9BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

FENIX4 Monitoring system – Commissioning instruction

Function description

Functions and settings via the display

Date and Time

The date and time are set from the factory, but can be eas-

ily changed on-site if necessary. The unit is equipped with

automatic summer and winter time adjustment.

Language

Easily choose between Swedish and English.

Zone dampers and smoke detector circuits

The dampers and smoke detector circuits can easily be

divided into up to four zones. The zones then serve as their

own fire compartments and the smoke detector circuits

can close one or more zones. This is a function that can

be used, for example, for tenant adaptations where the

entire system should not shut down on each local smoke

detector circuit.

Default setting: all smoke detectors and fire dampers

belong to zone 1.

Time of functional testing

Easily set the interval when functional testing of the fire

dampers is performed and when during the day to do it.

Selectable ranges:

• 1 time every 24 hours

• 1 time every 48 hours

(recommended and default setting on delivery) • 1

time per week

• 1 time per month

• 1 time every 6 months

Perform functional testing

If necessary, you can easily perform a functional test via

the display on FENIX4. Can also be performed by shorting

terminals 32 and 33.

Device information and communication settings

Simply set the desired communication settings for Modbus

TCP or BACnet IP via the display.

IP address is assigned automatically via Dynamic Host Con-

figuration Protocol (DHCP). If a fixed IP address is desired,

this can be configured via the settings in the touch display.

Delay External stop

If desired, functional testing of fire dampers can be delayed

by 5 minutes. Relay “EXT. STOP” between terminals 44

and 45 then breaks directly for internal functional testing,

the functional test of the dampers is performed first after a

5 minute delay, which then allows the electric heating coils

to cool down.

Default setting: no delay.

Automatic reset of External incoming alarm

Normally an External incoming alarm (34 + 35) needs to be

acknowledged on the unit via the display or terminal block

32 + 33 (default setting), this function permits External

incoming alarms to be acknowledged automatically when

a possible external alarm stops. Default setting: no auto-

matic reset.

System reset

The system is easily reset to the default settings when

necessary.

Automatic functions integrated in FENIX

Dynamic troubleshooting diagrams

Instead of the traditional troubleshooting documents that

previously accompanied older controllers, FENIX shows

exactly what fault occurred and proposed actions directly

on the display, such as if a damper does not make contact

with the limit switch for the closed position:

The unit then shows exactly what damper fault has been

identified, the possible slave unit FENIX+ that the damper

belongs to and which connection terminals and cables

should be checked and troubleshot. This function facili-

tates any service and troubleshooting in the event of a fault

during the lifespan of the property. The same pedagogical

approach applies to smoke detector circuits, external

alarms and other functions that trigger something in the

controller.

Dynamic trouble shooting diagrams and associated action

texts play an important role in the simplicity of FENIX.

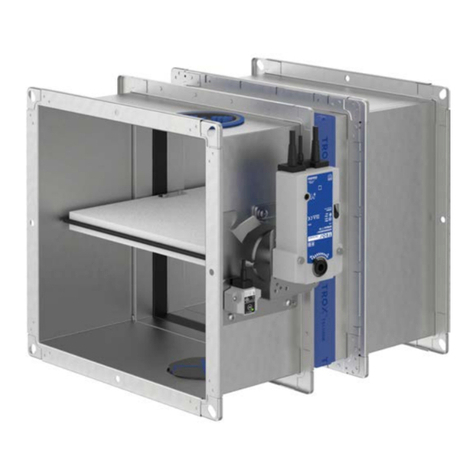

Automatic functional testing

All connected fire dampers are automatically functionally

tested. In order to ensure that regulating dampers work

at all damper angles, check the limit switches for both the

open and closed positions for all connected dampers.

Automatic shutdown of the entire system in the event

of alarms in two different zones

As a safety measure, all connected fire dampers are closed

if two smoke detectors from different zones alarm at the

same time. This is because it can then be assumed that

the fire has spread between the fire compartments and

that the entire system should be closed.