BIFFI F01-2000 Parts list manual

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

INDEX

1 General safety instructions������������������� 2

1.1 Range of application ................................. 2

1.2 Safety instructions for installation in

hazardous area ......................................... 2

1.3 Applicable standards and regulations..... 3

1.4 Terms and conditions ............................... 3

1.5 Identification of the main parts ................ 3

2 Storage and pre-installation����������������� 4

2.1 Tests to be carried out when

theactuatoris received ............................ 4

2.2 Storage procedure .................................... 4

2.3 Checks to be performed

beforeinstallation ..................................... 5

3 Installation �������������������������������������������� 5

3.1 Working condition ..................................... 5

3.2 Coupling block: disassembly from

theactuator ............................................... 5

3.3 Manual operation ...................................... 6

3.4 Mounting the actuator onto the valve ...... 7

3.5 Electrical connections .............................. 7

3.6 Removing the electrical enclosures’

covers......................................................... 8

3.7 Cable entries ............................................. 8

3.8 Terminal board.......................................... 9

3.9 Instructions for the explosion-proof

enclosures................................................. 9

3.10 Installation in environment with

explosivedusts........................................ 10

4 Lubrication ������������������������������������������ 10

4.1 Lubrication inspection ............................ 10

5 Operating the F01-2000 ���������������������� 11

5.1 Operation by handwheel......................... 11

5.2 Setting of mehanical stops..................... 11

5.3 Electrical operation................................. 12

5.4 Local control............................................ 12

5.5 Local indication ....................................... 12

5.6 Lock of the 3-position selector .............. 12

5.7 Remote control........................................ 13

5.8

Operating the F01-2000 for thefirsttime..

14

5.9 Optional modules.................................... 14

5.10 Base card of the F01-2000 v4................. 16

GENERAL INSTRUCTIONS FOR INSTALLATION

OPERATION AND CONFIGURATION

MAINTENANCE AND TROUBLESHOOTING

SPARE PARTS AND DRAWINGS

VCIOM-01249-EN 17/12www�biffi�it Copyright © Biffi. All rights reserved.

2

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

6 Local controls�������������������������������������� 17

6.1

Description of the local operator

interface

.................................................. 17

6.2 Configuration options ............................. 20

6.3 Entering the view mode .......................... 21

6.4 Entering the set-up mode ...................... 21

6.5 Exit from view and set-up mode ............ 21

7 Set-up menu���������������������������������������� 23

8 View menu������������������������������������������� 25

9 Set-up routines ����������������������������������� 27

9.1 Actuator set-up ....................................... 27

9.2 Valve data................................................. 35

9.3 Maintenance............................................ 36

9.4 Example of set-up routine...................... 38

10 View routines �������������������������������������� 39

10.1 Actuator set-up ....................................... 39

10.2 Nameplate............................................... 39

10.3 Valve data................................................. 39

10.4 Maintenance............................................ 40

10.5 Example of view routine.......................... 44

11 Maintenance���������������������������������������� 45

11.1 Standard maintenance ........................... 45

11.2 Special maintenance .............................. 45

11.3 Lithium battery change........................... 46

12 Troubleshooting���������������������������������� 47

12.1 The electronics do not switch on

whenpowered ......................................... 47

12.2 DC output voltage not available at

theterminals........................................... 47

12.3 The actuator does not work from

remotecontrols....................................... 47

12.4

The motor is very hot and does

notstart

.................................................. 48

12.5 The motor runs but the actuator

does not move the valve ......................... 48

12.6 The valve does not seat correctly........... 48

12.7 Excessive torque for valve operation ..... 48

12.8 The actuator does not stop in

fully open orfully closed position .......... 48

12.9 The numeric position display

indicates“E01” ........................................ 48

12.10

Diagnostic messages.............................. 49

13 Parts list and drawings ����������������������� 51

13.1 Introduction ............................................. 51

1 GENERAL SAFETY

INSTRUCTIONS

1�1 RANGE OF APPLICATION

F01-2000 electric actuators covered in this

I&O Manual are designed for the operation

of industrial valves used in heavy industrial,

chemical and petrochemical plants.

Biffi will not be liable for any possible damage

resulting from use in other than the designated

applications. Such risk lies entirely with the

user.

The noise emitted by the electric actuator

in normal working conditions is less than

66dB(A) with peak value 115 dB (C)� Standard

reference ISO 11202 (1st ed�, 1995-12-15)�

The electric actuators are designed in

accordance with the applicable international

rules and specifications but the following

regulations must be observed in any case:

- The general installation and safety

regulations

- T

he plant specific regulations and requirements

- The proper use of personal protective devices

(glasses, clothing, gloves)

- The proper use of tools, lifting and transport

equipment

1�2 SAFETY INSTRUCTIONS FOR

INSTALLATION IN HAZARDOUS AREA

WARNING

In case the electric actuator must be installed in a

HAZARDOUS AREA, as defined by the local rules,

it is mandatory to check if the nameplate of the

electric actuator specifies the appropriate degree

of protection. Maintenance and repair works must

be carried out by qualified personnel and checked

by responsible specialists.

Electric actuators F01-2000 have been designed

and manufactured according to ATEX94/9 EC

directive. Different types of protections are

available, depending on the marking printed

on the actuator label: ExdeIIBTxx and

ExtbTxxwith “Explosion proof” terminal board

enclosure, or ExdeIIBTxx and ExtbTxx with

“Increased safety” terminal board enclosure.

They are suitable for use in hazardous area

classified against the risk of explosion due to

the presence of gas and dust.

Actuators have IP68 degree of protection

according to EN 60529.

WARNING

It is assumed that the installation, setting,

commissioning, maintenance and repair works

are carried out by qualified personnel and

checked by responsible specialists.

1�2�1 Marking

IECEx INE XX.ZZZZ IECEx reference certificate

(CoC)

XX ATEX ZZZZ ATEX reference certificate

0080 Notified body for ATEX quality

assurance (INERIS)

II Group II (surface industries)

2Category 2 apparatus

GExplosive atmospheres caused

by gas, mists or vapors

DExplosive atmospheres caused

by gas dusts

IP66/68 Degree of protection

3

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

Hazardous zone Zone Categories according to 94/9/EC Directive

Gas, mists or vapors 01G

Gas, mists or vapors 12G or 1G

Gas, mists or vapors 23G or 2G or 1G

Dust 20 1D

Dust 21 2D or 1D

Dust 22 3D or 2D or 1D

1�3 APPLICABLE STANDARDS AND REGULATIONS

1�4 TERMS AND CONDITIONS

Biffi guarantees each single product to be free

from defects and to conform to current goods

specifications. The warranty period is one year

from the date of installation by the first user,

oreighteen months from the date of shipment

to the first user, whichever occurs first.

