BEYES AirLight M800 User manual

Instructions For Use

M800 High Speed Collection

Table of Contents

• Before You Begin

• Safety Information

• Technical Specifications

• Assembly & Removal

• Friction Grip Bur Specifications

• Bur Insertion & Removal

• Cleaning & Lubrication

• Warranty

WARNING!

(Risk of injury)

ATTENTION!

(To prevent damage)

Thermal washer

disinfectable

General

explanations,

without risk to

persons or objects

Sterilizable

up to the stated

temperature

Fig.1 Fig.2

Fig. 2.1

Intended Use

AirLight Dental Handpiece, models AirLight are intended to be used for removing carious

material, reducing hard tooth structure, cavity preparation, finishing tooth preparations

and restorations and polishing teeth.

Before You Begin

Please read this Manual prior to using your AirLight Highspeed Handpiece. The use of

this product is only intended for use by trained dental personnel. We recommend that

you retain this manual for future reference.

Safety Information

• High speed handpieces should be sterilized after each patient to prevent any

transmission of infective organisms.

• Suitable hygienic measures must be taken to prevent cross contamination between

patients, operators and other personnel.

• Only operate this highspeed handpiece when the bur is properly inserted in the chuck.

Do not attempt to extend the length of the bur by improper positioning in the chuck.

Technical Specifications

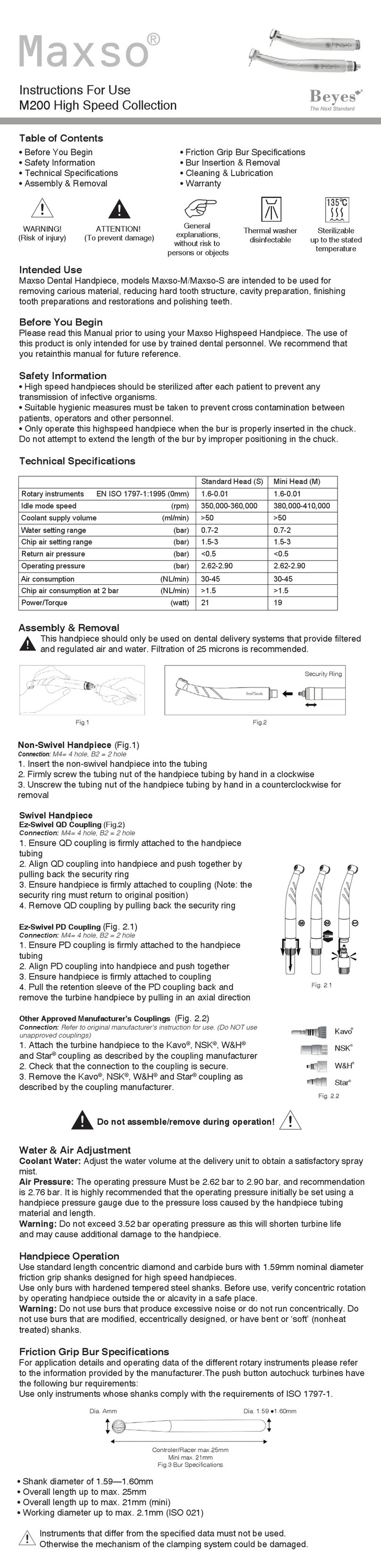

Assembly & Removal

This handpiece should only be used on dental delivery systems that provide filtered

and regulated air and water. Filtration of 25 microns is recommended.

Security Ring

Non-Swivel Handpiece (Fig.1)

Connection: M4= 4 hole, B2 = 2 hole

1. Insert the non-swivel handpiece into the tubing

2. Firmly screw the tubing nut of the handpiece tubing by hand in a clockwise

3.

