U.S.A./Canada Customer Service

195 Internationale Blvd.

Glendale Heights, IL 60139

630-237-5000

Toll Free Customer Service

and Technical Support

800-992-4657

Toll Free Fax

888-246-5732

Binks Sales and Service: www.binks.com

WARRANTY

This product is covered by Binks’ 1 Year Limited Warranty.

6/12 ©2012 Binks All rights reserved. Printed in U.S.A.

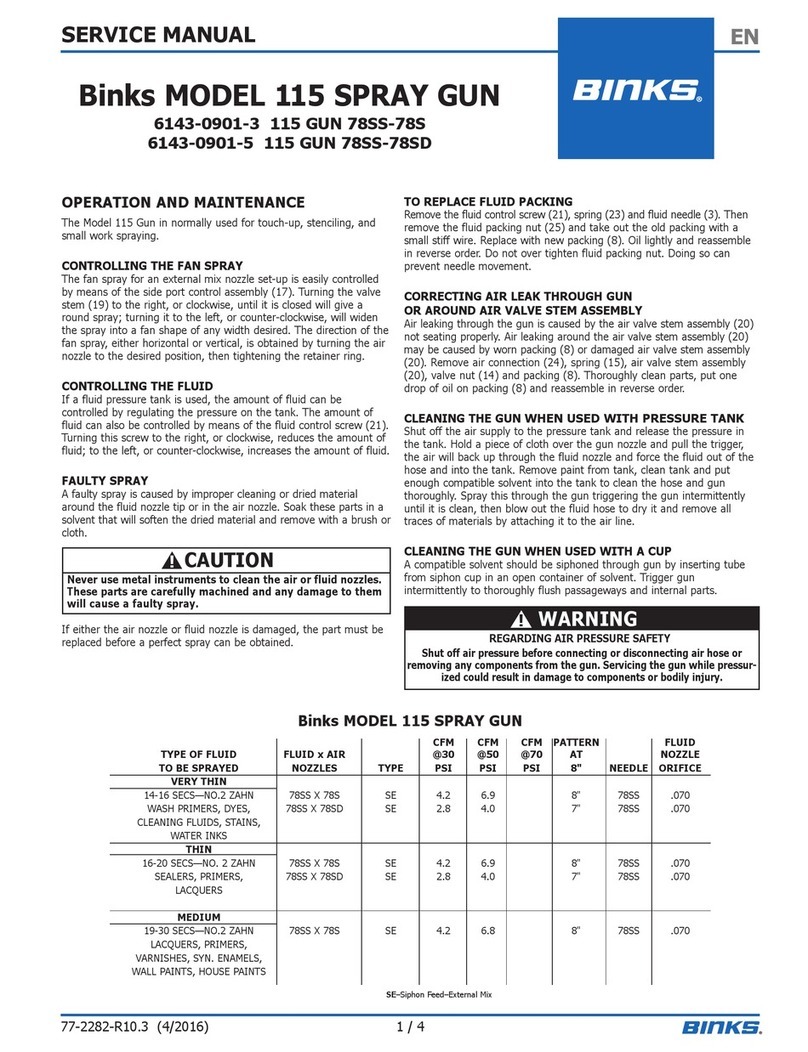

OPERATION AND CLEANING

Int rnal Mix Air Nozzl Application

OPERATION:

The intern l mix ir nozzle ccomplishes tomiz tion by

mixing the ir nd fluid within the ir nozzle.

1. Close ir djusting v lve by turning clockwise.

2. Set ir pressure t

Cle nAir filter unit

to pproxim tely

45 PSI.

3. Open ir djusting v lve nd llow ir to enter the gun.

4. Set fluid pressure t 20 lbs. nd djust higher or lower

until desired tomiz tion is effected. Air pressure

should be ltern tely djusted.

CLEANING

1. Open ir rele se v lve on pressure cup cover.

2. Reduce pressure in cup until g uge re ds zero, (turn

knob counter-clockwise).

3. Loosen cup cover nd set fluid tube on ngle in cup.

4. Loosen ir nozzle two turns, pl ce cloth over nozzle

nd pull the trigger to force p int into cup.

5. Remove cover nd cle n cup nd cover thoroughly.

6. With pproxim tely 1/4 to 1/2 cup of cle n solvent, tt ch

cover nd set fluid pressure t pproxim tely 10 PSI.

7. Close ir djusting v lve t spr y gun.

8. Trigger gun nd llow solvent to flow into cont iner

until it flows cle r.

9. Remove solvent, then cle n ir nozzle. If ny dirt

ppe rs in orifice, cle n with tooth pick Blow nozzle

nd cup dry. Repl ce nozzle nd cover loosely.