No warranty is given for products or

components (such as electric or pneumatic

mechanisms) manufactured by third-party

companies, or for goods which have been

subject to misuse, improper installation,

corrosion, or which have been modified or

repaired by unauthorized personnel. Repair

work due to improper use will be charged at

standard rates.

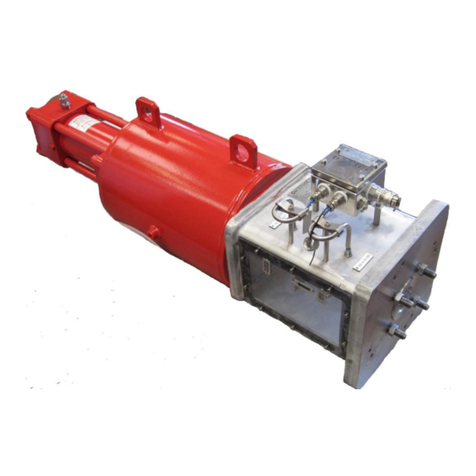

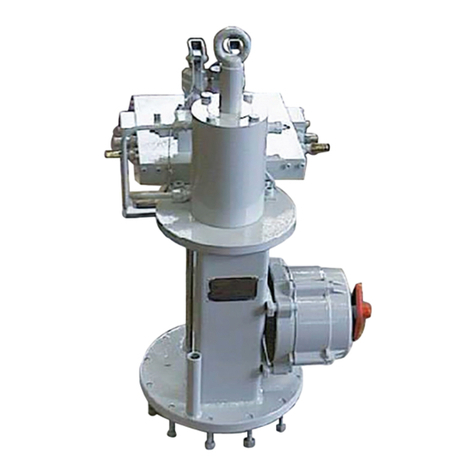

Coupling block

Gearing case

Terminal box

Local interface

Handwheel

1�5 IDENTIFICATION OF THE MAIN PARTS

EQUIPMENT PROTECTION LEVEL (EPL) EN 60079-14

Explosive atmosphere Zone EPL

Gas 0Ga

Gas 1Ga or Gb

Gas 2Ga or Gb or Gc

Dust 20 Da

Dust 21 Da or Db

Dust 22 Da or Db or Dc

EN ISO 12100-1 Safety of machinery - Basic concepts, general principles for design.

Part 1-Basic terminology, methodology

EN ISO 12100-2 Safety of machinery - Basic concepts, general principles for design.

Part 2-Technical principles and specification

EN 60204-1 Safety of machinery - Electrical equipment of industrial machines

2006/42/EC Machinery Directive

2006/95/EC Low Voltage Directive

2004/108/EC EMC Directive

94/9/EC ATEX Directive

4

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

2 STORAGE AND

PRE-INSTALLATION

2�1 TESTS TO BE CARRIED OUT WHEN

THEACTUATOR IS RECEIVED

If the actuator is received already mounted

on the valve, all operations should have

already been performed during valve/actuator

assembly.

• Check that the display is active.

• Turn the handwheel until the valve is in a

completely open position.

• Check that the display reads 100% indicating

that the valve is completely open.

• Rotate the handwheel clockwise and bring

the valve to a completely closed position.

• Check that the display reads 0% indicating

that the valve is completely closed.

If the test result is satisfactory, the actuator

has already been adjusted and you can proceed

with the electrical connection.

If the actuator is delivered separately from the

valve, or the above procedure shows that the

position is incorrect, all operations described in

this manual must be carried out.

• Check that no damage has occurred during

transport, especially to the push-buttons, the

display area glass and the selector.

• Check the information on the nameplate:

serial number and performance data

(nominal torque, operation speed, protection

class, motor supply voltage, etc.), and verify

the corresponding data on the display

(seechapter 10, View routines).

Make sure all accessories have been received

with the shipment, as described in the delivery

documentation.

2�2 STORAGE PROCEDURE

IMPORTANT

Not performing the following procedures will

invalidate the product guarantee.

2�2�1 General

The actuator leaves the factory in perfect

condition, as guaranteed by an individual

test certificate. In order to maintain these

characteristics until the actuator is installed

on site, proper procedures must be taken for

preservation during the storage period.

Biffi actuators are weatherproof to IP68 for a

submersion at depth of 15 metres for 90 hours.

Thiscondition can only be maintained if the

units are correctly installed/connected on site

and if they have been correctly stored.

The standard plastic plugs used to close the

cable entries are not weatherproof, they just

prevent the entry of undesired objects during

transport.

2�2�2 Storage for a brief period

(less than one year)

2�2�2�1 Indoor storage

• Make sure that the actuators are kept in a dry

place, laid on a wooden pallet and protected

from dust.

2�2�2�2 Outdoor storage

• Make sure that the actuators are protected

from the direct action of weather agents

(protection by a canvas tarp or similar cover).

• Place the actuators on a wooden pallet, or

some other raised platform, so that they are

not in direct contact with the ground.

• If the actuators are supplied with standard

plastic plugs, remove them from the cable

entries and replace them with weatherproof

plugs.

2�2�3 Long period storage

(more than one year)

2�2�3�1 Indoor storage

(In addition to the instructions at

paragraph2.2.2.1)

• If the actuators are supplied with standard

plastic plugs, replace them with weatherproof

plugs.

• In case the actuator is provided with an

lithium battery, remove it and store in dry and

clean place (see paragraph 11.3, Maintenance

- Lithium battery change)

2�2�3�2 Outdoor storage

(In addition to paragraph 2.2.2.2)

• Check the general conditions of the actuator,

paying particular attention to the terminal

board, fuse enclosure and local display glass.

• In case the actuator is provided with an

lithium battery, remove it and store in dry and

clean place (see paragraph 11.3, Maintenance

- Lithium battery change).

5

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

2�3 CHECKS TO BE PERFORMED BEFORE

INSTALLATION

• Make sure the valve to be motorised is the

appropriate one for coupling to the actuator.

• The electrical supply cables must be suitable

for the power rating (see the test certificate

that comes with the actuator).

• Gather the right tools for the assembly and

for setting the actuator controls.

