Bevent Rasch BSKC9 User manual

18/01/2022

www.bevent-rasch.com

BSKC9

Circular fire damper

FIRE SAFETY

2BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Fire damperBSKC9 EI90

Installation

BSKC9 is mounted on fire cell separating walls or floors,

alternatively in horizontal insulated ducts running through

fire cell separating building part, according to extensive

installation instructions. Should not be installed outdoors,

in damp or humid areas.

Actuator

BSKC9 is always supplied with an electric safety actuator

with spring return complete with thermal sensor equipped

with push button for local manual operating test. The sen-

sor breaks the power supply to the actuator device if the

temperature exceeds 72°C inside or outside the damper.

24 V actuators are always used with the MRB, MRB3,

FENIX monitoring systems. The damper can also be sup-

plied with 230V electric actuator.

Note that the damper is always supplied with a safety

actuator.

Activation

The Boverket Building Regulations state a requirement

for smoke detectors verified in accordance with

SS-EN 54-7 for activation of dampers. The obligatory

thermal sensor closes the damper at 72°C in accordance

with ISO 10294-4.

Control and monitoring

When the damper is used to prevent the spread of fire

and smoke it must be closed via inputs from the smoke

detector. This must be fitted in the ventilation duct near the

damper or in another suitable location. Smoke detectors

are monitored by means of Bevent Rasch’s monitoring sys-

tem or the like. The system also performs automatic func-

tion tests on the damper every 48 hours and is designed

so that faults are indicated immediately and the damper

closes. See www.bevent-rasch.se for further details.

Quick facts

• Fire classEI90 / EI90S

• Sizes from 100 mm to 630 mm

• Fitted safety actuator 24V or 230V

• Low weight

• Easy installation from one side of the building part

• CE-marked building product in acc. with

EN 15650:2010

• Available in MagiCAD

Use

Dampers in combination with walls or floors for fire-sec-

tioning of heating, ventilation and air conditioning instal-

lations in buildings. In accordance with the harmonised

European Standard EN 15650:2010. In designs according

to associated documents, installation instructions and

when the damper is used in combination with smoke

detectors and monitoring system (MRB, MRB3, FENIX), or

the like, the spread of fire/combustion gases is prevented.

No further action against the spread of fire/combustion

gases is required.

Performance

CoCP (Certificate of Constancy of

Performance) EN 15650:2010

0402-CPR-SC0051-19

Classification of fire resistance in

accordance with EN 13501-3

EI90 (ve ho i <–> o) S

For complete classification,

refer to the Performance Declaration.

3BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

EI90 Fire damperBSKC9

Size Ø100-630 mm.

Design

BSKC9 is supplied complete with a factory mounted,

maintenance-free, 24 V electric safety actuator with ther-

mal sensor featuring built-in contacts to indicate the damp-

er position. The damper comes as standard with spiral

duct connections.

Material and surface finish

- Casing and details of galvanized steel sheet according

of environmental class C3

- EPDM duct seals

- Blade seal of PE/PP

- Blade of Calcium Silicate

Accessories

BRTO Wire mesh grille

RCKB Junction box

RCDU MRB-system, max 2 dampers

RCBK4 MRB-system, max 4 dampers

RCMU8 MRB-system, max 8 dampers

RCKD/-RD Smoke detectors

RCTU/RCTC MRB3-system, max 236 dampers

FENIX2 max 2 dampers

FENIX4 / FENIX+ max 16 dampers

Specification

Installation options for BSKC9

Size Fire class Wall of drywall

EI90 Group A,

SS-EN1363-1

Solid wall Solid floor* Duct

Ø400 - Ø630 EI90S √ √ √

Ø100 - Ø315 EI90S √ √ √ √

*125 mm lightweight

concrete

Product data for BSKC9

Size Pressure

class

Casing

tightness

SS-EN1751

Tightness

over damper

blades

SS-EN1751

2-position

actuator

On-Off

Regulating

actuator

0°-90°

Actuator

type

Ø400 - Ø630 B C 3 √ √ Belimo BFN-T

Ø100 - Ø315 B C 3** √ √ Belimo BFL-T

Pressure class B:

2500Pa

**Size

Ø100-Ø125: 2

Example:

Fire damper BSKC9 - 400 - 1 - 1

Size, nom. diameter ØD mm

Material

Galvanized sheet steel = 1

Stainless EN 1.4404 = 3

Actuator

Electric 24V with thermal sensor = 1

Electric 230V with thermal sensor = 3

Electric 24V incl. RCTU = 5

Note Factory-fitted actuator device is always included.

4BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Fire damperBSKC9 EI90

Dimensions and weight

Size

Ø mm A B

Weight,

kg

100 450 – 3,0

125 450 – 3,2

160 450 – 3,5

200 450 – 4,0

250 450 30 4,5

315 450 60 5,5

400 550 60 10,5

500 550 110 13,0

630 550 180 17,0

Ød

max 55

max 200*

AB

max

65 30

Actuator - damper size

Actuator BFL-T, supplied for dampers in size Ø100-315 mm.

Actuator BFN-T, supplied for dampers in size Ø400-630 mm.

Electrical data (values in brackets refer to 230V)

* If necessary, the actuator can be rotated 90°.

Installation kit (sleeve rings) Union piece

Illustrated in

de-energised

state

Wiring

diagram

Tf1 Tf2 BAT72

Actuator

S

Ö

N

L1

M

1

2

1

2

3

4

5

6

5°

80°

Thermal

sensor

Acuator

Actuator type BFL... BFN...

Sizing, max 4 VA 6 VA

Running time.

– motor opening, max;

– spring return, max

60 s

approx. 20 s

60 s

20 s at -10 to +55°C

< 60 s at -30 to -10°C

Protection class IP 54 in all installation positions

Supply voltage 24V~ ±20%, 50/60Hz

24V= ±10% (220-240V~, 50/60Hz)

Design Imax 8,3A @ 5ms

Ambient temperature -30° to +50°C

Thermal sensor tripping

temperature

72°C

Mode contacts (Load) 1mA...3 (0,5 inductive) A, AC250V

Sound level when opening

< 43 dB (A)

Closing noise level

< 62 dB (A)

Maintenance

Maintenance-free

* Installation kit (sleeve rings)

