BISEN PY-L Guide

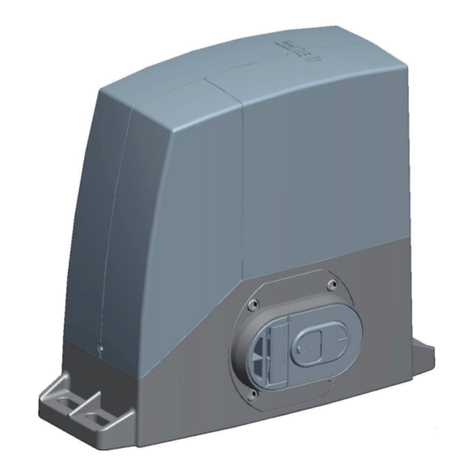

PY-L DC Brushless Sliding Gate Opener

INSTALLATION MANUAL & USER GUIDE

WARNING TO THE INSTEALLER AND USER

CAUTION! For personal safety it is important to follow all the instructions

carefully.Incorrect installation or misuse of the product may cause serious harm to

people.

Keep the instructions in a safe place for future reference.

This product was designed and manufactured strictly for the use indicated in this

document. Any other usage not expressly indicated in this Document,may damage

the product and /or be a source of danger.

BS accepts no responsibility due to improper use of the automatic machine (open-

er) or use other than that intended.

Do not install the machine in an area subject to explosion hazard.Inflammable

gasses or fumes are a serious safety hazard.

BS will not accept responsibility if the rules of good workmanship are disregarded

in installig the closing elements to be motorised, if any deformation occurs during

use of the said elements.

Before carrying out any work on the system, turn off the electricity supply.

The safety devices(e.g.photocells,sensitive edges,etc … ) may be used to prevent

any potential risk in dangerous areas where the moving mechanism is located,

such as crushing, dragging, or shearing.

BS accepts no responsibility regarding safety and correct operation of the

machine, should components made by manufacturers other than we be used in

the system.

Do not make any alterations to the components of the automatic machine (opener

and accessory ).

The installer must supply full information regarding operation manual of the

system in the event of any emergency and provide the system user with the

“INSTRUCTION”included with the product.

Do not allow children of other people to stand nera any moving part of the opener

or door construction while in operation.

Keep transmitters away from children to prevent the machine from being activated

accidentally.

The user must refrain from attempting to repair or adjust the system personally

and should only contact professional personnel.

Frequently examine the installation, in particular check cables, springs and

mountings for signs of wear, damage or imbalance, Do not use if repair or

adjustment is needed since a fault in installation or an incorrectly balanced door

may cause injury.

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

13)

14)

15)

16)

17)

18)

19)

20)

21)

22)

23)

24)

25)

This appliance is not intended for use by persons(including children)with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the ap-

pliance by a person responsible for their safety.

If the supply cord is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualified persons in order to avoid a hazard.

Disconnect the supply when cleaning or other maintenance is being carried out, if

the appliance is automatically controlled.

The temperature range marked on the drive should be suitable for the location.

The electrical cord plug must plug in indoor outlet or waterproof cover outlet.

Ensure that entrapment between the driven part and the surrounding fixed parts

due to the opening movement of the driven part is avoided.

After installation, ensure that the mechanism is properly adjusted and that the pro-

tection system and any manual release function correctly;

Permanently fix the label concerning the manual release adjacent to its actuating

member.

The drive cannot used with a driven part incorporating a wicket door.