If a long storage period has occurred,

beforereinstalling the actuator, please:

• Check the status of the O-ring seals.

• Check the installation of the plugs or cable

glands on the cable entries.

• Check whether the enclosure covers or the

actuator body are cracked or broken.

• Check the oil level in the actuator and top up

if necessary.

• Put the batteries back into place

(seeparagraph11.3, Maintenance - Lithium

battery change).

3 INSTALLATION

3�1 WORKING CONDITION

The standard actuators are suitable for

thefollowing environment temperatures:

-30°C +85°C (-22°F to +185°F)

Special versions are available for extreme

environment temperatures:

-40°C +70°C (-40°F to +158°F)

-55°C +70°C (-67°F to +158°F)

Note: only for Ex d or Ex d e versions, for

ambient temperature range, see the specific

attached addendum.

IMPORTANT

Check the “temperature environment range”

embossed on the nameplate, for the correct

utilisation with respect to the environment

temperature.

3�2 COUPLING BLOCK:

DISASSEMBLY FROM THE ACTUATOR

The bushing is delivered already assembled to

the drive sleeve, even when it is unmachined.

In order to perform the necessary machining,

remove the bushing from its housing. Remove

the fixing screws from the coupling block.

Actuator view from the coupling side, with the

bushing separated from the gearbox. Do not

lose the seal ring between the coupling block

and the gear reduction unit.

6

3�3 MANUAL OPERATION

To manually operate the actuator it is sufficient

to turn the handwheel in the desired direction.

WARNING

Do not manually operate the actuator with devices

other than the handwheel.

Using cheater bars, wheel wrenches, pipe

wrenches, or other such devices on the actuator

handwheel may cause serious personal injury

and/or damage to the actuator or valve.

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

7

4

1 2 3

11" M32x1.5

21-½" M40x1.5

31" M32x1.5

4* ¾" M25x1.5

F01-2000/150 26

F01-2000/300 26

F01-2000/600 28

F01-2000/150 40

F01-2000/300 40

F01-2000/600 80

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

3�4 MOUNTING THE ACTUATOR ONTO

THEVALVE

Lubricate the valve stem.

Thoroughly clean the coupling surfaces of the

valve and actuator flanges, degreasing them

carefully since torque is transmitted by friction.

Lift the actuator with slings suitable for its

weight.

Size

(DN)

Max� weight

(kg)

WARNING

Never lift the valve/actuator assembly without

securing slings to both the valve and the actuator.

YES NO

Check the dimensions of the valve mounting

details, paying particular attention to the

protrusions of the valve stem in order to avoid

any axial thrusts to the internal parts of the

actuator or the valve when the screws are

tightened.

Place the actuator vertically on the valve stem.

Carry out the coupling operations (if necessary

with the help of manual operation); make sure

no mating parts are forced.

3�4�1 Actuator fixing

Model Tightening torque (Nm)

IMPORTANT

In case the actuator is supplied without stud bolts

and nuts the following materials must be used as

a minimum:

- ISO class 8.8 for studs bolts and nuts

or

- ASTM A 320 Grade L7 (or L7M) for studs bolts

- ASTM A 194 Grade 4 for nuts

3�5 ELECTRICAL CONNECTIONS

Before powering to the actuator check that the

supply voltage details on the nameplate are

correct for the plant. Access to terminals for

electrical connections and commissioning is

through the terminal cover, since all settings

are non-intrusive. The removal of any other

covers without Biffi’s approval will invalidate

the warranty.

Biffi will not accept any responsibility for any

damage or deterioration that may be caused.

IMPORTANT

All the accessories (in particular cable glands)

must be certified according to 94/9/EC Directive).

3�5�1 Identification of entries

Electric actuators series F01 2000 are equipped

with 4 entries (3 are standard the fourth is

supplied when requested).

With reference to the attached picture, the

thread form/size for entry is as follows:

3�5�2 Plants requirements

Protection devices (overcurrent breakers,

magneto-thermal switches or fuses) should

be provided on the plant at Customer care,

to protect the mains line in case of motor

overcurrent or loss of insulation between

phases and earth.

Entry

NPT

size

Metric size ISO 965

(alternative)

* optional

8

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

3�7 CABLE ENTRIES

The sealing of cables and conduit entries

should be carried out in accordance with

National Standards or the Regulatory

Authorities that have certified the actuators.

This is particularly true for units that are

certified for use in hazardous areas where

the method of sealing must be to an approved

standard, and cable glands, reducers, plugs

and adapters must be approved and separately

certified.

Certified cable entries:

- Standard ASA/NPT

(cable entries 2x1”+1x1½”)

- Metric ISO 965

(cable entries 2xM32+1xM40)

Remove the cable entry plugs.

WARNING

Do not damage the mating surface of the cover.

IMPORTANT

In case the screws of the cover must be replaced,

a Stainless Steel AISI 316 must be used with

minimum yield strength of 450N/mm²

IMPORTANT

- To prevent any water infiltration through the

line cable conduits, make sure the cable glands

have the minimum protection degree required

by the plant.

- If rigid conduits are used, we suggest placing

a flexible pipe connection between the conduit

and the terminal board.

3�6 REMOVING THE ELECTRICAL

ENCLOSURES’ COVERS

Using a 8 mm Allen key, loosen the four screws

and remove the cover.

3�6�1 Terminal board enclosure

To guarantee weatherproof and explosionproof

fit, screw the cable glands tightly (at least

5turns) and block them with a thread sealant.

The use of a thread sealant is necessary in case

of explosionproof application.

If some parts of the cable glands have been

removed while working on the cable entries put

them back into place now to avoid losing the

dismantled parts.

Unused entries:

- For explosionproof construction:

unusedentries must be plugged with metal

explosionproof plugs and blocked with a

thread sealant.

- For weatherproof construction:

replace the plastic standard protection plugs

supplied with the actuator with metal plugs.

9

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

Terminate the ground connections to the

ground stud marked One internal

andoneexternal ground studs are provided.

Check the wiring diagram (always enclosed

with the actuator) and the layout displayed

on the back of the terminals enclosure cover,

to ensure a correct electrical connection.

3�9 INSTRUCTIONS FOR THE

EXPLOSIONPROOF ENCLOSURES

IMPORTANT

Electric actuator F01-2000 shall be installed

and maintained according to the applicable

rules regarding the electrical installations in

hazardous area (other than mines) classified

as zone 1 (gas); example: EN 60079-10

(hazardousareaclassification), EN 60079-14

(electrical installation), EN 60079-17

(maintenance), and/or other national standards.

