1

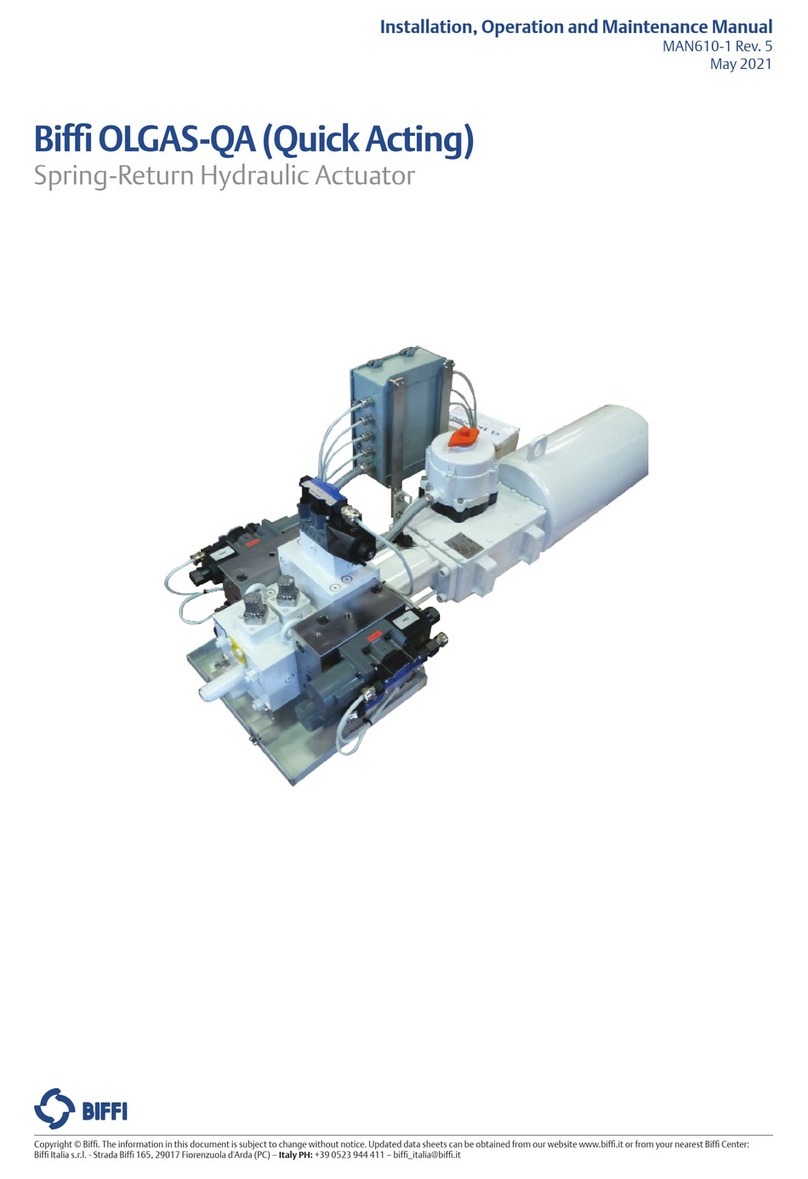

Installation, Operation and Maintenance Manual

MAN 607 Rev. 6 February 2022

General Warnings

Section 1: General Warnings

Section 1: General Warnings

NOTICE

The manual is an integral part of the machine, it should be carefully read before carrying

out any operation and it should be kept for future references.