Ø100-315 = 3 parts with 3 screws in each

Ø400-630 = 4 parts with 4 screws in each

5BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

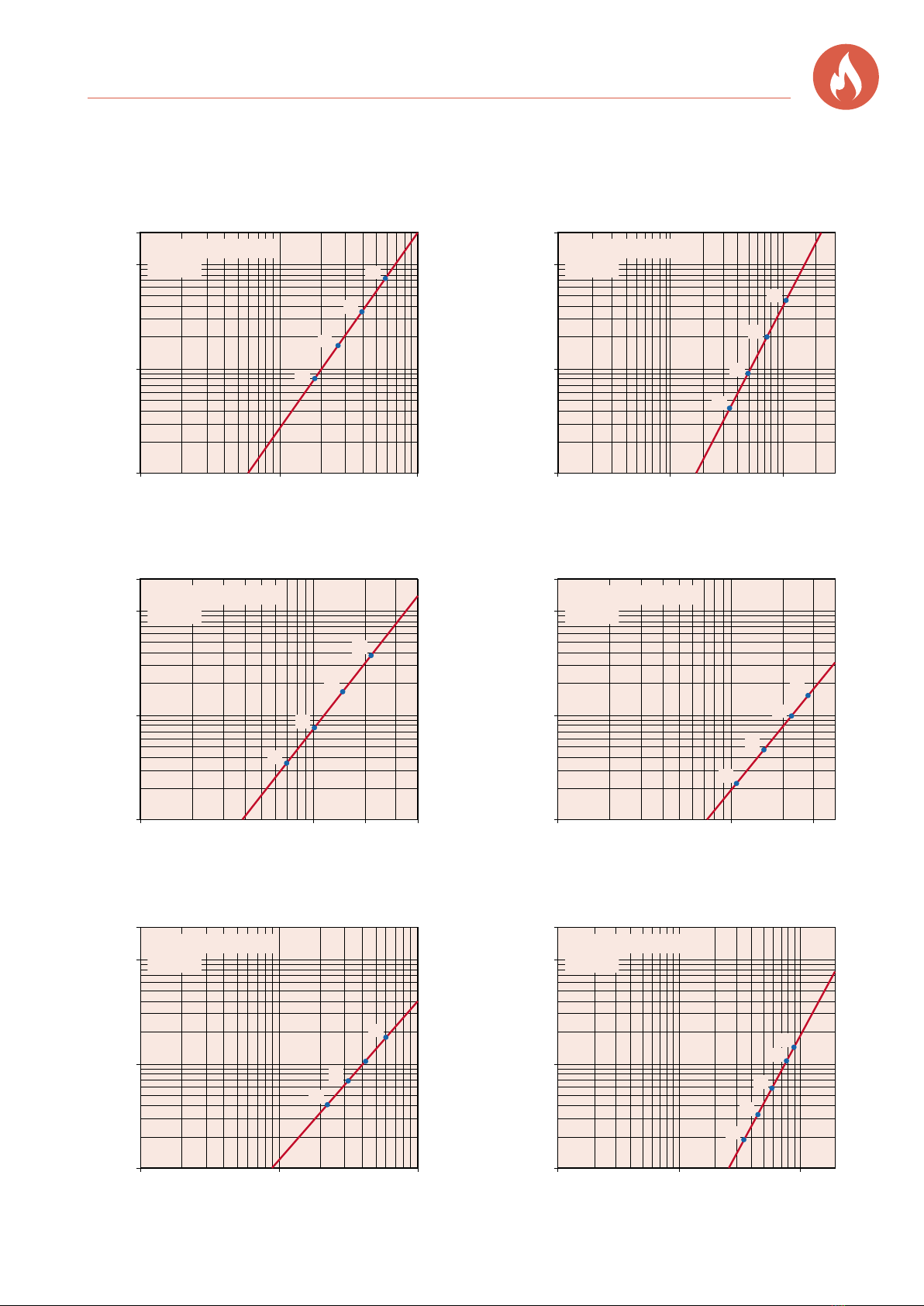

1

10

100

200

Air flow (l/s)

1 10010

Total pressure drop, Pa

Sound power level

LW, dB

45

50

55

40

1

10

100

200

100 200 40010

40

45

50

55

Air flow (l/s)

Total pressure drop, Pa

Sound power level

LW, dB

1

10

100

200

10 1000100

45

50

55

60

Air flow (l/s)

Total pressure drop, Pa

Sound power level

LW, dB

1

10

100

200

10 1000100

45

50

55

60

65

Air flow (l/s)

Total pressure drop, Pa

Sound power level

LW, dB

1

10

100

200

10 100 300

40

45

50

55

Air flow (l/s)

Total pressure drop, Pa

Sound power level

LW, dB

1

10

100

200

1 10010

40

45

50

55

Air flow (l/s)