Unscrew the tubing nut of the handpiece tubing by hand in a counterclockwise for removal

Swivel Handpiece

Ez-Swivel QD Coupling (Fig.2)

Connection: M4= 4 hole, B2 = 2 hole

1. Ensure QD coupling is firmly attached to the handpiece

tubing

2. Align QD coupling into handpiece and push together by

pulling back the security ring

3. Ensure handpiece is firmly attached to coupling (Note: the

security ring must return to original position)

4. Remove QD coupling by pulling back the security ring

Ez-Swivel PD Coupling (Fig. 2.1)

Connection: M4= 4 hole, B2 = 2 hole

1. Ensure PD coupling is firmly attached to the handpiece

tubing

2. Align PD coupling into handpiece and push together

3. Ensure handpiece is firmly attached to coupling

4. Pull the retention sleeve of the PD coupling back and

remove the turbine handpiece by pulling in an axial direction

Other Approved Manufacturer’s Couplings (Fig. 2.2)

Connection: Refer to original manufacturer's instruction for use. (Do NOT

use unapproved couplings)

1. Attach the turbine handpiece to the Kavo®, NSK®, W&H®

and Star®coupling as described by the coupling manufac-

turer

2. Check that the connection to the coupling is secure.

3. Remove the Kavo®, NSK®, W&H® and Star® coupling as

described by the coupling manufacturer.

Water & Air Adjustment

Coolant Water:

Adjust the water volume at the delivery unit to obtain a satisfactory spray mist.

Air Pressure: The operating pressure Must be 2.62 bar to 2.90 bar, and recommendation

is 2.76 bar. It is highly recommended that the operating pressure initially be set using a

handpiece pressure gauge due to the pressure loss caused by the handpiece tubing

material and length.

Warning: Do not exceed 3.52 bar operating pressure as this will shorten turbine life

and may cause additional damage to the handpiece.

Handpiece Operation

Use standard length concentric diamond and carbide burs with 1.59mm nominal diameter

friction grip shanks designed for high speed handpieces.

Use only burs with hardened tempered steel shanks. Before use, verify concentric rotation

by operating handpiece outside the or alcavity in a safe place.

Warning: Do not use burs that produce excessive noise or do not run concentrically. Do

not use burs that are modified, eccentrically designed, or have bent or ‘soft’ (nonheat

treated) shanks.

