BHM Medical VOYAGER 550 User manual

IMPORTANT: Read these instructions before installing, operating, or servicing this system

VOYAGER

®

550

BATTERY AND ELECTRIC VERSION

2 AND 4 FUNCTION

CEILING

LIFT SYSTEM

BHM MEDICAL INC., 2001 TANGUAY STREET, MAGOG, QUEBEC, CANADA, JIX 5Y5

Technical Manual Part #001.08865

TECHNICAL MANUAL

Revision 4, August 2002

DO NOT DESTROY

Technical-VOYAGER-550 2

.

Medical Inc. designs and manufactures quality

engineered patient lifting equipment for the care of the disabled in

hospitals, nursing homes and home care.

Please take the time to read the entire manual, including the section on Safety Instructions and Warnings.

It contains important information that will allow you to take advantage of all the characteristics of your

BHM patient lift.

BHM Medical Inc. Credentials

• FDA Registration # 9681684

• CE mark (European Union Listing)

• Global operations for in-warranty and out-of-warranty service support for Voyager Series lift.

• Each finished Voyager Series is individually tested in our laboratory.

• Lifting capacity ranges from 190-360 kg (420-800 lbs.). Engineering safety factor exceeds European

Standards.

• Complete range of patient lift slings and supports designed and manufactured by BHM Medical Inc.

using medical quality materials and fabrics.

• ISO 9001

• Voyager is a registered trademark of BHM Medical inc.

APPROVALS:

CSA 601.1

UL 2601.1

EN 60601.1

EN ISO 10535 (Lifting device) SGS

UK Test Report: DUR22107/AC/OO

Note: BHM Medical is constantly improving its products. For this reason, it may be possible to

encounter a modification of product without revision of this guide.

Thank you for trusting your BHM Medical Partners.

How to contact us:

North America: BHM Medical Inc.

2001 Tanguay Street

Magog (Quebec)

Canada J1X 5Y5

Phone: (819) 868-0441

service calls during business hours - extension #109

(8:00-12:00 and 1:00-5:00 p.m. E.S.T.)

service calls outside regular business hours

extension #6199 (you must press the pound key)

Fax: (819) 868-2249

Web site: www.bhm-medical.com

E-mail: [email protected]

BHM

TABLE OF CONTENTS

Technical-VOYAGER-550 3

INTRODUCTION ............................................................................................................. 4

How to use this Manual.............................................................................................................................. 4

Equipment Identification............................................................................................................................. 4

Receipt of Equipment................................................................................................................................. 4

Key to Symbols .......................................................................................................................................... 4

DESCRIPTION OF EQUIPMENT.................................................................................... 7

Lift Unit ....................................................................................................................................................... 7

What's included.......................................................................................................................................... 7

Parts Description........................................................................................................................................ 7

Dimensions ................................................................................................................................................ 7

OPERATION ................................................................................................................... 8

How to use Voyager 550............................................................................................................................ 8

Emergency Stop ........................................................................................................................................ 9

Emergency Lowering Feature.................................................................................................................... 9

Battery Information................................................................................................................................... 10

Charger Specification:.............................................................................................................................. 11

MAINTENANCE ............................................................................................................ 11

Daily Check List ....................................................................................................................................... 11

Inspection and Cleaning .......................................................................................................................... 11

Strap Inspection ....................................................................................................................................... 11

Lubrication ............................................................................................................................................... 12

Handling and Storage .............................................................................................................................. 12

Battery Replacement ............................................................................................................................... 12

Strap Replacement .................................................................................................................................. 13

Drum Replacement .................................................................................................................................. 14

Horizontal Motor Replacement ................................................................................................................ 15

Vertical Motor Replacement..................................................................................................................... 16

Limit Switch Replacement........................................................................................................................ 16

Limit Switch Rod Replacement ................................................................................................................ 17

Maintenance Inspection Checklist ........................................................................................................... 18

TROUBLESHOOTING .................................................................................................. 20

PARTS LIST.................................................................................................................. 22

ACCESSORIES ............................................................................................................ 28

WARRANTY.................................................................................................................. 29

INTRODUCTION

Technical-VOYAGER-550 (REV 4) 4

INTRODUCTION

How to use this Manual

DO NOT ATTEMPT TO USE THIS

EQUIPMENT WITHOUT UNDER-

STANDING THIS MANUAL.

To ensure safe operation, read the entire

manual carefully, especially the section on

“Safety Instructions and Warnings”, before

installing, operating, or servicing this

equipment.

If anything is not completely understood,

please contact your supplier for more

details. Failure to comply with warnings in

this manual may result in injury.

Keep this manual with the lift and refer to it

as required. Contents of this manual are

subject to change without prior notice to

users.

Throughout this manual, the following symbols

may appear. Pay particular attention to the

information provided under these headings.

These special annotations are easily recognised

as follows:

WARNING: this symbol is

intended to alert the user to

hazards or unsafe practices,

which could result in serious

bodily harm.

CAUTION: this symbol is intended

to alert the user of the presence of

important operating and

maintenance instructions, which

could prevent product damage or

possible personal injury.

NOTE: this symbol offers helpful

information concerning certain

operating procedures.

Additional copies of this manual can be

purchased by contacting your supplier. Include

the User Manual product number and equipment

identification numbers.

Equipment Identification

The unit's identification number (specification,

model, serial number) appears on a silver

nameplate attached to the back of base.

Receipt of Equipment

Upon receipt of the equipment, verify it against

the packing list to ensure it is complete and

inspect the equipment for possible damage due

to shipping. If there is any damage, DO NOT

USE the equipment and notify the carrier

immediately to file a claim. Provide complete

information concerning damage claims or

shipping errors to your supplier. Include all

equipment identification numbers and group part

numbers (if any) as described above along with

a full description of damaged parts.

Key to Symbols

The following symbols are used on lifter’s

attachment labels:

This symbol is required to be displayed

on regulated products for sale in the

European Market. It indicates that the

product complies with applicable

European Directives related to health,

safety, environment and consumer

protection.

Safe Working Load represents the

maximum load the lifter is rated for safe

operation.

The following symbols are used on sling labels

and related to washing instructions:

Maximum washing temperature 60°C

(140°F) permanent cycle.

Do not use bleach.

Do not dry clean.