During the dismantling and subsequent

reassembling of the explosionproof enclosures

(covers, cable glands, joints) be careful to bring

these enclosures back to their original condition

3�8 TERMINAL BOARD

Ground studs

IMPORTANT

The removal of any other covers without Biffi’s

approval will invalidate the warranty. Biffi will

not accept any responsibility for any damage or

deterioration that may occur as a result of cover

removal.

Allterminations should be made by insulated

ring or spade connectors using the appropriate

crimping tool. This operation will ensure easy

and correct electrical connection.

Connect the motor supply cable previously

sized in accordance with:

- The absorbed current correspondent to the

actuator nominal torque with the torque

limiting device set at 100 percent (see the test

certificate attached to the actuator).

- The applicable plant and safety norms.

Assemble the power terminals protective

barrier, located in the terminal board

compartment, using the enclosed screws.

The control circuit (controls and signals) must

be connected by means of a multicore cable

to the corresponding numbered terminals

according to the wiring diagram.

The internal cables of the actuator are also

numbered according to the wiring diagram.

Actuators are always delivered with the

motors wound and connected in accordance

to customer requests. Voltage and frequency

values are stated on the motor nameplate.

Connections for Ex e terminals enclosure

The wires must be terminated in accordance

with the following method (see connection table

below):

CONNECTION TABLE

Power cables Control cables

Type of terminal Insulated ring tongue

Eye dimensions (mm) 5.50 3.20

Recommended tightening torques (Nm) 2.0 - 2.8 1.0 - 1.5

Wires section (mm2) 4 2.5

BOLTING TABLE

Model

Motor

cover

Terminal enclosure/

local interface covers Material

F01 M10x35 M10x30 AISI 316/ASME B16.11 A182-F316 (yield strength ≥ 450N/mm2)

to maintain their integrity. In particular, be

sure the joint surfaces of all enclosures are

spread with a film of recommended grease

(seechapter4, Lubrication).

So please:

• Do not damage the explosionproof mating

surfaces on the housing and on the electrical

enclosures covers.

• Reinstall all the screws that go with the

dismantled parts, and block them with a

thread sealant after spreading them with

a film of copper- or molybdenum-based

grease. This will keep screws from sticking

and make maintenance operations easier.

• Check that the bolts and screws are the

same dimension and quality as the original

ones (see bolting table below), or of a

betterquality.

10

1

2

F01-2000/150 0.7

F01-2000/300 0.7

F01-2000/600 0.8

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

4 LUBRICATION

4�1 LUBRICATION INSPECTION

The actuator is lubricated for life, therefore

under normal working conditions it is not

necessary to replace or refill the oil. However

it is recommended to check the oil level every

3-5 years using holes 1 or 2 depending on

mounting position.

The actuator is fitted with oil plugs (parts 1, 2),

so that any assembly on the valve has at least

one oil plug on the upper part of the housing

and one on the lower part.

The actuator is supplied with oil and greased

where necessary.

Actuator size Oil quantity (l)

In case of maintenance the following oils are

recommended:

Ambient temperature from -30°C to +85°C

(-20°C to +60°C only for Ex d e or Ex tb

versions)

• SHELL - TIVELA OIL SC320

Other equivalent:

• EXXON TERESSTIC SHP320

• MOBIL OIL - GLYGOYLE HE 320

• KLUBER LUBRICATION - KLUBERSYNTH

EG4-320

Ambient temperature from -55°C to +70°C

• SHELL - CASSIDA FLUID HF 68

Other equivalent:

• SYNECO - WINTER PLUS

In case of maintenance the following greases

are recommended:

Ambient temperature from -30°C to +85°C

(-20°C to +60°C only for Ex d e or Ex tb

versions)

• ISO viscosity grade X1 (EP1)

Other equivalent:

• ESSO BEACON EP1

• AGIP GR MU/EP1

• AEROSHELL GREASE for explosion-proof

joints in ATEX version

Ambient temperature from -55°C to +70°C

• FUCHS FN20

Other equivalent:

• TEXACO low temperature grease EP

• AGIP FN20/00

3�10 INSTALLATION IN ENVIRONMENT WITH

EXPLOSIVE DUSTS

IMPORTANT

Electric actuator F01-2000 shall be installed and

maintained according to the applicable rules

regarding the electrical installations in hazardous

area (other than mines) classified as zone 21

(dust); example: EN 61241-14 (dust) and/or other

national standards.

Please make sure that:

- The joint surfaces are greased with silicon oil

or equivalent before assembly.

- The cable glands have minimum protection

degree IP68 (EN 60529).

- Periodically verify the quantity of dust

deposited on the enclosure and clean it if

more than 5mm.

• Replace the weatherproof seals that may

have been removed (O-ring for the covers,

O-ring for the explosionproof joint of the

motor).

When the Ex d e version is supplied, according

to the protection degree shown on the

nameplate, waterproof cable glands with a

minimum IP68 protection degree, can be used.

WARNING

Do not operate the actuator electrically when the

electrical enclosures are removed. Operating the

unit with the electrical enclosures removed could

cause personal injury.

11

L min.

L max

F01-2000/150 24 16

F01-2000/300 24 16

F01-2000/600 29 18

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

5 OPERATING THE F01-2000

5�1 OPERATION BY HANDWHEEL

To manually operate the actuator it is sufficient

to turn the handwheel in the desired direction.

The manual operation is always possible

without any clutching mechanism.

5�2 SETTING OF MECHANICAL STOPS

Necessary equipment: a 3 mm hexagonal key.

According to the type of valve to be operated,

the actuator can be stopped by means of torque

or position limit switches, as detailed in the

following list:

Valve type: metal seated butterfly valve

Closing: torque

Closing: position

Valve type: ball valve, butterfly valve, plug valve

Opening: position

Opening: position

Before any setting operation, it is necessary to unscrew the adjustable mechanical stops.

Hold the lock nut and remove the mechanical stop protection by unscrewing it.

Remove the seal washer.

Hold the mechanical stop by means of a suitable Allen key and in the same time loosen the lock

nut by one turn.

Screw the closing or opening mechanical stop until it reaches the end stroke.

From here unscrew it by half a turn and lock it with the lock nut.

