i

Installation, Operation and Maintenance Manual

MAN 605 Rev. 4

Table of Contents

February 2021

Table of Contents

Table of Contents

Section 1: General Warnings

1.1 Generalities................................................................................................... 1

1.2 Identification Plate ........................................................................................ 2

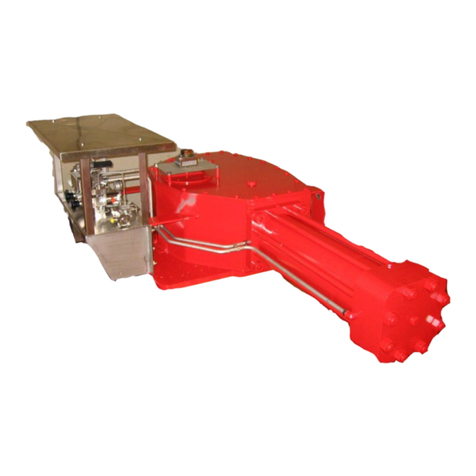

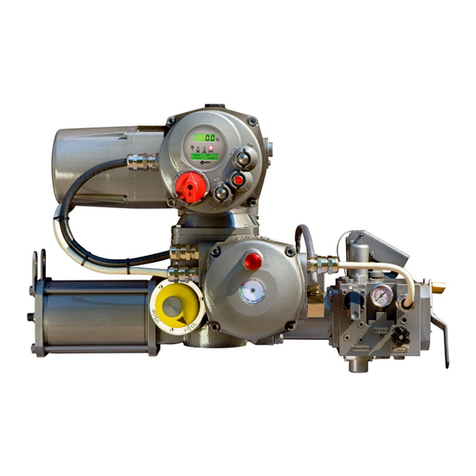

1.3 Introducing the Actuator............................................................................... 3

1.4 Data Sheet .................................................................................................... 4

Section 2: Installation

2.1 Checks Upon Actuator Receipt ...................................................................... 5

2.2 Actuator Handling......................................................................................... 5

2.3 Storage ......................................................................................................... 7

2.4 Actuator Assembly on the Valve.................................................................... 7

2.5 Hydraulic Connections................................................................................ 10

2.6 Electrical Connections (If Any)..................................................................... 11

2.7 Commissioning........................................................................................... 11

Section 3: Operation and Use

3.1 Operation Description................................................................................. 12

3.2 Residual Risks.............................................................................................. 14

3.3 Operations.................................................................................................. 14

3.4 Calibration of the Angular Stroke ................................................................ 14

3.5 Calibration Of Microswitches (If Foreseen) .................................................. 16

3.6 Calibration of the Operation Time............................................................... 19

Section 4: Operational Tests and Inspections

Operational Tests and Inspections..........................................................................20

Section 5: Maintenance

5.1 Periodic Maintenance.................................................................................. 21

5.2 Extraordinary Maintenance ......................................................................... 23

5.3 Lubrication of Mechanism ........................................................................... 26

5.4 Dismantling and Demolition ....................................................................... 27

Section 6: Troubleshooting

6.1 Failure or Breakdown Research.................................................................... 28

Section 7: Layouts

7.1 Spare Parts Order........................................................................................ 29

7.2 Parts List ror Maintenance and Replacing Procedure.................................... 30

Section 8: Date Report for Maintenance Operations

Date Report for Maintenance Operations...............................................................32