Bio-Optica Trimming Tech 90 Troubleshooting guide

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 1 of 44

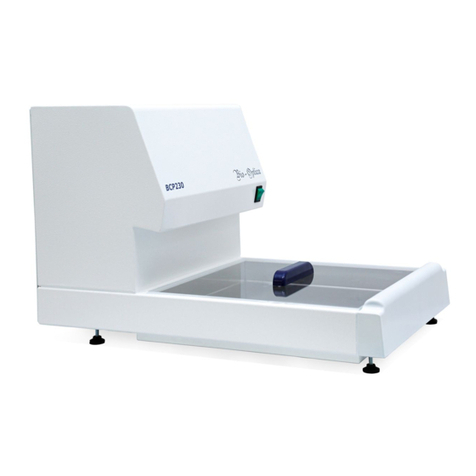

TRIMMING TECH HOOD

Codes:

50-090-001, 50-090-002

50-130-001, 50-130-002

50-150-001, 50-150-002, 50-150-003

50-180-001, 50-180-002, 50-180-003

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 2 of 44

USE PRECAUTIONS

Before using the instrument, read carefully the instructions and warnings contained in

this manual and keep it for further reference. They supply important indications regarding

the functions and safety for installing, using and maintaining the instrument.

Bio-Optica Milano S.p.A. cannot be held responsible for any damage caused by improper

or incorrect use and by the non-observance of any of the prescription provided in this

manual and by the safety regulations in force.

1. After unpacking, make sure that the instrument is complete and not damaged by transport.

2. Before connecting the instrument to the power supply make sure that its rating corresponds to that of the power

supply.

3. This instrument must only be used for the purpose for which it was designed, that is, as aspirated hood for

histology for laboratory use. Any other use is to be considered improper and therefore hazardous.

4. The instrument must only be used by authorized and professionally qualified technician.

5. The electrical safety of this instrument can be guaranteed only if it is correctly connected to an efficient earth

circuit as indicated by current electrical safety regulations. It is necessary to check this fundamental safety

prerequisite, and if in doubt, ask to check the circuit. The instrument is provided with a power supply cable having 2

wires + ground tap that have to be connected to the power supply socket.

6. Do not remove the chassis or parts of it during operation. Switch off the instrument and disconnect the power

supply cable before opening it. This operation must to be effected only by authorized and professionally qualified

technician.

7. To eliminate instrument malfunctioning risks, do not work near strong magnetic fields and do not use transmitters

such as cellular phones near the instrument. In case of serious malfunctioning switch off the instrument and contact

the Technical Assistance Service.

8. All waste material, both infectious and radioactive, deriving from the appliance working cycle must be disposed in

compliance with the regulation in force.

This appliance is marked from this symbol, in compliance with EU directive 2002/96/CE regarding

electric and electronic appliances waste. This mean that the instrument, at the end of its useful life, must be

collected separately from other refuse. The user must deliver it to the special differentiated refuse collection centres,

that are predisposed by the public authority.

9. The contents of this manual is subject to change without further notice.

10. Please find enclosed the declaration of conformity.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 3 of 44

11. Graphic symbols indicated on the label (positioned near the instrument’s power supply socket):

Symbol for CATALOGUE NUMBER:

Symbol for SERIAL NUMBER:

Symbol for ALTERNATING CURRENT:

Symbol for FUSE:

Symbol for CONSULT THE INSTRUCTIONS:

Symbol for EC MARK:

Symbol for IN VITRO DIAGNOSTIC-MEDICAL DEVICE:

Symbol for DISPOSAL OF ELECTRIC AND ELECTRONIC EQUIPMENT:

Symbol for DATE OF MANUFACTURE:

Symbol for MANUFACTURER:

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 4 of 44

INDEX

1) Technical features. Page 5

2) Installation. Page 9

3) Water and electric connections. Page 14

4) Aspiration system. Page 16

5) Replacement of filter, prefilter and interventions on electric installation Page 18

6) Manual unlocking of electric glass. Page 24

7) Control panel. Page 26

8) Replacing the lamps. Page 34

9) Replacing the fuses. Page 35

10) Garbage disposal unit. Page 35

11) Cleaning and maintenance. Page 36

12) Optional accessories. Page 38

13) Main components. Page 40

14) Electric wiring diagrams. Page 42

15) Declaration of conformity. Page 44

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 5 of 44

1) TECHNICAL FEATURES

Aspirated hood for histology designed for cutting and reduction of histological samples. Designed to prevent

biological and chemical risk during manipulation of anatomy finds preserved in formalin.