Check the protrusion of the mechanical stop:

for a stroke of 90° ± 5°, length “L” should be within the following values:

Size L max� (mm) L min� (mm)

WARNING

Do not manually operate the actuator with devices

other than the handwheel. Using cheater bars,

wheel wrenches, pipe wrenches, or other such

devices on the actuator handwheel may cause

serious personal injury and/or damage to the

actuator or valve.

12

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

5�3 ELECTRICAL OPERATION

Before connecting power to the actuator check

that the voltage is correct and according to the

indications on the nameplate. Wrong power

supply could cause a permanent damage to the

electrical components. Check of phase rotation

is not necessary since the unit is provided with

automatic phase rotation correction. Place

the 3-position selector in OFF and then switch

on the power. Do not operate the actuator

without first checking that the configuration is

according to the required application. Usingthe

“VIEW and SET-UP” features can do this

(seeparagraph 6.4, Local controls - Entering

the set-up mode).

5�4 LOCAL CONTROL

After configuring the actuator, if no alarm is

present, place the 3-position selector in LOCAL

and control the actuator by OPEN, CLOSE and

STOP push-buttons.

If “push-to-run” was selected the actuator can

be driven to the desired position by pressing

and holding the OPEN/YES or CLOSE push-

button. As the push-button is released, the

motor is de-energized.

If “latched” was selected, as the OPEN or

CLOSE push-button is pressed the motor is

energized, and it runs on after the control

is released. To stop the motor, press the

STOP push-button. Toreverse the direction,

press the STOP push-button and then press the

push-button relevant to the opposite direction.

In “latched with instant reverse” mode, the

local controls work as in the “latched” mode,

but to reverse the motor direction you only

need to press the push-button relevant to the

opposite direction.

5�5 LOCAL INDICATION

The upper display (3½ LCD) indicates the

valve position as a percentage of opening

(open=100%).

The lower display has two alphanumeric lines.

The upper line indicates the actuator status and

the 3-position selector status. The lower line

indicates the actuator operation.

Two LED’s indicate the actuator position /

operation, while a third LED indicates alarms.

5�6 LOCK OF THE 3-POSITION SELECTOR

The 3-position selector can be locked in any of

its three positions by means of a padlock.

OPEN/YES

STOP

CLOSE/NO

Status Operation

or Position

request R%

Local selector

position

13

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

5�7�1 Remote commands

Using the “VIEW and SET-UP” features may

configure different control modes.

4 WIRES (see the remote connections diagram)

In “4 wires latched” (OPEN, CLOSE, STOP,

COMMON) mode, with the OPEN or CLOSE

signal switched to ON, the motor is energized,

and it runs on after the signal returns to OFF.

To stop the motor, press STOP. To reverse

the direction, press STOP and then press the

button relevant to the opposite direction.

OPTION A1)

OPTION B1)

3 WIRES (see the remote connections diagram)

With option “3 wires” (OPEN, CLOSE, COMMON),

the actuator can be driven in either “push-to-

run” or “latched with instant reverse” mode.

In “ push-to-run ” mode, the actuator can be

driven to the desired position by switching the

OPEN or CLOSE signal to ON. As the signal

returns to OFF, the motor is de-energized.

In “latched with instant reverse” mode, when

the OPEN or CLOSE signal switches to ON,

the motor is energized, and it runs on after the

signal returns to OFF. If the signal relevant to

the opposite direction goes ON, the actuator

reverses its direction and maintains the new

direction also if the signal returns to OFF.

The circuits associated to the inputs can be

supplied by the internally-generated 24 V DC

or by an external 20-125 V DC or 20-120 V AC

(50/60 Hz).

The signal levels are the following:

- Minimum ON signal > 20 V DC or 20 V AC

(50/60 Hz)

- Maximum ON signal < 125 V DC or 120 V AC

(50/60 Hz)

- Maximum OFF signal < 3 V DC or V AC

5�7�2 Output contacts

- Monitor relay: on the terminal board, the

voltage-free, change-over contacts of the

monitor relay are available. The monitor relay

indicates that the actuator can be remotely

controlled or that there is a problem or

condition which prevents remote control of

the valve. The conditions that cause the relay

to switch over are listed in paragraph 9.1.6,

Output relays.

- AS1,2,3,4 relays: on the terminal board, the

voltage-free contacts of 4 latching relays are

available. The status (make or break) and the

conditions that cause the switching of the

relay can be viewed and configured by using

the “VIEW and SET-UP” features. The status

of the latching relays is immediately updated

as the associated conditions for change

occur. Moreover, the status of the above

contacts is cyclically updated (every 500 ms)

- Contact rating:

Max. voltage 250 V AC/30 V DC

max. current 5 A;

Min. voltage 5 V DC;

min. current 5 mA

2 WIRES (see the remote connections diagram)

With the “2 wires” option 2 different activities

may be selected:

In “2 wires, signal ON to open”, the actuator

opens if the signal switches to ON and closes

if the signal goes to OFF. In “2 wires, signal

ON to close”, the actuator closes if the signal

switches to ON and opens if the signal switches

to OFF.

OPTION A2)

OPTION B2)

OPTION A3)

OPTION B3)

5�7 REMOTE CONTROL

Place the 3-position selector in REMOTE to

transfer the actuator control to a remote

device. LocalOPEN or CLOSE operation will

be inhibited. Only local STOP control remains

active.

Using the “VIEW and SET-UP” features may

configure different control modes. The remote

controls are opto-coupled.

A non-regulated 24 V DC voltage (variable from

23 to 27 V DC, max. 4 W) is available on the

actuator terminal board to supply the remote

controls or external devices.

- Minimum signal duration > 300 ms.

- Total current drawn from remote controls

< 25 mA

5�7�3 ESD operation

An ESD (Emergency Shut Down) signal

can be sent to the actuator to override any

existing command and to drive the valve to a

predetermined position.

The control is not self-maintained, that is, the

ESD action continues until the relevant signal is

present. The “VIEW and SET-UP” features can

configure different ESD options.

The ESD command is opto-coupled.

Thecircuits associated to the input can be

supplied by the internally generated 24 V DC

or by an external 20-125 V DC or 20-120 V AC

(50/60 Hz).

The signal levels are the following:

- Minimum ON signal > 20 V DC or 20 V AC

(50/60 Hz)

- Maximum ON signal < 125 V DC or 120 V AC

(50/60 Hz)

- Maximum OFF signal < 3 V DC or V AC

- Current drawn from ESD controls < 15 mA

WARNING

If customers wish the motor thermostat to be

by-passed during ESD operation any certification

for actuator enclosure in hazardous area would be

invalidated.

