SEFRAM MDPP2S V2 User manual

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 1 sur 10

Version:

MDPP2S V2

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 2 sur 10

SUMMARY

Page

- CHARACTERISTICS 2

- DESCRIPTION 2

- FRONT PANEL

DESCRIPTION 3

-

TO ADJUST SET POINTS

3

- WARNING 4

- ADJUST « ZERO » 4

- ADJUSTMENT 4

- INSTALLATION &

MAINTENANCE 4

- WARRANTY 4

- PRECAUTIONS 5

- ELECTRICAL

CONNECTIONS 6

- SPACE & FIXING 7

- EC CONFORMITY

CERTIFICATE 8

CHARACTERISTICS:

Supply voltage 115 or 230VAC ±10% 50/60Hz

24VDC

Consumption 12VA (AC power supply)

12W (DC power supply)

Relay contact characteristics

1 x NO / NC - 1A 250V AC1

To be protected by the user

Remote interfacing 4-20mA output

integrated supply

maxi load: <500 Ohms

Scale measure 6.00 Bars

Proof pressure 300 PSI (20 Bars)

Burst pressure 450 PSI (30 Bars)

Humidity limits 0-100% HR

Pressure media No corrosive

Material in contact with pressure

media

Glass-filled nylon, ceramic AI

2

O

3

,

silicon, RTV

Device precision ±1% maxi of full scale

(10 Bars)

Operating temperature -10° to 70°C compensated from

0 to 70°C

Storage temperature -25°C to 85°C

Using position Vertical

Electrical protection By fuses: T 160mA in 115VAC

T 80mA in 230VAC

T 500mA in 24VDC

Case Polycarbonate IP65

Xk1 and Xk2 thresholds

adjustment 0.00 to 6.00 Bars

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 3 sur 10

DESCRIPTION:

The MDPP2Sv2 is a pressure switch used to measure differential or relative pressure.

Pressure measurement is displayed on a 3 ½ digit super bright led display.

Its running suits to supervision of a compressed air network intended to filters declogging.

The devise includes two relays. It can be equipped of a 4-20mA signal output or a RS422 link (options).

Each relay is ordered by an adjustable threshold and there states are reported in the device front panel by leds.

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 4 sur 10

FRONT PANEL DESCRIPTION:

TO ADJUST SET POINTS:

Different thresholds adjustment:

- Press the “SELECT” key until the yellow led comes on in front of the wanted threshold. Display the value you

want with the “+” and “-“ keys.

- Come back to the pressure reading mode by “SELECT”. Each threshold is stored in a memory every time it’s

adjusted.

NB. After 30 seconds of inactivity, automatic comeback in the pressure reading mode.

Xk1 relay running:

If the pressure is higher than Xk1 threshold, Xk1 relay is supplied (contact between 11 and 14) and Xk1 red led is

switched off.

If the pressure is lower than Xk1 threshold, the relay is no longer supplied (contact between 11 and 12) and Xk1

red led is switched on.

Note: Xk1 relay response time 5 seconds, Xk1 relay is supplied if the threshold adjustment is on 000.

Xk2 relay running:

If the pressure is higher than Xk2 threshold, Xk2 relay is supplied (contact between 21 and 24) and Xk2 red led is

switched off.

If the pressure is lower than Xk2 threshold, the relay is no longer supplied (contact between 21 and 22) and Xk2

red led is switched on.

Note: Xk2 relay response time 5/100 seconds, Xk1 relay is supplied if the threshold adjustment is on 000.

SUPPLY VOLTAGE

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 5 sur 10

WARNING:

All parameters are stored in memory. If at starting,

there’s an error, the display shows “CFX”.

X corresponds to an error code (0: zero adjustment,

1: measure scale, 2: Xk1 threshold, 3: Xk2 threshold,

9: ID number, A: 4mA, B: 20 mA, C: 4-20 mA

scale.

If any problem, please contact us.

If “CFX” fault, 4-20 mA output is to 0mA.

ADJUST « ZERO »:

It’s possible to adjust « zero » pressure:

- put the device out of pressure (disconnect

pneumatic connections).

- in the mode display of the pressure, press and held

the "-" key.