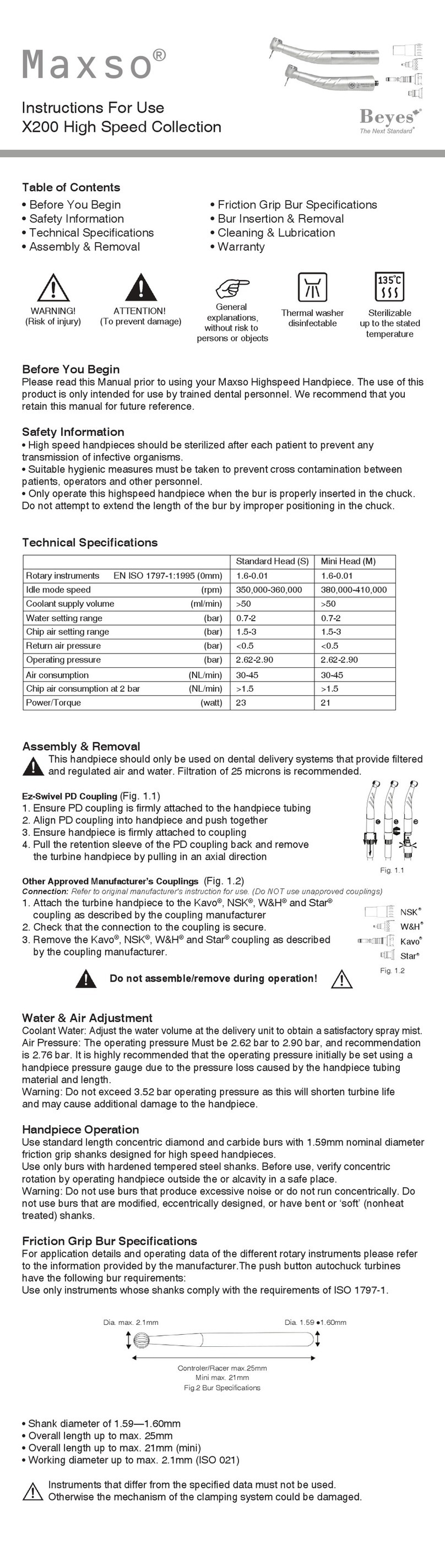

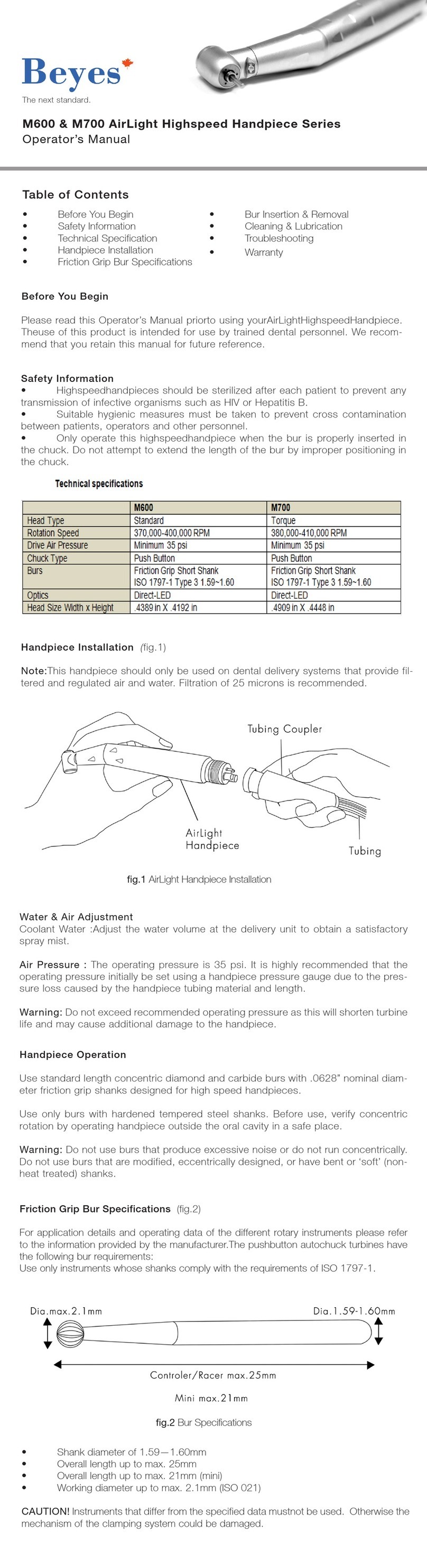

Friction Grip Bur Specifications

For application details and operating data of the different rotary instruments please refer to

the information provided by the manufacturer.The push button autochuck turbines have the

following bur requirements:

Use only instruments whose shanks comply with the requirements of ISO 1797-1.

• Shank diameter of 1.59—1.60mm

• Overall length up to max. 25mm

• Overall length up to max. 21mm (mini)

• Working diameter up to max. 2.1mm (ISO 021)

Instruments that differ from the specified data must not be used.

Otherwise the mechanism of the clamping system could be damaged.

Fig. 2.2

KavoR

NSKR

W&HR

StarR

Do not assemble/remove during operation!

Rotary instruments

Idle mode speed

Coolant supply volume

Water setting range

Chip air setting range

Return air pressure

Operating pressure

Air consumption

Chip air consumption at 2 bar

Intensity of illumination

Standard Head (S)

350,000-360,000

1.6-0.01

>50

0.7-2

1.5-3

<0.5

30-45

>1.5

22,000 22,000

>1.5

30-45

0.7-2

1.5-3

<0.5

>50

1.6-0.01

380,000-410,000

2.62-2.90 2.62-2.90

Mini Head (M)

EN ISO 1797-1:1995 (0mm)

(rpm)

(ml/min)

(bar)

(bar)

(bar)

(bar)

(NL/min)

(NL/min)

(Lux)

25 22Power/Torque (watt)

Dia. Amm Dia. 1.59 ●1.60mm

Controler/Racer max.25mm, Mini max. 21mm

Fig.3 Bur Specifications

Fig.5

Document #: ENI007

Rev.4 / 23.07.19

Fig.4

Fig.8

Fig.6.2

Fig.7

Fig.6.1

0197

Bur Insertion (Fig.4)

1. Insert bur into autochuck until resistance is felt.

2. Depress the autochuck end cap button and continue to feed-in the

bur until it clicks and stops.