14

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

5�8 OPERATING THE F01-2000 FOR THE

FIRSTTIME

Before attempting to operate the F01-2000

for the first time, check that the actuator is

correctly mounted on the valve. Place the

3-position selector in OFF and switch the

power on. The alphanumeric display shows the

following message for about 3 seconds:

5�9 OPTIONAL MODULES

Additional modules can be plugged in the base

card of the F01-2000 to provide the following

functions:

5�9�1 Fieldbus interface for remote control via

FIELDBUS

This card allows to connect the F01-2000 to

FIELDBUS.

The following bus interface cards are available:

- Profibus DPVO

- Profibus DPV1 with or without redundancy

- Foundation Fieldbus

- LonWorks

- Modbus RTU

A Hardware alarm is generated if the F01-2000

was set to be equipped with bus card, but the

card is damaged or missing. A BUS REPORT

is also present in the list of reports if the card

is present (see chapter 6). See the specific

manuals for instructions and the setting of the

above modules.

Then the new message should be:

according to the configuration present in the

memory.

If the upper line of the display shows

“ALARM OFF”, remove the alarm before

going ahead (see paragraph 12.10).

If the upper line of the display shows

“WARNING OFF”, a warning condition

is present. You can go ahead since the

F01-2000 is working well, but some datum is

not according to the configured parameters

(seeparagraph 12.10).

If the following message appears, the base

card is F01-2000 v4 type, but the actuator is

equipped with an F01-2000 v0 series terminal

board. This may happen if the F01-2000 v4 base

card was supplied as a spare card, to replace

the base card of the F01-2000 v0 series (see

the previous revision of instruction manuals

relevant to the F01-2000 and its optional

modules).

5�9�2 Ain/Aout card

With the above card the F01-2000 is provided

with a 4-20 mA analog input and a 4-20 mA

analog output. This card should be plugged

on the base card, replacing the “TERMINAL

BOARD ADAPTOR” card supplied as standard.

A Hardware alarm is generated if the F01-2000

or

Biffi Italia

F01-2000 v4 ntb

NORMAL OFF

STOP

NORMAL OFF

R%: xxx�x

Biffi Italia

F01-2000 v4 otb

Do not operate the actuator without first

checking that the configuration is according to

the required application by using the “VIEW and

SET-UP” features (see chapter 6/10).

Set torque limits, position limits and close

direction by means of the “stroke limits

routine” of the “actuator set-up” menu

(see chapter 9).

When the stroke limits and the configurations

are correct, bring the 3-position selector to

LOCAL and drive the actuator to open or closed

position (see paragraph 5.4).

If the upper line of the display shows

“INT OFF”, an Interlock input is active.

If the upper line of the display shows

“ESD ON OFF”, the ESD input is active.

was set to be equipped with an Ain/Aout

card, and the card is damaged or missing.

An Ain/Aout REPORT is also present in the list

of reports if the card is present (see chapter 6).

5�7�4 Interlock inputs

Two additional inputs are available to inhibit

actuator movement in open or close direction.

The controls are momentary, and the inhibit

action continues until the relevant signal

is present. The interlock controls work

when the local selector is in either LOCAL

or REMOTE positions. The ESD control

overrides the interlock controls. The “VIEW

and SET-UP” features can configure the

polarity of INTERLOCK signal as described in

paragraph9.1.10, Interlock.

The interlock inputs are opto-coupled and can

be supplied by the internally generated 24 V DC

or by an external 20-125 V DC or 20-120 V AC

(50/60 Hz).

The signal levels are the following:

- Minimum ON signal > 20 V DC or 20 V AC

(50/60 Hz).

- Maximum ON signal < 125 V DC or 120 V AC

(50/60 Hz).

- Maximum OFF signal < 3 V.

- Total current drawn from remote controls

< 20 mA.

OPTION D1)

OPTION D2)

OPTION E1)

OPTION E2)

15

B6

B7

B7

C10

B9

B8

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

• 4-20 mA analog output

The 4-20 mA output can be configured to

provide a signal proportional to either “position”

or “torque”. The polarity option allows to

reverse the relationship between the position

or torque and the 4-20 mA output signal. See

“VIEW and SET-UP” features (paragraph 9.1.9,

OUT 4-20 mA).

The 4-20 mA output is opto-coupled. It should

be powered by a 20-30 V DC voltage (externally

or internally generated) and the maximum load,

including the cable resistance, should be less

than 300 ohm.

Figure A shows the wiring diagram.

Actuator terminals ACTIVE LOOP

Cable

GROUND

Shield

20-30

V DC

External power supply

LOAD: max 300 ohm

Internal power supply

Cable

GROUND

Shield

LOAD: max 300 ohm

The behaviour in case of loss of main

voltage is different if the power supply of the

4-20 mA output stage is internally or externally

generated:

- Internal power supply (or passive loop):

In case of loss of main voltage the output

4-20 mA drops to 0. The correct output will be

restored when the main voltage returns.

- External power supply (or active loop):

If the actuator is provided with an lithium

battery (or supplied by the auxiliary 24 V DC)

and if the main voltage fails, the output

4-20 mA maintains the last value. If the

actuator is moved by handwheel, the output

4-20 mA will be updated.

If the actuator is not provided with an lithium

battery (or not supplied by the auxiliary

24 V DC) and if the main voltage fails, the

output 4-20 mA maintains the last value.

If the actuator is moved by handwheel, the

output 4-20 mA will not be updated.

• 4-20 mA analog input

The 4-20 mA analog input is the position

request R% signal and is used by the F01-2000

to position the valve in inching and modulating

actuators. The “POSITIONER” routine

processes the input signal, compares the

present actuator position % with the position

request R% and if the difference is greater than

the dead band, the actuator is driven to reach

the requested position. 4 mA corresponds to

request R% = 0% = valve closed and 20 mA

corresponds to request R%=100% = valve

open. The relationship between position

and request signals can be reversed by the

“Polarity” function. The 4-20 mA input is

opto-coupled. The input impedance is less than

500 ohm. The loss of the 4-20 mA input signal

is indicated as follows:

- Change-over of the monitor relay

- Alarm LED on

- List of ALARMS (see paragraph 12.10,

Diagnostic messages)

- Alarm log

Figure B shows the wiring diagram.