- press the "SELECT" key.

- loosen keys: the zero is adjusted

ADJUSTMENT:

The device leaves our workshops the scale pressure

in order from zero to full scale.

Adjustments Made after stabilisation and at 20° C.

INSTALLATION & MAINTENANCE:

The installation must be realised by skilled staff.

The device is a pressure controller, so to maintain a good

accuracy, the zero pressure offset must be adjusted over a

one year period (see adjust « zero »).

WARRANTY:

The MDPP2 Sv2 is 2 years limited guarantee (return of the

device in our workshops).

The guarantee doesn’t agree in these cases :

- handle without care, without package,

damage due to bad use (bad connections, over pressure,

over voltage, etc. …),

- all interventions in the device except connecting.

SEFRAM reserves the right to make changes to its devices.

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 6 sur 10

PRECAUTIONS:

-In version AC: The MDPP2Sv2 leaves our workshops with jump position for using in 230VAC (except if

specified at the order). Check jump position according to supply voltage:

-If you have to change fuse, replace it by the same calibre: T160mA for a 115VAC supply voltage, T80mA

for a supply voltage in 230VAC or T500mA for a supply voltage in 24VDC.

-Fix the MDPP2Sv2 in vertical position.

-Avoid the input of dust air at pressure connections.

-Take care about device characteristics (humidity, maxi pressure, etc.).

-Don’t remove the MDPP2Sv2 front panel in order to connect (only connections cover)

-To connect the 4-20mA, it’s advised to use some shielded cable and not to follow power cables.

-Interventions must always be realised by a skilled staff.

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 7 sur 10

ELECTRICAL CONNECTIONS:

Bottom card: user connections. To access to this card: remove the “connections” cover of the box.

According to device configuration, some parts can be not provided.

At rest, out of voltage : contacts between C and NC (11 and 12; 21 and 22)

Pneumatic connections:

By tube rilsan 4x6

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 8 sur 10

SPACE & FIXING:

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 9 sur 10

General instructions for safety, assembly, commissioning, usage and maintenance

to be read before working on the device

I.

GENERAL

These instructions must be read jointly with:

+the standard NFC15-100

+the technical data sheet specific to the device

The Sefram devices are designed to be assembled,

commissioned and used in compliance with the

characteristics/data given in the technical data sheet.

Always adhere to all of directives, legislation, orders

and most recent standards in force for the stated field of

application.

The assembly, commissioning, usage and maintenance

operations must always be carried out by qualified and

authorised personnel.

Personnel working on the devices must be familiar with

the safety rules and requirements in force regarding the

components, devices, machines and electrical

installations.

II. RECEPTION - STORAGE

After unpacking the device, check that this latter has not

been damaged during transport; for certain devices,

remove the protective film from the cover. The material

must be stored inside in a dry place.

In the event of a problem, please contact Sefram.

III. ASSEMBLY

The assembly operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

The box must be mounted vertically.

For material connected permanently to the network, a

quickly accessible cut-off device must be incorporated

into the cabling installation of the building.

The device supply must be equipped with a device for

protection against risks of over-current and fault

isolation. The number of poles protected must be

appropriate to the neutral regime of the building and to

the regulations in force.

The equipment must be connected to the PE protection

mass by green/yellow wires (NFC15-100).

The device is compatible with the neutral regimes TT,

TN or IT;

Nevertheless, we recommend that the device is

supplied through the intermediary of an insulation

transformer for which the primary is supplied between

phases and not between phase and neutral, so as to

avoid any accidental over-voltage caused when the

neutral is cut before the phases.

In the event of a problem, please contact Sefram.

IV.

COMMISSIONING AND USAGE

Commissioning is authorised only after duly

establishing that the device, the machine or the

installation in which the device has been integrated in a

compliant manner, satisfies all of the directives,

legislation, orders and most recent standards in force.

Commissioning operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

Note: correct operational functioning does not in itself

constitute an indication of conformity to the

recommendations for the use of the material in

complete safety.

Also read the maintenance recommendations which

equally apply during commissioning and use.

In the event of a problem, please contact Sefram

V. MAINTENANCE

The device does not require any special maintenance.

