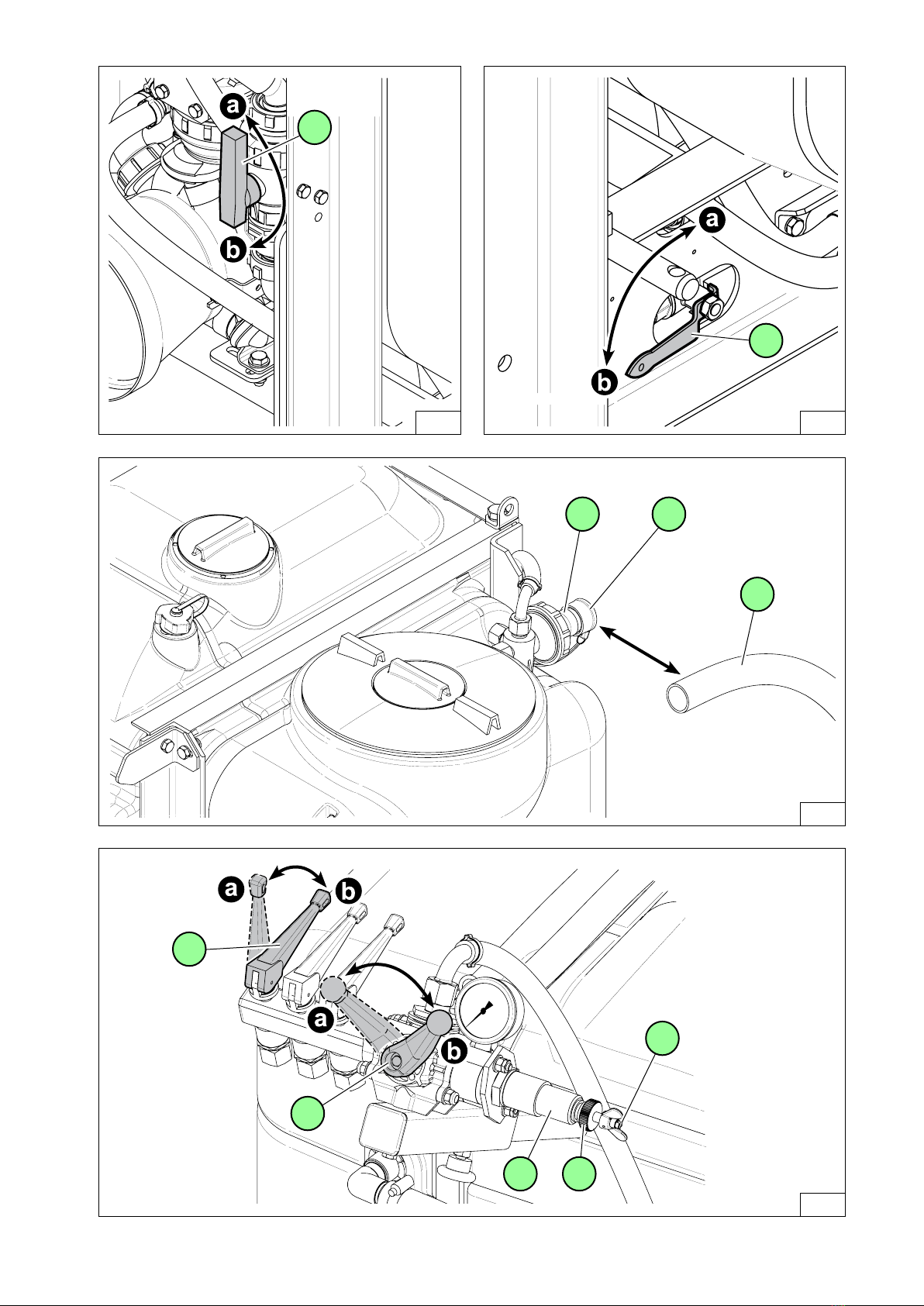

FILLING

- Close the drain valves.

According to the cases:

▪ Put the valve (V1) (gure 3) to opened position .

▪ Put the valve (V4) (gure 4) to closed position .

OPERATION WITHOUT FILLER HOSE

- Remove the lid on the top of the tank.

- Fill through the ller hole of the main tank

USING THE FILLER HOSE

- For this system to work properly, it is necessary to have some water into the main tank to prime the pump

before starting it.

- Pour 30 to 50 litres of water, through the lter, into the ller hole.

NOTE: The lling ow rate can be increased considerably using the hydro-injector (1) (gure 5).

CONNECTING THE FILLER HOSE (gure 5)

Connect it directly to the hydro-injector’s (1) suction hose:

- Remove the plug (2) and connect the ller hose (3).