1.1 Generalities

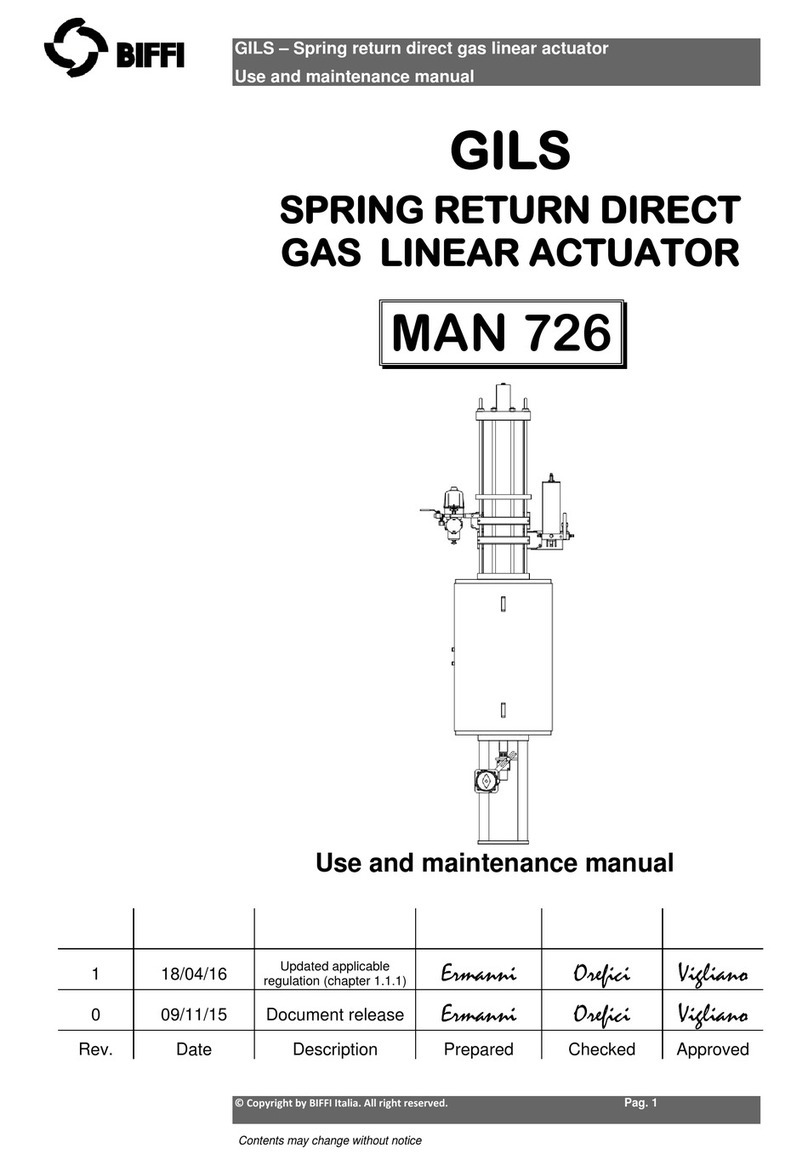

Bif Italia s.r.l. actuators are conceived, manufactured and controlled according to the

Quality Control System in compliance with EN-ISO 9001 international regulation.

1.1.1 Applicable Regulation

EN ISO 12100:2010: Safety of machinery – General principles for design – Risk

assessment and risk reduction

2006/42/EC: Machine directive

2014/68/EU: Directive for pressure PED equipment

2014/35/EU: Directive for low voltage equipment

2014/30/EU: Directive for the electromagnetic compatibility

2014/34/EU: Directive and safety instructions for use in hazardous area

NOTICE

Bif Italia s.r.l. pays the highest attention to collecting and verifying the documentation

contained in this Installation, Operation and Maintenance Manual. However, Bif Italia

s.r.l. is not liable for any mistakes contained in this manual and for damage or accidents

due to the use of the latter. The information contained is of exclusive reserved ownership

of Bif Italia s.r.l. and may be modied without prior notice. All rights reserved.

1.1.2 Terms and Conditions

Bif Italia s.r.l. guarantees that all the items produced are free of defects in workmanship

and manufacturing materials and meet relevant current specications, provided they

are installed, used and serviced according to the instructions contained in the present

manual. The warranty can last either one year from the date of installation by the initial

user of the product, or eighteen months from the date of shipment to the initial user,

depending on which event occurs rst. All detailed warranty conditions are specied in

the documentation forwarded together with the product. This warranty does not cover

special products or components not warranted by subcontractors, or materials that were

used or installed improperly or were modied or repaired by unauthorized staff. In the

event that a fault condition be caused by improper installation, maintenance or use, or by

irregular working conditions, the repairs will be charged according to applicable fees.

The warranty and Bif Italia s.r.l. liability shall lapse in the event that any modication

or tampering whatsoever be performed on the actuator.