For devices equipped with the pressure measurement,

in order to retain a precise pressure measurement, an

annual calibration is advised particularly at « zero »

(see § calibration on the technical data sheet)

The following operations are recommended; they

constitute a minimum:

- Before any work intervention, we recommend

that the dust is removed before opening the

box,

- The MDPP2S-V2 uses double pole neutral

fusing. Power-off the system and replace both

fuses with appropriate replacement fuses.

- The device must not be opened in an

excessively dusty environment,

- The settings must be carried out in the shortest

lapse of time so as not to engender any risks,

- The integrity of the joints must be checked:

remove any trace of dust or other deposit,

- Remove any trace of dust which could have

penetrated during the setting operation,

- Always ensure that the transparent cover is

correctly closed.

Maintenance operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

In the event of a problem or any questions during these

operations please contact SEFRAM.

ATEX version : See FI 72.0172 or FI 72.0341

instructions

DIFFERENTIAL PRESSURE SWITCH

Technical Notice

FI 72.0226.1016E

Page 10 sur 10

WARRANTY

The MDPP2S-V2 is 2 years limited guarantee.

The guarantee doesn’t agree in these cases : handle without care, without package, damage due to bad use (bad

connections, over pressure, over voltage, etc. …), all interventions in the device except connecting.

For ATEX devices : no intervention.

Any action on the device is forbidden. You must send us back the device in our workshops, otherwise the

certification and the guarantee are lost.

In case of failure, no action is permitted and the unit must be returned to the following address:

13 - CERTIFICATE:

The MDPP2S-V2 respects the European directives ( CEM, BT and ATEX ), which concerns it.

However, it must be used correctly in applications for which it is intended, and should be linked or near

CE approved products.

Certificate available on request.

SEFRAM reserves the right to make changes to its devices.