Total pressure drop, Pa

Sound power level

LW, dB

EI90 Fire damperBSKC9

Dimensioning diagram

Size - 160 Size - 200

Size - 100 Size - 125

Size - 250 Size - 315

6BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

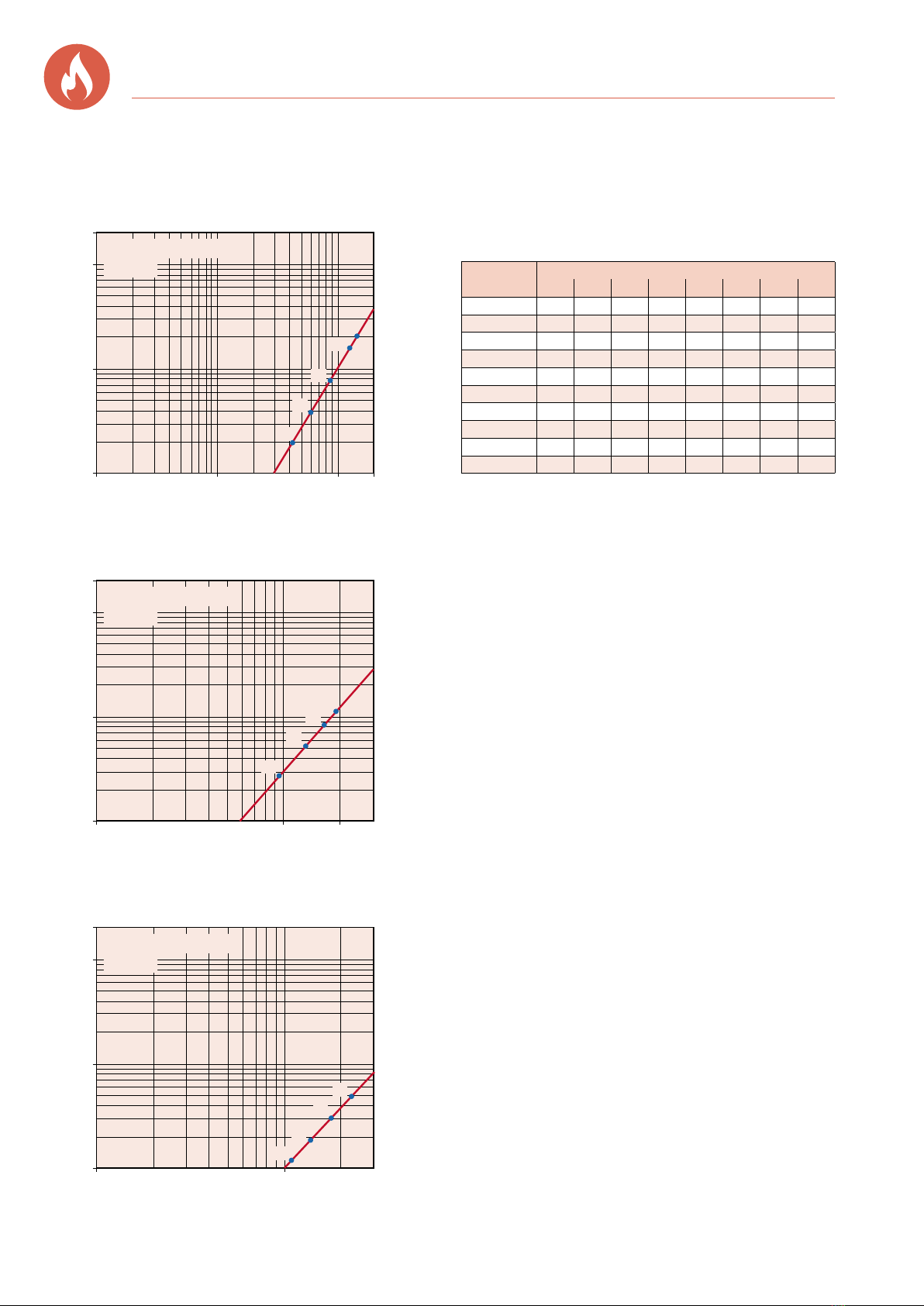

Fire damperBSKC9 EI90

Size - 500

Size - 400

Size - 630

Dimensioning diagram contd.

1

10

100

200

10 1000 2000100

45

50

55

60

65

Air flow (l/s)

Total pressure drop, Pa

Sound power level

LW, dB

1

10

100

200

100 1000 2000

50

55

60

65

Air flow (l/s)

Total pressure drop, Pa

Sound power level

LW, dB

1

10

100

200

100 1000 3000

50

55

60

65

Air flow (l/s)