Provided with vapours aspiration system from the working surface, the frontal side and the top; predisposed for

fumes discharge outside.

Electrical connections

Power supply: 230V~ 50/60Hz.

Rated output: 1 Kw.

Nominal current: 10A, with delayed fuses.

Power supply socket: Situated on the left back side at a height of ca. 2 metres.

Protection device: Magnetothermic switch.

Emergency power supply: Not necessary.

Fuses: See paragraph 9) Fuses replacement.

Other connections

Water connections: Hot water connection: 1/2”. Cold water connection: 1/2”.

Waste water connection: 1”1/4 standard siphon placed at ca. 40 cm from the

ground (at ca. 20 cm with garbage disposal unit) on the back side of the hood.

Its position depends on the sink placement.

Fumes discharge: The hood is provided with 250 mm collector on its upper side in order to

allow the connection to the hospital’s centralized canalization system for fumes

discharge outside.

Connection of external

instruments:

The hood is provided with n. 2 Schuko universal power supply sockets for a

possible connection of external instruments, placed in the lower frontal side

externally the working area (one on the right, the other one on the left).

Possibility of enable/disable the power supply to the sockets.

Lighting

Models 90: N. 3 led tubes, total 1500 lux, 10 Watt/each.

Models 130: N. 3 led tubes, total 1500 lux, 14 Watt/each.

Models 150 and 180: N. 2 led tubes, total 1500 lux, 19 Watt/each.

N. 2 adjustable halogen spotlights of 50 Watt, 150 lux (only for models 150 and 180).

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 6 of 44

It is possible to manage ignition and switching off of each single lamp independently through the manual switch

positioned on the lamp holder.

Structural features

Structure made entirely of satinized, thickness 15/10, AISI 304 stainless steel with smooth surface and rounded

edges (in compliance with the regulation in force).

6/7 mm accident prevention stratified frontal glass with electric vertical slide to contain toxic fumes inside the

hood (in compliance with the regulation in force). Run stop at 230 mm from work surface (descent), at 500 mm

from work surface (ascent). The system of glass lifting is provided with manual unlocking in case of emergency.

Automatic function of increase of the ventilation during the phase of lifting of the frontal glass.

6/7 mm accident prevention stratified side glasses in order to increase internal visibility, avoid draughts near the

work surface and contain fumes inside the hood (in compliance with the regulation in force).

Shelf placed in the frontal side over the working plane (see arrow in the photo).

Shelf placed in the central side (see arrow in the photo).

White polyethylene plate for pieces reduction - 350x450x20 mm (WxDxH) - provided with N. 4 support feet 30

mm high.

Antistatic and antislip adjustable feet allow to get a perfect horizontal position of the working surface.

Removable filtering basket for formalin sink. It avoids the obstruction of the discharge tube to the cans, keeping

the solid waste also of small dimensions. Since it is removable, it can be removed and properly washed when

necessary.

Cover for formalin sink.

Formalin dispensing system including: 10 litres load can with filter and pump, supplying tap with pedal control,

10 litres formalin discharge can with level sensor and visual and acoustic alarm.

Canholder trolley provided with handbrakes and front door. The trolley is provided with system of fumes

aspiration with collector situated on the back side that can be removed in case of maintenance. The trolley can

contain also two cans of 20 litres.

Throttle tap of interception formalin discharge to avoid possible accidental leaks during the replacement of the

formalin can. The tap must be closed before replacing the can and reopened after the replacement.

