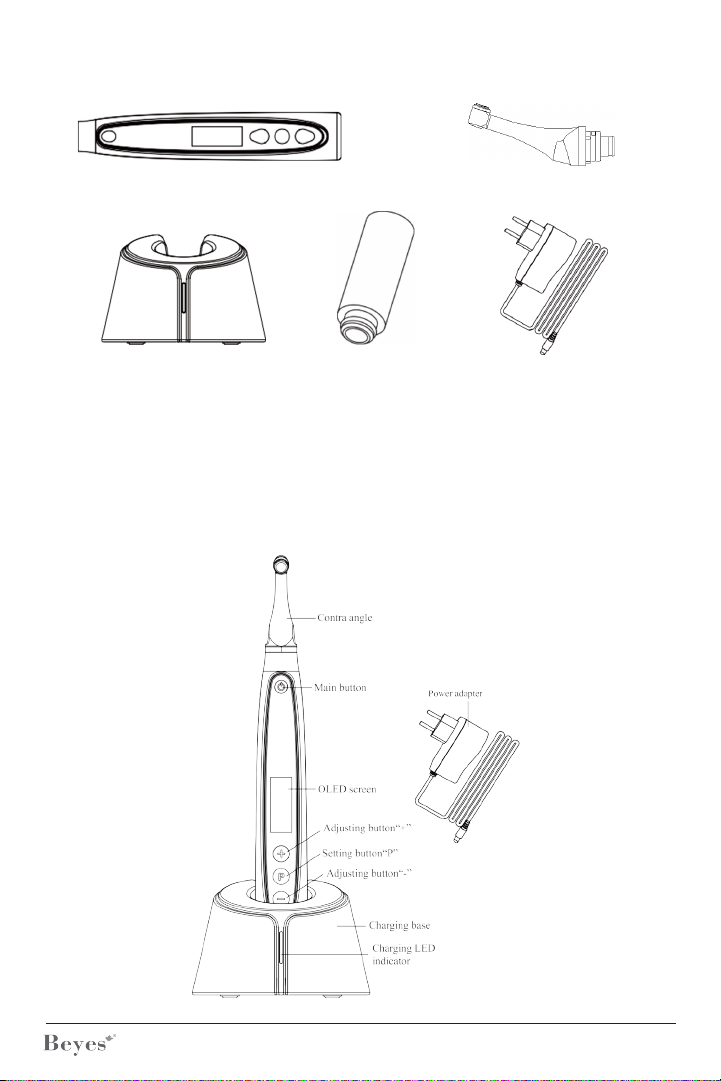

BEYES ApexPilot G2 User manual

Table of contents

Other BEYES Dental Equipment manuals

BEYES

BEYES AirLight M800 User manual

BEYES

BEYES AirLight M800 User manual

BEYES

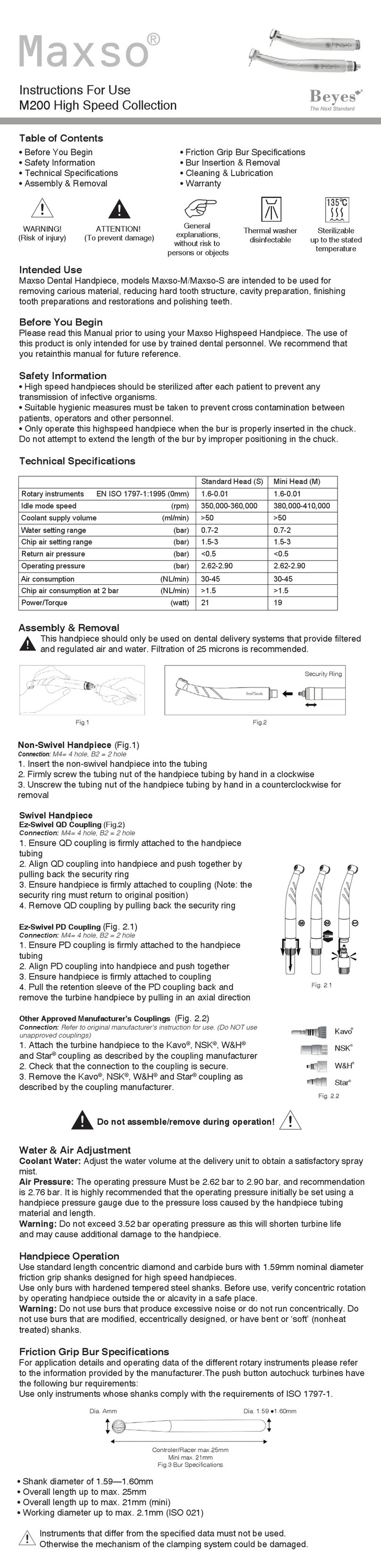

BEYES Maxso E600P User manual

BEYES

BEYES AirLight M800 User manual

BEYES

BEYES GPRO P1 User manual

BEYES

BEYES Accurator A2 User manual

BEYES

BEYES Comfort-Sonic P6 Plus User manual

BEYES

BEYES Comfort-Sonic P9 User manual

BEYES

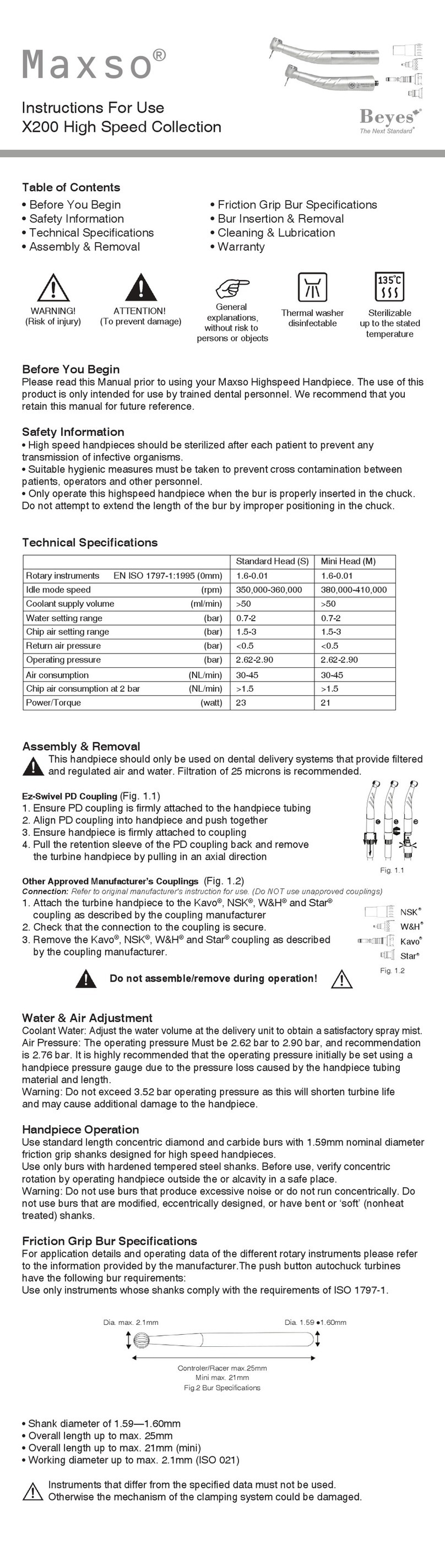

BEYES Maxso X200 User manual

BEYES

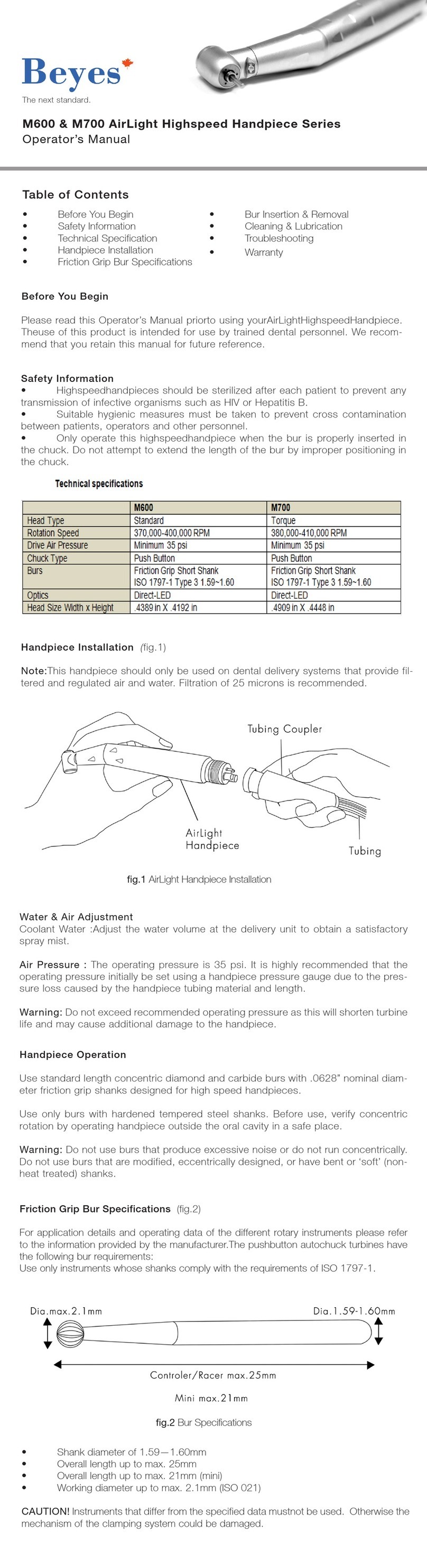

BEYES AirLight Highspeed Handpiece Series User manual

Popular Dental Equipment manuals by other brands

Komet

Komet SFS99 Instructions for use

hatch

hatch comfort TAURAUS C1 User's operating manual

BK-Medent

BK-Medent Art Waxer User's operation manual

Aseptico

Aseptico ADC-10 AseptiStool Operations manual & parts list

SciCan

SciCan STATIS 1.1 ST operating instructions

Acteon

Acteon X Mind Unity Installation & maintenance manual

Dentsply Sirona

Dentsply Sirona SINIUS installation instructions

Durr Dental

Durr Dental PTS 120 Installation and operating instructions

3M

3M NobelProcera quick start guide

KaVo

KaVo INTRA LUX head 66 LU Instructions for use

Dentsply Sirona

Dentsply Sirona inLab Profire operating instructions

Dentsply Sirona

Dentsply Sirona Orthophos SL 2D operating instructions