6/16

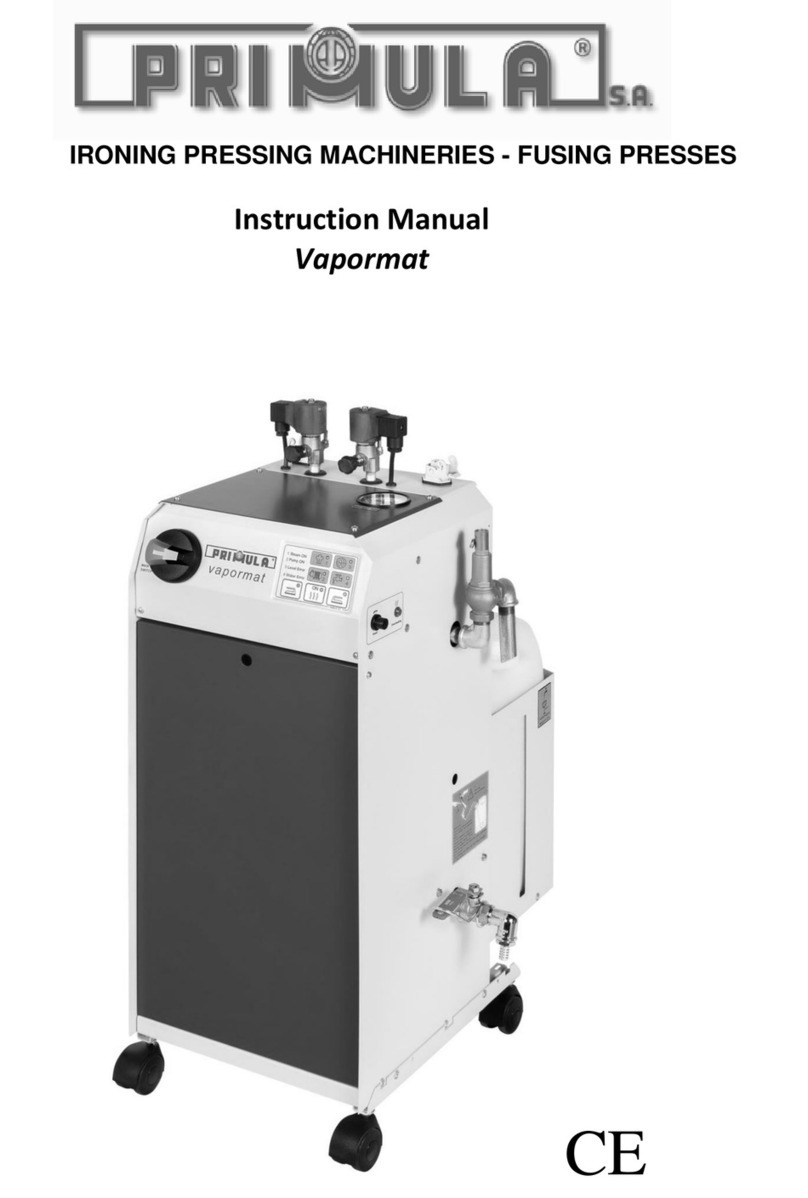

“AUTOMATIC VAPOR” USE AND MAINTENANCE MANUAL

2. OPERATING AND SAFETY

INSTRUCTIONS

1. This appliance is intended for the solely use it is

designed for, the manufacturer cannot be held re-

sponsible for eventual damages for improper use.

2. The fair use of this appliance is exclusively the

one described in this instrucon manual.

3. Aer the removal of the package make sure of

the appliance’s integrity. Eventual damages must

be reported immediately to the seller.

4. This appliance is not intended for outdoor use

or for enviroments with freezing risks.

5. The iron must be placed and used on a at

stable surface.

6. Before the use, check for visible damages.

Never put the machine into operaon in case of

damages and/or water loss and/or fall. In this case

the machine must be sent to the proper service

centre: the security standards could be compromi-

sed and the use could be dangerous.

7. Surfaces next to the boiler, the ironing board

and the iron, might overheat while in operaon

and, therefore, being dangerous.

8. When present and when in operaon, the iron

must be laid on the rubber mat included in the

package.

9. The use of this machine is forbidden to children

and anyone not aware of the risks connected to its

use.

10. Do not leave the machine unaended when

children or anyone not aware of the risks or ani-

mals are around.

11. Children or anyone not aware of the risks are

forbidden to use the packaging or any of its parts:

risk of choking.

12. Do not leave the machine powered when not

necessary, once ended the usage, turn o the

switches and unplug the machine.

13. Connect the machine to an electric outlet

compable with the plug included, checking its

integrity. Only if necessary, use only CE branded

plugs/extension cables in compliance with euro-

pean norms and/or properly set and with a groun-

ding system.

ATTENTION:

Before using the machine, please read care-

fully all the safety and operang instrucons

as described in this manual. KEEP THESE IN-

STRUCTIONS FOR FUTURE REFERENCE.

14. Any type of maintenance and/or cleaning must

be performed with the machine o, cooled and

unplugged.

15. Use only original spare parts and accessories.

16. Installaon, maintenance and repairing ope-

raons must be performed solely by qualied

personnel authorized by the manifacturer.

17. Before connecng the appliance verify that the

line voltage matches with the data wrien on the

label on the back; if you are not sure of your line

voltage, contact qualied personnel.

18. The electrical system to which the appliance

will be connected must be wired and supplied

with a residual current device (lifeline wiring) and

an earthed conductor lead, mandated by law.

Make sure of these security basic requirements,

and if in doubt, contact a qualied technician. The

manufacturer is not responsible for eventual da-

mages to persons and/or things caused by absen-

ce or malfuncon of the residual current device or

the earthed conductor lead.

19. Safe funconing is guaranteed only when the

appliance is connected to the public power grid

with a 3 poles plug (no xed connecon). Once

connected, the plug must be accessible so it can

be unplugged in case of need.

20. To avoid damages, the connecon data on the

machine plate (protecon, frequency, voltage)

must match with the ones of the power grid to

which the machine will be connected. In case of

doubt apply to a qualied technician.

21. When showing even small signs of damage, re-

place the power cable with one of the same type

(available at the authorized technical assistance).

The replacement must be done only by authorized

personnel or by the technical assistance authori-

zed by the manufacturer.

22. The security stopper/security valve must be

replaced every once a year from the rst ignion.

23. Do not pour chemicals, acids, solvents, deter-

gents, corrosive or toxic substances, perfumes etc.

inside the boiler, pour only water.

24. Do not clean the machine by water spraying,

do not dip into water, use only a wet cloth with

the machine o, unplugged and cooled. Do not

use any type of detergents.

25. Never touch the machine while plugged with

wet hands and/or barefoot.

26. Do not use the machine next to water (sinks,

pools, bathtubs, containers, etc.), in places with a