Total pressure drop, Pa

Sound power level

LW, dB

Correction of sound power level, LWok, in octave band

Lwok = Lw+ Kok

Sound data

Correction, Kok

Size

Ø mm

Centre Frequency Hz

63 125 250 500 1000 2000 4000 8000

100 -4 -9 -10 -10 -10 -15 -18 -22

125 -4 -8 -8 -9 -10 -15 -21 -22

160 -4 -7 -9 -11 -14 -16 -20 -25

200 -2 -8 -11 -14 -15 -18 -23 -25

250 -2 -11 -11 -14 -14 -21 -27 -28

315 -1 -12 -14 -16 -15 -23 -29 -29

400 -2 -10 -13 -15 -15 -21 -28 -29

500 -1 -11 -14 -17 -18 -24 -31 -32

630 -1 -11 -15 -17 -17 -25 -28 -31

Tol. ± dB 1 2 5 6 6 4 3 4

7BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

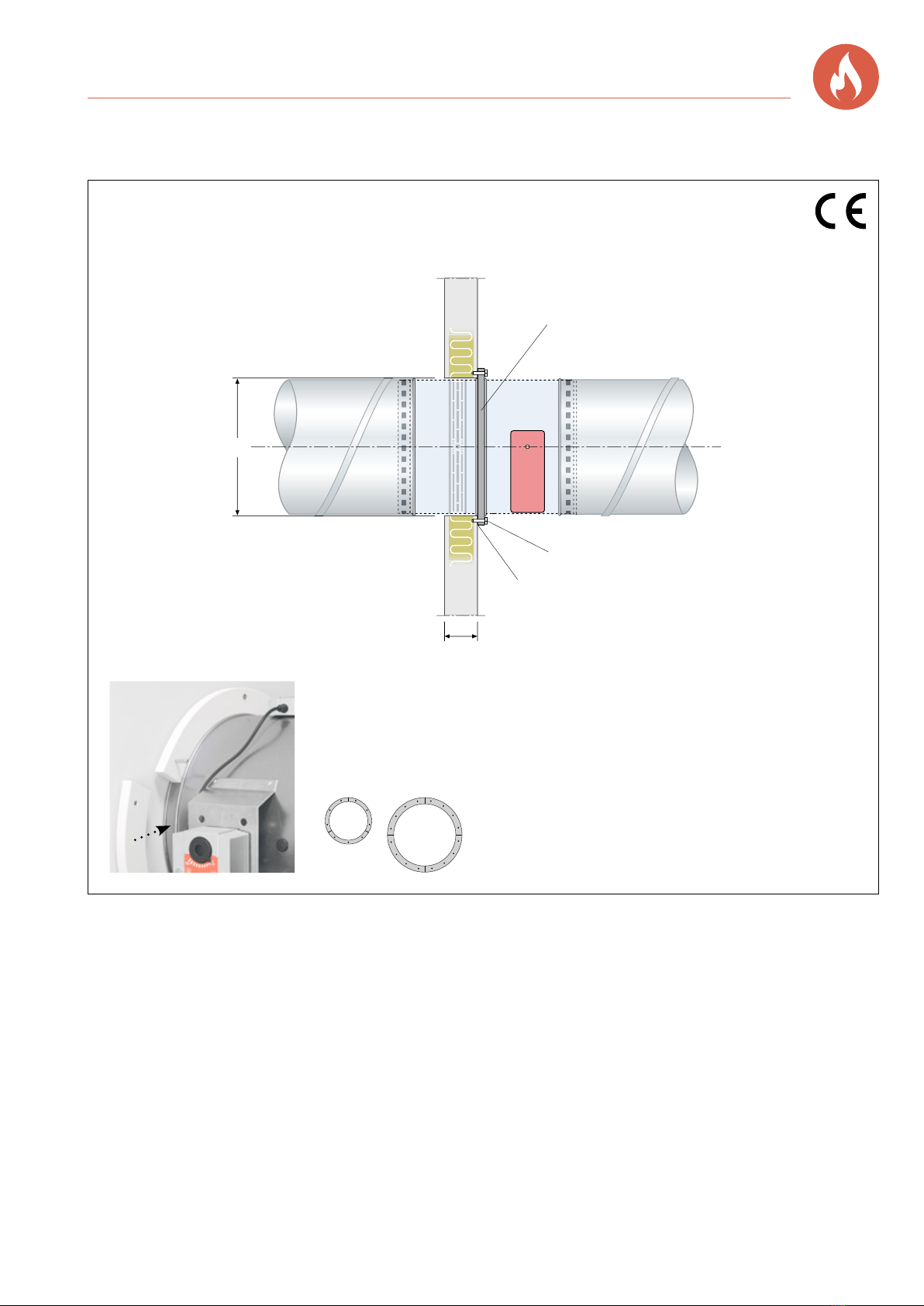

EI90 Fire damperBSKC9

1. Make a hole for size in question (d + 5mm).

2. Apply fire sealant on the wall, 20mm around the

periphery of the hole.

3. Secure the damper flat and tight with the installation kit

placed in the groove as shown in the photo. Make sure

that the shape of the damper is not impacted when

mounting.

4. Seal joints between the installation kit and damper

casing with fire sealant.

5. When installing without a duct connection, the damper

should be fitted with an incombustible grille. The

minimum distance between the open damper blade

and grille should be 50mm.

Installation in wall, fire resistance class EI90

Damper’s fire resistance class: EI90

(ve ho i <–> o) S.

EG-certificate 0402-CPR-SC0051-19

6. The duct system is fitted in accordance with current

requirements. Ensure that suspension and duct

systems do not affect the movement of the damper

blade.

• Damper for installation in walls and floors with fire re-

sistance class EI90.

• The shortest distance between dampers must be

200 mm.

• The minimum distance to the connecting structure

should be 75 mm.

• Free position on damper spindle.

d+5

Installation kit*

Screw 5x65 mm

Seal acc. to section 2 and 4.

DuctDuct

Min. thickness 95 mm

Installation instructions

* Installation kit (sleeve rings)

* Installation kit (sleeve rings)

