Berthoud PULVASOL 200 User manual

1

82.321-M - Pulvasol 1 and 2 / Pulvigne

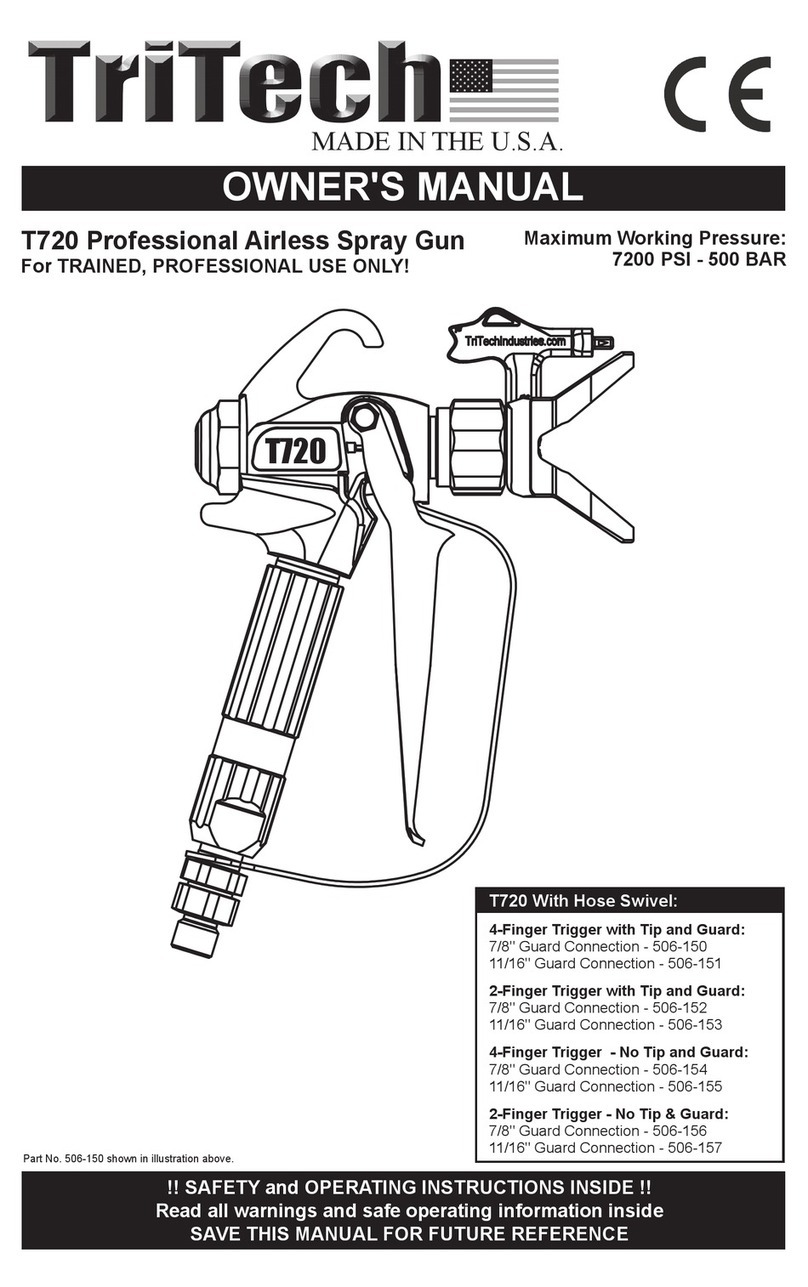

PULVASOL 1 AND 2

PULVIGNE

82.321-M ENGLISH

to be read attentively

and kept for further reference

R

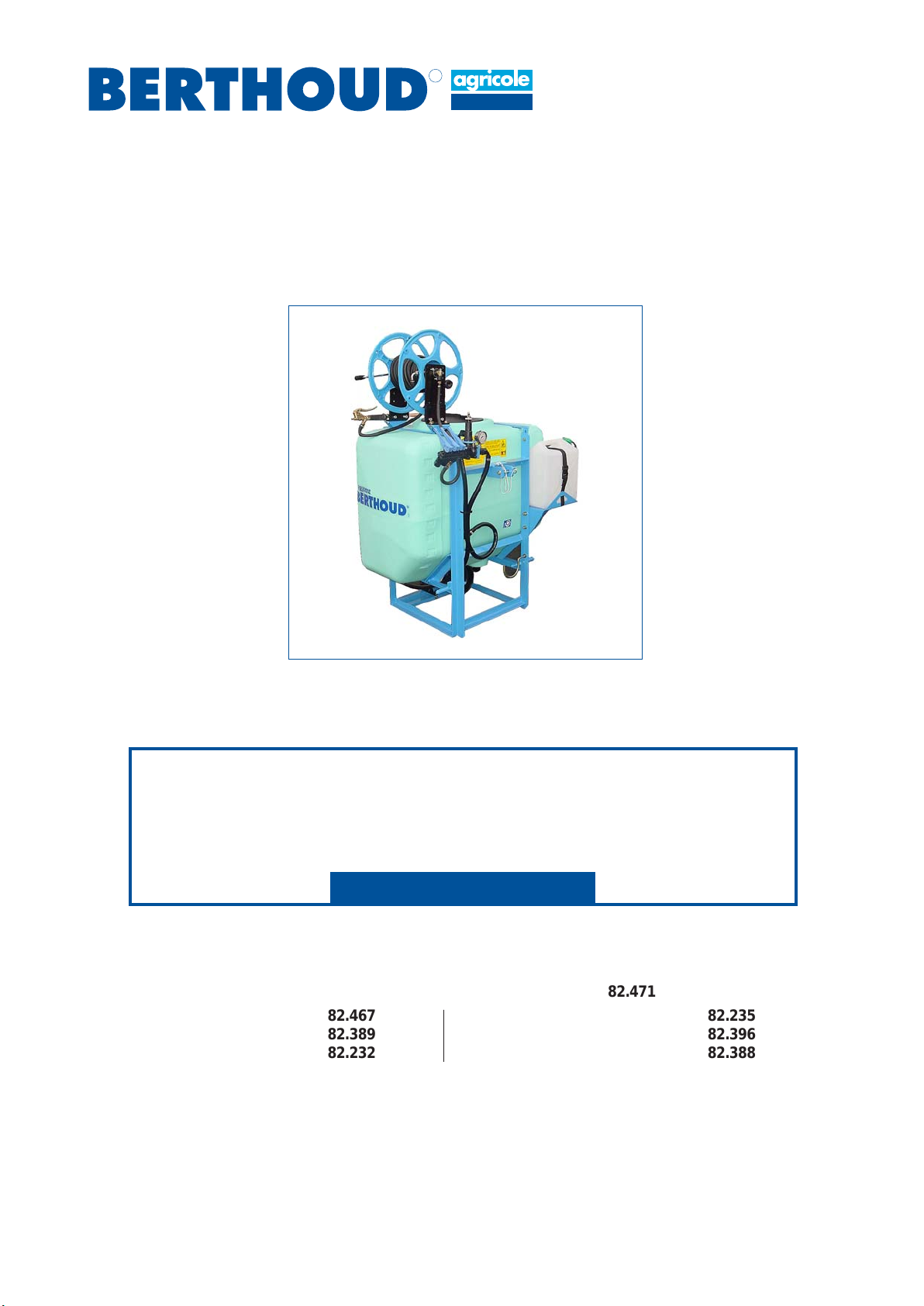

NOZALnozzles: see manual 82.467

BERJUST 2: see manual 82.389

TLP 7 boom: see manual 82.232

Safety, checks, maintenance of the sprayers: see manual 82.471

GC 9 boom: see manual 82.235

XR 12 boom: see manual 82.396

EC 7/9/12 boom: see manual 82.388

© BERTHOUD Agricole 04/2005

82471

82467

82389

82232

82235

82396

82388

282.321-M - Pulvasol 1 and 2 / Pulvigne

3

82.321-M - Pulvasol 1 and 2 / Pulvigne

See pages

- GENERAL AND SAFETY

(See manual No. 82.471)

.Technical specifications............................................................ 7

.Descriptive plate ....................................................................... 8

.Table of weights........................................................................ 8

.Position of the safety stickers ................................................... 9

- STARTING-UP THE SPRAYER

(See manual No. 82.471)

.Rinsing the sprayer before first use .......................................... 12

.

Checks to be carried out every time before the machine is used ....