SEFRAM

PLACE GUTENBERG

59175 TEMPLEMARS - FRANCE

This manual suits for next models

1

Table of contents

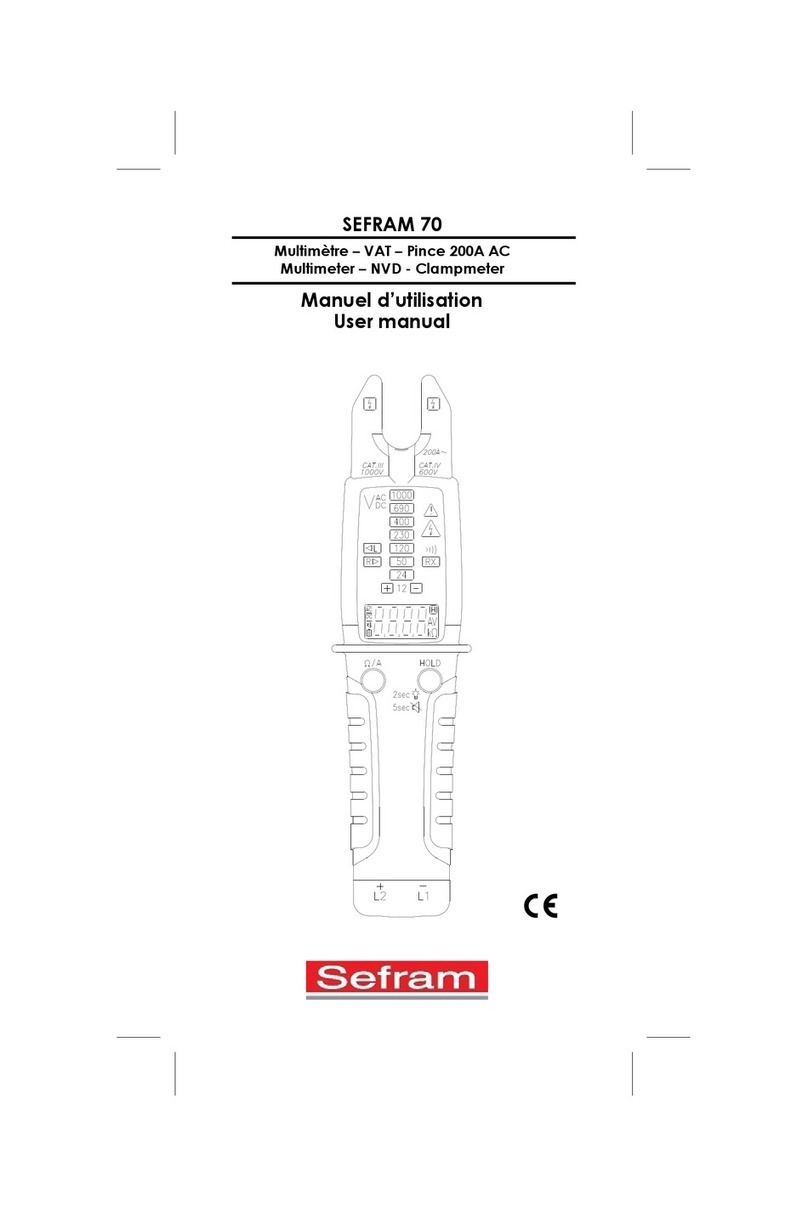

Other SEFRAM Measuring Instrument manuals

SEFRAM

SEFRAM CDM User manual

SEFRAM

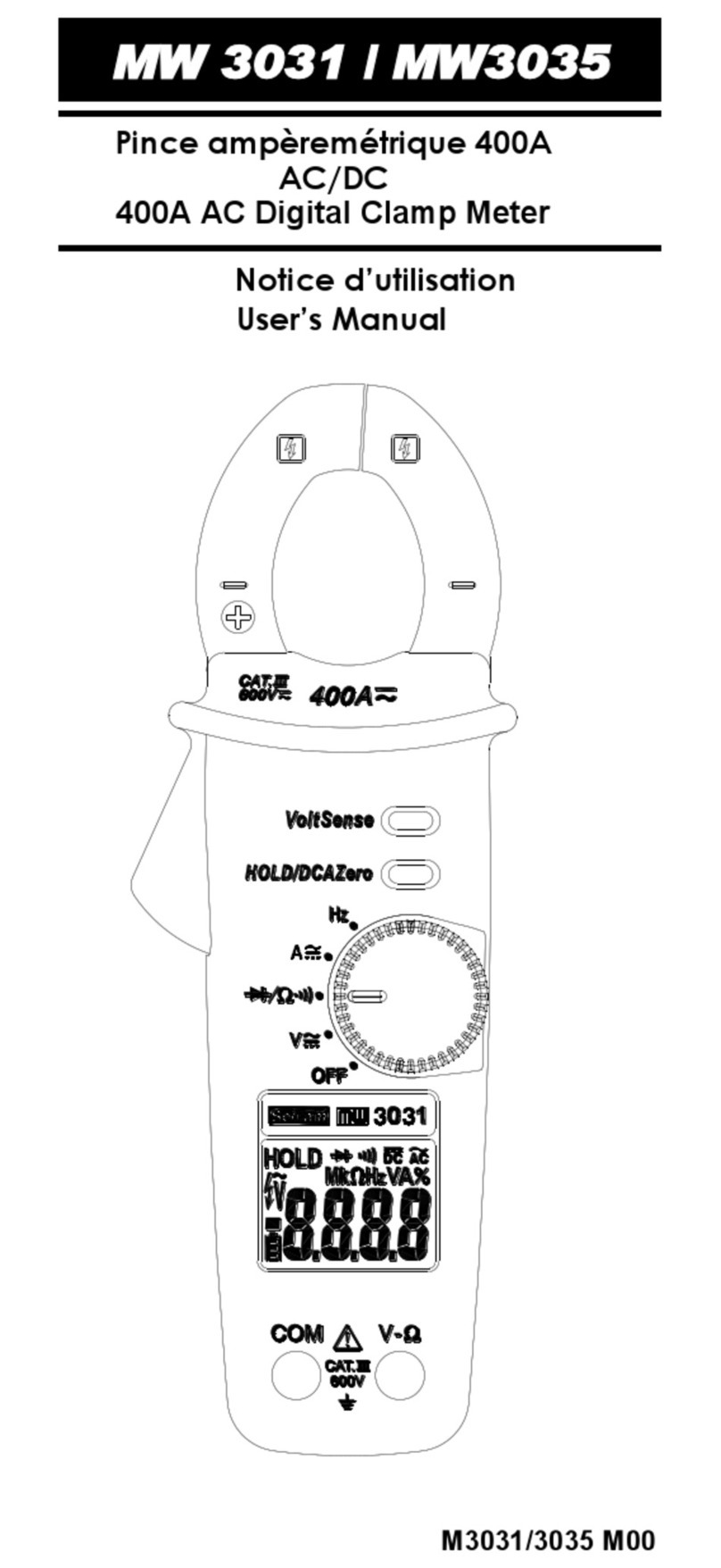

SEFRAM MW 3031 User manual

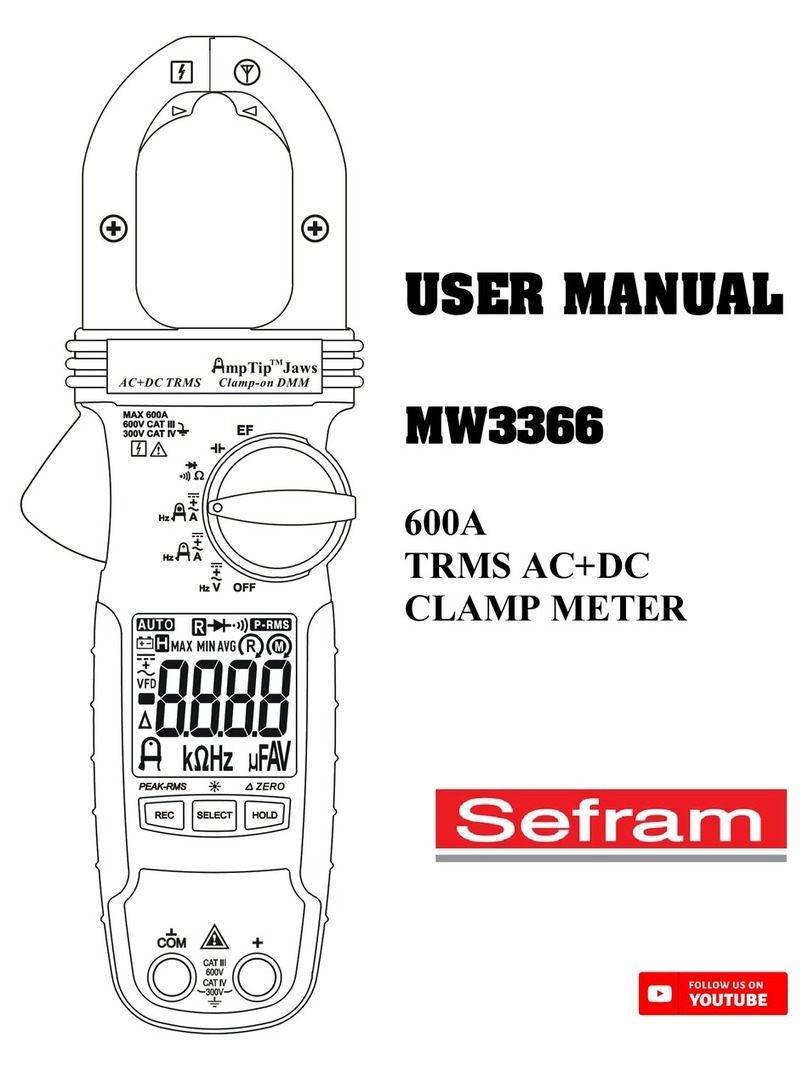

SEFRAM

SEFRAM MW3366 User manual