Tumble dry low temperature.

Do not iron.

Please refer to individual sling labels for

complete instructions regarding washing and

drying.

SWL

60ºC

SAFETY INSTRUCTIONS AND WARNINGS

Technical-VOYAGER-550 (REV 4) 5

SAFETY INSTRUCTIONS AND WARNINGS

A. GENERAL

IMPORTANT – READ THESE INSTRUCTIONS CAREFULLY OR SERIOUS INJURY MAY RESULT.

KEEP THESE INSTRUCTIONS AND THE KEY PROVIDED WITH THE LIFT AT ALL TIMES.

READ OPERATION AND MAINTENANCE INSTRUCTIONS IN THIS MANUAL BEFORE

INSTALLING, OPERATING, OR SERVICING THIS EQUIPMENT.

An authorized contractor or installer must install BHM Medical ceiling lifts.

YOUR LIFT is for transferring patients only. Do not use the lift for any other purpose.

ALWAYS carry out the daily checklist before using the lift.

BHM Medical ceiling lifts are specifically designed for BHM Medical ceiling rail systems, slings

and accessories. Slings and accessories designed by any other manufacturer are prohibited

and will void BHM Medical’s warranty. Use only BHM Medical slings and accessories to

maintain patient safety and product utility.

BHM Medical ceiling lifts are intended to be used for patients within the specified weight limit

indicated for the lift. Do not attempt to lift more than the weight limit indicated.

Before attempting to transfer, the patient must be assessed by a qualified professional.

BHM Medical ceiling lifts must be used by a caregiver with proper training to work with the

patient to be transferred.

ONLY trained and qualified caregivers should transfer a patient. DO NOT attempt to use the lift

if you have not been properly trained to do so.

ALWAYS be prepared before attempting to transfer a patient.

DO NOT use a sling that is not recommended for the lift.

NEVER use a damaged, torn or frayed sling.

ALWAYS place the sling around the patient according to the instructions enclosed.

FOLLOW lifting procedures outlined in this manual.

USE all controls and safety features only according to the rules specified in this manual.

Never attempt to force a control or button on the lift.

DO NOT store the charger in a shower, bath or other areas with high humidity.

DO NOT drop the patient lift or battery. Dropping the battery or lift may cause internal damage

that is not easily seen. If lift is suspected to be damaged, take to an authorized technician for

servicing.

IMPORTANT: Keep all components of the lift clean and dry, and have electrical and mechanical

safety checkpoints done as instructed in the Maintenance section of this manual.

Replace any precautionary or instruction labels that cannot be easily read.

• Avoid violent shock during transportation.

B. SHOCK PREVENTION

DO NOT touch or use a lift with bare conductors or a damaged power cord. Electrically live

equipment can electrocute a patient. If the lift or charger has any exposed or damaged wires

contact your local dealer immediately.

DO NOT cut or remove the round grounding prong from any plug. All BHM lifts are equipped

with three-prong plugs to protect from shock hazard or electrocution. Any two-prong electrical

outlet must be replaced with a properly grounded three-prong outlet according to the National

SAFETY INSTRUCTIONS AND WARNINGS

Technical-VOYAGER-550 6

Electrical Code and local codes. It is the responsibility of the customer to have the work done

by a qualified electrician.

Do not splash or expose electric parts of the device to water or moisture.

Check nameplate for voltage and cycle requirements. These requirements differ by country.

Do not attempt to use the lift in an area that has a different voltage and cycle requirement.

DO NOT attempt to expose, service or repair the lift, battery or charger. If any unit is

malfunctioning, contact your local dealer.

READ the battery and charger instructions thoroughly before using or storing them.

C. FIRE AND EXPLOSION PREVENTION

Batteries may explode, leak and cause personal injury if not disposed of properly

• Do not place or store the battery under direct sunlight or near a heat source

• Do not dispose of in fire

• Do not short the battery terminals

• Do not incinerate

• Flush with water if electrolyte (Acid) comes in contact with skin or eyes.

Batteries must be recycled, disposed of according to local law regulations. When returning

batteries, insulate their terminals with adhesive tape, etc. Otherwise, the residual electricity in

used batteries may cause fire or explosion.

D. EQUIPMENT WARNING LABELS

Inspect all precautionary labels on the equipment. Order and replace all labels that cannot be

easily read.

DESCRIPTION OF EQUIPMENT

Technical-VOYAGER-550 (REV 4) 7

DESCRIPTION OF EQUIPMENT

(Stainless steel model available for chlorinated

area)

Lift Unit

The lift unit is a steel frame based system driven

by a gear reduced high torque motor.

OPERATING FEATURES

• Lifting capacity: 250 kg (550 lbs.)

• Average weight: 22.73 kg (50 lbs.) battery

included.

• Electronic soft-start and soft-stop motor

control.

• Manual and electric emergency lowering

device.

• Emergency brake (in case of mechanical

failure). Operates on the same principle as a

car safety belt mechanism.

• Emergency stopping device.

• Current limit for circuit protection in case of

overload.

• Low battery disconnect system to protect

batteries from being drained.

• Lifting speed: 6 cm/sec. (2.4 in./sec.).

• Horizontal displacement speed: 15 cm/sec.

(6 in./sec.).

• Vertical axis motor: 24 VDC, 1/8HP.

• Horizontal axis motor: 24 VDC, 1/10 HP

• Strap length up 3.6 m (144 inches) tested for

1363.6 kg (3000 lbs.).

• CSA No. 601.1, UL No. 2601-1 and CE

certifications.

• Respects EMI standards.

• ISO 10535.

What's included

ITEM QTY

Voyager 550 lift 1

Battery (inside unit) 1

Integrated Charger Stopper 1

Rail Stopper 1

Handset 1

Carry bar 1

Power cord 1

Instruction manual 1

4 mm Allen Key 1

Parts Description

Dimensions

Power cord

Rail sto

pp

er Fuse magazine

Trolley

Charging light

Handset

Control

switches

Low-battery

indicator

Carry bar

Emergency stop

Emergency

lowering

4-function

2-function

Integrated

char

g

er sto

pp

er

Allen key

Rail

Charger

Stopper for UK

only

Allen key

OPERATION

Technical-VOYAGER-550 (REV 4) 8

OPERATION

How to use Voyager 550

READ "SAFETY INSTRUCTIONS

AND WARNINGS" BEFORE

ATTEMPTING TO USE THE

VOYAGER 550.