Children should be supervised to ensure that they do not play with theappliance

1. Introduction

⑴

⑵

⑶

⑷

⑸

⑹

⑺

⑻

⑼

⑽

⑾

262 mm 165 mm

198 mm

248 mm

58 mm

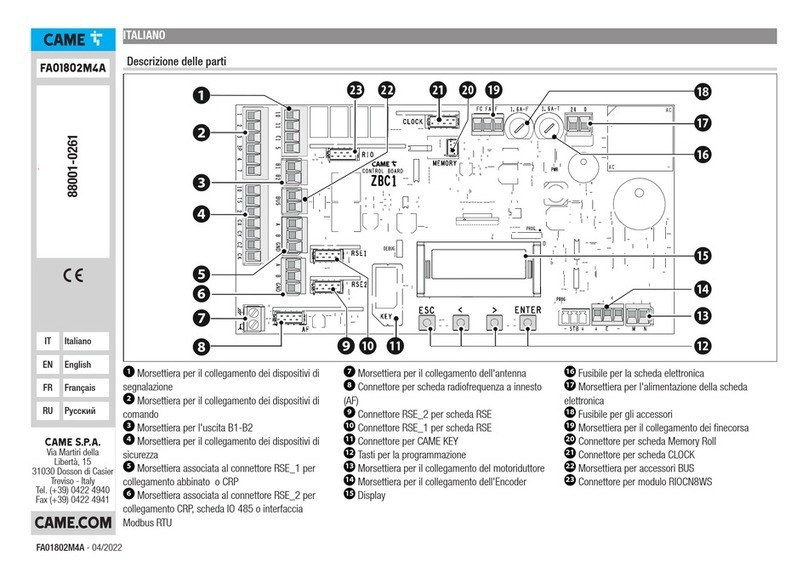

1.1 Main Components

1.2 Dimension

Built-in control board.

Terminals for Push button,Photocell,Alarm lamp.

Auto-closing is available,time delay is adjustable.

(1) Gearbox

(2) Release Clutch

(3) DC Motor

(4) Electromagnetic Brake

(5) Transformer

(6) LED Light

(7) Motor Cover

(8) Gear Reducer

(9) Control Board

(10) Limit Switch

(11) Output Pinion

4

Model

Type

Motor voltage

Motor Power

Output rotational speed

Operate speed

Max weight of gate

Working temperature

Remote range

BS-PY82L-120DC

DC Brushless Motor

24VDC

120W

54r/min

12m/min

<1200Kg

-30℃~+60℃

≥30m

1.4 Feature

1.3 Technical Specifications

1.The eletromagnetic brake could lock the operator when power off.

2.In case of power failure, the gate can be opened and closed manually after

release clutch.

3. Soft start function.

4.Reverse or stop when meet obstacle, the two functions is optional.

5.Soft stop or limit brake function is optional.

6.Auto close delay function.

7.Applicable to access control system.

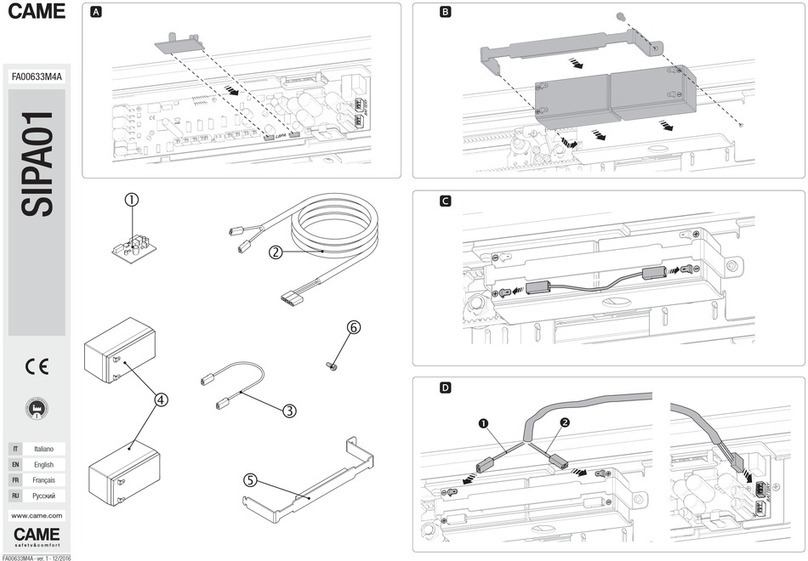

2.1 Example of a sliding gate operator installation

Before using the machine, check power supply, grounding, voltage, etc.

Check whether it is connected according to the demand of wiring diagram.

The gate should be pulled easily and smoothly manually when the worm gears are

released.

The worm gears will be coupled before power on.

The product must be installed by professional person.

Means for disconnection must be incorporated in the fixed wiring in accordance

with the wiring rules.

The diameter of wire on the wall not less than 1mm²,the diameter of wire that con-

nect to appliance not less than 0.5mm²

The external diameter of power line not more than 14mm, the power line should

have polychloroprene sheathed cable and at least normal polychloroprene

sheathed cable.

2. Installation

BS-PY82L

Alarm Lamp

Gate wheel

Photocell (Optional)

Rack

Transmitter

Photocell (Optional)

1

2

3

4

5

6

7+8

2

3

4

5

6

7

8

1

6

2.2.1 Install baseplate on the ground, then,fasten the sliding motor on the baseplate.

Key: Ensure baseplate on level position.