Lamp switch ON/OFF

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 7 of 44

Tap for adjustment of shower water pressure (see arrow in the photo).

Water dispensing tap for basins wash (only on models 130, 150 and 180) (see arrow in the photo).

Arrangement for system of acquisition of image (only on models 130, 150 and 180).

Cover for formalin sink Filtering basket

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 8 of 44

Working surface features

Weldings-free, thickness 10/10, AISI 304 stainless steel surface, provided with liquids containing rim.

Sinks (n. 1 for hood 90, n. 2 for hoods 130 and 150, n. 3 for hood 180) dimensions 400x400x200 mm of which

n. 1 for hood 90, 130, 150, n. 2 for hood 180 with perforated removable surface of support in stainless steel.

The 7 mm holes allow water draining in the sink and fumes aspiration from the top itself. The sinks assigned

to the cut are provided with system of aspiration of fumes.

Double washing system consisting in: 1) Shower, provided with extensible flexible arm, to clean the whole

working surface provided with independent tap for the adjustment of the pressure of the water 2) Cleaning

system inside the basins assigned to the cut (only for hoods with more than one sink).

Hot/cold water sink provided with pedal control distributor and stainless steel smaller sink for formalin

discharge. Both of them are placeable on request on the right or on the left.

Tap of

interception

Formalin dischar

g

e

Tap of interception.

Remember to reopen the

tap after the replacement

of the can.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 9 of 44

2) INSTALLATION

During the unpacking and positioning manoeuvring, proceed cautiously in order to avoid possible damages. Pay

particular attention to the glass parts placed in the frontal and side parts.

For safety matters, it is recommended to dismantle the distributors or lift the glass to end run before beginning the

moving.

Position the lower part of the hood on a floor. Then, put on the upper part and connect the connector of power supply

to the upper side.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 10 of 44

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 11 of 44

Important:

The weight of the upper part is equal to ca. 100 kg: effect the positioning manoeuvring making use of adequate staff

and equipment.

Get the upper part slide on the lower part. The upper part is kept in guide by proper supports preassembled on the

pallet.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 12 of 44

Fix the two parts screwing the provided 4 bolts in the proper seats.

Fumes aspiration system: Once positioned the upper part on the lower part, connect the 40 aspiration pipes

getting them pass through the holes made in the back side. Connect a tube to the trolley and a tube to the sinks

using the provided clips.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 13 of 44

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 14 of 44

3) WATER AND ELECTRIC CONNECTIONS

Water inlet

The tap of the water sink (mixer) can supply hot and cold water while the tap of the central basin and the flexible

shower can supply only cold water.

The mixer is connected to N. 2 flexible pipes of 1/2” (one for hot water, the other one for cold water). They must be

connected to the laboratory’s water system using flexible pipes (not provided).

If the laboratory’s water system cannot supply hot water, it is necessary to close the provided hot water pipe using a

1/2” plug.

The hood is provided with valves of interception hot and cold water. In case of maintenance or failure it is possible to

close the valves in order to interrupt the dispensing of water to all the plumbing of the hood.

Water outlet

Near the water sink there is a 1”1/4 standard siphon. Except changes on request, it is placed on the back side of

the hood at ca. 40 cm from the ground (at ca. 20 cm with garbage disposal unit). Its position depends on the sink

placement.

Important: The outlet system must have a minimum inclination of 1,5°.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 15 of 44

Electrical connections

Before connecting the instrument to the electric system using the provided cable, verify the adequacy of the electric

line, the existence of ground tap and the compliance of the electric system with the law in force.

Important: Do not use any extension or adapter and do not modify the provided cable.

Height from the

ground ca. 40 cm

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 16 of 44

4) ASPIRATION SYSTEM

Trimming Tech hoods are provided with:

Anti-spark three-phase electrofan adjustable through inverter (preinstalled).

N. 1 synthetic fibres prefilter (preinstalled) to retain possible impurities and improve the filter’s efficiency.

N. 1 alumina filter for formalin (preinstalled), whose replacement happens from the frontal side simply and

cleanly. Instead of alumina filter, it is possible to ask for activated charcoal filter.