12

.Calculating boom flow per minute ............................................. 12

- CHOICE OF NOZZLES AND TABLES OF FLOW RATES

(See NOZAL nozzles manual No. 82.467)

- USING THE SPRAYER

(Berjust 2 monitor, see manual No. 82.389)

.Filling ........................................................................................ 14

.Spraying.................................................................................... 16

.Rinsing the equipment .............................................................. 18

.Height of the boom ................................................................... 20

.Stirring ...................................................................................... 20

.Draining the tank....................................................................... 20

- MAINTENANCE OF THE SPRAYER

(See manual No. 82.471)

.Practical recommendations for the servicing of your sprayer ....... 22

.Checks before spray season .................................................... 22

.Maintenance after operation ..................................................... 23

.Winter storage .......................................................................... 23

.Precautions to be taken against frost........................................ 24

.Nozzles or filters dirty................................................................ 24

.Cleaning the filter ...................................................................... 24

.Handwash tank ......................................................................... 24

.Lubrication and greasing........................................................... 26

.Inflation of the air chamber ....................................................... 26

.Operational problems ............................................................... 28

.Product foaming and pressure drop.......................................... 28

- MAINTENANCEDIAGRAMS

.Hydraulic circuit of the PULVASOL sprayer .............................. 30

.Hydraulic circuit of the PULVIGNE sprayer ............................... 32

.Notes on the treatments carried out during the season............. 35

contents

482.321-M - Pulvasol 1 and 2 / Pulvigne

5

82.321-M - Pulvasol 1 and 2 / Pulvigne

Warning.

Acceptable use of the sprayer.

General safety instructions.

Hitching, unhitching.

Maintenance

Adapting the PTO shaft.

Counter-indications.

Meaning of the safety stickers.

See manual "SAFETY, CHECKS, MAINTENANCE" No. 82.471.

GENERAL

AND

SAFETY

682.321-M - Pulvasol 1 and 2 / Pulvigne

7

82.321-M - Pulvasol 1 and 2 / Pulvigne

PULVIGNE

Sprayer

1752

TECHNICAL SPECIFICATIONS

PULVASOL Range

Sprayer with constant pressure control

providing a constant application rate/hectare

for a constant forward speed

- TANK in high density polyethylene of 200/300/400/

600/800 litres capacity.

- STEEL protected by U.H.R. polyester paint.

- FILLING: (see options)

- STIRRING: hydraulicbynon-sprayedliquidreturnto

tank.

- PISTON/DIAPHRAGM PUMP:

- B.P. 60 (60 l/min - 20 bar) or

- B.P. 105 (105 l/min - 20 bar).

- FILTERS:

Suction:

- Filter, mesh 6/10º.

- Valve block comprising:

- a main 1/4 turn valve,

- 3 boom section plugs,

- a pressure regulator,

- a glycerine pressure gauge, 0-25 bars,diameter

60 mm.

- 2 position coupling on 200/300/400 litres.

- Universal joint drive.

- Handwash tank 15 litres capacity.

BOOMS:

TLP 7 metres - GC 9 metres - XRT/XRS T 12 metres.

OPTIONS :

Hose reel,

0.60 m gun with 10 m of hose,

Filling with hydro-injector,

4 or 6 metres filler pipe with strainer,

Independent filling hopper,

Handwash tank 18 litres capacity (except 200 L)

Berjust 2 (in-cab display monitor showing speed and

volume/hectare).

DIMENSIONS

EQUIPMENT A B C

PULVASOL 200 0.80 m 0.51 m 1.22 m

PULVASOL 300 0.85 m 0.75 m 1.25 m

PULVASOL 400 1.10 m 0.75 m 1.25 m

PULVASOL 600 1.30 m 0.90 m 1.40 m

PULVASOL 800 1.77 m 0.95 m 1.60 m

(tank width) (depth) (tank height)

C

B

882.321-M - Pulvasol 1 and 2 / Pulvigne

DESCRIPTIVE PLATE

TABLE OF WEIGHTS

SPRAYERS BOOMS > ECO 9 ECO 12 TLP 7/14 GC 9/18 XRT 12/24 XRST

12/24

Kerb weight 100 120

Gross vehicle

weight 310 320

Kerb weight 135 110 130

Gross vehicle

weight 470 430 450

Kerb weight 140 140 120 130

Gross vehicle

weight 560 560 540 550

Kerb weight 160 160 130 145 260 260

Gross vehicle

weight 790 790 760 775 890 890

Kerb weight 190 190 165 180 295 295

Gross vehicle

weight 1030 1030 1005 1020 1135 1135

PULVASOL 800

Weights in kg

PULVASOL 200

PULVASOL 300

PULVASOL 400

PULVASOL 600

- The location of the descriptive plate on your machine is indicated on the view 3/4 opposite.

- The box "Type" is made up of letters and figures.

- Exemple : PUL M 6 GC 9

Manual, 600 litre PULVASOL,

with a 9 metre GC boom.

The"Kerbweight"and "Gross vehicule weight"boxes

use the data in the table below.