Unit will not lower or lift when in

contact with the charger.

1. Install the patient sling

Move the lift directly over the patient.

2. For two-function battery pull the unit

manually directly over the patient or for four

function battery, use the handset.

If the buttons do not operate on

the handset, pull the red cord

gently, once until you hear a

“click”

3. Using the handset button, lower the

carry bar below the patient’s chin (to avoid

the risk of facial contact caused by a sudden

movement of the carry bar) before beginning

to attach the sling straps. If lift will not

operate – pull red cord once gently, until you

hear a click.

Hold the lift carry bar with one

hand at all times when near a

patient.

Note: In a lying down position, lower the

carry bar near the thorax, then install the

straps.

4. Attach the straps to the desired position.

5. Carefully observe the patient to ensure

his/her safety as you press the control button

.

BEFORE LIFTING THE PATIENT :

1. Make sure that all straps are

attached to the carry bar.

2. Make sure the patient is

comfortable.

3. Make sure the sling is not

caught on any obstruction

(wheelchair brake or arm of

chair).

If any of the above occur - lower the patient

immediately and correct the problem.

Lift until the patient's buttock

clears the arm supports or the top

of the bath or bed before moving

the patient. Guide the legs past

any obstacle.

6. When the patient is located

above the desired point of

transfer, press the button.

7. Use the handles on the back

of the sling to position the patient when

transferring into a chair. Hold the handles

firmly as the sling lowers; the sling will tilt

back to position the patient.

8. Once the patient is properly seated and the

straps are loose, remove the sling from the

lift.

Hold the lift carry bar with one hand

at all times when near a patient.

9. Slide the lift away from the patient.

10. When lift is no longer required:

2-function - gently return the unit to charger

manually.

4-function - engage the automatic return to

charger function by pressing .

11. Check the charging indicator light to ensure

the charger is working.

OPERATION

Technical-VOYAGER-550 9

Emergency Stop

(Red cord)

1. This can be activated at any

time to stop the functioning

of the lift.

2. To stop the lift in an

emergency, pull the red cord

once gently, you will hear a

“click”.

Do not pull the red cord

forcefully. If cord pulled too

forcefully, the lift may become

inoperable.

3. When you initially receive your lift the

emergency stop is in the “off” position. To

activate the lift, pull the red cord once gently.

To re-activate pull the red cord once gently,

you will hear a “click”.

Emergency Lowering Feature

(White cord)

In the event of an electrical or

functional failure, the Voyager

550 has an emergency

electrical and manual lowering

feature.

Only to be used in case of an

emergency.

If the lift malfunctions when a patient is being

transferred, the emergency lowering device

provides a safe way of lowering the patient onto

a chair or bed.

To operate the emergency lowering features:

Electrical Version

Move the patient over a bed or a chair, and then

gently pull down on the white cord. If this does

not function then go to step 2.

Manual Version:

Find the rubber stopper and label on the side of

the lift.

VOYAGER 550

1. Pull the rubber stopper out of the Voyager

casing – DO NOT DISCARD.

Use the Allen key provided with this

manual, turn the key clockwise to lower the

patient into a chair or bed. As the key turns

the motor directly, each key turn will move

the patient slightly

.

To lower the patient more quickly, use a

power drill with a 4 mm Allen key bit.

OPERATION

Technical-VOYAGER-550 10

2. Once the patient is lowered safely into a

chair or bed, call a certified technician to

have lift serviced.

Emergency Brake

•

The emergency brake is

made of a metal bar

fixed to the drum.

•

In case of a chain, gear or motor breakage,

the centrifugal force created would block the

bar against the frame.

Frame with mechanical clips

•

Supporting structure is welded

and reinforced with metal

clips.

Battery Information

• 24 Vdc, 7 Ah rechargeable battery.

• Provides up to 150 transfers with load of 75

kg (165 pounds).

Life cycle (number of charging cycles) of the

battery is largely dependent on the depth of

discharge in each cycle. The more the battery is

drained the shorter its life span. The life of the

battery is also related to such factors as varying

temperatures and rest periods between charge

and discharge.

Graph 1: Number of recharges vs. Depth of

discharge

Graph 1 illustrates the relationship between

discharging depth and expected battery life.

If you drain the battery until it beeps every time,

you can expect the battery to fully charge only

600 times.

To prolong battery life – Return

the lift to the charger WHENEVER

THE LIFT IS NOT IN USE.

The battery will not overcharge.

BHM uses sealed lead-acid batteries.

Contrary to nickel-cadmium, BHM batteries

do not have any memory effect. Therefore,

batteries should not be completely drained

before recharge.

Graph 2: Number of lifts vs. Lift load

The graph above (Graph 2) illustrates the

relationship between the load lifted and the

number of lifts that can be done with one

recharged battery.

Do not drain the battery

excessively. This will

dramatically reduce the battery

life span.

If the low battery buzzer sounds and red

light flashes, be sure to recharge the battery

as soon as possible.

Charging the battery

DO NOT operate the charger unit

with a damaged cord or if the unit

has been dropped or damaged.

DO NOT forcibly bend the power cord or

place a heavy object on it. This will

damage the cord and may cause fire or

electrical shock.

DO NOT pour liquid on or near the charger.

Do not place the unit in locations

that are:

• Extremely hot

• Dusty or dirty

• Very humid

• Moving or vibrating

The recharging steps should be as follows:

For the 4-function, return to charge and press

0

20

40

60

80

100

120

Charge/discharge cycles

100%

50%

30%

0

50

100

150

200

250

300

350

100 200 300 420

weight

number of lifts

MAINTENANCE

Technical-VOYAGER-550 (REV 4) 11

the button on the handset. The lift cannot

return to charger with a 50-pound load.

For the 2 function, pull the lift gently over to the

charger and ensure it is properly connected.

DO NOT SLIDE THE LIFT OVER TO

THE CHARGER FORCEFULLY OR

QUICKLY. THE CHARGER MAY

BECOME DAMAGED.