Arrangement for HEPA filter housing.

The hood is provided with 250 mm collector on its upper side in order to allow the connection to the hospital’s

centralized canalization system for fumes discharge outside.

The electrofan allows fumes aspiration from the perforated working surface (over the collecting basin), the

frontal grid (under the shelf) and the grid placed on the upper part (the aspiration from the top is activated

separately, moving the manual lever near the grid). The air is purified passing through prefilter and filter and can

be discharged in this way:

1) FANPREFILTER + FILTERDISCHARGE OUTSIDE THROUGH A NON-ASPIRATED CANALIZATION SYSTEM

(draining pipe not longer than 3 metres, with diameter equal to 250 mm).

2) FANPREFILTER + FILTERDISCHARGE OUTSIDE THROUGH AN ASPIRATED CANALIZATION SYSTEM.

Important:

- In case of non-aspirated canalization, the length of the draining pipe must not be higher than 3 metres, the

diameter must be equal to 250 mm.

Flows

Instrument Flow m³/h

MODELS 90 900

MODELS 130 1300

MODELS 150 1460

MODELS 180 1839

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 17 of 44

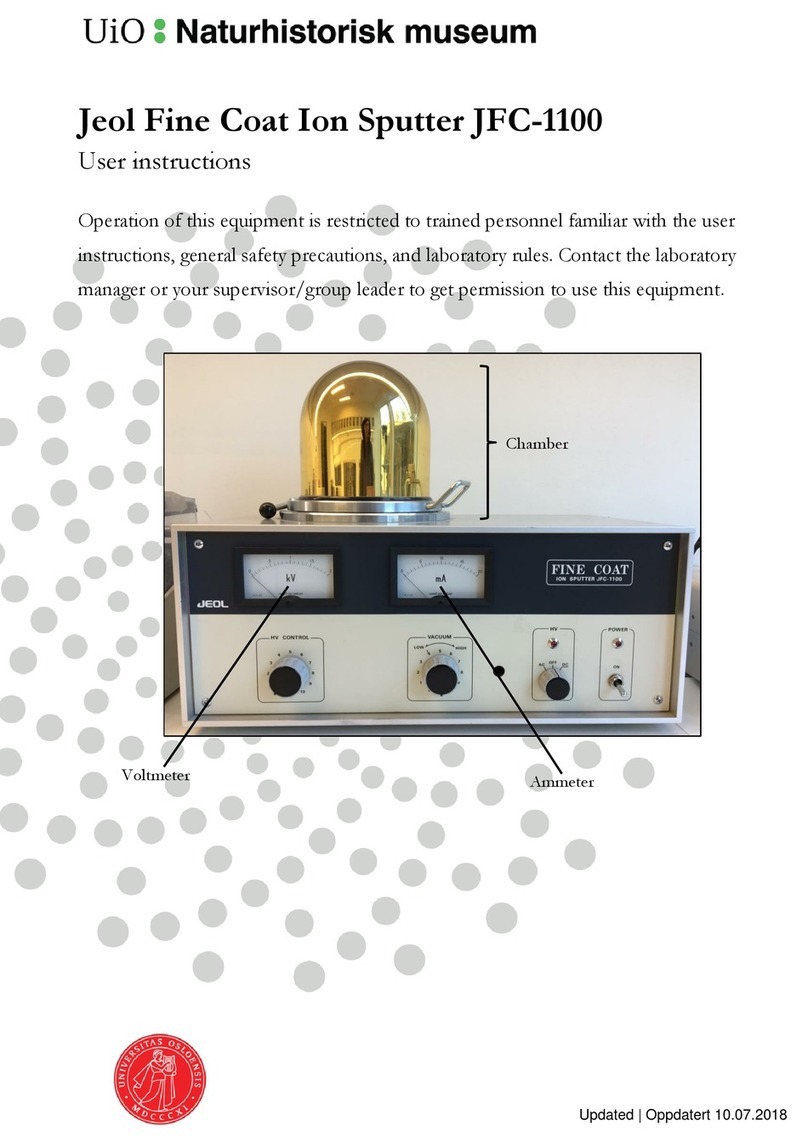

Aspiration system diagram

Aspiration from the top.