Actuator terminals

Cable

0 V DC

4-20 mA

GROUND Shield

4-20 mA

generator

PASSIVE LOOP

4-20 mA

0 V

4-20 mA

FIGURE A

FIGURE B

The “VIEW and SET-UP” features can configure

different options which are described in

paragraph 9.1.7, Positioner.

If the POSITIONER function is active the

alpha-numeric display indicates the value of the

position request in % (R%: xxx.x).

NORMAL REMOTE

R:47% NEXT?

0 V

V+

0 V

16

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

Ain/Aout card

This optional card is used in place of the

Terminal Board Adaptor (TBA) card when

an analog 4-20 mA input and output signal

is requested. This card cannot be used in

the actuators with terminal board series

F01-2000 v0 (see paragraph 5.8, Operating the

F01-2000 for the first time).

5�10 BASE CARD OF THE F01-2000 V4

Bottom view of base card

Terminal Board

Adaptor card (TBA)

Fieldbus interface card

The type of card depends on the fieldbus

present in the plant.

Base card equipped with fieldbus interface card

and Terminal Board Adaptor card.

Top view of base card

Bluetooth™

Potentiometer card

this card allows the base card to read position

and torque values from the potentiometers

installed on the actuator

17

4

6

1

3

2

5

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

6 LOCAL CONTROLS

Numeric display to indicate the present

valve position as a % of the opening.

Display resolution in function of the actuator

stroke turns:

- From 2.8 to 5.5 turns = 1%

- From 5.5 to 13.8 turns = 0.5%

- From 13.8 to 27.7 turns = 0.2%

- From 27.7 to 10,000 turns = 0.1%

3-position selector to set the following

operation modes:

- LOCAL: for local control only

- OFF: no control is active but the actuator is

still connected to the mains

- REMOTE: for remote control only

Alphanumeric display: during normal

operation the alphanumeric display shows the

present status (NORMAL, ESD ON, ALARM,

WARNING, INTERLOCK), the 3-position

selector status (LOCAL, OFF, REMOTE) and the

actuator action (OPEN, OPENING, CLOSED,

CLOSING, STOP or

R% : xxx.x). If the local selector is in OFF or

REMOTE, pressing the YES push-button it is

possible to scroll the list of variables, alarms

and reports:

CLOSE/NO

STOP

OPEN/YES

The F01-2000 can be provided with a

radiofrequency wireless connection based on

a qualified Bluetooth™ class 1 module. This

allows to establish a connection and exchange

data with a PDA or PC with built-in Bluetooth™

technology. The following tasks can be

wirelessly performed:

- View and change configuration

- Set maintenance function

- Read maintenance data

- Download new firmware to the F01-2000

- The blue LED indicates that the

communication with a host device is

established

Local controls: OPEN/YES, CLOSE/NO,

and STOP push-buttons.

The STOP push-button resets any existing

command and is active both in local and

remote.

If the 3-position selector is in LOCAL, the

OPEN / YES, and CLOSE /NO push-buttons

work as OPEN and CLOSE commands.

If the 3-position selector is in REMOTE or

in OFF, the OPEN / YES and CLOSE / NO

push-buttons work as YES and NO to answer

the prompt (next? OK? view?, change? exit?) of

the alphanumeric display.

In OFF, the OPEN / YES and CLOSE / NO

push-buttons allow to scroll down the menu,

to view and change the actuator configuration

or to scroll the list of variables, status, and

alarms.

In REMOTE, the above push-buttons allow

scrolling the list of variables, status, alarms

and reports but the actuator configuration

cannot be viewed or changed.

6�1 DESCRIPTION OF THE LOCAL OPERATOR

INTERFACE

The following functions are available by the

F01-2000 local operator interface:

- actuator control

- actuator configuration

- actuator status visualisation

The figures on the following pages describe

the function of each component of the local

operator interface.

1

3

2

4

5

6

output torque mot temp

motor speed term temp

main voltage log status

current wireless report

temperature node report *

time FDI report *

date base report

alarm term report

warning Ain/Aout report *

Ktemp

The data with * are only present if the relevant

modules are present.

Three LED’s to indicate the actuator

status according to the following logic:

- green ON/ red OFF: the actuator is stopped in

open position

- green OFF/ red ON: the actuator is stopped in

closed position

- green OFF/ red flashing: the actuator is

running in closing direction

- green flashing/ red OFF: the actuator is

running in opening direction

- green ON/ red ON: the actuator is stopped in

intermediate position

- yellow ON: alarm

- yellow flashing: warning

The above color combination is supplied as

standard, but it may be changed (red with

green, green with red, and yellow with red),

during actuator setting operations.

18

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

The warning condition occurs when a variable

reaches a critical value and/or a maintenance

action is required, but the actuator control

functions are still available. The alarm

condition occurs when a variable is out of the

acceptable range and the actuator control

functions are not available.

The alarm and warning lists only contain

the present alarms and warnings. When the

fault condition disappears, the corresponding

alarm or warning disappears from the list.

A reset routine is provided to clear the

type of alarm/warning that are memorized

(over-torque, jammed valve,etc.).

DESCRIPTION OF VARIABLES AND REPORTS

torque output torque in % of the nominal torque stated in the NAMEPLATE menu

motor speed RPM of electrical motor

main voltage voltage (V) and frequency (Hz) of mains

current current (A) absorbed by the motor

temperature temperature (°C), inside the electronic compartment

time present time

date present date

alarm list of present alarms (see paragraph 12.10, Diagnostic messages)

warning list of present warnings (see paragraph 12.10, Diagnostic messages)

Ktemp temperature factor

mot temp temperature (°C) of the electrical motor

term temp temperature (°C) inside the terminal board compartment

log status data logger status (off, ready, in progress: E: event number - n° of memory cycle

or R: sample number - n° of memory cycle)

wireless report Bluetooth™ interface status (ready, not ready)

node report report of bus interface card (only present if the bus card is present)

(see the relevant instruction manual)

FDI report report of FDI function (only present if the LonWorks bus card is present)

(see the relevant instruction manual)

base report base card report

- card code

- manufacturing week and year

- electrical diagram, etc.

term report terminal board card report

- card code

- manufacturing week and year

- electrical diagram, etc.

Ain/Aout report Ain/Aout card report (only present if the card is present)

- card code

- manufacturing week and year

- electrical diagram, etc.