Year of manufacture

The box "No. of series" is made up

of

6 figures.

Example : 95 1042 = order number.

9

82.321-M - Pulvasol 1 and 2 / Pulvigne

417.597

417.579

418.630

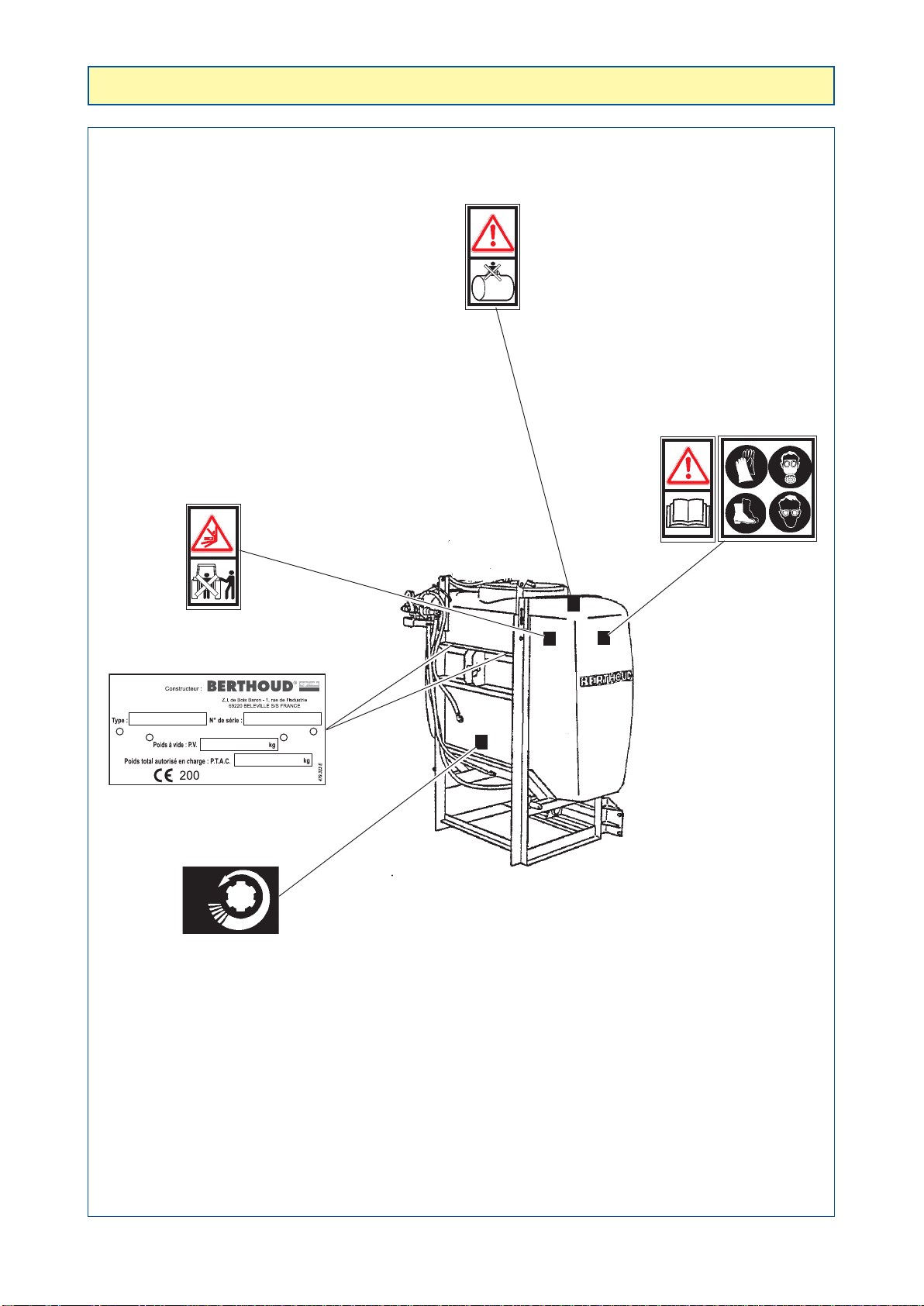

POSITION OF SAFETY STICKERS

417.590

417.572

540

Tmin

Rmin

Umin

Gmin

- PULVASOL -

It is very important that the safety stickers be kept in place and in good

condition as they draw your attention to possible dangers. Refer to the

operator’s manual.

Check their location on the sprayer and refer to Security Manual

No. 82471" for their meaning.