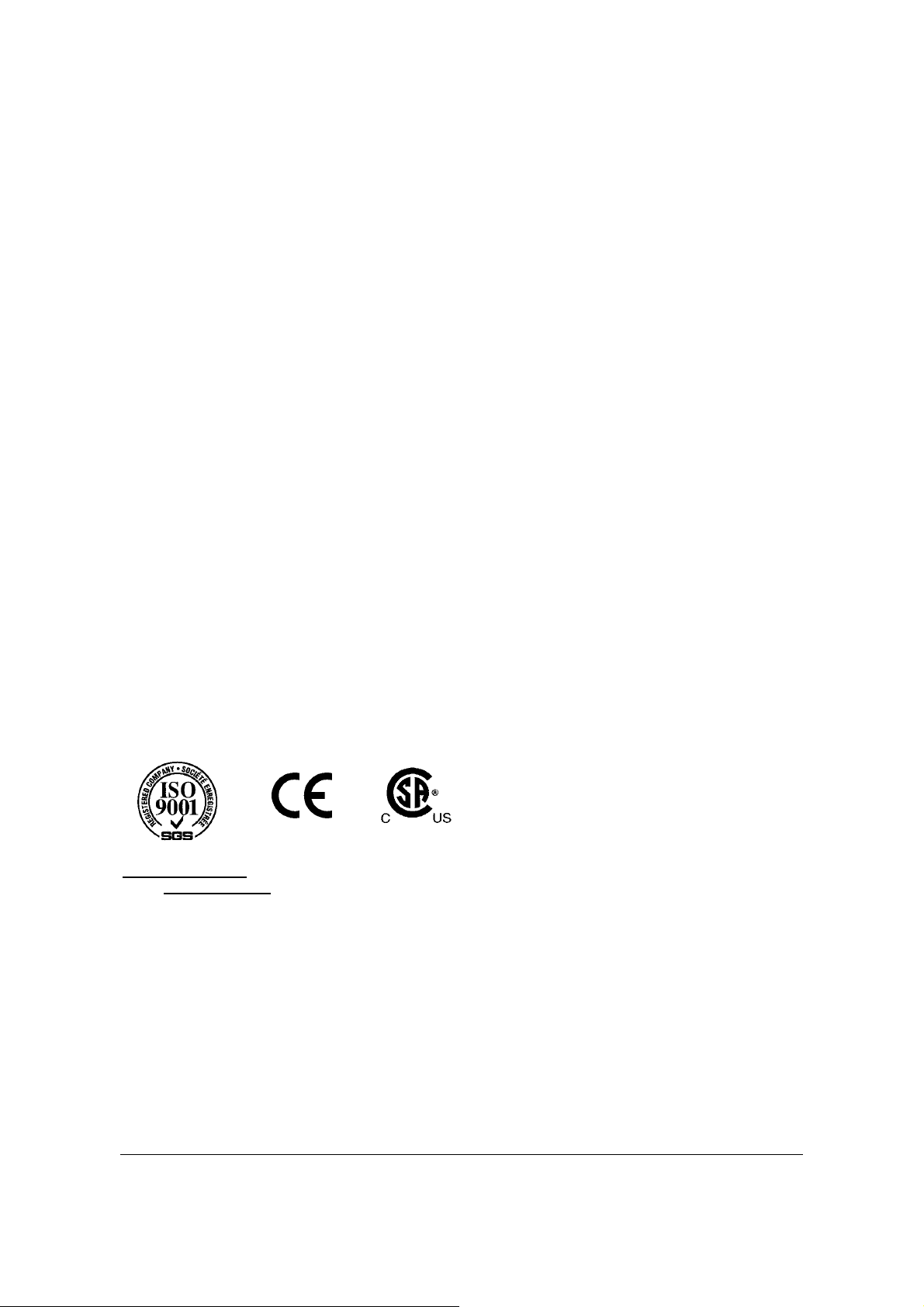

• The indicator light will illuminate red to green

depending on the battery drain. If the light

does not go on, check “Troubleshooting”

section in this manual for assistance.

• If the battery is low, the light will show red or

orange when you return the lift to the

charger. The light will gradually turn to

green when fully charged.

Whenever possible leave the lift

on the charger when the lift is not

in use. At minimum, charge the

battery until the light is green

before using it again. This will

extend the life of the battery.

Charger Specification:

• Hospital grade charger cord and plug.

• Charger input: 120 Vac, 60 Hz, 0.5 A. (North

America) / 240 Vac, 50 Hz, 0.25 A

(European).

MAINTENANCE

ALWAYS CARRY OUT THE DAILY

CHECKLIST BEFORE EACH LIFT

USE.

Alterations made to the VOYAGER 550 by

someone other than a certified technician

may cause serious injury and will void

warranty.

The VOYAGER 550 and accessories must

be inspected ANNUALLY by a certified

technician in addition to the daily and other

periodic visual checks done by the user

specified in this section.

Preventive maintenance specified in this

manual can prevent accidents and reduce

repair costs.

Note all service or repairs to the VOYAGER

550 or its accessories in the log book at the

end of this manual. Have the document

signed by the certified technician.

Daily Check List

THE FOLLOWING PROCEDURES MUST

BE FOLLOWED BEFORE EACH USE.

• Has the battery been charged? Park the lift

on the charger whenever the lift is not in use.

• Inspect the lift for any damage. If the lift

casing does not look properly aligned, or

there are any cracks or other damage on the

lift, or any parts are missing - DO NOT USE

IT. Contact your local representative to

have the lift serviced.

• Inspect the visible strap for any signs of

wear, frays, loose threads or other damage.

If there is any evidence of damage- DO NOT

USE IT. Contact your local representative to

have the lift serviced.

• Inspect the sling for tears, frayed straps or

loose stitching. If the sling has any of the

above damage, DO NOT USE IT. Contact

your local representative to have the sling

replaced or repaired.

• Inspect the carry bar for any signs of

cracking or damage.

• Ensure the ring and cotter pins that attach

the carry bar to the strap are secure.

Inspection and Cleaning

Clean the Voyager 550 with a soft dry cloth, or a

soft cloth lightly moistened with a mild detergent

solution. Do not use any type of solvent that may

damage the finish.

Do not immerse lift in water.

To ensure a better rolling surface for the trolley

wheels, clean the inside of the track every 4

months. To do so, insert a damp cloth in the

opening and slide it from one end of the track to

the other.