Frontal and lower aspiration.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 18 of 44

5) REPLACEMENT OF FILTER, PREFILTER AND INTERVENTIONS ON

ELECTRIC INSTALLATION

The control system is provided with a digital timer preset at 600 working hours (filter’s middle life).

The control system emits a sound and visual signal (intermittent) to advise when remains ca. 30 hours to reach the

600 expected hours. The warning signal repeats every hour and visualizes the residual hours of use of the hood in

safety.

This alarm can be stopped by pressing the proper key on the touch screen.

When is reached the value of 600 hours, the residual hours of use of machine in safety will be equal to 0 and the

control will show a message of alarm for the replacement of the filters.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 19 of 44

For the replacement proceed in the following way:

1) Switch off the instrument and unplug the cable form the socket.

2) Wear individual protection devices in compliance with the regulation in force.

3) Lower the glass to end run.

4) Remove the central panel.

5) Unscrew the fixing hand-wheels of the frontal panel and remove the closing panel.

User and service manual TrimmingTech (sn 501437061, 501451072, from sn 501505075)

Bio Optica Milano S.p.A. via San Faustino 58 I-20134 Milano

Tel. +39 02.21.27.13.1 Fax Acquisti/Export +39 02.21.54.155

Fax Assistenza/Contabilità +39 02.26.41.74.48 Fax Vendite +39 02.21.53.000

Revision 151231 of 31/12/15

Page 20 of 44

6) Remove the consumed filter, the prefilter and the possible HEPA filter getting them slide on the guides.

Filter.

Prefilter.

This manual suits for next models

13

Table of contents

Other Bio-Optica Laboratory Equipment manuals

Bio-Optica

Bio-Optica AUS124 Troubleshooting guide

Bio-Optica

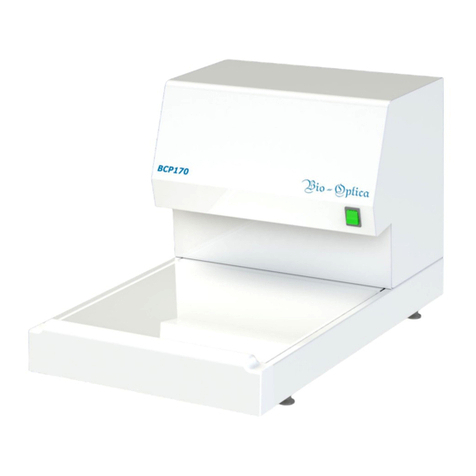

Bio-Optica BCP170 User manual

Bio-Optica

Bio-Optica PF200 Troubleshooting guide

Bio-Optica

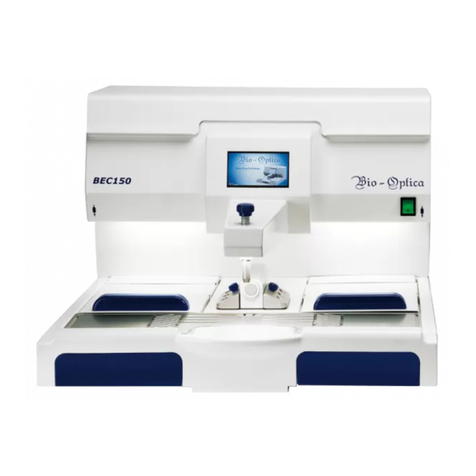

Bio-Optica BEC150 User manual

Bio-Optica

Bio-Optica AUS124 Troubleshooting guide

Bio-Optica

Bio-Optica DP500 User manual

Bio-Optica

Bio-Optica TV410 Troubleshooting guide

Bio-Optica

Bio-Optica AUS124 Troubleshooting guide

Bio-Optica

Bio-Optica Piastra Fredda PF100 Troubleshooting guide

Bio-Optica

Bio-Optica UT200 Troubleshooting guide