10 82.321-M - Pulvasol 1 and 2 / Pulvigne

11

82.321-M - Pulvasol 1 and 2 / Pulvigne

STARTING-UP

THE SPRAYER

Checking power take-off speed.

Checking forward speed.

Checking engine speed.

Checking flow rate/hectare.

Check of wheel travel distance (Berjust).

See manual "SAFETY, CHECKS, MAINTENANCE" No. 82.471.

12 82.321-M - Pulvasol 1 and 2 / Pulvigne

CALCULATING BOOM FLOW PER MINUTE

To obtain the desired spray configuration, the traditional formula is used:

Boom flow Volume width Advance

x x

hectare treated speed

= -----------------------------------------------

600

Example:

We wish to spray 500 litres/hectare with a 9 metres boom and at a calibrated tractor speed of 6.8 km/h.

We obtain:

- It is most important that maximum pump flow should satisfy the demands made on it for the desired spraying

conditions (advance speed, volume/hectare, width treated).

- The boom flow per minute should be 10 % less than maximum pump flow to ensure liquid return to the tank

and thus hydraulic agitation.

RINSING THE SPRAYER BEFORE FIRST USE

Before using your sprayer for the first time with phytosanitary product

(weedkillers, insecticide or other product), rinse the machine completely.

- Remove the nozzles if they are fitted.

- Undo the end plugs on the pipes.

- Fill 1/5th of the volume of the tank with water.

- Spray (Refer to the pump OPERATION chapter).

- Remove and clean the filters.

- Retighten the pipe end plugs.

- Fit the nozzles.

- Any foreign particles which may be in the spraying circuit will thus be eliminated and there will be no risk of

them blocking the holes in the nozzles.

CHECKS TO BE CARRIED OUT EVERY TIME BEFORE

THE MACHINE IS USED

- Check the condition of the protectors on the drive shafts.

- Make sure that there is no foreign matter in the tank.

- Check the condition of the hoist as well as the boom's lifting rope.

- Check the oil levels and the greasing of the various elements (see "lubrication and greasing" section).

- Check the cleanness filters:

- suction,

- delivery.

500 x 9 x 6.8

= ------------------- = 51 litres/minute

600

Boom flow per minute

Maximum

pump flow Maximum

boom flow Minimum return

flow to tank

Pump

BP 60/20

BP 105/20 60 l/min.

100 l/min. 54 l/min.

90 l/min. 6 l/min.

10 l/min.