Always reinstall rail end stoppers

(if they have been removed) after

servicing.

Strap Inspection

This equipment is built with a strap that can

withstand a load of 1364 kg (3000 lbs.).

Nonetheless, if this strap is damaged or shows

signs of wear, the acceptable load on the strap

before rupture can drop rapidly and present a

danger for the patient and/or caregiver.

MAINTENANCE

Technical-VOYAGER-550 12

BHM Medical recommends thoroughly

inspecting the strap every 2 months as follows:

1. Completely unwind the strap.

2. Look for any signs of wear:

If there is any sign of wear as

indicated above or any other

visual defect, strap should be

changed immediately. By

continuing to use the lift without

changing the strap, caregiver and

patient safety is greatly

compromised.

In any case, the manufacturer recommends

changing the strap at least every two years.

By continuing to use the lift without

changing the strap, caregiver and patient

safety is greatly compromised.

Lubrication

Even if lubrication is not mandatory, we

recommend putting white grease machinery

grade and NLGI 2 type on drum teeth to reduce

friction once a year.

Handling and Storage

Avoid violent shock during transportation.

The lift should not remain stored for long periods

of time without recharging the batteries.

BHM Medical recommends

charging of batteries at least every

two weeks even if the lift is not

used. This will prevent premature

aging of batteries.

Battery Replacement

BHM uses sealed lead-acid batteries. Contrary

to nickel-cadmium, BHM batteries do not have

any memory effect. Therefore, batteries should

not be completely discharged before recharge.

Battery life expectancy is 3000 cycles (average

of 165 pounds and 24 inches travel and 30%

deep of discharge). The 3000 lift cycles

represent the "half-capacity" of the battery,

meaning that the battery is half of a new one.

After this half-capacity, the battery will degrade

rapidly. Therefore, we recommend changing for

a new one.

1. Place the VOYAGER 550 on a solid table.

You can use two pieces of wood to secure

the unit to avoid breaking the trolley.

Remove the cab from the chassis by

unclipping the 4 screw caps with a small

blade and use an 8 mm socket to unscrew

the 4 screws.

2. Unplug red/white and black/white wires from

batteries. Unplug the blue jumper. Unscrew

nuts (8 mm socket) which are retaining

batteries support. Do not completely

unscrew. Unscrew until batteries are loose.

3. Remove batteries and replace them by new

batteries. Tighten nuts (8 mm socket) and

plug in the blue jumper. Plug black/white and

red/white wires. Be careful of the colour

code (black = negative, red = positive). You

can use a hot glue gun to affix the wire to the

battery terminal.

4. Replace the cab. Place the cords and the

handset in their respective hole. Screw back

in and put on the screw caps.

Charger Fuse Replacement

If the light does not illuminate when there is a

battery in it, do the following steps:

Loose threads in stitched area.

Noticeable discoloration by having

a

Lighter color strap than the double

Side wear.

Middle wear.

thickness stitched area.

MAINTENANCE

Technical-VOYAGER-550 13

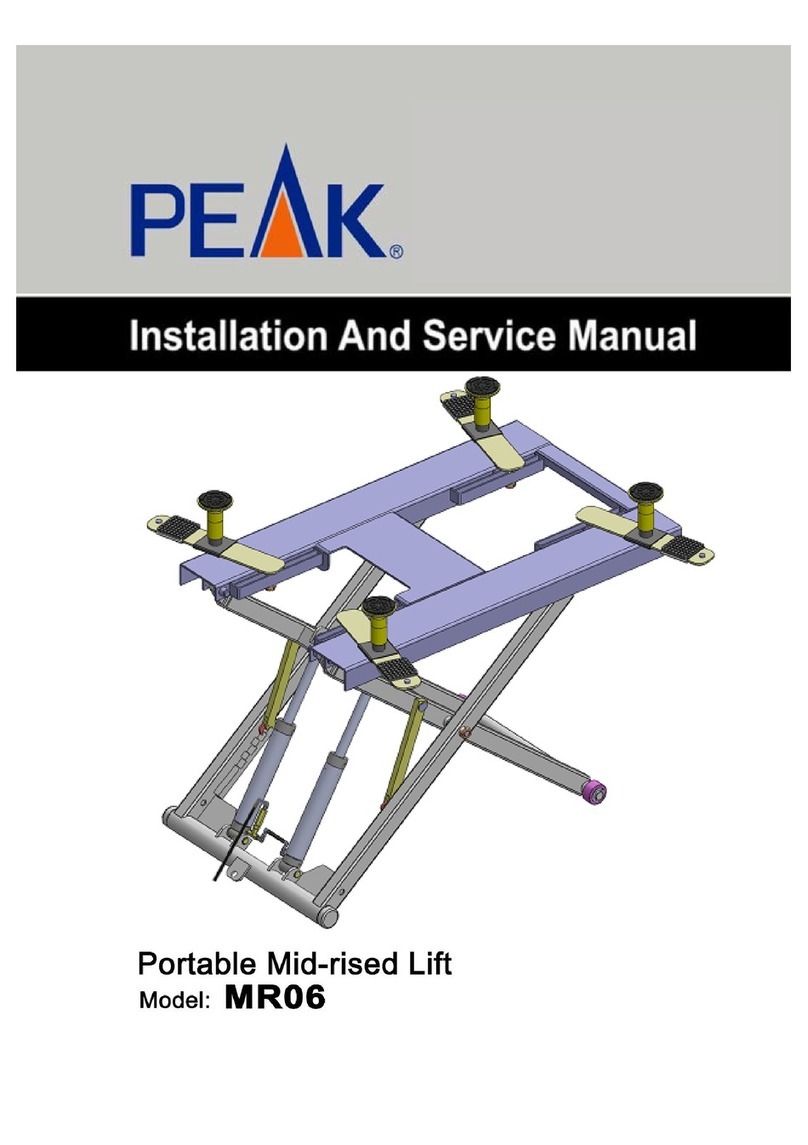

1. Check to make sure the power cord is

correctly plugged into the charger in the

wall.