3. Release the autochuck end cap button. (Always pull on the bur after

it has been installed to confirm that it is seated properly).

4. Never depress the autochuck end cap when the bur is rotating.

Use only faultless burs and diamonds. These must be clean to prevent

dirt from being transferred into the chuck.

Bur Removal (Fig.5)

1. Grasp handpiece firmly so your thumb touches the end cap of the

autochuck and push until a slight ‘click’ is noticed.

2. Pull bur straight out.

3. Release end cap.

Never depress the autochuck end cap button or rest the

end cap against any part of the oral cavity during operation.

Depressing the end cap while a bur is rotating can activate

the chuck mechanism and result in the end cap button with

excessive heat and / or loss of bur retention.

External Cleaning

LED Light

Clean the LED light using isopropyl alcohol or other disinfection agents.

Super soft cleaning cloth must be used. Never use a cleaning agent

that has an ammonium, chlorine, or acid base. (Fig.6.1)

External Surface

Clean debris from the external surface by using isopropyl alcohol

or other disinfecting agents. Never use a cleaning agent that has

an ammonium, chlorine, or acid base. Dry thoroughly.

Never immerse the handpiece in disinfection baths.

Improper care and maintenance may lead to a premature

wear and failure of the handpiece. (Fig.6.2)

Beyes Dental Canada Inc.

23-595 Middlefield Road

Toronto, Ontario, M1V 3S2

Canada

Tel: 1-416-281-1888

Email: [email protected]

Web: www.beyes.ca

Lotus NL B.V.

Koningin Julianaplein 10, Ie Verd,

2595AA, The Hague,

Netherlands

Tel: +31645171879 (English)

+31626669008 (Dutch)

Operating conditions for high-tempearture washer-disinfectors

* When using a high-temperature washer-disinfector to clean the handpiece,

strictly adhere to the conditions specified below.

High-temperature cleaning conditions

Unit Name

Miele G7881 Vario TD

Mode Detergent

(concentration)

neodisher Mediclean

(0.3-0.5%)

Neutralizer*

(concentration)

neodisher Z

(0.1 - 0.2%)

neodisher mieclear

(0.02-0.04%)

Rinse

(concentration)

* After cleaning there may be streaks or white spots on the instrument.

Use a neutralizer only if there are streaks or white spots.

Operating Precautions

• Always use a handpiece holder when washing the handpiece, making sure to rinse the

inside of the handpiece thoroughly.

• If any medical agent remains inside the handpiece, it may corrode or clog the air or

water pipe, resulting in a malfunction of the handpiece.

• For details on handling medical agents or adjusting their concentration, refer to the user

manual for the washing device.

• After washing is complete, check to see if the handpiece, including its inside, is

completely dry. If any water remains inside the handpiece, expel it with an air gun or

another such tool. Failure to do so could result in the remaining water coming out during

use and cause poor lubrication or sterilization.

• Always lubricate the handpiece after washing.

Inappropriate cleaning methods and solutions will damage the handpiece

Do not clean the handpiece using strong acidic or alkaline solutions that could

cause the metal to corrode.

Do not leave a handpiece inside the high-temperature washer-disinfector.

Lubrication

Chuck System Lubrication (Fig.7)

1. Fit the spray nozzle onto the spray can

2. Grip the handpiece firmly

3. Press the tip of the spray nozzle firmly into the chuck system

4. Spray about 1 second

5. Push the button three times

Handpiece Lubrication (Turbine)

• After internal cleaning

• Prior Sterilization

•

The Handpiece must be cleaned and sterilized between patient uses, or at least once daily.

The handpiece must be cleaned and sterilized between patient uses.