13

82.321-M - Pulvasol 1 and 2 / Pulvigne

CHOICE OF NOZZLES

AND

TABLES OF FLOW RATES

USING

THE SPRAYER

See manual No. 82.467

NOZAL nozzles

Berjust 2 monitor option,

see manual No. 82.389

14 82.321-M - Pulvasol 1 and 2 / Pulvigne

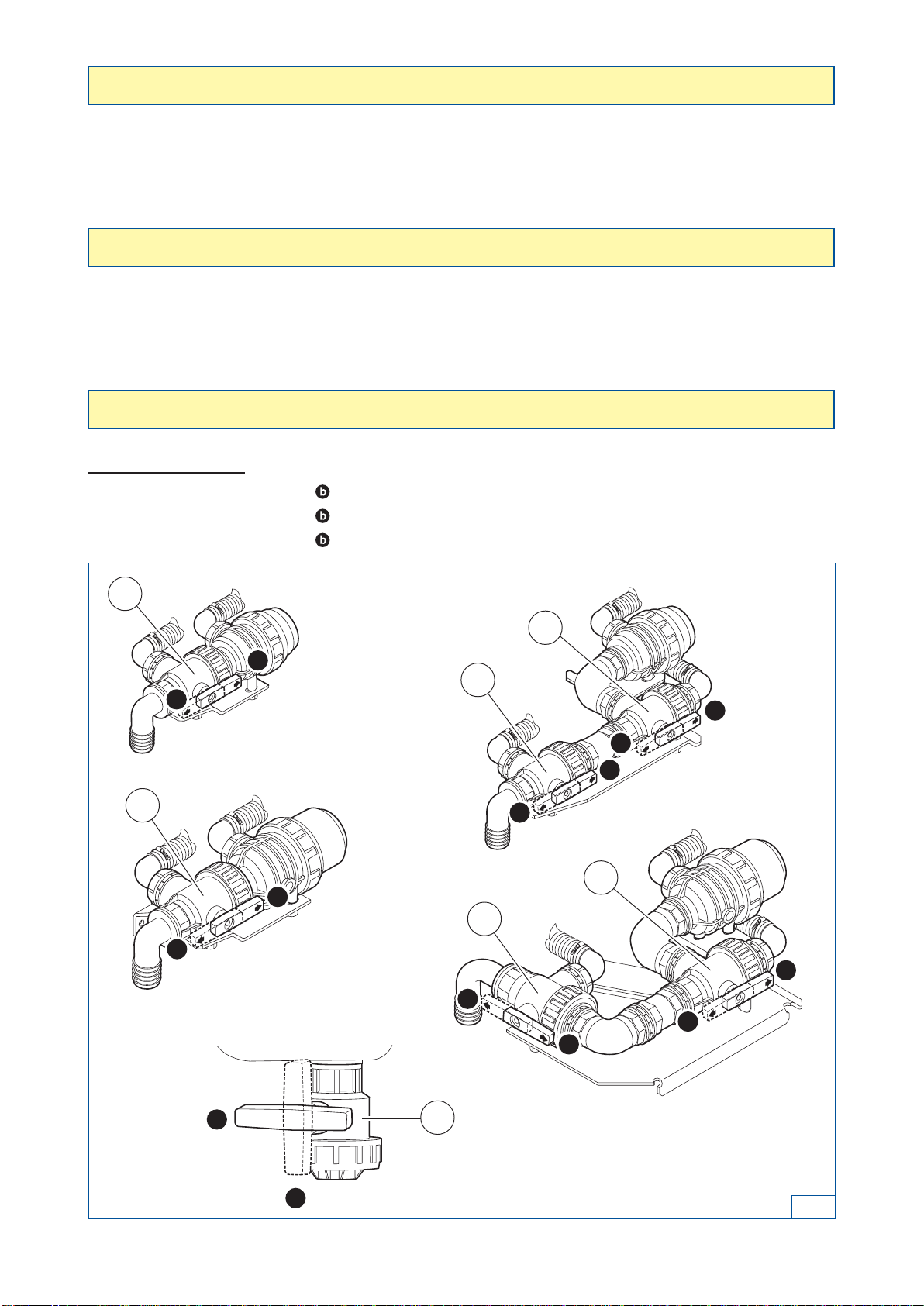

FILLING

- Close the drain valves (see figure 8, page 20)

According to the cases:

- place the valve (V1) in position .

- place the valve (V2) in position .

- place the valve (V4) in position .

OPERATION WITHOUT FILLER PIPE

- Remove the lid on the top of the tank.

- Fill through the filler hole in your tank.

USING THE FILLER PIPE

For this system to work properly, it is necessary to have some water in the tank to prime the pump before

starting it.

- For 30 to 50 litres of water into the filler hole through the filter.

- The filling rate can be increased considerably using the hydro-injector.

SPRAYERS WITH VANNOFILTER (800 L)