M8 Bolt

Door opener

Base Plate

2.2 installation and adjustment

~

Bolt

Output pinion of sliding gate opener

Rack

173m

m

300mm

20mm

B

AC

Power

>300mm

Baseplate

Baseplate

Wheel

Slide way

Gate

Rack

Expansion

Bolt

Concrete base

7

AC Fire line

Null line

220V

2.2.2 Before place the limit magnet on the rack, the gear box of the operator

must be released asper Fig7, use the key turn clockwise to release the gear.

release key

unlock

lock

release cover

2.3 Power Connection

Rack

Gate

Output Pinion

Wheel

Slide way

Gasket

Base plate

Fig7

Concrete base

8

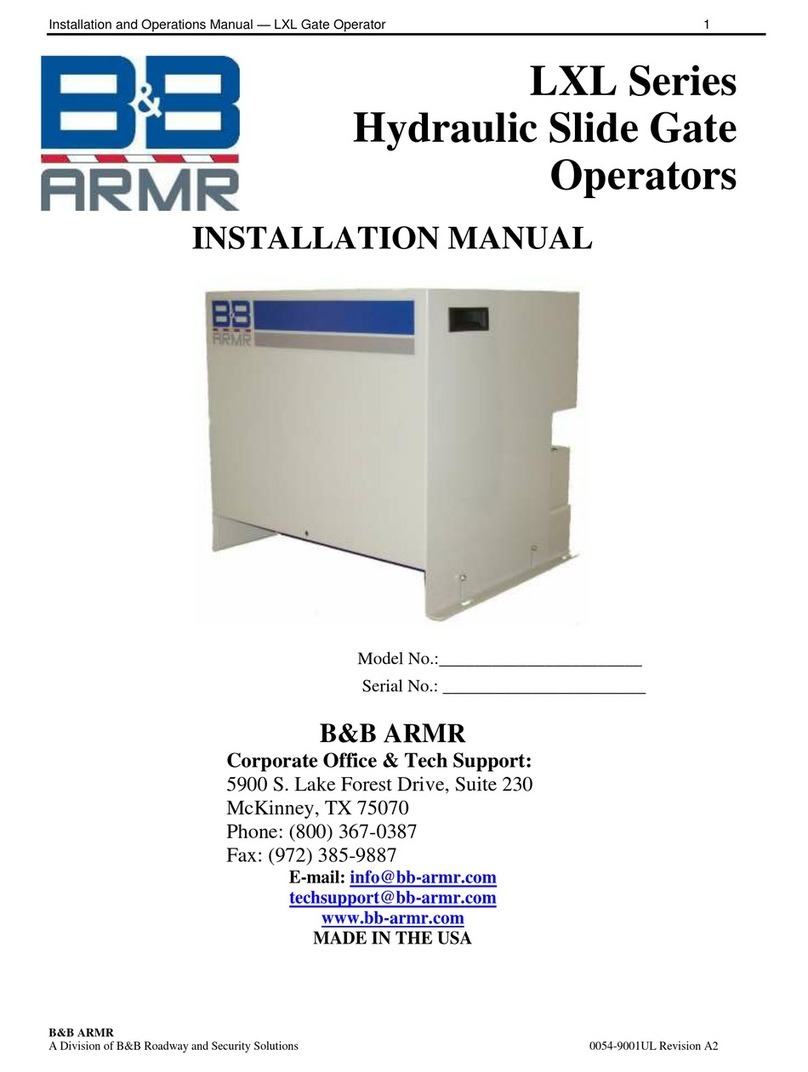

DIP1--DIP3 back up

DIP4:

ON: Change running direction of motor, if the motor rotate in opposite direction,

turn this switch.

OFF: Default state display.

Running state display:

1 2 3 4

ON DP

Dip switch

Function

Opening Closing Stop

Reach open limit Reach close limit

Set transmitter

LED Set transmitter

button

DIP Switch

Loop

Close

Stop

Open

Photoccll

Close limit

Open limit

Electromagnetic

Brake

Motor wires

Transformer

24V input

LED

Alarm Lamp

Yellow

Green

Blue

10A Fuse

Airwave

switch

Receiue Trans

mitter

Y G B

3. Control board

Display

9

4.1 Setting

Press and hold “SET” for 3 seconds, display “P1”

Power on

Press “OPEN” or “CLOSE” to switch Parameters

Each click “OPEN” increases value by 1; press and hold “OPEN” value increase till reduse the button.

Each click “CLOSE” reduces value by 1; press and hold “CLOSE” value reduced till reduse the button.

Press "SET" ,enter next parameter set interface

(Save parameter only finish setting the final interface).

Mark : 1. In any state from "P1" to "L2", press "STOP " to save parameters.

