4. Screw the needle locknut out for

more trigger movement, in for

less trigger movement.

5. Adjust the fluid needle so the

trigger moves the air valve

assembly (29) 1/16" before the

fluid needle assembly moves.

6.

Place the needle locknut in the

hex-shaped hole of the rear hous-

ing (25). Be sure the locknut is

properly positioned.

7. Tighten the needle cap with

wrench.

8. Replace stainless steel spring

(20) and fluid control knob (19).

GENERAL INSTRUCTIONS

FOR AIR-SUPPLIED PAINT

SPRAYING

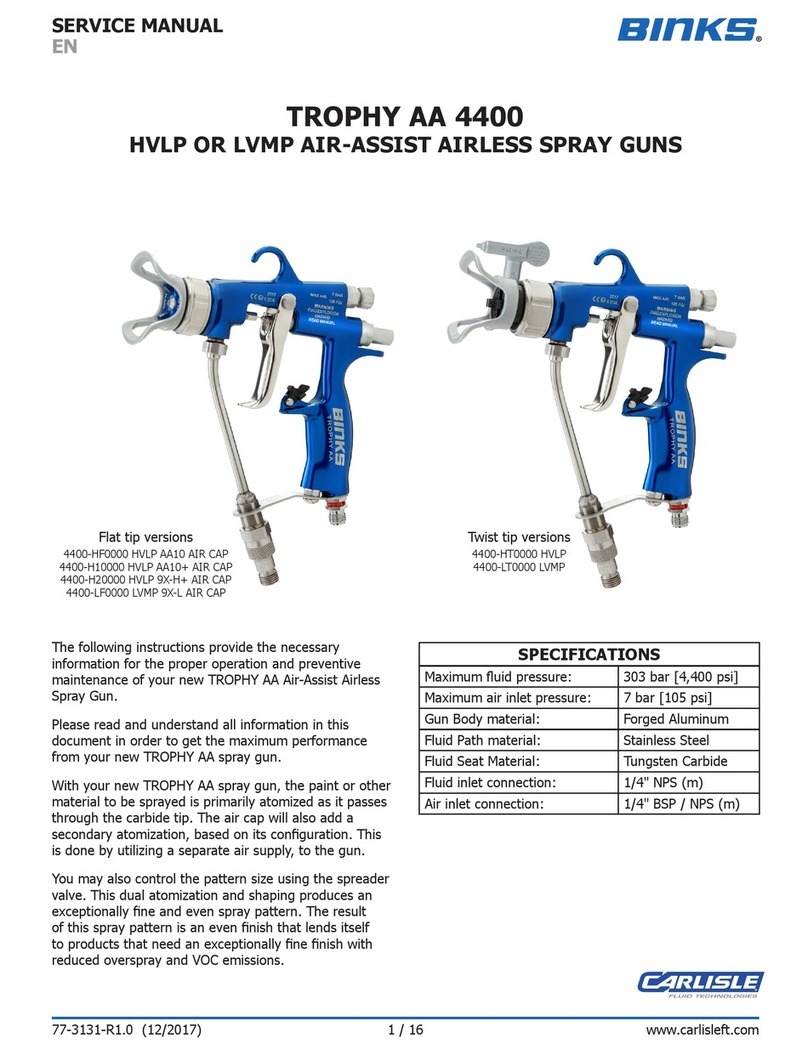

To reduce overspray and obtain

maximum efficiency, always spray

with the lowest possible air pres-

sure that produces an acceptable

spray pattern. Excessive atomizing

air pressure can increase overspray,

reduce transfer efficiency, and with

some materials, result in poor finish

quality from dry spray. Atomizing

air pressures should not exceed

10 psi. See the tables on page 6

and Important Regulatory Note on

page 8.

Generally use 30-35 psi air at the gun

inlet. Unusually heavy or difficult to

atomize materials may require up to

50 psi inlet air. Refer to air pressure

recommendations on page 6.