Ext rnal Mix Air Nozzl Application

OPERATION:

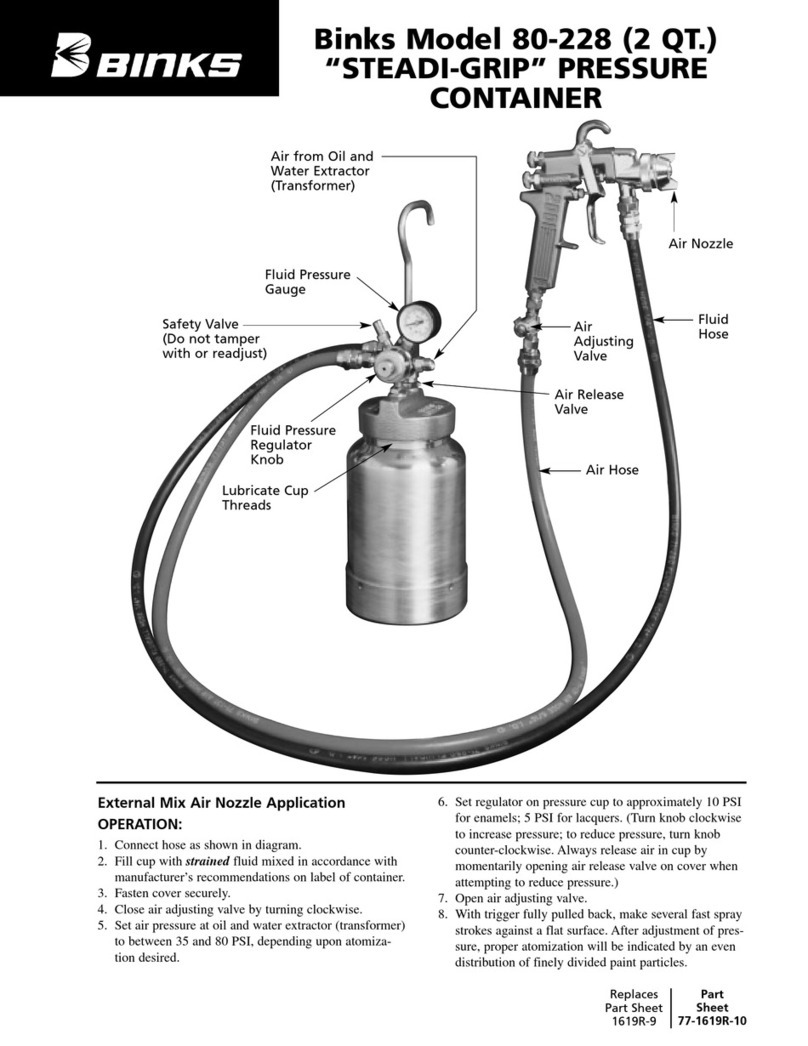

1. Connect hose s shown in di gr m on front p ge.

2. Fill cup with strained fluid mixed in ccord nce with

m nuf cturer’s recommend tions on l bel of cont iner.

3. F sten cover securely.

4. Close ir djusting v lve by turning clockwise.

5. Set ir pressure t Cle nAir filter unit to between 35

nd 80 PSI, depending upon tomiz tion desired.

6. Set regul tor on pressure cup to pproxim tely 10 PSI

for en mels; 5 PSI for l cquers. (Turn knob clockwise

to incre se pressure; to reduce pressure, turn knob

counter-clockwise. Alw ys rele se ir in cup by

moment rily opening ir rele se v lve on cover when

ttempting to reduce pressure.)

7. Open ir djusting v lve.

8. With trigger fully pulled b ck, m ke sever l f st spr y

strokes g inst fl t surf ce. After djustment of pres-

sure, proper tomiz tion will be indic ted by n even

distribution of finely divided p int p rticles.

IMPORTANT

The most efficient tomiz tion ir pressure is the lowest

ir pressure th t will properly tomize the p int. This will

minimize the overspr y, deposit more p int on the surf ce

nd elimin te p int w ste.

If f ster cover ge is necess ry, first incre se fluid pressure

nd then djust tomiz tion ir pressure. If slower

cover ge is more desir ble, first reduce the fluid pressure

nd then djust tomiz tion ir pressure. Alw ys ttempt

to m int in the lowest pressures for m ximum efficiency.

For e se of removing cup cover nd to prevent le k ge,

lw ys thoroughly gre se the thre ds on the cup.

CAUTION

If th cup is accid ntally tipp d ov r or h ld at too gr at an

angl , fluid will load up th und rsid of cup cov r, and l ak

into r gulator. In th v nt this happ ns, cl an imm diat ly!

!

NOTE

Th st ps ar th sam as with th xt rnal mix nozzl s,

xc pt th air and fluid pr ssur s ttings ar diff r nt.

NOTE

N v r allow solv nt to r main in cup; solv nt vapors t nd

to r duc s rvic lif of gask t. S parat storag of cup

and cov r r comm nd d.

CAUTION

N v r us a wir or m tal obj ct to cl an th air nozzl —th y

may damag th nozzl and caus faulty spray.

!

77-2823R-5 R visions: (P1) Updated image.