Ø100-315 = 3 parts with 3 screws in each

Ø400-630 = 4 parts with 4 screws in each

8BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

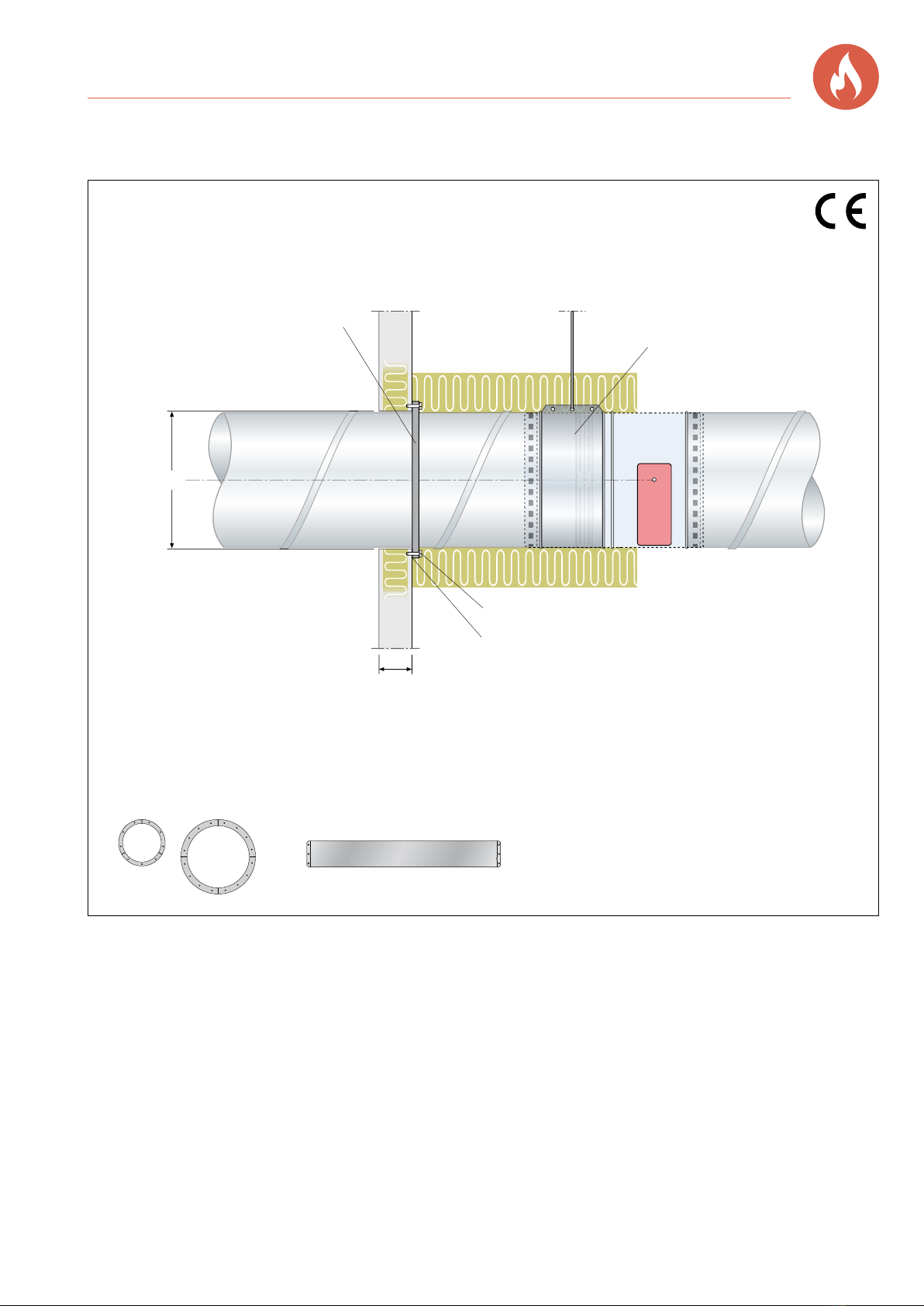

Fire damperBSKC9 EI90

1. Make a hole for size in question (d + 5mm).

2. Apply fire sealant on the floor, 20mm around the pe-

riphery of the hole.

3. Secure the damper flat and tight with the installation kit

placed in the groove as shown in the photo. Make sure

that the shape of the damper is not impacted when

mounting.

4. Seal joints between the installation kit and damper

casing with fire sealant.

Installation in floor or joist systems, fire resistance class EI90.

Damper’s fire resistance class: EI90

(ve ho i <–> o) S.

EC certificate 0402-CPR-SC0051-19

5. When installing without a duct connection, the damper

should be fitted with an incombustible grille. The

minimum distance between the open damper blade

and grille should be 50mm.

6. The duct system is fitted in accordance with current

requirements. Ensure that suspension and duct

systems do not affect the movement of the damper

blade.

• Damper for mounting in floors or joist systems of at

least 125 mm lightweight concrete.

• The shortest distance between dampers must be

200mm.

• The minimum distance to the connecting structure

should be 75mm.

d+5

Installation kit*

Screw 5x65 mm

Seal acc. to section 2 and 4.

Min. thickness 125 mm

(lightweight concrete)

Duct

Duct

Installation instructions

190121.0001_ENG / Jan. 2022 teamfront.se

* Installation kit (sleeve rings)

* Installation kit (sleeve rings)

Ø100-315 = 3 parts with 3 screws in each

Ø400-630 = 4 parts with 4 screws in each

9BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

EI90 Fire damperBSKC9

1. Make a hole for size in question (d + 5mm).

2. Apply fire sealant on the wall, 20mm around the

periphery of the hole.

3. Secure the installation kit flat and tight to the wall.

4. Seal joints between the installation kit and duct with fire

sealant.

5. Fit the metal union piece over the red decal on the

cover of the damper.

6. When installing without a duct connection, the damper

should be fitted with an incombustible grille. The

minimum distance between the open damper blade

and grille should be 50mm.

Installation in horizontal ducts for size up to Ø315.

Damper’s fire resistance class: EI90

(ve ho i <–> o) S.

EC certificate 0402-CPR-SC0051-19

7. Insulate the duct, from the hole in the wall to the

actuator of the damper. Insulate the duct system EI90

according to the supplier’s instructions.