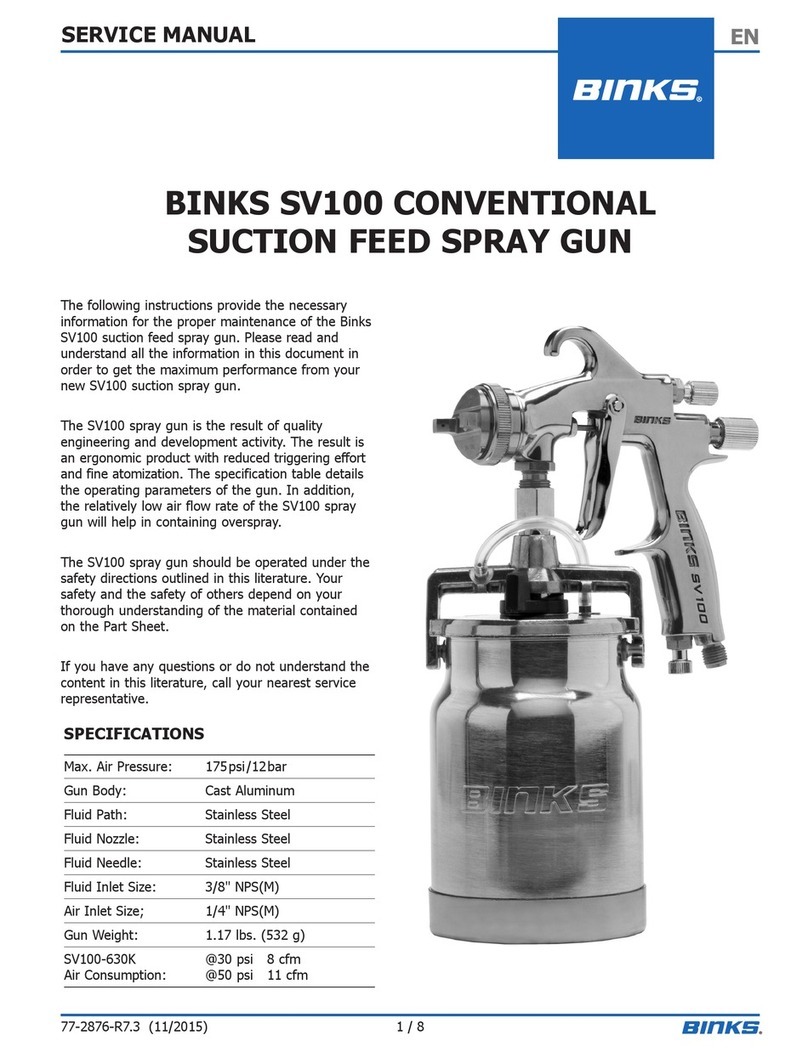

SPRAY TECHNIQUE

To get a good finish you must handle

the gun properly. Hold the gun per-

pendicular to the surface you are

painting. Each paint stroke should be

made parallel to the plane of the sur-

face being painted. Start the stroke

before you trigger the gun and release

the trigger before you end the stroke.

This will give you accurate control of

both gun and material and will prevent

excessive build-up of material at the

stroke ends.

The distance between the gun and

surface should be 6"-10" depending

on the material and the atomizing

pressure. The material deposited

should always be even and wet. Lap

each stroke about half of the preced-

ing stroke to obtain a uniform finish.