2. Pull the power cord out of the charger.

Under the socket for the power cord, there

is a drawer or magazine where there are

fuses. Using a pen or screwdriver, pull the

drawer out gently. Pull the burned fuse out

of the drawer that is next to the charger

(see diagram below) and discard. Take the

replacement fuse and place it in the same

slot where the burned fuse was. Slide the

drawer back into the charger. Plug the

power cord into the charger. Place the lift

onto the charger and check for the light.

3. Check the outlet to make sure it has power

to it.

4. If the light does not illuminate, contact your

local dealer or representative for

assistance.

Replace the fuse with the following:

Fuse: GMC 0.5 A 250 V North America (when

input is 120 Vac) Product # C8FGMC0.5

GMC 0.25 A 250 V European (when input

is 240 Vac) Product # C8FGMC0.250

The fuse may also be ordered through your local

dealer or representative.

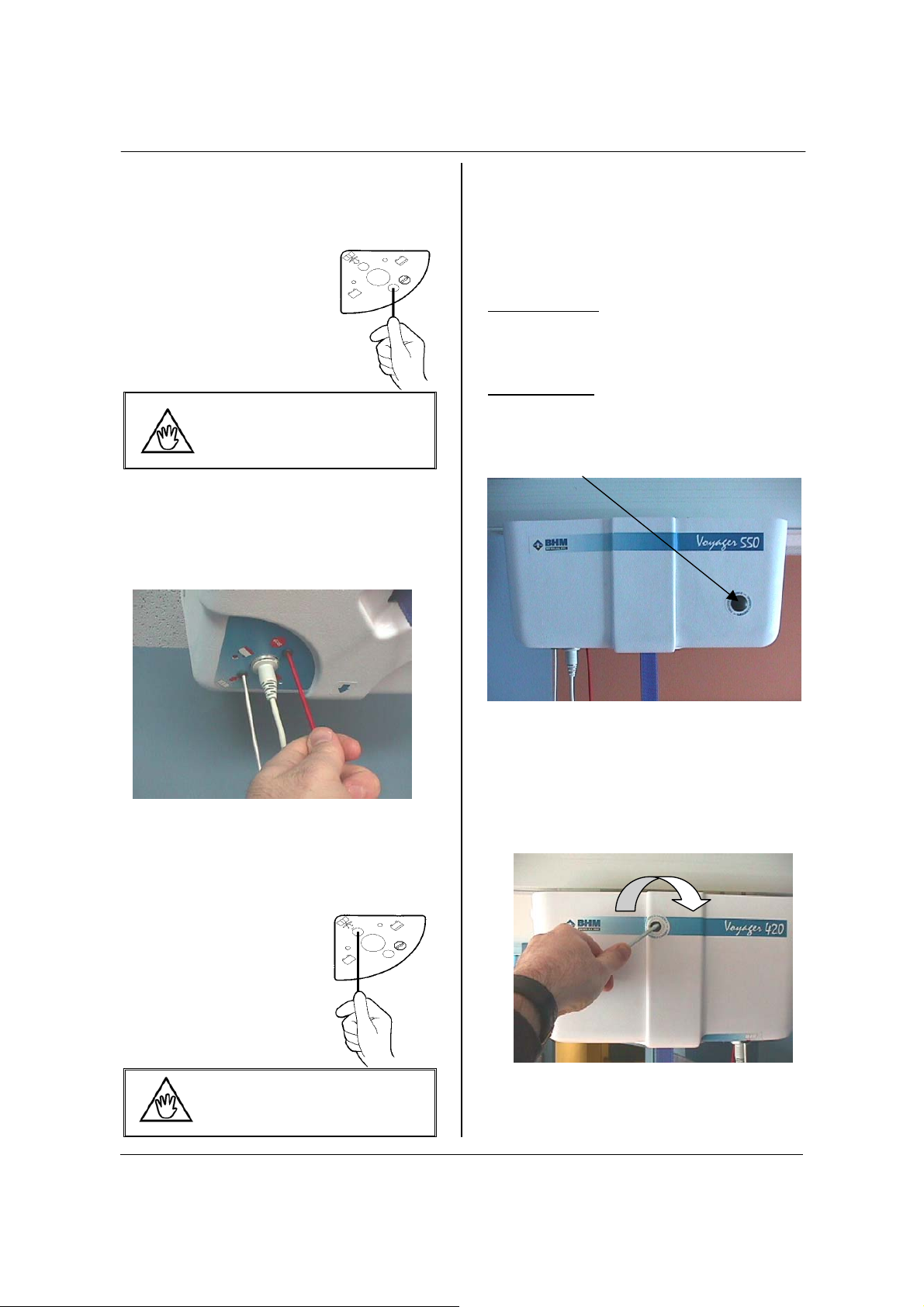

Charger Fuse Replacement (for UK

only)

If the light does not illuminate when there is a

battery in it, do the following steps:

1. Check to make sure the power cord is

correctly plugged into the charger in the

wall.

2. Disconnect the power cord from the wall.

3. Unscrew the fuse holder cap.

4. Replace the fuse with the following:

Fuse: GMC 0.5 A 250 V North America

(when input is 120 Vac) Product

# C8FGMC0.5

GMC 0.25 A 250 V European

(when input is 240 Vac) Product

# C8FGMC0.250

The fuse may also be ordered through

your local dealer or representative.

5. Screw back the fuse holder cap

Strap Replacement

1. Place the VOYAGER 550 on a solid table.

You can use two pieces of wood to secure

the unit to avoid breaking the trolley.

Remove the cab from the chassis by

unclipping the 4 screw caps with a small

blade and use an 8 mm socket to unscrew

the 4 screws.

2. Activate the white cord and pull the entire

strap out of the drum until you align the drum

screw in front of the second frame hole.

3. Unplug the 15-pin power connector from the

circuit board. Remove the circuit board by

unscrewing the two 5 mm screws.

MAINTENANCE

Technical-VOYAGER-550 14

4. Find the second hole on the frame (circuit

side) and unscrew the long bolt of the drum

and remove the strap

5. Install the new strap in the drum (leather

piece upside: wrong side can disable the

limit switch functions) and screw the long

bolt through the strap to the drum.

6. Unscrew nuts (8 mm socket) which are

retaining batteries support and position the

batteries on the frame to give you access to

the limit switches.

7. Insert the other end of strap through the limit

switch, around the guide roll and slide it

between the two limit switches and the guide

roll. With one hand insert the end of strap

and with the other hand using one finger

push the limit switch and with another finger

guide the strap through the hole.