ADJUSTING THE DISTRIBUTION UNIT (gure 6)

- Put the valve (V1) in position (gure 3).

- Put the supply shutters (1) of the spraying boom's sections at position .

- Put the handle of the main valve (V2) in position .

- Adjust the pressure to the maximum using the regulator (2), for that, untighten the knurled nut (3) and screw

the regulator stem (4) fully.

FILLING

1. Engage the tractor’s power take-off and raise its rotation speed to 540 rpm.

2. Your tank will start to ll. Keep the rotation speed of the power take-off at 540 rpm.

WHEN FILLING IS COMPLETE

- Reduce the engine speed (to idle).

- Take the hose (3) (gure 5) out of the water point. This has the effect of emptying it.

- Remove the hose (3) from the hydro-injector (1).

- Ret the plug (2).

17

82493 - ALTO

5

6

43

V4

V1

1

1

2 3

4

2

3

V2

18 82493 - ALTO

SPRAYING

POWER TAKE-OFF SPEED

- With the power take-off connected (following lling), increase its speed to 540 rpm by bringing the needle of

the rev counter opposite the mark (R) (see manual No. 82.471).

ADJUSTING THE VOLUME/HECTARE

In order to program your volume/hectare

- You need to know, for the gear chosen, the forward speed in km/h, at 540 rpm at the power take-off (see

manual No. 82.471).

- Bearing in mind the required volume/hectare, refer to the rate chart of the selected nozzle(s) (see nozzle

manual No. 82.467).

▪ In the column corresponding to the forward speed in km/h, nd: the nozzle and pressure which will enable

the required volume/hectare to be obtained.

Example:

- Speed in km/hour: 6 km/h

- Volume/hectare: 260 litres/ha

- Selected nozzles: ALUMINE AFX (0.50 m spaced).

Possible choice:

- ALUMINE AFX BLUE ........................ 3.5 bar, 256 litres/ha

TO OBTAIN REQUIRED VOLUME/HECTARE

- Fit the chosen nozzles.

- Put the handle of the main valve (V2) in position (gure 7).

- Increase the power take-off speed to 540 rpm.

- Display on the pressure gauge (1) the pressure previously read from the ow rate table, using the screwed

rod (4) on the regulator (2) and lock with the knurled nut (3) (gure 7).

- From now on, you can work.

SPRAYING CONTROL

- Put the valve (V1) in position (gure 3, page 17).

- Put the supply shutters (1) (gure 8) of the spraying boom's sections at position .

- Put the handle of the main valve (V2) in position .

TO STOP THE SPRAYING

Closure of one or more sections:

- Close the shutter or shutters by putting them in position (gure 8).

Total closure:

- Leave the supply shutters in "opened" position and adjust the main valve (V2), putting its handle in

position (gure 8).

19

82493 - ALTO

7

8

1

1

2 3

4

V2

V2

20 82493 - ALTO

RINSING THE SPRAYING CIRCUIT WITH THE RINSING TANK

- Sprayer off.

- Disengage the power take-off.

- Supply shutters (1) in position (gure 9).

▪ Handle of the main valve (V2) in position (gure 9).

▪ Handle of the valve (V1) in position (gure 10).

- Engage the power take-off to idle at 150 rpm max until the rinsing tank is empty.

This operation is not enough when changing the chemical products.

RINSING THE SPRAYING CIRCUIT WITH THE MAIN TANK

For the chemical product changing.

- Sprayer off.

- Put 300 litres of clear water with a cleaning product (ALL CLEAR type) into the main tank.

- Supply shutters (1) in position (gure 9).

▪ Handle of the main valve (V2) in position (gure 9).

▪ Handle of the valve (V1) in position (gure 10).

- Engage the power take-off to idle at 150 rpm max until the main tank is empty.

RINSING THE EQUIPMENT

This manual suits for next models

3

Table of contents

Other Berthoud Paint Sprayer manuals

Berthoud

Berthoud COSMOS 18 PRO User manual

Berthoud

Berthoud WIN'AIR 600 User manual

Berthoud

Berthoud HERMES 800 User manual

Berthoud

Berthoud ELYTE Series Installation and operation manual

Berthoud

Berthoud VERMOREL 3000 ELECTRIC User manual

Berthoud

Berthoud RAPTOR 2540 User manual

Berthoud

Berthoud PULVASOL 200 User manual

Berthoud

Berthoud ELYTE 2 360 EPDM User manual

Berthoud

Berthoud MAXAIR 240 User manual

Berthoud

Berthoud ULV User manual