IF YOU HAVE TROUBLE

WITH GUN OPERATION

OR RESULTING FINISH

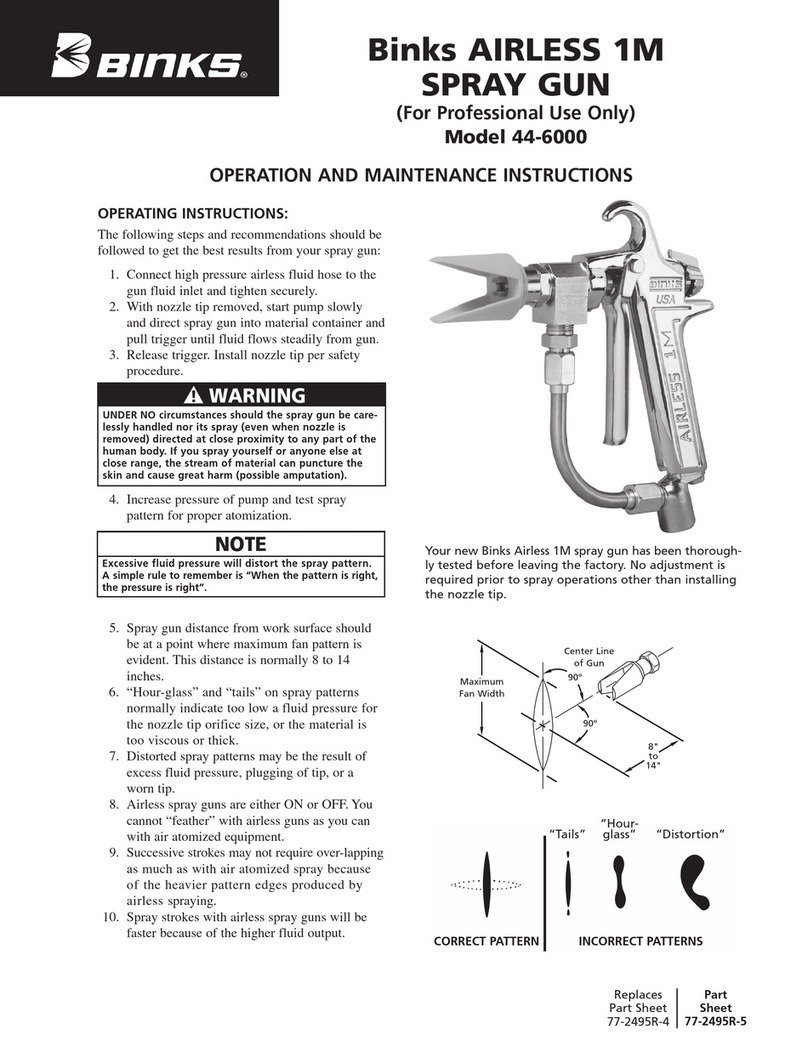

FAULTY SPRAY PATTERN

A faulty spray pattern is often

caused by dried materials around

the fluid nozzle tip or in the air

nozzle left behind by improper

cleaning. Soak these parts in thin-

ner to soften the material and

remove it with a brush or cloth.

INTERMITTENT SPRAY

Fluttering spray is caused by one of

the following problems:

1. Air leaking into the fluid pas-

sages due to any of the follow-

ing: The packing nut (36) may

be loose. The packing (37) may

be worn and need replacement.

The fluid nozzle (42) may be

loose. The cup assembly (5)

may be loose in the gun. The

fluid inlet seal (39) may be

worn.

2. Insufficient fluid available.

SPITTING

Spitting is caused by anything that

restricts the movement of the fluid

needle assembly (21). The probable

causes include:

1. The packing nut (36) is too tight.

2. The needle assembly (21) is bent.

You may be able to straighten it.

3. Dried material has built up on the

needle or in the fluid nozzle (42).

4. Lumps or impurities in the fluid.

Regulator pressures are based on 25

feet of 1/4" hose in good condition

without quick disconnects or other

restrictive fittings. Gun inlet pres-

sures are measured at the gun air

inlet with the gun triggered. Use the

air nozzle test gauge accessory

54-4150 to confirm the atomizing/

regulator pressure relationship for

your actual air supply setup. These

recommendations are for typical or

average fluids, and are intended to

serve as a starting point. Adjust as

necessary for your specific applica-

tion. Regulator pressures for 5/16"

hose are 3 to 5 PSI lower.

CLEANING and MAINTAINING YOUR Binks CUB SLG GRAVITY-FEED HVLP SPRAY GUN

5

CAUTION

Never use anything metal to clean

the air nozzle or fluid nozzle. These

parts are precisely machined, and

any damage to them will cause

faulty spray patterns.

!

CAUTION

Do not over-tighten as this may

damage the threads and make

future adjustments difficult

.

!

6"-10"

Start

Stroke

Trigger

Gun

End

Stroke

Release

Trigger

SPRAY TECHNIQUE

WARNING

Always wear appropriate gloves,

eye protection and a respirator

when using your gun. Atomized

materials may cause bodily injury.

!