2. In“L2”state,press "SET" to save parameters.

Press "STOP" save and quit set interface

Px setting ,X=1-9

No Parameter Description

Protect time for motor running,unit:second,motor will stop when over time

Motor speed:Lever 1 to 5 ,Min=1, Max=5

Reduce speed distance : 0-15

Sensitivity of reverse when obstacle 0-50

Limit set : 0=Normal Open, 1=Normal Close

Auto close delay time: 0-99. 0=no Auto close

Sofe stop reduce speed 1-5, 1=Fastest, 5=Slowest

Sofe stop, 0=no Soft stop, 1=valid

Test mode for engineer only default=0

Brake rate for engineer only default=0

Display mode. 0=Running state, for engineer only, default=0

Motor speed when the first time after power on, lever1 to 5 ,Min=1, Max=5

Factory set

1

2

3

4

6

7

5

8

9

10

11

P1

P2

P3

P4

P5

P6

P7

L0

L1

P8

P9

20

1

1

1

0

0

0

80

4

3

6

12

L2

0

4. Parameters setting

10

4.2 Note

Specification maybe changed without a prior notification.

4.2.1. Learn travel

No Trouble Possible Reason Solution

1

2

3

4

5

6

Motor can not work

Motor is running even when

gate reaches limit position

Reverse when closing

Motor stops after opening 2s,

or renerse after closing 2s

Motor is functional

but gate doesnot work

Release clutch could not

release but gate does not work

1. No power supply

2. Break fuse

3. capacitor decay

4. Surpass load

5. Effected by the thermal protection

1.Release handle is broken

2.Release clutch is block

Release clutch is unlock

1.Obstacle or the gate is over weight

2.Reverse parameter is not proper

1. There is obstacle in front of gate

2. Photocell is not triggered or damaged

1. Limit magnet is broken

2. Limit magnet is not installed properly

3. The magnet pole is incorret

1.Change a new handle

Check the release clutch

1.Remove obstacle, or decrease the weight of gate

2.Increase P5

1. remove the obstacle

2. Adjust or change the photocell

1. Change limit magnet

2. Rectify limit magnet

3. Adjust the magnet pole

1. Check power supply

2. Change fuse

3. Change capacitor

4. Check if any barrier on track

5. Restart after 20 minutes

4.2.2. Erase travel

Gate opener must relearn travel and limit position, method is: power on, operate

the opener open and close one time (don’t push stop,or don’t active photocell),if

display “YS”, means learning successfully, if not, repeat learning travel.

4.2.3. Transmitter's code setting

Press "LEARN BUTTON", the "LEARN LED" light, then, press the button which you

choose on the transmitter till the "LEARN LED " flash and go out, Now, the transmitter

is coded. Other transmitters can be coded as this way.

4.2.4. Erasing transmitter's code

Erasingtransmitter codes: Press "LEARN BUTTON" and hold on to make the "LEARN

LED" light till go out. Now, all codes of transmitters which had been learnt are cleared.

If the factory setting travel is not match with the length of sliding gate,stop the gate,

press and hold “STOP”, mean while, press and hold “OPEN” together for more than

3 seconds,till alarm sound three times, display “CLR”, means erase successfully,

then relearn travel. Or power off, restart the opener.

5. Trouble shooting

11

E1

E2

E3

E4

E5

E6

E7

4

5

6

1

2

3

7

8

EH

No Code Meaning Solution

Motor operation time out

incorret parameter setting

Motor locked rotor

Motor is ressisted

Potocell is triggered

Motor current is over

Main chip is fault

Hull is fault

Set the running time based on actual operation

Control board could reset

Check motor wires connectors

Move away the obstacle or adjust the reverse level

Remove the object that block the photocell

Remove the obstacle orcheek the motor

Restart or change the control board

Check the hull connectors, or change the motor

Error Codes

6. Maintain

1. Frequently cheek the wires connectors, especially the outter connetors.

2.Check the GND, make swire connection are as required.

3.Check carefully the power, voltage, frequency are match with request

4. Check and replace wearing parts accordingly.

This manual suits for next models

1

Table of contents

Other BISEN Gate Opener manuals

Popular Gate Opener manuals by other brands

Aprimatic

Aprimatic SLIDE 230 Electrical installation, Use and Maintenance instructions

Gatekeeper

Gatekeeper SKC-500DC owner's manual

Nice

Nice HySecurity CBOX936 Installation and programming manual

Elsema

Elsema iS2000 user manual

Nice

Nice HYPPO HY 7005 Instruction manual and spare parts catalogue

Chamberlain

Chamberlain GJ owner's manual