8. Put the batteries and the battery rack back in

place and screw them in with the two 5 mm

locknuts. Put the circuit board back in place

by screwing the board to the frame with the

two 8 mm screws. Plug the 15-pin power

connector to the circuit board.

9. Plug in the handset and push the up button

until the entire strap rolls on the drum.

10. Replace the cab. Pass the cords and

handset through their respective holes.

Screw back in and put on the screw caps.

NOTE: For the first use of the new strap, rewind

the entire strap with light load (50 lbs.) to give a

proper tension.

Drum Replacement

1. Place the VOYAGER 550 on a solid table.

You can use two piece of wood to secure the

unit to avoid breaking the trolley. Remove

the cab from the chassis by unclipping the 4

screw caps with a small blade and use an 8

mm socket to unscrew the 4 screws.

2. Pull the white cord and turn the drum until

you place the connecting link of the chain at

an upper position.

Connecting

link

MAINTENANCE

Technical-VOYAGER-550 15

3. Unplug red/white and black/white wires from

batteries. Unscrew nuts (8 mm socket) which

are retaining batteries support. Remove the

battery rack and the batteries.

4. Unplug the 15-pin power connector from the

circuit board. Remove the circuit board by

unscrewing the two 5 mm screws.

5. Remove the connecting link from the chain

and leave the chain down.

6. Remove the snap ring on the center shaft of

drum and pull out the shaft through the

frame. Remove the drum from the frame.

7. Install the new drum to the frame and insert

the shaft through the drum and frame hole.

Put the snap ring back in place.

8. Insert the end of strap through the limit

switch hole. With one hand insert the end of

strap and with the other hand using one

finger push the limit switch and with another

finger guide the strap through the hole.

9. Install the circuit board by screwing in the

two 5 mm screws. Plug the 15-pin power

connector to the circuit board.

10. Replace the batteries. Tighten nuts (8 mm

socket). Plug black/white and red/white

wires. Be careful of the colour code (black =

negative, red = positive). You can use a hot

glue gun to affix the wire to the battery

terminal to prevent against vibration.

11. Replace the cab. Pass the cords and the

handset through their respective holes.

Screw back in again and put on the screw

caps.

Horizontal Motor Replacement

1. Place the VOYAGER 550 on a solid table.

You can use two pieces of wood to secure

the unit to avoid breaking the trolley.

Remove the cab from the chassis by

unclipping the 4 screw caps with a small

blade; use an 8 mm socket to unscrew the 4

screws.

2. Unplug the 15-pin power connector from the

circuit board. Remove the motor by

unscrewing the four (4) 6 mm nuts. Unplug

the motor from the 15-pin power connector

with a pin extractor tool. Identify their

respective positions (+) and (-).

MAINTENANCE

Technical-VOYAGER-550 16

3. Put the new motor in place. Screw the motor

to the frame with the four (4) 6 mm bolts and

washers. Install the 2 pin connectors

4. Install the circuit board by screwing in the

two 8 mm screws. Plug the 15-pin power

connector to the circuit board.

5. Replace the cab. Pass the cords and the

handset through their respective holes.

Screw it back on and put on the screw caps.

Vertical Motor Replacement

1. Repeat steps 1 to 5 from the drum

replacement instructions except do not

remove the circuit board.

2. Unplug the motor. Remove the motor by

unscrewing the four (4) 6 mm bolts.

3. Pull the motor out with the sprocket

assembly. Do not separate the sprocket from

the motor. In case of sprocket replacement,

Unscrew the screw with a 1/8 hexagonal key

and gently pull out the drive from the motor

4. shaft by sliding it out.

5. Insert the new motor and screw in it with the

two (2) screws at the bottom. Align the upper

screw and secure it in place. Tighten the 2

other screw.

6. Replace the cab. Pass the cords and the

handset through their respective holes.

Screw back in and put on the screw caps.

Limit Switch Replacement

(For models before serial number ABL2-*F*-

1644)

1. Repeat 1 and 5 from the drum replacement

instructions.

2. Unplug the 15-pin power connector from the

circuit board. Remove the retaining ring on

the center shaft of strap guide roll and pull

the shaft out through the frame. Pull out the

strap guide roll from the frame.

3. Remove the strap guide roll with the center

shaft and snap ring.

4. Remove the limit switch by unscrewing the

½ in. nut.

5. Unpin the limit switch from the 15-pin

connector and replace by the new one.

6. Put the strap guide roll in place with the

center shaft and snap ring.

7. Plug the 15-pin power connector to the

circuit board. Replace the cab. Pass the

cords and the handset through their

respective holes. Screw back in and put on

the screw caps.

(For models after serial number ABL2-*F*-

1644)

1. Repeat 1 and 2 from the horizontal motor

replacement instructions.

2. Unplug, in order, the purple, blue and gray

wires from the limit switch.

MAINTENANCE

Technical-VOYAGER-550 17

3. Unscrew the 2 screws with a flat tip

screwdriver and the appropriate key.

4. Remove the limit switch and replace it by a

new one.

5. Screw back in the 2 screws of the new limit

switch.

6. Plug back, in order, the purple, blue and

grey wires.

7. Put the horizontal motor in place. Screw the

motor to the frame with the four (4) 6 mm

bolts and washers. Install the 2 pin

connectors.

8. Install the circuit board by screwing in the

two 8 mm screws. Plug the 15-pin power

connector to the circuit board.

9. Replace the cab. Pass the cords and

handset through their respective holes.

Screw it back on and put on the screw caps.

Limit Switch Rod Replacement

1. Repeat 1 and 2 from the horizontal motor

replacement instructions.

2. Repeat step 1 to 3 from the vertical motor

replacement instructions.

3. Drill out the rivet that holds the limit switch

rod.

4. Remove the spring that holds the rod.

5. Pull out the limit switch rod.

6. Insert the new rod and hold in place by

popping the rivet as shown in the diagram

below.

7. Put the spring back on.

8. Insert the vertical motor and screw in it with

the two (2) screws at the bottom. Align the

upper screw and secure it in place. Tight the

2 other screws.

9. Put the horizontal motor in place. Screw the

motor to the frame with the four (4) 6 mm

bolts and washers. Install the 2 pin

connectors.