19

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

The following drawing shows the use of the OPEN / YES, CLOSE / NO and

STOP push-buttons in function of the local selector position.

LOCAL OFF REMOTE

3-POSITION SELECTOR

= OPEN/YES push-button

= CLOSE/NO push-button

= STOP push-button

ALPHANUMERIC DISPLAY

Only OPEN,

CLOSE and STOP

controls available

Language

selection

View mode Set-up mode

To view

menus

To set-up

menus

View/Set-up mode

selection

Place the

3-position

selector in LOCAL

or REMOTE or

press YES and NO

simultaneously

to exit from VIEW

and SET-UP

MENUS

VIEW AND SETUP MENUS

Press YES

and STOP

simultaneously to

enter VIEW and

SET-UP menus

Press YES or NO to answer the

prompt (view? next?).

If the prompt is “next?” press YES

to view the next variable, press NO

to return to the beginning.

If the prompt is “view?” press

YES to enter the sub-menu of the

variable, press NO to skip to the

next variable.

YES

YES

YES

YES

YES

YES

YES

NO

NO

YES

NO

Variable alarm

and report list

TORQUE % next?

MOTOR SPEED RPM next?

VOLTAGE V,Hz next?

CURRENT A next?

TEMPERATURE °C next?

TIME next?

DATE next?

NO ALARMS/ALARMS next/view?

NO WARNING/WARNINGS next/view?

K TEMP next?

MOTOR TEMP °C next?

TERM TEMP next?

LOG STATUS next?

WIRELESS REPORT view?

NODE REPORT view?

FDI REPORT view?

BASE REPORT view?

TERM REPORT view?

A in /A out REPORT view?

ALARM # 1 next?

..................

..................

ALARM # n next?

RESET ALARMS OK?

WARNING # 1 next?

..................

..................

WARNING # n next?

RESET WARNING OK?

msg # 1 next?

..................

..................

msg # n next?

XXXXXX REMOTE

XXXXXX NEXT?

XXXXXX OFF

STOP NEXT ?

XXXXXX LOCAL

XXXXXX ?

Password

NO

20

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

6�2 CONFIGURATION OPTIONS

The F01-2000 actuator can be totally configured

from the local interface by means of a series

of menus that can be selected from the

alphanumeric display. The operator is guided

through the different displays by answering

YES or NO to the appropriate prompt (change?

OK?, view?, next?, etc.) in the right corner of the

lower row of the alphanumeric display.

To access the menus: set the local selector in

OFF and then simultaneously press OPEN/YES

and STOP. The alphanumeric display will now

show the present language. Press YES if the

language is correct, press NO to scroll the list

of available languages and then YES to select.

After choosing the language, the next step

is the selection among view and set-up

mode. Use “View” mode to see the actuator

configuration, and use “Set-up” mode to

change the present configuration. Unauthorized

access to the set-up mode is prevented by

a 4-character alphanumeric password. The

actuator is supplied by Biffi with the default

password “0 0 0 0”.

Once the correct password has been entered,

the actuator parameters can be configured.

The present password can also be modified by

the “set password” routine in the Maintenance

menu. After entering the new password, the

old one ceases to be valid, so it is important to

record the password in a secure location for

future retrieval.

The configuration functions (view and set-up

mode) are grouped in 4 main menus:

Actuator set-up, Nameplate, Valve data,

Maintenance.

Nameplate

This menu includes a series of data identifying

the actuator characteristics, service, and

utilisation mode. The data are entered by the

manufacturer and can only be viewed (i.e., this

menu is only available in View mode).

List of routines:

- serial number

- actuator type

- torque/thrust

- actuator speed

- power supply

- motor data

- test date

- wiring diagram

- enclosure

- certificate

- lubricant

- revision

- torque sensor

Valve data

This menu includes a series of data relevant to

the valve. The valve manufacturer and end user

should enter the data.

List of routines:

- tag name (max 28 characters)

- manufacturer (max 28 characters)

- break OP torque (max 28 characters)

- serial number (max 28 characters)

- break CL torque (max 28 characters)

- max stem thrust (max 28 characters)

- flange type (max 28 characters)

Maintenance

This menu includes all diagnostic and historic

data which can help the operator in case of

failure or during maintenance operations.

The Maintenance menu also includes the

“Set password” routine.

List of routines:

• Set-up mode

- set new password

- clear alarm log

- set torque profile reference

- set torque curve reference

- clear recent data log

- set maintenance date

- set data logger

• View mode

- alarm log

- torque profile

- torque curve

- operation log

- maintenance date

- data logger

Actuator set-up

This menu includes the routines that allow

the actuator to be configured according to the

requested control mode and to the valve it is

mounted on.

- stroke limits

- torque set-up

- ESD set-up

- remote controls

- local controls

- output relays

- positioner *

- fail safe *

- out 4-20 mA *

- interlock

- 2-speed timer

- Bus *

- miscellaneous

The routines with * are only available if the

relevant modules are present. If bus interface

is LonWorks, the “BUS” routine changes to

“FDI control”.

The parameters appear on the alphanumeric

display in the same order both in view and

set-up mode. At the end of each routine the

program will automatically return to the

beginning of the routine, and the operator can

choose to either re-enter (by pressing YES) or

to move on to a next routine (by pressing NO).

Other manuals for F01-2000

1

Table of contents

Other BIFFI Controllers manuals

BIFFI

BIFFI RPD Series User manual

BIFFI

BIFFI ICON3000 Series User manual

BIFFI

BIFFI ALGA - EAC User manual

BIFFI

BIFFI ECU 1000 Manual

BIFFI

BIFFI HLAS-C Series User manual

BIFFI

BIFFI ICON3000 Series User manual

BIFFI

BIFFI ICON3000 Series Setup guide

BIFFI

BIFFI FCB Series Operating instructions

BIFFI

BIFFI HLAS User manual

BIFFI

BIFFI RPS Series User manual

BIFFI

BIFFI ALGA-EAC Series User manual

BIFFI

BIFFI F02 manual

BIFFI

BIFFI HLA Series User manual

BIFFI

BIFFI OLGA-H User manual

BIFFI

BIFFI HLRA User manual

BIFFI

BIFFI ALGAS-MHP User manual

BIFFI

BIFFI FCB Series User manual

BIFFI

BIFFI PLA User manual

BIFFI

BIFFI ALGAS User manual

BIFFI

BIFFI PLAS Series User manual