SEFRAM

SEFRAM MW 3015 User manual

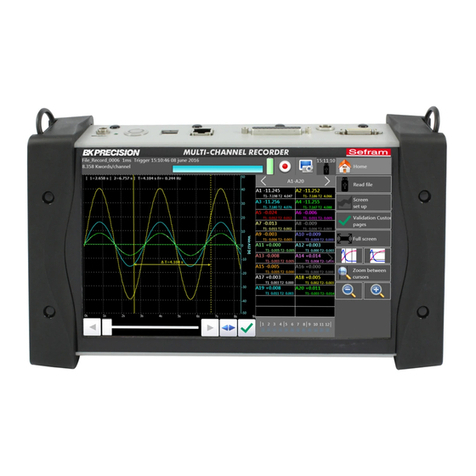

SEFRAM

SEFRAM BK Precision DAS30 User manual

SEFRAM

SEFRAM 87 User manual

SEFRAM

SEFRAM MW 3352 User manual

SEFRAM

SEFRAM MW3035 User manual

SEFRAM

SEFRAM DAS240BAT User manual

SEFRAM

SEFRAM SEQUENCER EC8-18 User manual

Popular Measuring Instrument manuals by other brands

Peak Electronics

Peak Electronics DCA75 user guide

Lykketronic

Lykketronic Flex Counter Standard instruction manual

JENCO

JENCO 6179M Operation manual

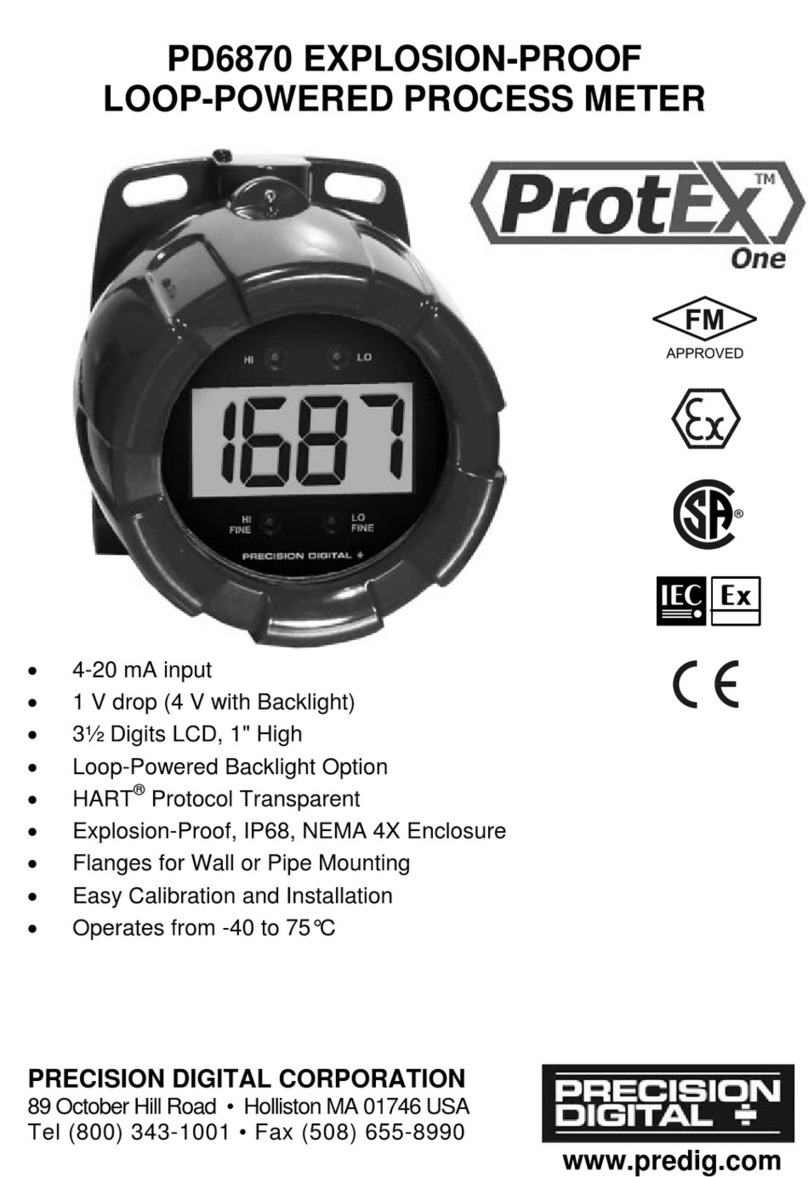

Precision Digital Corporation

Precision Digital Corporation ProtEx One PD6870 manual

Kimo

Kimo CT 100 Series user manual

sauter

sauter HBA 100-0 instruction manual