7

5.Now,unscrewthesilversleevefromtheblackendpiecerevealingtheSMAconnector

(Figure4).

6.Slidethesilversleeveovertheendofthefiberopticconnectorandcable,leavingthe

threadedendtowardtheendofthecable.

7.AttachthefiberopticcabletotheSMAconnector.

8.Holdingtheblackendpiece,screwthesilversleevebackintoplace.

9.InserttheSMAconnectorandsilversleeveintotheholeintheopticalassembly.Forafirst

adjustment,inserttheassemblyuntilthealignmentgrooveisevenwiththefaceofthelens

assembly.Later,youcanoptimizethesignalintensitybyslidingtheSMAconnectorand

silversleeveindeeper.

D.SoftwareInstallation

NOTE:IFYOUPURCHASEDTHET‐AppPROGRAM,DONOTPLUGINTHEUSBCABLEUNTILTHE

SOFTWAREISLOADED!IFYOUDO,WINDOWSMAYAUTOMATICALLYINSTALLANINCORRECT

DRIVERTHATWILLBEDIFFICULTTOREMOVE.

1.IfyoupurchasedtheT‐Appprogramforexternalcontroloftheturret 6,inserttheCDinto

thedrive.Iftheinstallationdoesnotstartautomatically,locatetheSETUP.exefileintheroot

directoryandrunit.Theinstallationprocessstartswithasmallblackwindowthatisshown

duringinstallationofthedriversneededtocontroltheturret 6throughaUSBconnection.

Thiswindowwillthenbereplacedbythesoftwareinstallationwindow.Followtheonscreen

promptstocompletetheinstallation.

2.Connecttheturret 6toyourcomputerusingtheUSBcableprovided.TheNewHardware

installationprocesswillbeginautomaticallyandtakeafewmomentstofinish.

E.SystemOperation

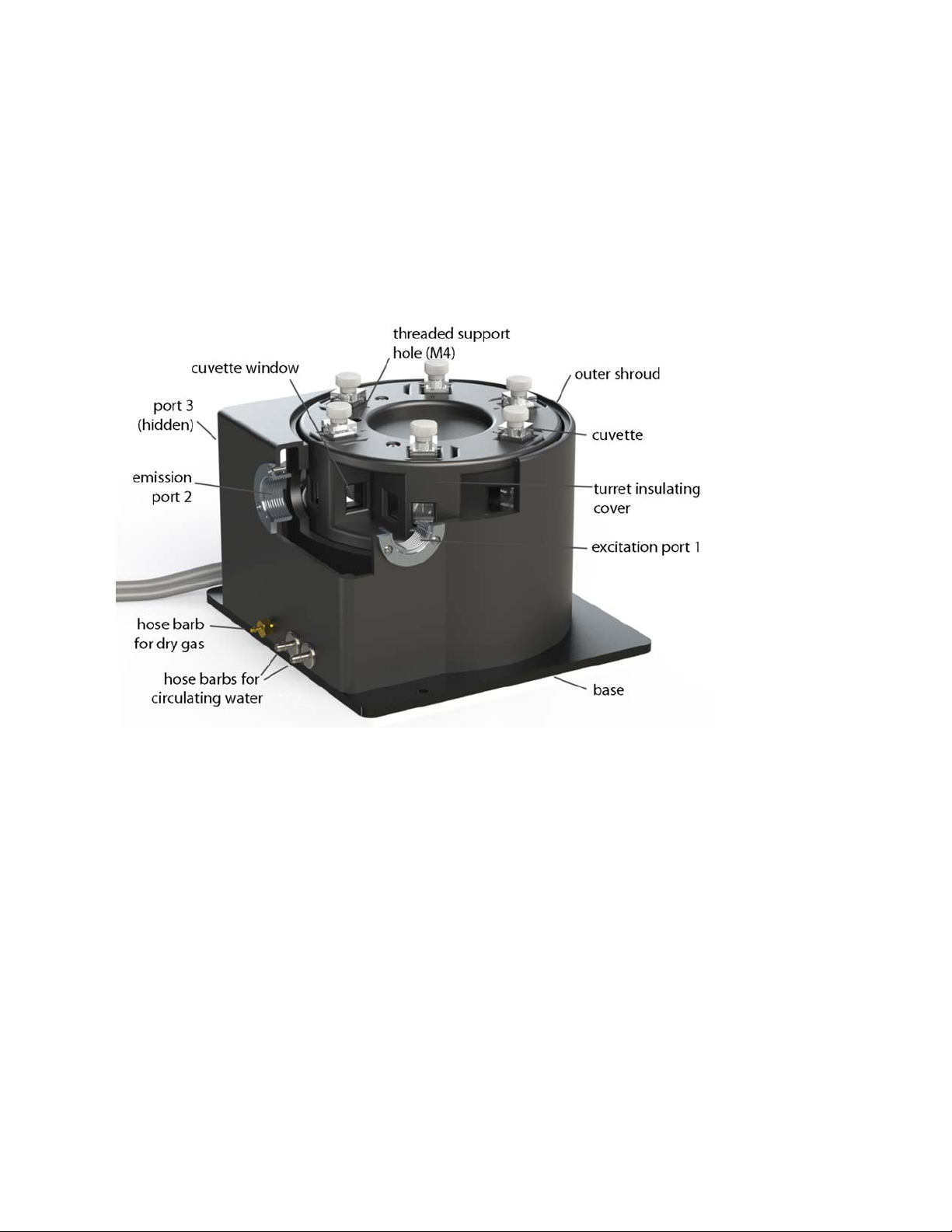

1. Useliquidsamplesinstandard1x1‐cmsquarecuvettesandplacethecuvettesintheturret

6.

2. Placeamagneticstirbarineachcuvette.

3. Ifyouwishtomonitorthetemperatureinsideacuvette,plugastandardSeries400orSeries

500thermistorprobe(notprovided)intothe¼‐inchphonejacklabeled“probe”intheback

paneloftheTC1.Placetheendoftheprobeinaregionofthesolution,whereitwillnot

occludethespectrometerlightbeam.

4. TurnontheTC1controllerusingtheswitchonthebackpanel.