Purging

Connect handpiece to tubing and run handpiece for 20-30 seconds to purge remaining lubricant.

Automatic Handpiece Lubrication

After cleaning the handpiece simply connect the handpiece to the correct adaptor and

activate the Lubrication System according to the manufacturer’s system instructions.

Manual Lubrication (Fig.8)

After cleaning the handpiece apply lubricant

BEFORE sterilization

1. Use only a high quality lubricant such as Beyes Lube.

2. Ensure the correct application nozzle is connected to

the plastic valve at the top of the spray can.

3. Firmly insert the application nozzle into the rear

of the handpiece

4. Spray for 2-3 seconds

5. Connect it to the tubing and run it with bur for 25 seconds.

6. Wipe any excess lubricant from the handpiece.

Packing

Approved Sterilization Procedure

Following your country specific directives, standard and guidelines

• Steam sterilization class B (pre and post vaccum) with sterilizers in accordance with

EN 13060. Sterilization holding time a minimium of 3 minutes at 134°C (273°F)

OR

• Steam sterilization class S with sterilizers in accordance with EN 13060

The sterilizer manufacturer must give the express approval for the sterilzation of turbine

handpieces. Sterilization holding time a minimium of 3 minutes at 134°C (273°F)

An unwrapped handpiece needs to be used immediately or sterility is not maintained.

Do not exceed the sterilizer manufacturer’s guidelines for load capacity.

Use steam sterilization exclusively for complete sterility. Never dry heat sterilize,

ultrasonically clean, or expose handpiece or swivel to chemical disinfection or cold

sterilization.

Limited Warranty

Beyes Dental Canada hereby warrants against defect in material and workmanship that for a

period of 12 months from the date of purchase, this product will perform satisfactorily under

normal use and service. No warranty claim can be inferred here, as wear may occur earlier or

later than indicated above depending on use, frequency of sterilization and frequency of

maintenance. Beyes shall under no circumstances be liable for incidental or consequential

damages or damage due to improper use or maintenance.

This Warranty is subject to the following conditions.

Beyes will, without charge repair or replace (at Beyes sole discretion) any defective part/s

covered in this warranty.If the conditions are met, the defective item must be returned to an

authorized Beyes service center or distributor. Accompanied by the original invoice or packing

list. This warranty is in lieu of all other warranties, expressed or implied .

* This device is not field repairable * All brands are holders of their respective trademarks.

!

!

!

Federal law restricts this device to sale by or on the order of a dentist, physician, or any other practitioner licensed by the law of the states in

which he or she practices to use or order the use of this device. Beyes Dental Canada Inc. is not responsible for any typographical errors.

Subjects to technical changes without notice.

Place the handpiece in a sterilization pouch.

Table of contents

Other BEYES Dental Equipment manuals

BEYES

BEYES Maxso X200 User manual

BEYES

BEYES Maxso E600 User manual

BEYES

BEYES Comfort-Sonic P6 Plus User manual

BEYES

BEYES Maxso X99 Series User manual

BEYES

BEYES AirLight Highspeed Handpiece Series User manual

BEYES

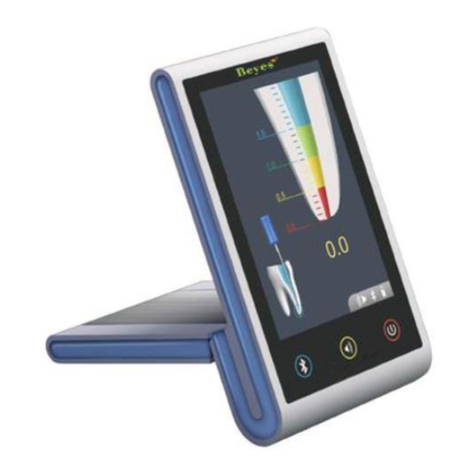

BEYES ApexPilot G2 User manual

BEYES

BEYES EndoPilot User manual

BEYES

BEYES SLimax-C User manual

BEYES

BEYES Accurator A2 User manual

BEYES

BEYES AirLight M800 User manual