Contents

1 Basic Introduction................................................................................. 1

1.1 Function............................................................................................................... 1

1.2 Summary of Source and Measure Functions....................................................... 1

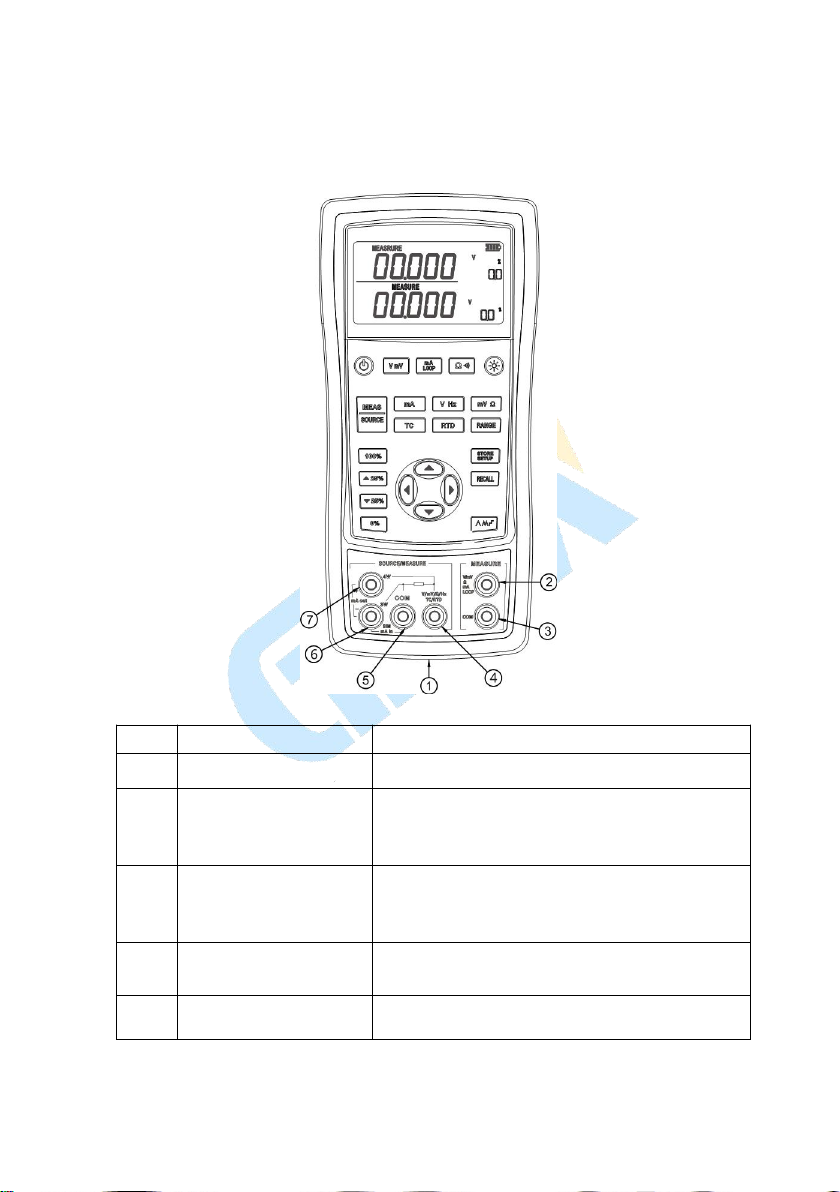

1.3 Terminal Description............................................................................................2

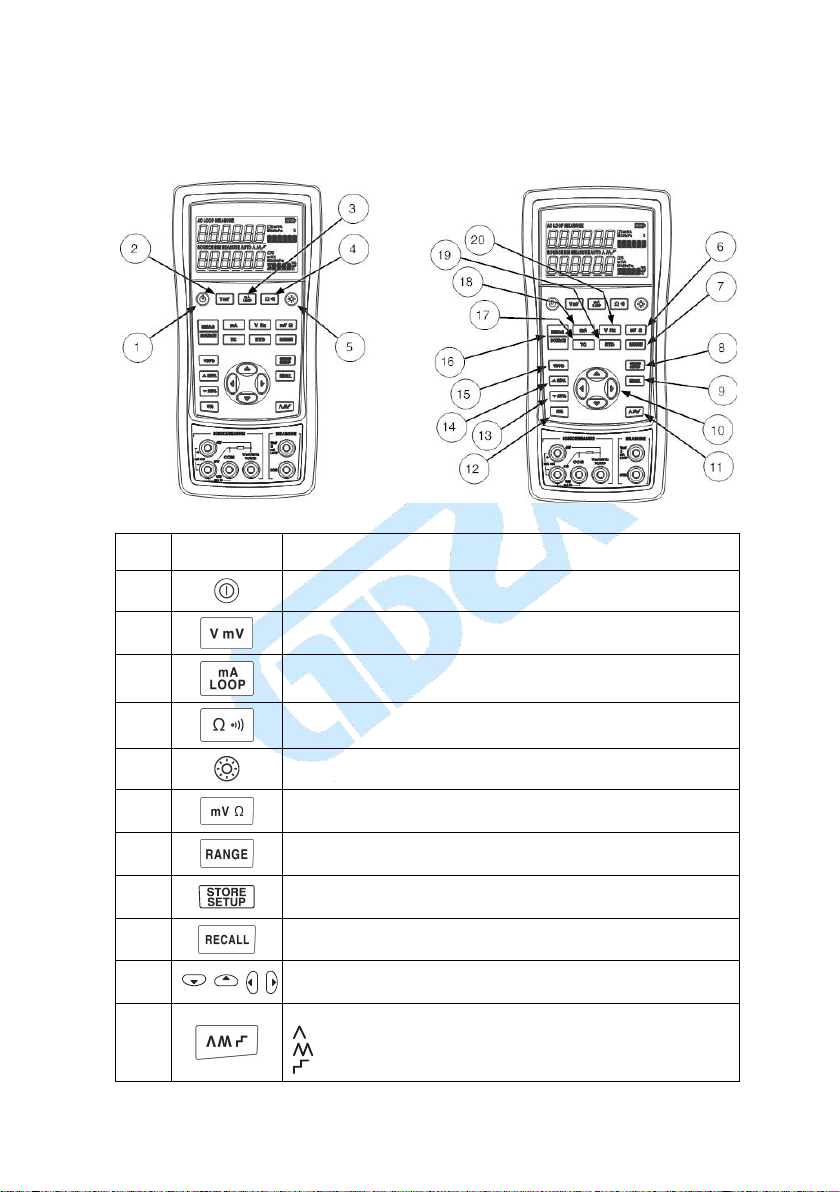

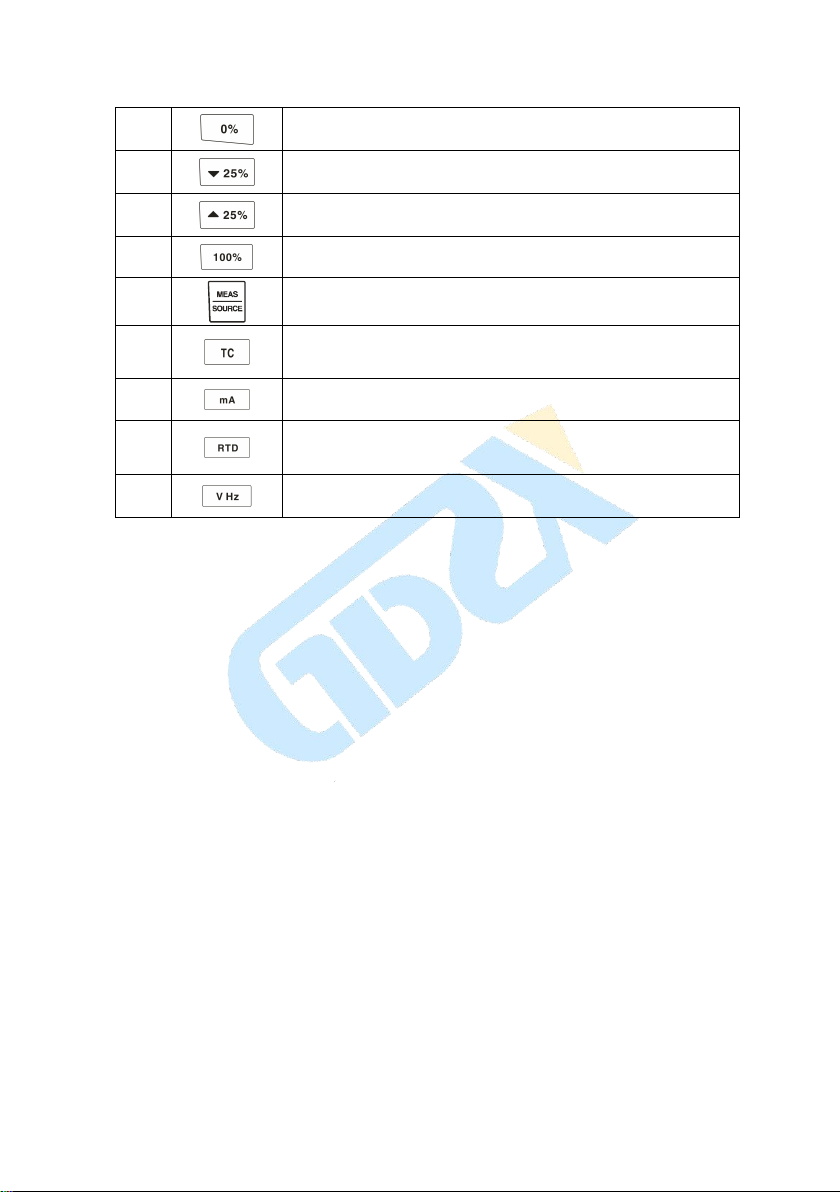

1.4 Keys description...................................................................................................3

2 Basic Operation.....................................................................................5

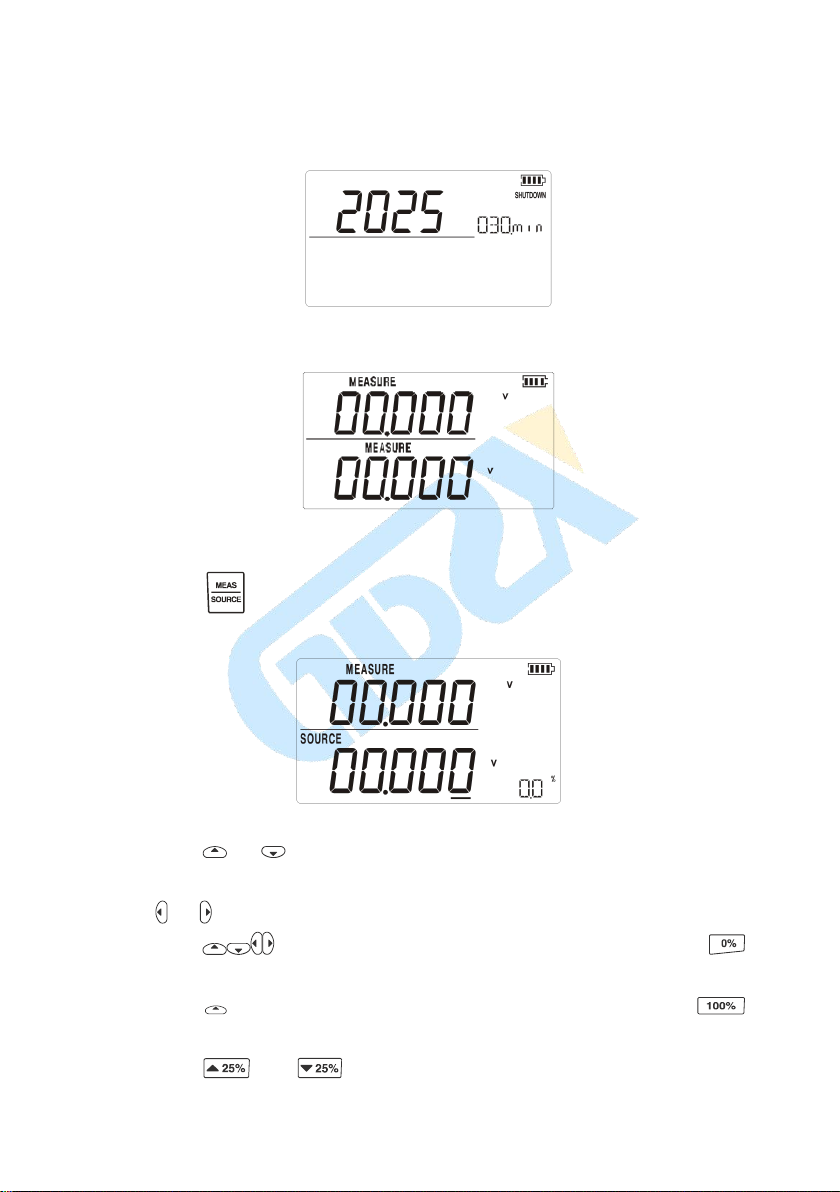

2.1 Measure and Source............................................................................................. 5

2.2 Shut Down Mode................................................................................................. 7

2.3 Backlight brightness Adjustment......................................................................... 7

3 Functions of Upper Display.................................................................. 9

3.1 DC V and DC mV Measurement......................................................................... 9

3.2 DC mA Measurement...........................................................................................9

3.3 Current Measurement with Loop Power..............................................................9

3.4 Resistance measure and continuity test..............................................................10

4 Functions of Lower Display................................................................11

4.1 Measure and Source of DC V and DC mV........................................................ 11

4. 2 DC mA Measurement........................................................................................11

4.3 DC mA Source(active)..................................................................................12

4.4 Simulating a 4- to 20-mA Transmitter............................................................... 13

4.5 Measure and Source of Resistane...................................................................... 14

4.6 Measure and Source of Frequency.....................................................................15

5 Temperature Measurement..................................................................17

5.1 Using Thermocouples (TC)................................................................................17

5.2 Using Resistance Thermometer Detector (RTD)............................................... 20

6 Simulation of temperature sensor........................................................22

6.1 Simulating Thermocouples................................................................................ 22

6.2 Simulating RTD................................................................................................. 22