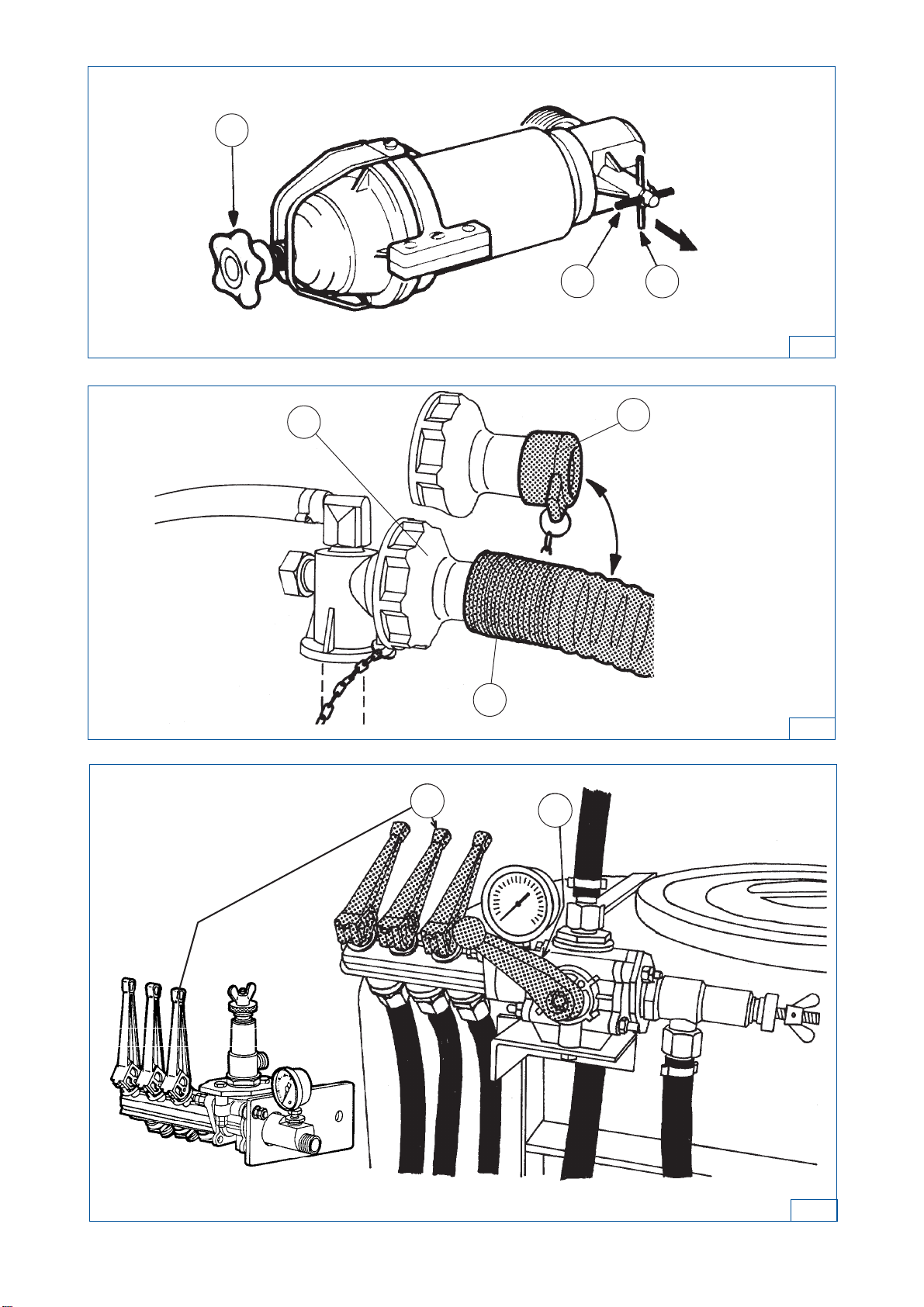

The vannofilter (figure 1) must be open. Check that it is.

- If not: to open it, pull item (1) towards you, then turn it a quarter of a turn to put it in position (2).

- If leaking occurs at the cover, slightly tighten the star-shaped knob (3).

CONNECTING THE FILLER HOSE

-With B.P. pumps (figure 2) :

Connect it directly to the hydro-injector’s (1) suction hose:

- Remove the plug (2) and connect the filler hose (3) in its place.

FILLING

1. Engage the tractor’s power take-off and raise rotation speed to 540 rpm.

2. Your tank will start to fill. Keep the rotation speed of the power take-off at 540 rpm.

3. When filling is complete:

- reduce the engine speed (tick-over),

- take the hose (3) out of the water point. This has the effect of emptying it (3) (figure 2),

- remove the hose (3) from the hydro-injector (1),

- re-fit the plug (2).

ADJUSTING THE CONTROL VALVE (figure 3) :

- With rinsing tank option: place the valves (V3) in position (figure 8, page 20).

- Put the supply plugs on the spray boom sections in position (1).

- Put the handle on the main valve in position (2).

15

82.321-M - Pulvasol 1 and 2 / Pulvigne

3

12

2

12

3

21

3

1

16 82.321-M - Pulvasol 1 and 2 / Pulvigne

OPENING THE VANNOFILTER (case of sprayers with vannofilter) (800 L):

- Make sure that the vannofilter is open (see page 15, figure 1).

POWER TAKE-OFF SPEED:

- With the power take-off connected (following filling), increase its speed to 540 rpm by bringing the needle of

the rev counter opposite the mark (R). (see manual No. 82.471).

ADJUSTING THE VOLUME/HECTARE:

IN ORDER TO PROGRAM YOUR VOLUME/HECTARE

- You need to know, for the gear chosen, the forward speed in km/h, at 540 rpm at the power take-off (see

manual No. 82.471).

- Bearing in mind the required volume/hectare, refer to the rate chart of the selected nozzle(s) (see nozzle

manual No. 82.467).

- Inthe column corresponding to the forward speed in km/h, find: the nozzle andpressurewhichwillenable the

required volume/hectare to be obtained.

Example:

- Speed in km/hour 6 km/h

- Volume/hectare 260 litres/ha

- Selected nozzles ALUMINE AFX (0.50 m spaced).