10. Install the circuit board by screwing in the

two 8 mm screws. Plug the 15-pin power

connector to the circuit board.

11. Replace the cab. Pass the cords and

handset through their respective holes.

Screw it back on and put on the screw caps.

Purple Blue

Grey

Spring

MAINTENANCE INSPECTION CHECKLIST

Technical-VOYAGER-550 18

Maintenance Inspection Checklist

THING TO BE INSPECTED BY USER

ITEM INITIALLY BEFORE

EVERY

USE

EVERY 2

MONTH

EVERY 6

MONTH

EVERY

YEAR

EVERY 2

YEARS

LIFT DEVICE

Inspect for missing hardware or broken panel. X X X

Inspect strap for wear. X X

Recharging battery X

Inspect trolley in rail for damage, rust or cracks.

Replace if damaged.

X

Overall inspection by authorized personnel. X

SLINGS AND HARDWARE

Check all sling attachments for sign of wear. X

Inspect sling material for wear or deterioration. X

Inspect sling straps for wear. X

Inspect for any defect or loose threads

in the "stitched areas".

X

Cleaning sling as indicated on the tag. When Necessary

Verify strap extension for wear.

Check stitching and check for degradation due to

chemical attack

X

Verify emergency stop cord for wear. X

Verify emergency lowering cord for wear. X

Replace strap. X

Completely unwind the strap and check stitching and

fraying and check for degradation due to chemical

attack.

X

Check the carry bar for freedom of rotation. X

Check for wear on the central pivot of the carry bar and

lubricate it with any light, mineral based grease.

X

Inspect carry bar connecting joint for proper

attachment.

X

Check for presence and correct fitting of the split rings

on the carry bar.

X

Inspect for excessive wear on the sling hooks and any

side suspenders used in conjunction with the spreader

bar.

X

Check for adequate padding of the carry bar. X

Inspect sprockets and chain for wear. X

Lubricate chain and sprockets. X

Inspect trolley wheels for damage, carrying or rust.

Check also the wear on the axles and check for firm

attachment.

X

MAINTENANCE INSPECTION CHECKLIST

Technical-VOYAGER-550 19

ITEM INITIALLY BEFORE

EVERY

USE

EVERY 2

MONTH

EVERY 6

MONTH

EVERY

YEAR

EVERY 2

YEARS

Inspect the welding aspect on the frame to detect

cracks.

X

Inspect connecting joints for proper attachment. X

Confirm the correct operation of the emergency brake

by making sure it is moving freely on the drum.

X

Confirm correct function of the mechanical emergency

lower.

X

Check for firm fixing of the charger to the track. X

Confirm correct mating of the lift to the charger. X

Confirm correct functioning of the charger. X

Check corrects fuse rating. X

Check mains lead plug and socket for proper mating,

look for damage, evidence of burning or arcing.

X

Inspect "Quick Release" system for wear. X

Load test with the SWL (maximum capacity). X

Maintenance inspection points are suggested by the manufacturer. However, in certain

case, some inspections should be done on a more frequent basis. By continuing to use

the lift without replace the listed parts in this maintenance, caregiver and patient safety is

greatly compromised.

TROUBLESHOOTING

Technical-VOYAGER-550 (REV 4) 20

TROUBLESHOOTING

ELECTRICAL SHOCK HAZARD – Before checking electrical components, remove fuses,

unplug the device or disconnect battery.

CAUTION: HIGH VOLTAGE FROM TEST EQUIPMENT can damage electronic circuit and

other parts.

What might seem to be a power failure is not always the case. First check the following:

PROBLEMS TO CHECK

The unit starts and stops repetitively • If the load is over the safe working load, the unit will not

work due to an overload protection on the motor.

• Has the lift been making a “beeping” sound? The battery is

low and needs to be charged.

The lift emits a "beep" and a red light

flashes during utilisation. The unit may

stop lifting but you can still lower it.

• Batteries are low, return to charger.

Charge indicator on the lift (green-red)

doesn't light up when the lift is on the

charger

• Is the charger stopper plugged into a standard outlet? If so

does the outlet have power?

• Check the condition of the fuse. If needed, change it with a

spare one. (see “Maintenance” section of this manual)

Battery is always dead after a few

transfers. (3 to 5)

• Replace battery with a new one, the life of the current one

is probably nearly over.

(Contact your local dealer or representative to have battery

replaced)

The light on the charger shows green yet

the lift will only do one or two transfers.

• Contact your local dealer or representative to have battery

replaced.

The light on the charger shows green yet

the lift will only work when there is no

one in the lift. When you attempt to

transfer someone, the lift stops.

• Contact your local dealer or representative to have battery

replaced.

The lift does not work when you press

the buttons on the handset

• Is the charger light on? Lift must be moved away from the

charger in order to operate.

• Is the emergency stop activated? Gently pull the red cord

once until you hear a ‘click’. Try the buttons again.

• Is the handset properly plugged into the lift? The handset

may be slightly pulled out of its socket yet appear as

though it is plugged in. The lip of the handset must be

flush with the cab of the lift. The socket and handset

connector is a tight fit – press firmly to ensure the handset

is plugged in properly.

• If the handset was not properly plugged into the lift, it may

be necessary to gently pull the red cord once again.

• Slide the lift over to the charger. Is the light red or not on

at all? Battery likely needs to be charged. See

troubleshooting situations above for more information.

• If, after testing all of the above, the lift will not operate,

contact your local dealer or representative.

The charging light on the lift remains

red and does not turn to green after an

overnight charge.

• If available, try another integrated charger stopper from

another lift or a spare one; plug it into the rail and charge

for 3 hours. If the light does not change to white or green,

contact your local dealer or representative.

• Using a voltage meter, test the two contact points on the

Table of contents

Other BHM Medical Lifting System manuals

Popular Lifting System manuals by other brands

stellar labs

stellar labs Slider40 owner's manual

Pride Mobility

Pride Mobility Go-Go Travel Lift owner's manual

Savaria

Savaria M2LIFT-40 owner's manual

matev

matev FPS-JD 3036 Original operating manual

Skyjack

Skyjack SJ40 T+ Operation manual

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL MONOLIFT 800 Instruction and maintenance manual