8. The duct system is fitted in accordance with current

requirements. Ensure that suspensions and duct

systems do not affect the shape of the damper or

impede the movement of the damper blade.

• Dampers for installation in duct systems,

size Ø100 - Ø315.

• The shortest distance between dampers must be

200mm.

• The minimum distance to the connecting structure

should be 75mm.

• Free position on damper spindle.

d+5

Installation kit* is mounted on the

same side as the fire damper

Suspension with

union piece

Screw 5x65 mm

Seal acc. to section 2 and 4.

Min. thickness 95 mm

DuctDuct

Installation instructions

190121.0001_ENG / Jan. 2022 teamfront.se

* Installation kit (sleeve rings and union piece)

* Installation kit (sleeve rings)

Ø100-315 = 3 parts with 3 screws in each

Ø400-630 = 4 parts with 4 screws in each

Table of contents

Other Bevent Rasch Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

pottorff

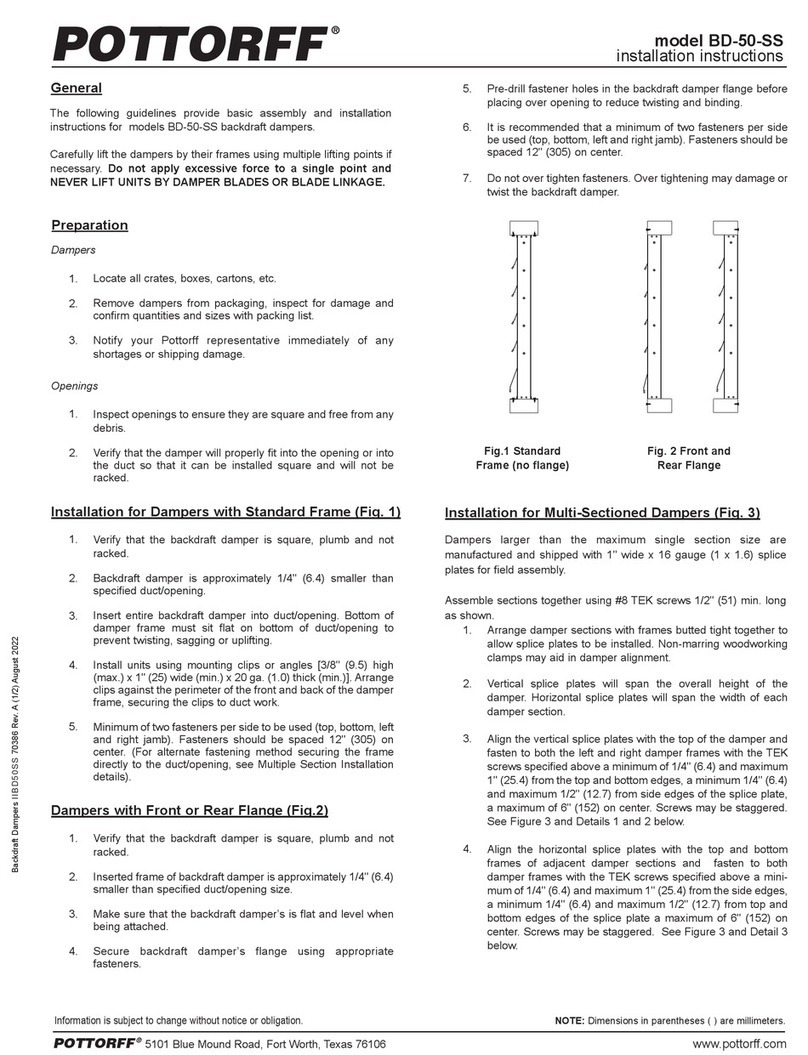

pottorff BD-50-SS installation instructions

Swegon

Swegon actionair DWFX-F installation guide

Fantech

Fantech FQ-FD Installation and operation manual

HVC

HVC Airtechnic NCA 100 Series Operation and maintenance manual

Lindab

Lindab FNC1 Installation booklet

mercor

mercor mcr ZIPP Operation and maintenance manual