Possible combinations:

- ALUMINEAFX BLUE ............3.5 bars 256 litres/ha

- ALUMINEAFX RED .................2 bars 258 litres/ha

Youwillchoosethereforeoneoftheabovecoloursdependingontherequirednozzlepressureduringtreatment.

TO OBTAIN REQUIRED VOLUME/HECTARE:

- Fit the chosen nozzles,

- Put the lever on the main valve in position (2), (figure 4)

- Take power take-off speed to 540 RPM.

- Display on the pressure gauge (1) the pressure previously read from the flow rate table, using the nut (3) on

the controller (5) and lock it with the knurled nut (4). (figure 4)

- From now on, you can work.

SPRAYING:

- With rinsing tank option: place the valves (V3) in position (figure 8, page 20).

- Set the stopper controlling supply to boom sections in position (1) (figure 5).

- Put the lever on the main valve in position (4) (figure 5).

TO STOP SPRAYING

Total closure:

- Leave the shut-offs in the "OPEN" position (1) and adjust the main valve, putting its handle in position (3)

(figure 5).

Closure of one or more sections:

- Close the plug or plugs by putting them in position (2).

- All the liquid comes out through the top of the valve and returns directly to the tank, or passes through the

hydro-injector (machines with a hydro-injector), thus continuing the agitation of the spraying mixture, but

without passing through the controller.

SPRAYING

17

82.321-M - Pulvasol 1 and 2 / Pulvigne

12

3

4

5

4

3

2

1

4

5

18 82.321-M - Pulvasol 1 and 2 / Pulvigne

RINSING THE EQUIPMENT

RINSING THE SPRAYING CIRCUIT WITH THE RINSING TANK

- Sprayer off.

- Disconnect the power take-off.

- Plugs (1) in position , (figure 6).

- Valve (2) in position (figure 6).

- Valves (V2) in position (figure 7) (600 L).

- Valves (V3) in position (figure 7) (600 L).

- Valves (6) in position (figure 7) (800 L).

- Run at low speed at 150 rpm max.

- Engage the tractor power take-off and run until the rinsing tank is empty.

This operation is not sufficient for a product change.

RINSING THE SPRAYING CIRCUIT WITH THE MAIN TANK

In the case of a product change.

- Sprayer off.

- Put 300 litres of clear water into the main tank with a ALL CLEAR type cleaning product.

- Plugs (1) in position , (figure 6).

- Valve (2) in position (figure 6).

With rinsing tank option:

- Valves (V2) in position (figure 7) (600 L).

- Valves (V3) in position (figure 7) (600 L).

- Valves (6) in position (figure 7) (800 L).

- Run at low speed at 150 rpm max.

- Engage the tractor power take-off and run until the tank is empty.

19

82.321-M - Pulvasol 1 and 2 / Pulvigne

a

a

b

b

a

a

a

b

b

b

a

a

b

b

cuve

principale

cuve de

rin

ç

age

(600L)

(800L)

6

2

7

1

V2

V3

V2 V3

6Main tank

Rinsing tank

20 82.321-M - Pulvasol 1 and 2 / Pulvigne

- 50 cm to 80 cm above the surface to be treated depending on the spray angle of the nozzles and their

spacing.

If the boom is higher, there is a risk of drift.

HYDRAULIC STIRRING:

- The pump has a fixed output. This output supplies the spray boom. The surplus goes back to the tank via the

flow regulating valve. It is this surplus which provides hydraulic agitation.

HEIGHT OF THE BOOM

STIRRING

DRAINING THE TANK

a

a

b

b

a

ba

a

b

b

a

b

a

b

According to the cases:

- Place the valve (V1) in position .

- Place the valve (V2) in position .

- Place the valve (V4) in position .

8

V1

V2

V3

V2

V3

V1

V4

This manual suits for next models

8

Table of contents

Other Berthoud Paint Sprayer manuals

Berthoud

Berthoud MAXAIR 240 User manual

Berthoud

Berthoud ELYTE 2 360 EPDM User manual

Berthoud

Berthoud WIN'AIR 600 User manual

Berthoud

Berthoud ALTO 300 User manual

Berthoud

Berthoud ULV User manual

Berthoud

Berthoud VERMOREL 3000 ELECTRIC User manual

Berthoud

Berthoud RAPTOR 2540 User manual

Berthoud

Berthoud ELYTE 2 VITON User manual

Berthoud

Berthoud VERMOREL 3000 ELECTRIC User manual

Berthoud

Berthoud VANTAGE E.C.TRONIC 28-30 User manual