Page 3 SBBI-2-181-B

OPERATION

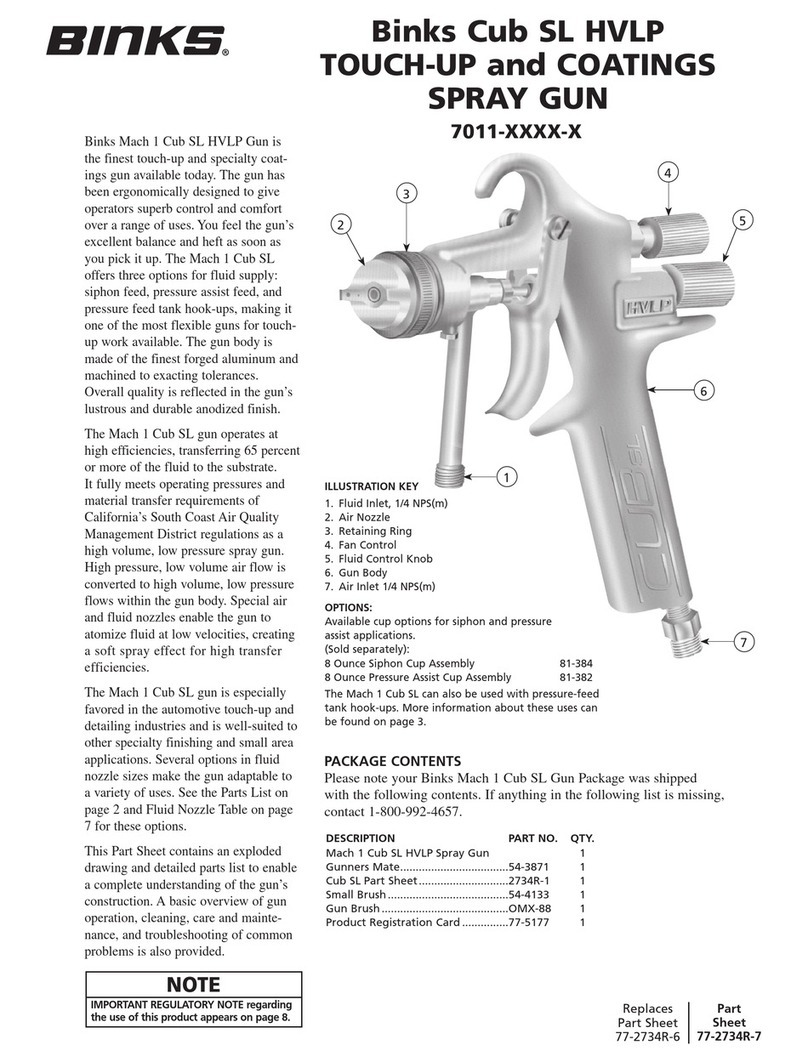

Turn on air supply and set gun inlet

pressure to lowest recommended

pressure for material being sprayed.

Best atomization will occur with 10

PSIG air cap pressure. However, some

materials can be sprayed at lower

pressures, improving transfer effi-

ciency.

If the finish is too sandy and dry, the

material flow may be too low for the

atomization air pressure being used.

If the finish sags, there is too much

material flowing for the atomizing air

pressure being used.

Both of the above can be corrected by

increasing or decreasing the atomiza-

tion air pressure or the material flow.

Pattern width can be altered by

turning the side port knob either clock-

wise to decrease the width or counter-

clockwise to increase the width.

IMPORTANT: This gun may be used

with most common coating and

finishing materials. It is designed for

use with mildly corrosive and non-

abrasive materials. If used with other

high corrosive or abrasive materials, it

must be expected that frequent and

thorough cleaning will be required

and the necessity for replacement of

parts will be increased.

CUP CLEANING

NOTE

For routine cleaning, it is not

necessary to remove cup from

gun. Do not remove cup gasket

from gun. If gasket is removed,

it must be replaced.

Do not soak the lid in solvent

for extended periods of time.

Doing so could cause cup/lid

sealing problems and leakage.

The cup lid is designed to be dispos-

able, but may be cleaned and reused if

slightly contaminated with overspray.

If lid becomes tight, or does not fit, it is

due to extended soaking in solvent. Let

lid air dry overnight and the lid should

return to its original size and fit.

1. Remove lid and properly dispose of

any excess paint.

2. Pour in a small amount of clean

solvent. The amount will vary with

different coatings and solvents.

3. Reinstall lid. Hold lid with finger

covering vent hole. Shake cup to

wash down the inside surfaces.

4. Pull trigger to allow some solvent

to be flushed through gun.

5. Remove lid and pour out dirty

solvent. Add a small amount of

clean solvent and repeat proce-

dure.

6. Wipe exterior of lid with a clean

cloth and clean solvent.

If a paint filter was used in the bottom

of the cup outlet, it should be removed

and cleaned or replaced at this time.

Dispose of used cup lid if contami-

nated and replace with new.

GUN CLEANING

To clean air nozzle and fluid nozzle,

brush exterior with a stiff bristle brush.

If it is necessary to clean air nozzle

holes, use a broom straw or toothpick

if possible. If a wire or hard instru-

ment is used, extreme care must be

used to prevent scratching or burring

of the holes which will cause a

distorted spray pattern.

To clean fluid passages, remove

excess material from the cup, then

flush with a suitable solvent. Wipe gun

exterior with a solvent-dampened

cloth. Never completely immerse in

solvent as this is detrimental to the

lubricants and packings.

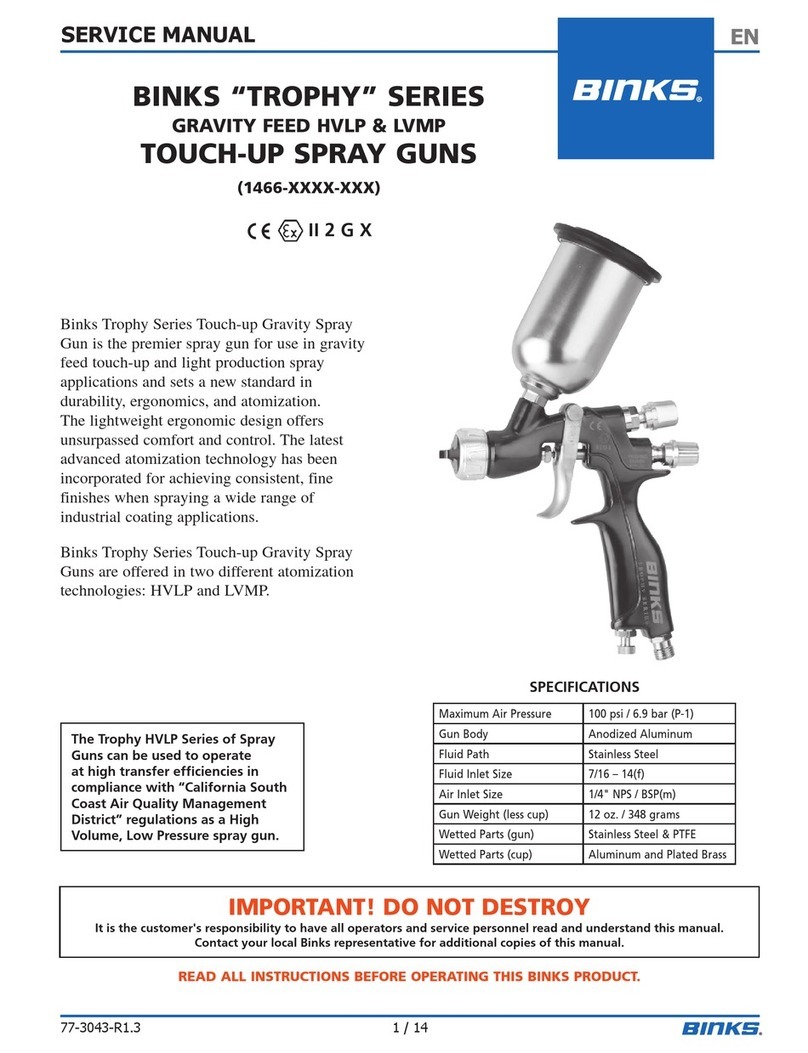

SPRAY GUN LUBRICATION

Use Binks Gunner’s Mate lube to lubri-

cate the areas shown below.

PARTS REPLACEMENT

Fluid Nozzle and Needle:

When replacing the fluid nozzle or

fluid needle, replace BOTH at the same

time. Using worn parts can cause fluid

leakage. Also, replace the needle seal

cartridge assembly at this time. Lightly

lubricate the threads of the fluid tip

before reassembling. Torque to 10-12

ft. lbs. Do not overtighten the fluid tip.

To prevent damage to fluid

nozzle or fluid needle, be sure

to either pull the trigger and

hold while tightening or loos-

ening the fluid tip.

Air Valve Assembly:

Remove material control knob, spring

and fluid needle. Unscrew housing and

remove spindle assembly with springs,

seal retainers and o-rings. Lubricate

new o-rings with Gunner’s Mate.

Assemble components using material

needle. Place this assembly along with

housing into gun body and screw into

position. Remove material needle and

tighten housing.

Cartridge Assembly (Needle Packing):

Remove material valve control knob,

spring and fluid needle. Pull back

trigger and remove seal cartridge

assembly. Remove and discard plastic

shipping pin in new cartridge assembly.

Pull back trigger and insert new seal

cartridge assembly. Reassemble

needle assembly, spring and material

valve control knob.

Continued from Page 1

A. Trigger Points

B. Needle Seal Cartridge

C. Adjusting Knobs

D. Baffle Threads

E. Spindle Assembly

A

D

B

E

C

A